A method for obtaining low bit discrepancy density extension thin film via using neck down extension

An epitaxial thin film, low dislocation technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high cost, thick buffer layer, poor compatibility, etc., and achieve the effect of good surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

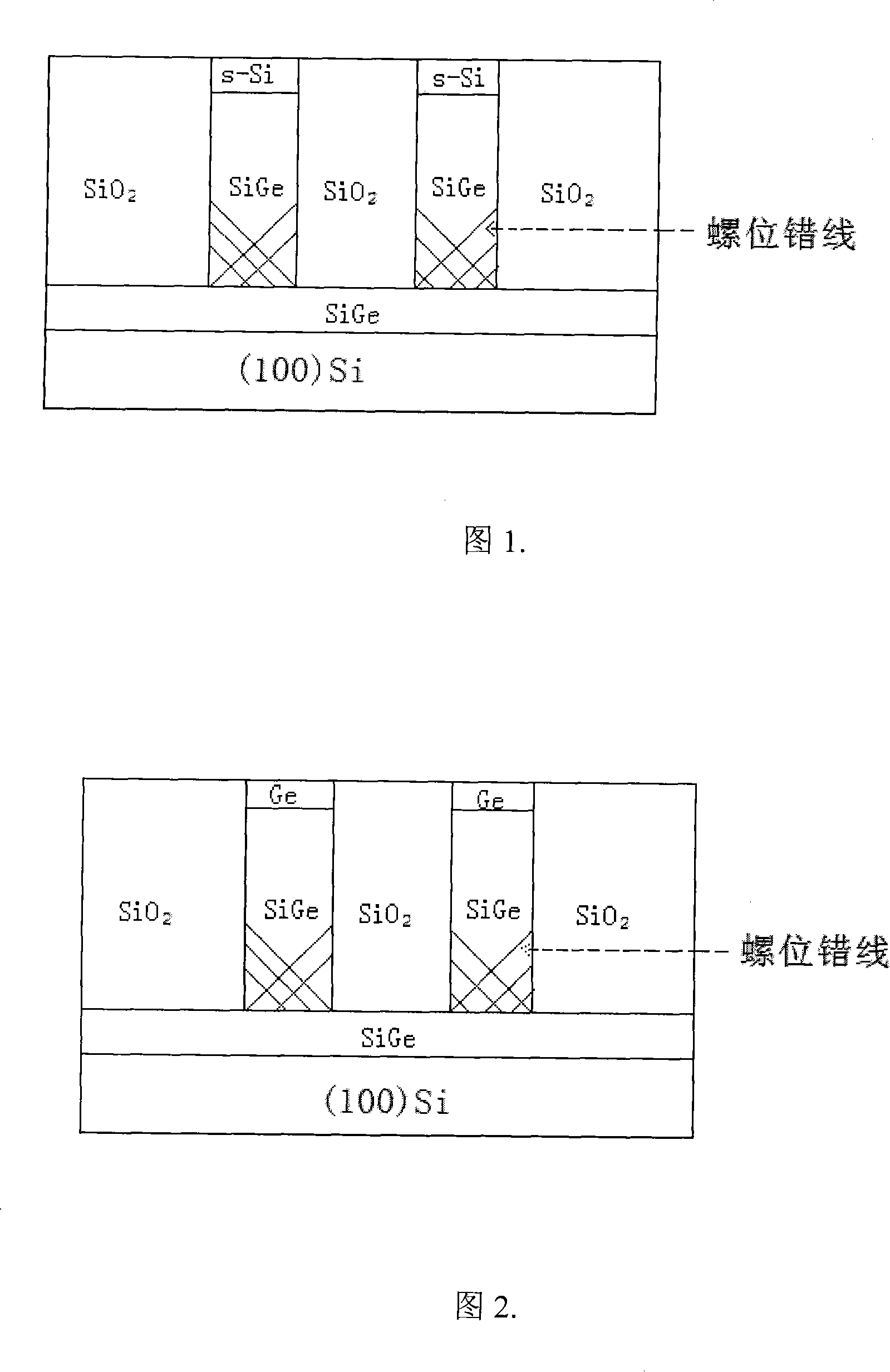

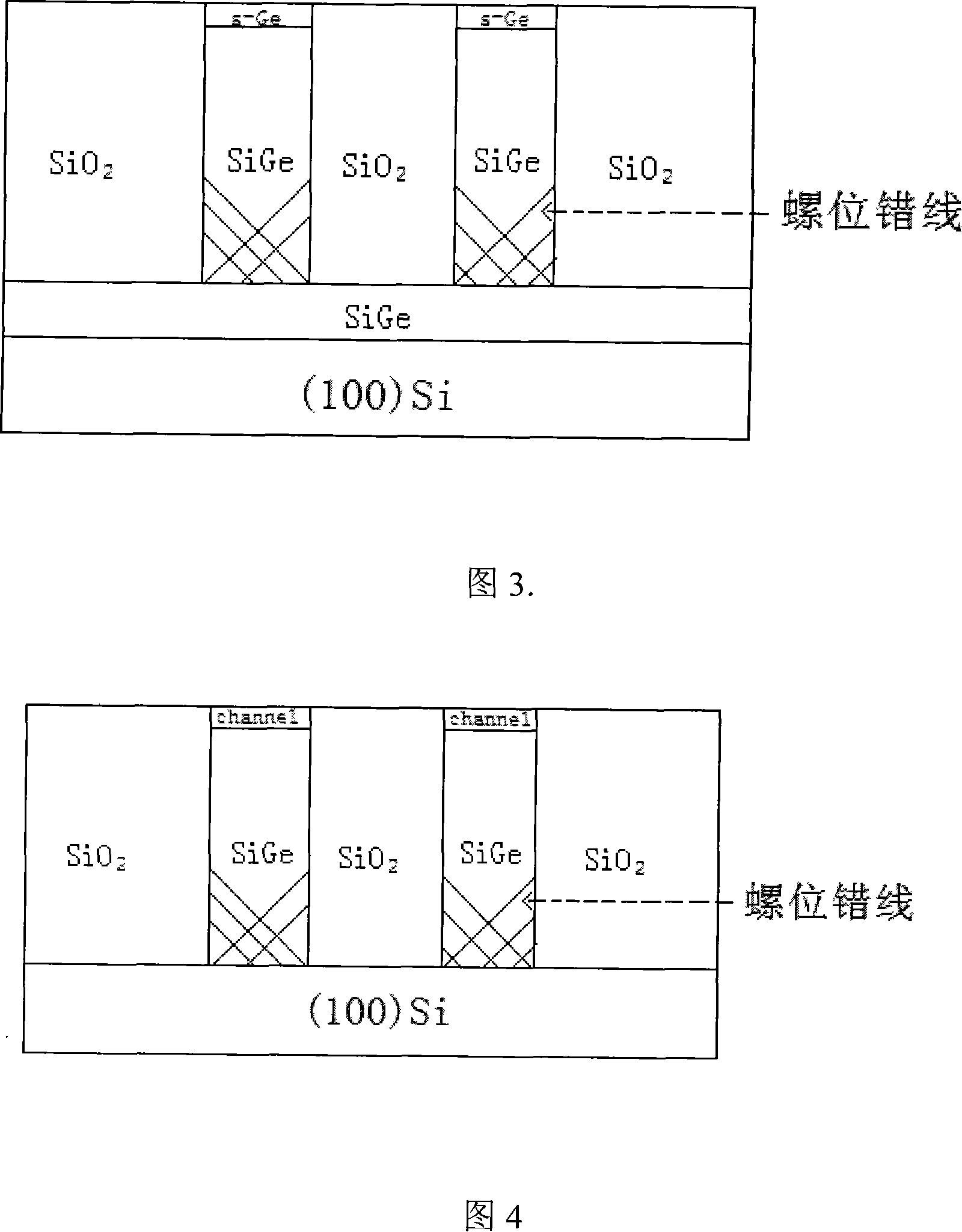

[0037] The invention provides a method for obtaining epitaxial film with low dislocation density by using neck-in epitaxy. The method uses the preparation methods of deposition, selective epitaxy and thermal oxidation to manufacture a silicon germanium substrate with low dislocation density and a channel with high mobility.

[0038] 1-3 are schematic cross-sectional views of growing strained silicon, germanium, and strained germanium channel structures on silicon germanium substrates, respectively. The manufacturing process of these three structures is: first deposit a layer of silicon germanium with low germanium content on the surface of the silicon wafer, oxidize the silicon germanium layer to increase the proportion of germanium in it; grow thick silicon germanium on the concentrated silicon germanium Silicon dioxide layer, photolithography and etching this layer of silicon dioxide to obtain a series of hole structures, and the bottom of the hole is a silicon germanium lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com