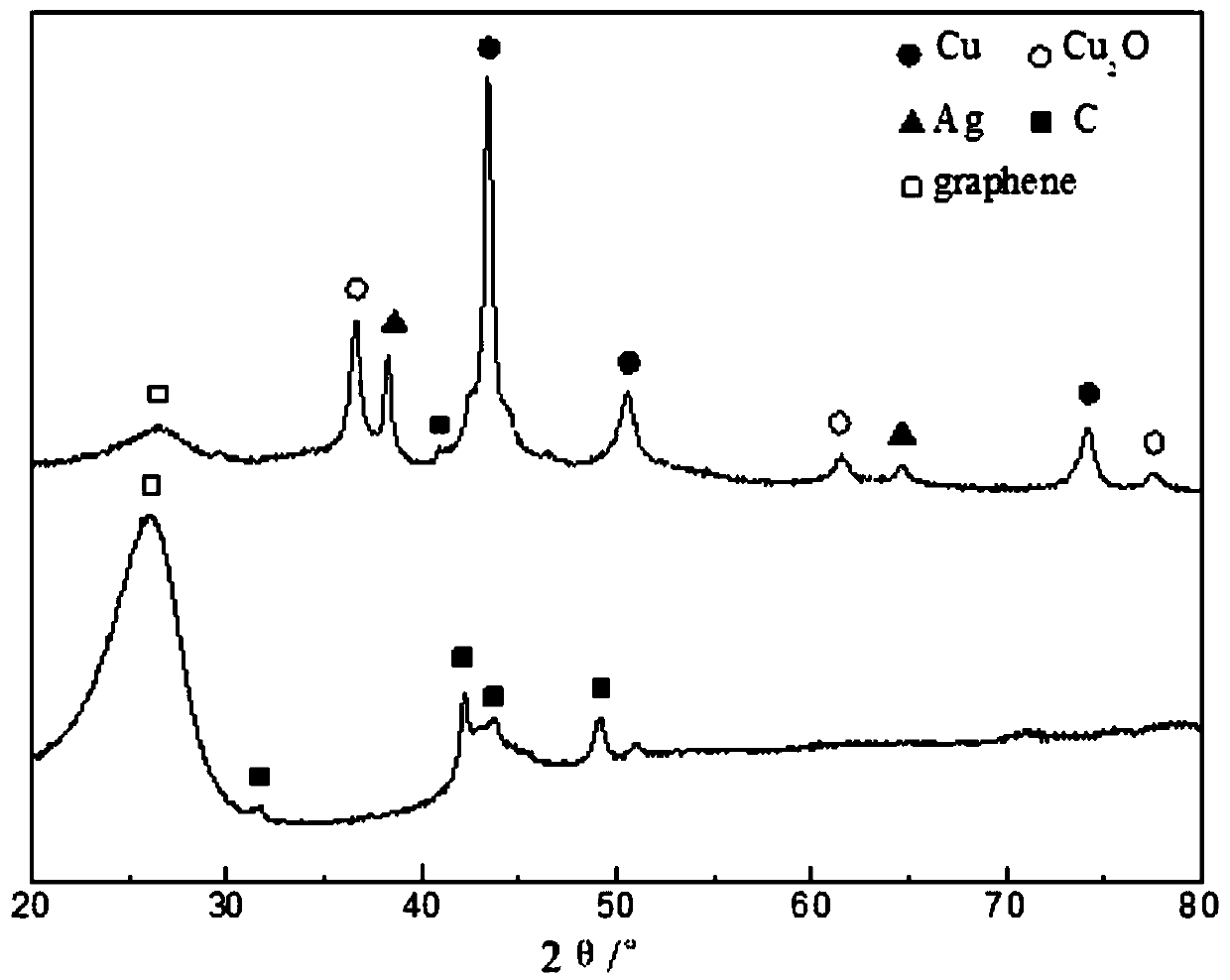

Graphene-loaded nano copper particle composite material and preparation method thereof

A composite material and graphene technology, which is applied in metal material coating technology, metal processing equipment, liquid chemical plating, etc., can solve the problems affecting the performance of composite materials, reducing the performance of graphene, and weak interface binding force, etc., to achieve improvement Comprehensive performance, improved dispersion, and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Immerse graphene in water, carry out ultrasonic dispersion treatment on graphene for 10 minutes, the solid-to-liquid ratio of graphene to water is 2g / L; then take out graphene, put it into sensitization solution, and sensitize treatment at 90°C for 10 minutes to obtain Sensitized graphene;

[0046] The sensitizer is made of SnCl 2 solution mixed with hydrochloric acid, SnCl 2 The concentration of the solution is 10g / L, the mass concentration of hydrochloric acid is more than 36%, and the concentration of hydrochloric acid and SnCl 2 The volume ratio of the solution is 0.01;

[0047]After the sensitized graphene is taken out, it is washed with water until the washing solution is neutral, then placed in the activation solution, and activated for 4 minutes under stirring conditions to obtain activated graphene;

[0048] The activation solution is made of AgNO 3 solution and ammonia solution, AgNO 3 The concentration of the solution is 1g / L, and the amount of ammonia w...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] (1) Ultrasonic dispersion treatment for 30 minutes, the solid-to-liquid ratio of graphene and water is 2.5g / L; sensitization treatment at 95°C for 8 minutes;

[0056] (2) SnCl 2 The concentration of the solution is 20g / L, hydrochloric acid and SnCl 2 The volume ratio of the solution is 0.02;

[0057] (3) Activation treatment for 7 minutes; the AgNO used in the activation solution 3 The concentration of the solution is 1.5g / L;

[0058] (4) When preparing the plating solution, CuSO 4 ·5H 2 The amount of O is 25g / L water, the amount of formaldehyde solution is 32mL / L water, the amount of EDTA·2Na is 40g / L water, C 4 h 4 KNaO 6 The dosage is 20g / L water, and the consumption of 2,2-bipyridine is 2g / L water;

[0059] (5) The temperature of the plating solution is raised to 40°C, and NaOH solution is added dropwise to adjust the pH value to 12.5, and then kept for 35 minutes;

[0060] (6) Dry at 100±2°C for 2h;...

Embodiment 3

[0065] Method is with embodiment 1, and difference is:

[0066] (1) Ultrasonic dispersion treatment for 20 minutes, the solid-to-liquid ratio of graphene and water is 1.5g / L; sensitization treatment at 100°C for 5 minutes;

[0067] (2) SnCl 2 The concentration of the solution is 30g / L, hydrochloric acid and SnCl 2 The volume ratio of the solution is 0.03;

[0068] (3) Activation treatment for 10 minutes; AgNO used in the activation solution 3 The concentration of the solution is 2g / L;

[0069] (4) When preparing the plating solution, CuSO 4 ·5H 2 The amount of O is 37.5g / L water, the amount of formaldehyde solution is 48mL / L water, the amount of EDTA·2Na is 60g / L water, C 4 h 4 KNaO 6 The consumption of 30g / L water, the consumption of 2,2-bipyridine is 3g / L water;

[0070] (5) The temperature of the plating solution was raised to 45°C, and NaOH solution was added dropwise to adjust the pH value to 12, and then kept for 40 minutes;

[0071] (6) Dry at 100±2°C for 3h; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com