Aqueous cleaning compositions for semi-conductor copper processing

A cleaning composition, a technology for the composition, applied in the directions of detergent compositions, non-surface-active detergent compositions, semiconductor/solid-state device manufacturing, etc., can solve the problem of copper wire wafer open circuit/short circuit test reliability test deterioration, surface roughness To solve problems such as deterioration of the degree, to achieve the best surface roughness and reduce the number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

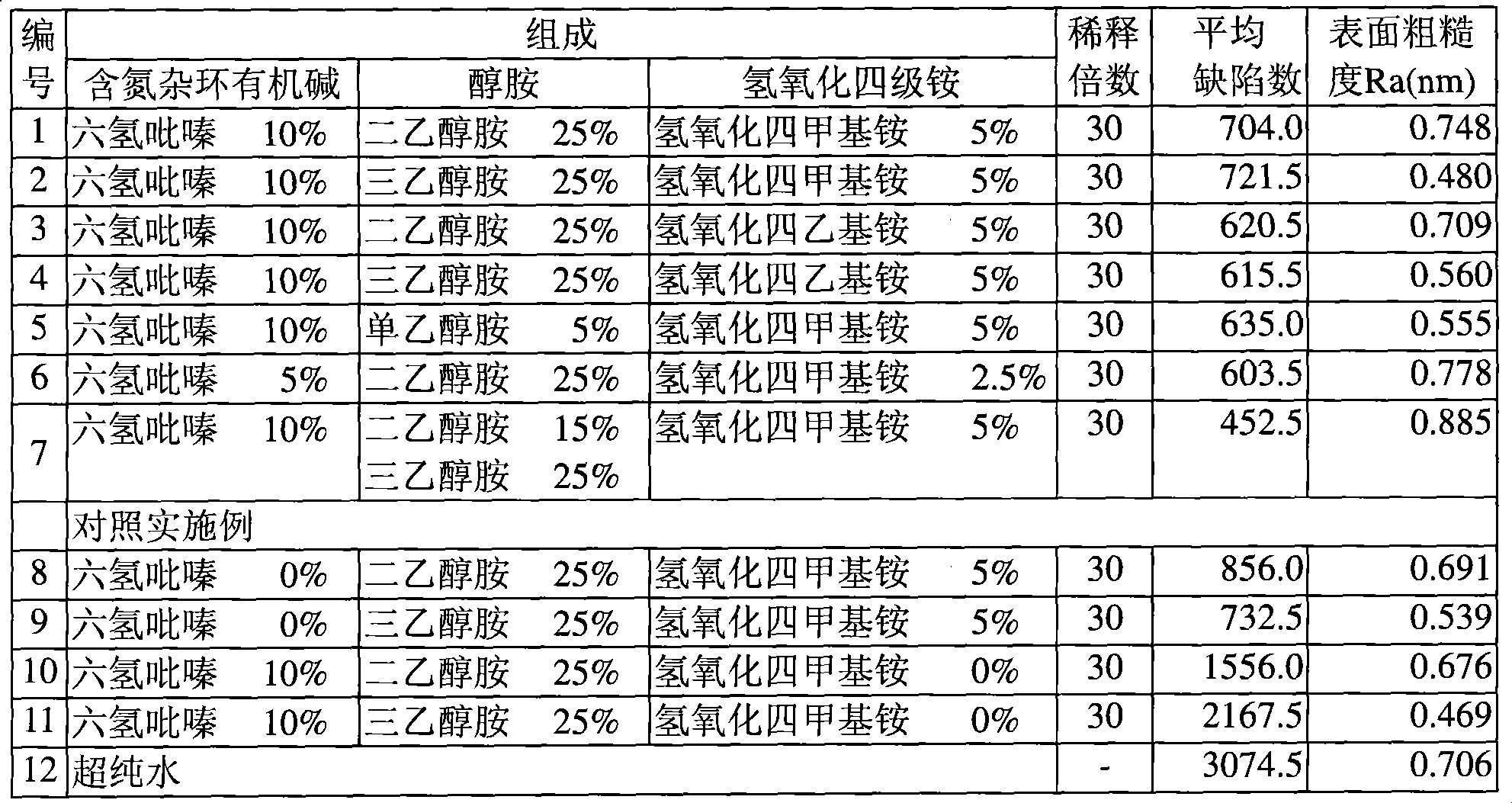

[0030]Cleaning compositions with different compositions were prepared with nitrogen-containing heterocyclic organic bases, alcohol amines, and quaternary ammonium hydroxide. The cleaning compositions were diluted 30 times with ultrapure water on the cleaning machine Ontrak, and the ground copper blank wafers were processed Cleaning, the cleaning time is two minutes, and the cleaning agent flow rate is 600 ml per minute. After cleaning, measure the number of defects on the surface of the copper wafer with a TOPCON WM-1700 wafer particle measuring instrument, and measure the surface roughness (Ra) of the copper wafer with an atomic force microscope (AFM).

[0031] Table 1: Number of surface defects and roughness after cleaning the copper wafer with the cleaning composition

[0032]

[0033] From the results of the above compositions 1 to 11, comparing the cleaning compositions of numbers 1, 8 and 10, and the cleaning compositions of numbers 2, 9 and 11, it can be seen that wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com