Porous Electrolessly Deposited Coatings

a technology of electroless coating and porous coating, which is applied in the direction of liquid/solution decomposition chemical coating, cell components, physical/chemical process catalysts, etc., can solve the problems of changing the size of the pores, and achieve the effects of good thermal conductivity, low sulfer content, and longer reaction channel length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

REFERENCE)

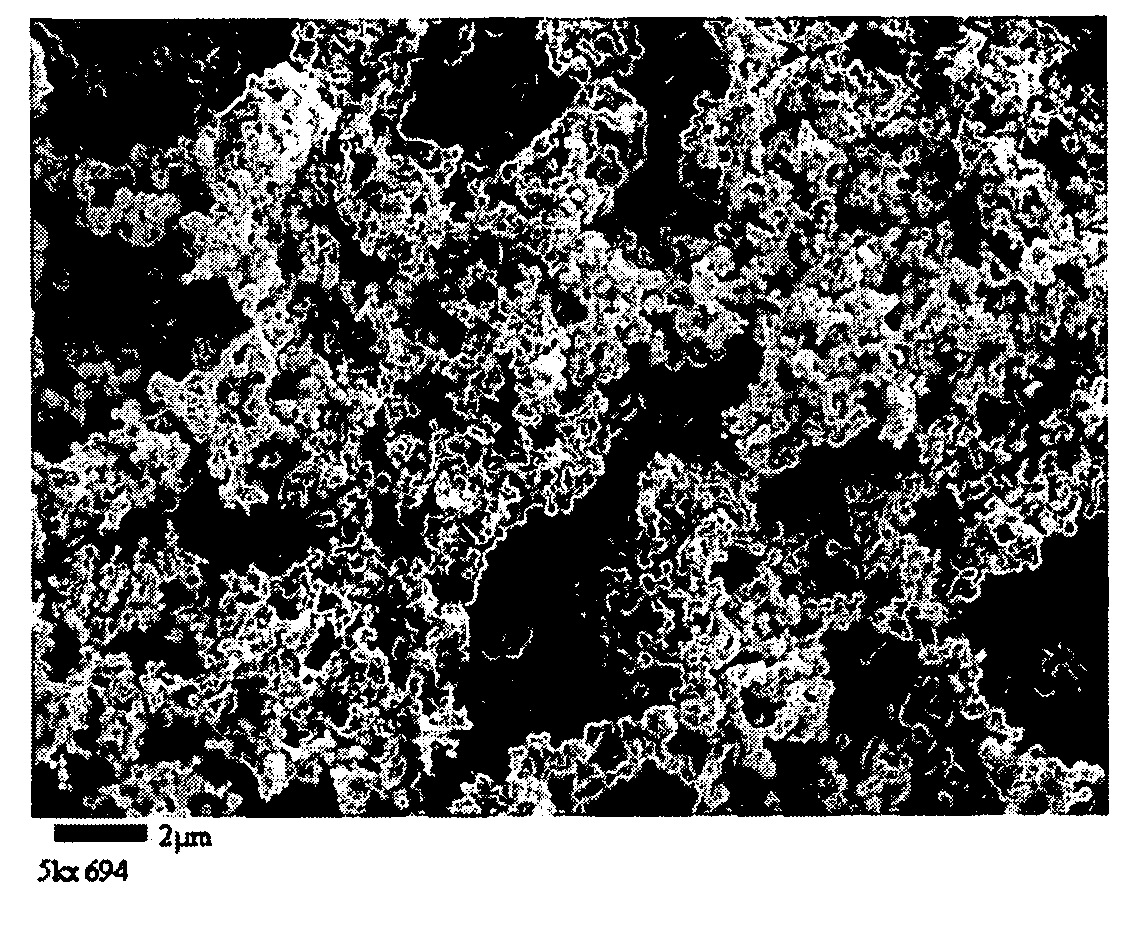

[0041]A solution consisting of Pt(NH3)4(OH)2, (0.2 wt % Pt) and 0.2 wt % N2H4·H2O was prepared. An aluminized alloy 617 coupon was heat-treated at 1050° C. for 10 hours before use. The surface of this coupon was covered by an α—Al2O3 scale. The coupon was hung in the solution at room temperature overnight. 11.4 mg / in2 Pt was plated on the coupon. After that, the Pt plated coupon was put in a new Pt plating solution with the same composition for 3 hours. Next the coupon was cleaned and calcined at 500° C. for 1 h in air. The final Pt loading was 15.7 mg / in2. The SEM micrograph shows that the Pt layer is flat and dense (FIG. 1).

example 2

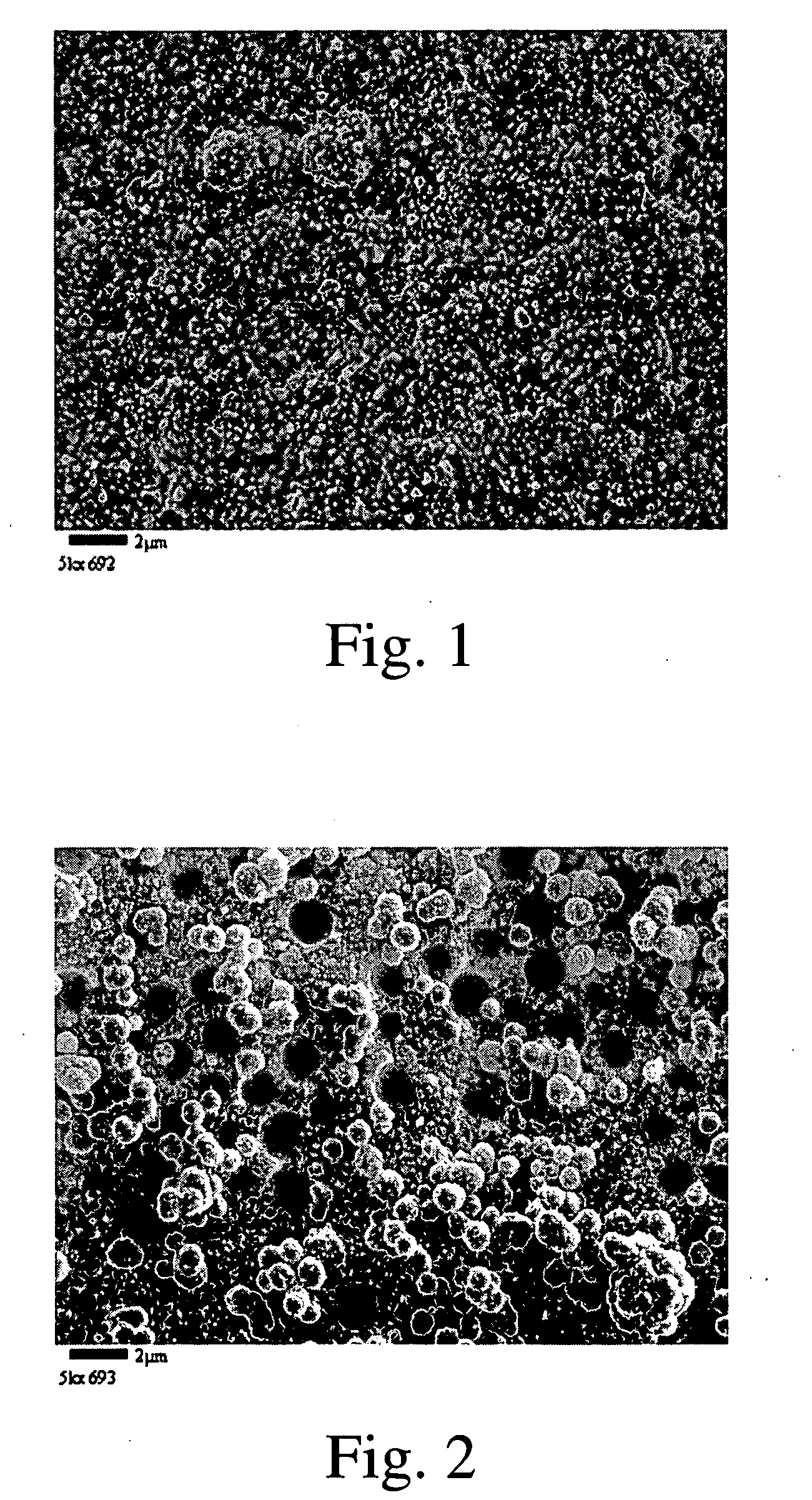

[0042]An aluminized Inconel 617, heat treated and Pt-plated coupon (15 mg / in2 Pt) was coated with 0.11 mg polystyrene microsphere (1.7 μm) and dried at room temperature. Next the coupon was put in a solution consisting of Pt(NH3)4(OH)2, (0.2 wt % Pt) and 0.2 wt % N2H4·H2O for 20 hours at room temperature. The coupon was then cleaned and calcined at 500° C. for 1 h in air. 11 mg / in2 Pt was plated on the coupon. SEM micrograph shows that the surface Pt layer is porous (FIG. 2). Bimodal pores (1.7 μm and 50-100 nm) are observed.

example 3

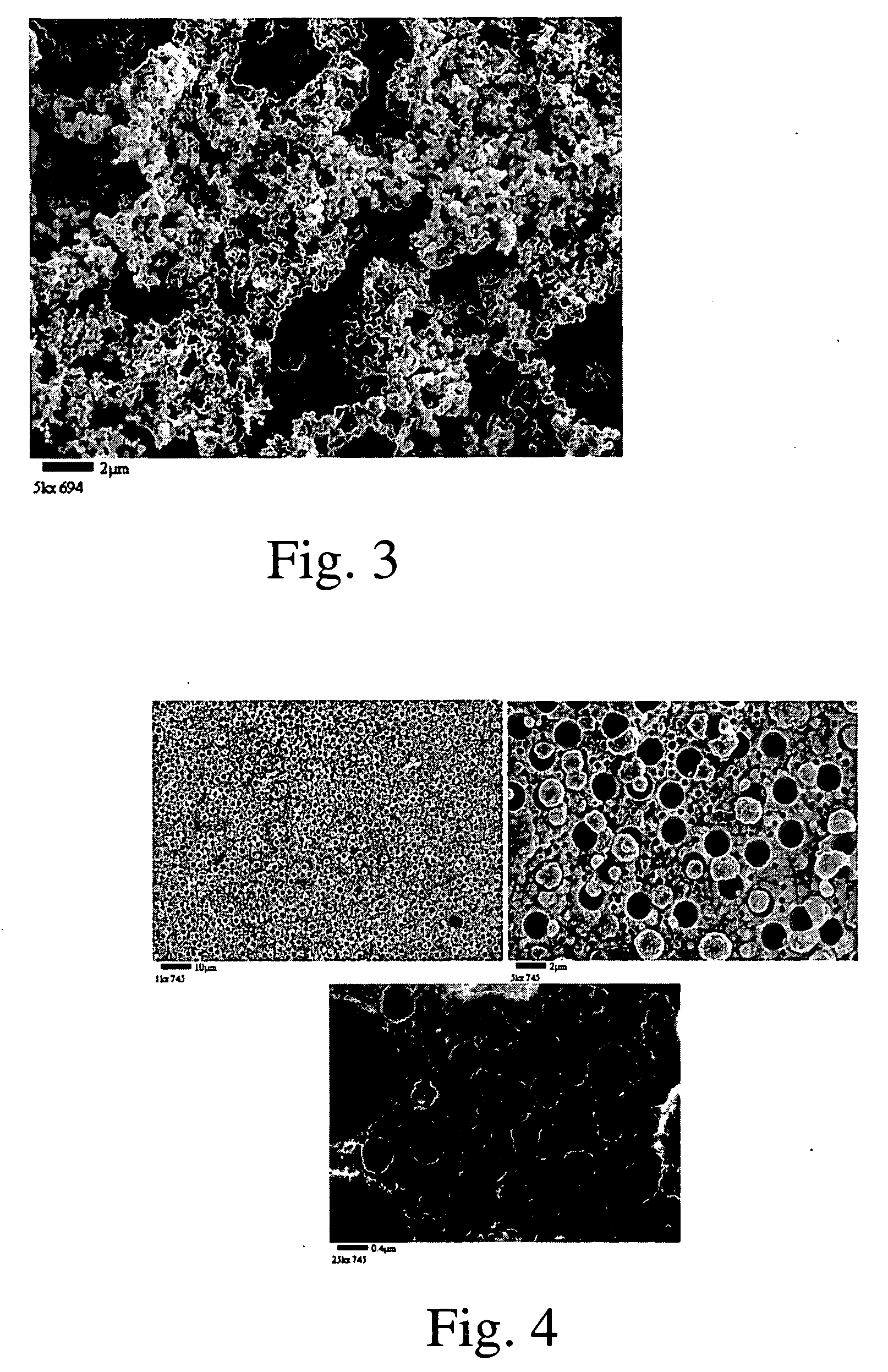

[0043]An aluminized Inconel 617, heat treated and Pt-plated coupon (15 mg / in2 Pt) was put in a solution consisting of Pt(NH3)4(OH)2, (0.2 wt % Pt), 0.2 wt % N2H4·H2O and 1.0 wt % polystyrene microsphere (1.7 μm) for 20 hours at room temperature. The coupon was then cleaned and calcined at 500° C. for 1 h in air. 12 mg / in2 Pt was plated on the coupon. SEM micrograph shows that the surface Pt layer is very porous (FIG. 3). Pt particle size is in the range of 100 to 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com