Carbon dioxide laser processing method and processing device for pcbn

A laser processing method, carbon dioxide technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of low ultrasonic cutting efficiency, low cutting efficiency, poor processing quality, etc., to reduce the heat-affected zone and heavy The formation of the cast layer, the effect of improving efficiency and improving the roughness of the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

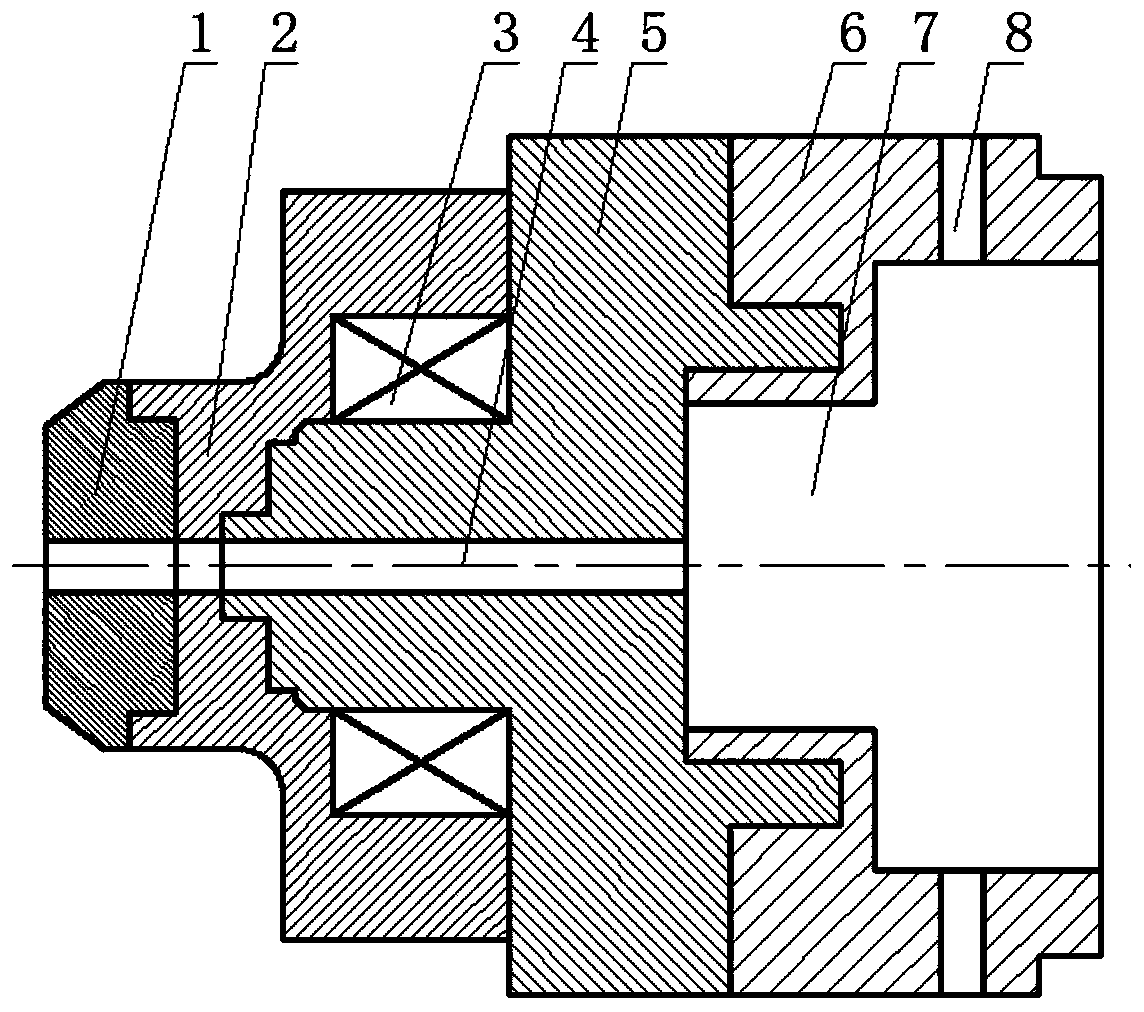

[0023] The present invention uses a carbon dioxide laser, and the structure of the laser head is as follows: figure 1 As shown, it includes the spray head 1, the rotating disk 2, the separation base 5 and the connection seat 6 which are connected coaxially in sequence. A laser through hole 4 is coaxially connected to the center of the spray head, the rotating disk and the separation base. The laser through hole It communicates with the laser through hole 7 of the connecting seat, and the rotating disk is connected with the separation base through the bearing 3 . A plurality of auxiliary gas inlet holes 8 are formed in the connecting seat, and the auxiliary gas inlet holes communicate with the laser t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com