Nickel alloy light guide plate cavity

A technology of nickel alloy and light guide plate, which is applied in the field of light guide plate, can solve the problems of time-consuming, diamond tool breakage, high cost, etc., and achieve the effect of good surface roughness and fast production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

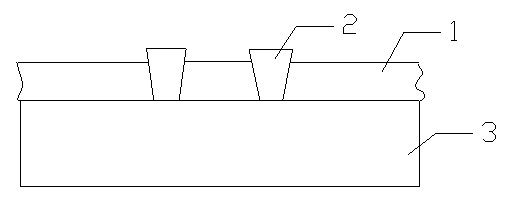

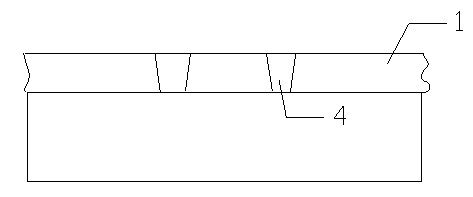

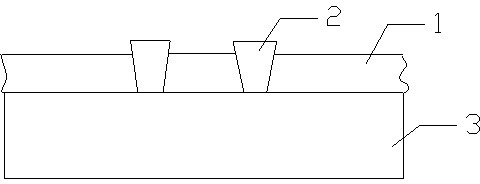

[0013] The figure shows a preferred embodiment of the present invention. The present invention will be further described with reference to the accompanying drawings. Among them, 1 electroformed nickel layer, 2 photoresist pattern, 3 substrate, 4 micropores.

[0014] figure 1 It is a schematic diagram of the structure of the nickel alloy light guide plate mold core of the present invention; the nickel alloy light guide plate mold core includes a substrate 3, a photoresist film (not shown completely) coated on the substrate 3, and electroforming deposited on the surface of the photoresist film and On the surrounding electroformed nickel layer 1, the photoresist film is provided with a photoresist film pattern (ie, photoresist pattern 2), and the electroformed nickel layer 1 is provided with a plurality of uniform micropores 4. The substrate 3 is used as a base, and the material is a silicon wafer; a mask plate (ie, a mask) with a certain three-dimensional pattern is produced accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com