Method of producing polishing sheet

Inactive Publication Date: 2010-11-25

NIHON MICRO COATING

View PDF25 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0031]The present invention provides a polishing sheet capable of efficiently polishing a target object with a good surface roughness without generating polishing flaws.

[0032]The present invention makes it possible in particular to obtain polishing sheet having polishing particles mutually separated as seen in the direction of their plane by using a water

Problems solved by technology

Especially for the purpose of polishing a target object at an extremely high level of precision, arrangements of particles wherein the individual particles are fixed to the substrate in an aggregated form are not desirable.

There are many situations in which the particles are not uniformly arranged if they are viewed microscopically.

When the polishing particles are thus arranged, the surface roughness of the polishing sheet becomes uneven, and only polishing operations of the kind resulting in scratches on the surface of the target object are possible.

If polishing particles are thus covered with a binder that does not contribute to the polishing, their polishing performance is significantly affected negatively.

Even if a classification process is carried out for making the sizes of the polishing particles uniform, there is a limit to the degree of classification and the polishing particles have a specified

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

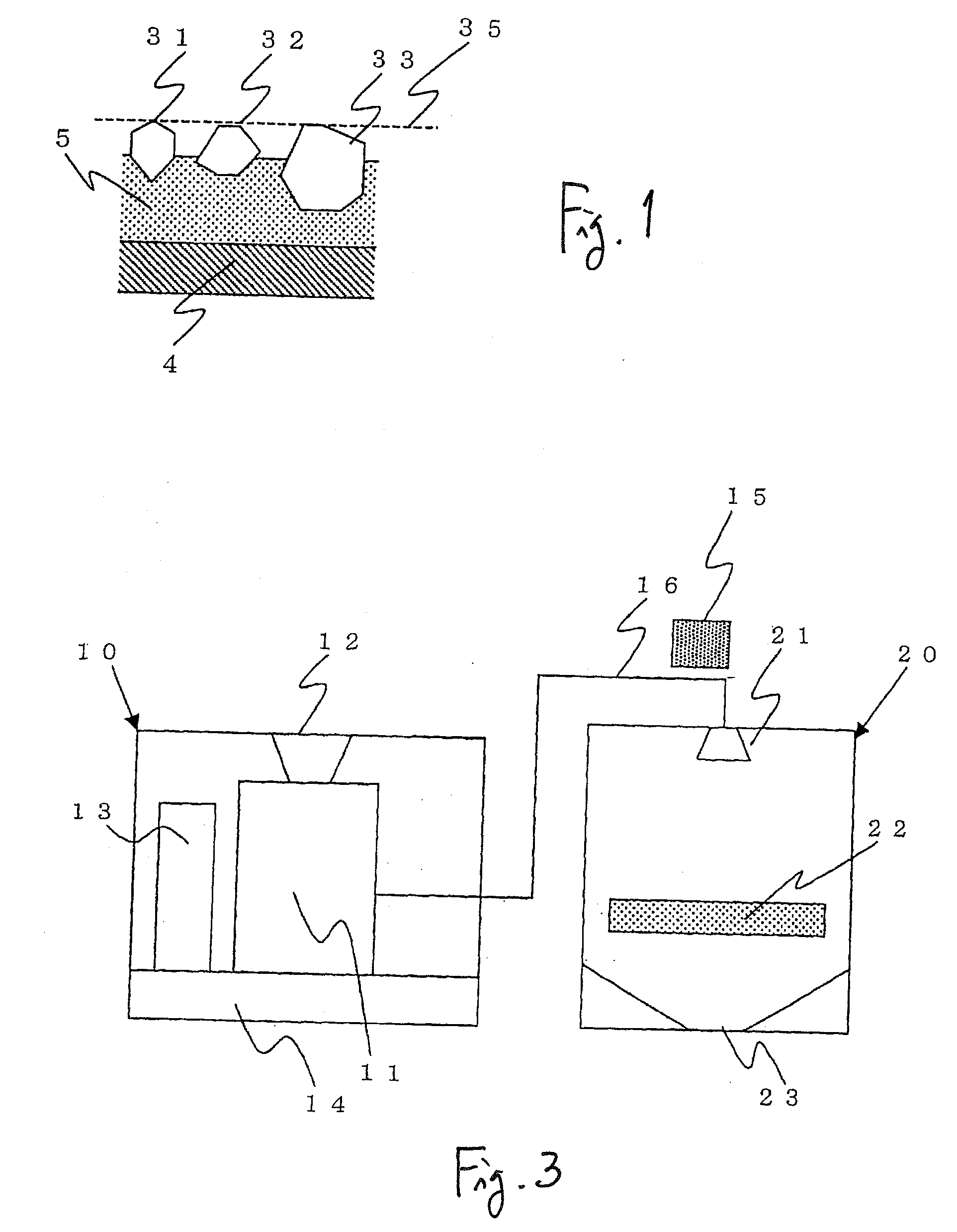

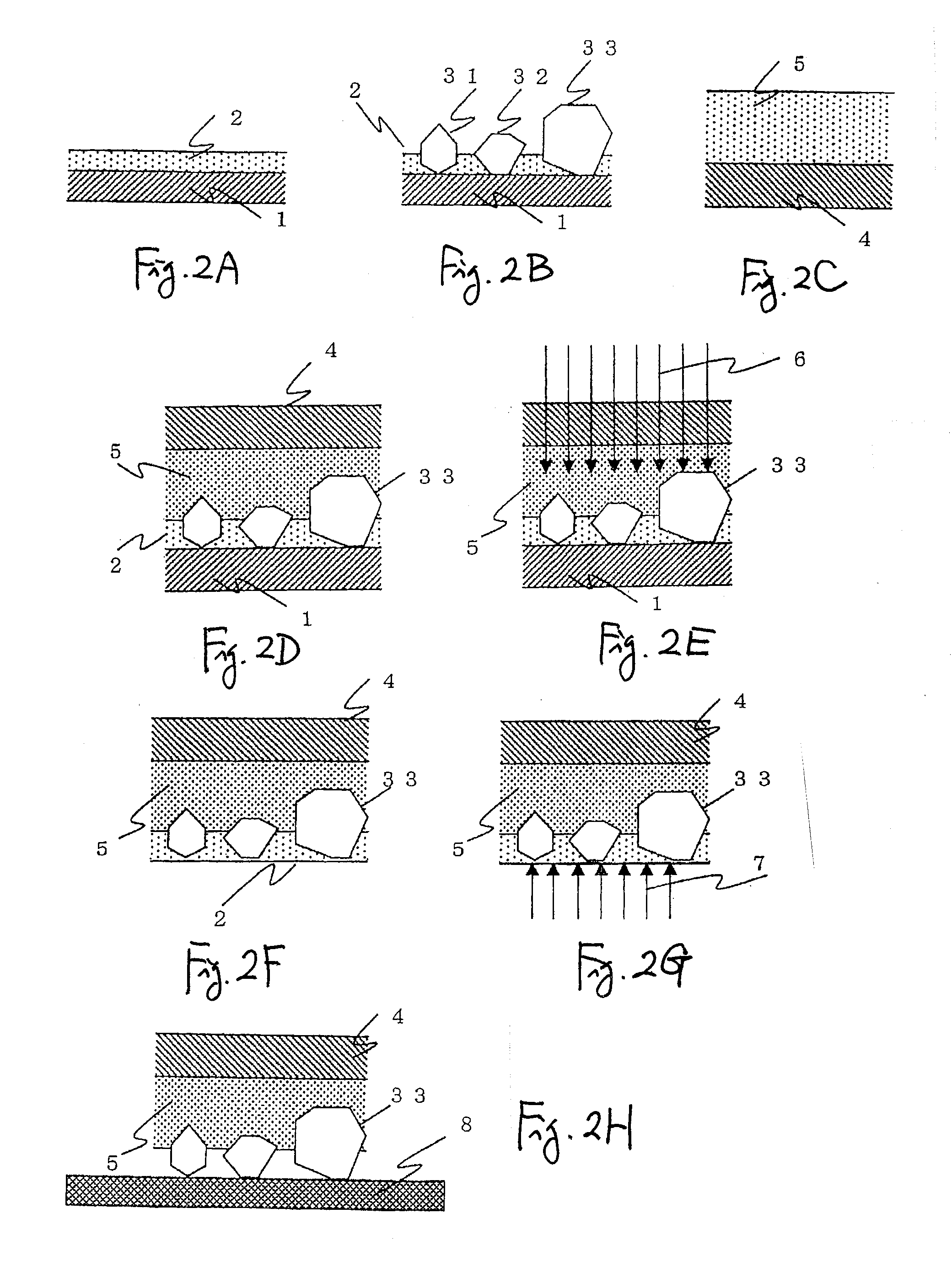

A polishing sheet, having polishing particles fixed to a base sheet in a single-layer formation by an adhesive agent so as to be mutually separated in the direction of their plane and having cutting edges exposed and arranged to be coplanar, is produced by forming on a provisional base sheet a film of a provisional adhesive agent of a thickness smaller than the average diameter of the polishing particles, dispersing the polishing particles onto the film of the provisional adhesive agent so as to contact the provisional base sheet, pressing the base sheet covered with the adhesive agent onto the polishing particles with the adhesive agent facing towards the polishing particles, hardening the pressed adhesive agent, and removing the provisional base sheet and the film of the provisional adhesive agent. The polishing particles are charged in a same polarity when dispersed.

Description

TECHNICAL FIELD OF THE INVENTION[0001]This invention relates to a polishing sheet for smoothly polishing a magnetic disk substrate, a silicon wafer, a glass substrate for a display device, the end surface of optical fibers and the surface of a variety of objects to be polished such as a lens, and more particularly a polishing sheet for polishing a target object to be polished extremely precisely, as well as a method of its production.TECHNICAL BACKGROUND[0002]While polishing particles as small as possible are used for polishing the surface of a target object smoothly and flatly, methods of polishing may be roughly classified into the free particle method which is carried out by supplying polishing particles to the target object from outside and the fixed particle method carried out by using a polishing sheet having polishing particles fixed to a substrate. The fixed particle method is widely used because it does not require a large amount of polishing material, unlike the free parti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24D11/00B24D3/00

CPCB24D18/0054B24D11/001

Inventor WATANABE, NOBUYOSHITANI, KAZUNORI

Owner NIHON MICRO COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com