Organosilicon coating for electroplating and preparation method thereof, and protective coating for electroplating

A technology of silicone coating and protective coating, applied in the direction of coating, etc., can solve the problems of poor operability and achieve the effect of excellent storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

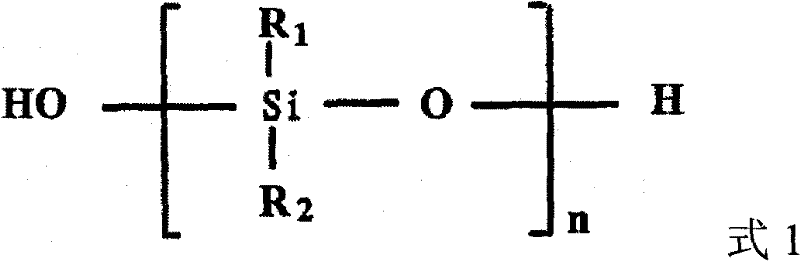

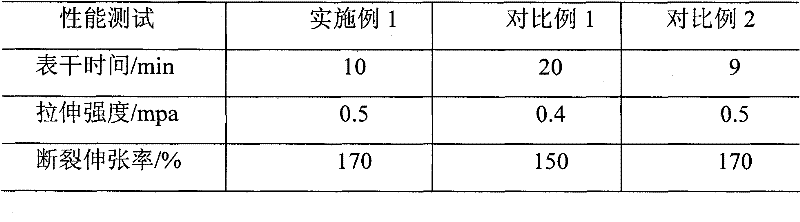

[0052] Take 100 parts of hydroxyl-terminated polyorganosiloxane with a viscosity of 2000mpa.s, 100 parts of diluent acetone solution, and stir evenly in a closed mixer at normal temperature and pressure; then add 40 parts of reinforcing filler, plasticizer 20 parts of simethicone oil, 0.5 parts of colorant, and 10 parts of heat-resistant agent continue to stir; under the protection of nitrogen, add 2 parts of stabilizer, 5 parts of crosslinking agent, and 2 parts of catalyst and mix well to obtain silicone coating A1, seal save.

[0053] Coat the silicone coating A1 on the aluminum substrate, test the surface drying time of the silicone coating A1, form the silicone coating C1 after curing, and test the tensile properties of the silicone coating C1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com