Patents

Literature

41results about How to "Reduce corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

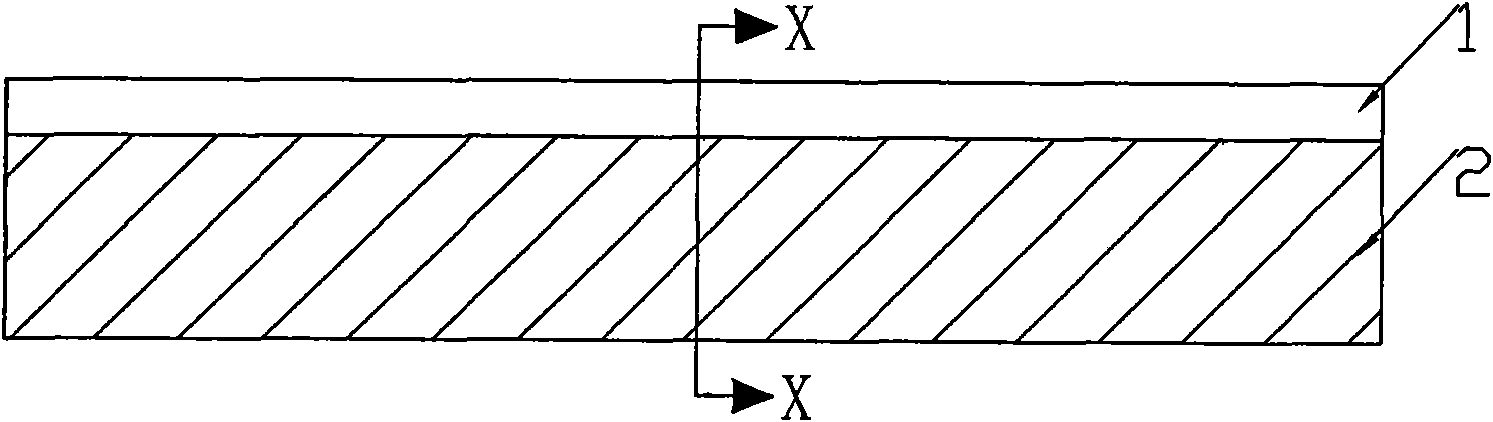

Lithium battery and manufacturing method thereof

InactiveCN101593849AImprove cycle lifeGuaranteed to workElectrode manufacturing processesFinal product manufactureInternal resistancePole piece

The invention discloses a lithium battery and a manufacturing method thereof, which belong to the field of batteries. The lithium battery comprises a positive pole, a negative pole and a diaphragm arranged between the positive pole and the negative pole. The manufacturing method comprises the following steps: making active matters into a mixed paste; preserving blank positions on the front and back sides of an edge in the lengthwise direction of a positive pole piece, coating the paste on other parts of the positive pole piece completely, preserving blank positions on the front and back sides of an edge in the lengthwise direction of a negative pole piece, and coating the paste on other parts of the negative pole piece completely; covering the pasted positions of the negative pole piece with the diaphragm, placing the positive pole piece, and staggering the blank positions of the positive pole piece and the blank positions of the negative pole piece at two ends respectively to arrange the positive pole with blanks at one end and the negative pole with blanks at the other end; welding the blanks of the positive pole with a positive pole tab and the blanks of the negative pole with a negative pole tab; and placing a battery cell welded with the pole tabs in a packaging shell, packaging the shell, drying the shell under vacuum, filling liquid, sealing the shell, and obtaining the battery after formation, capacity grading and examination. The lithium battery and the method have the advantages of reducing the distance from the pole pieces to pole terminals, internal resistance and heat generated during charge and improving safety, reducing pressure drop caused by internal resistance and discharge platform.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

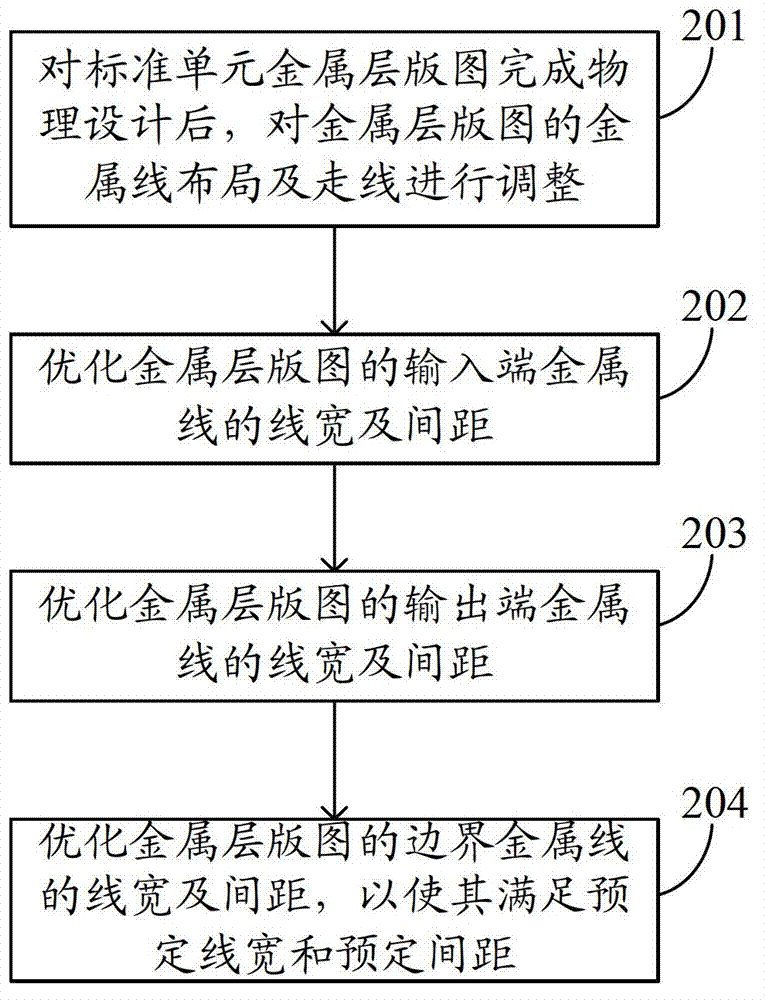

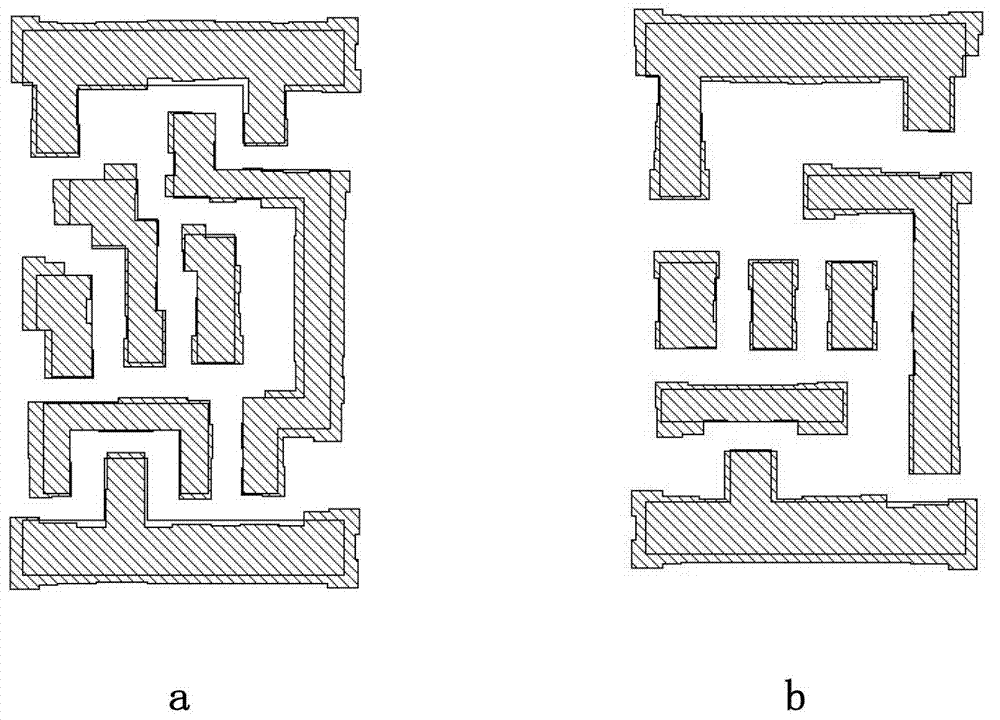

Optimizing design method of nanometer technical metal layer map

InactiveCN102855360AReduce cornersUniform density distributionSpecial data processing applicationsDensity distributionOptoelectronics

The embodiment of the invention provides an optimizing design method of a nanometer technical metal layer map. The method comprises the steps as follows: physically designing a standard unit metal layer map, and then adjusting the arrangement and direction of metal lines of the metal layer map; optimizing the width and spacing of the metal lines at the input end of the metal layer map; optimizing the width and spacing of the metal lines at the output end of the metal layer map; and optimizing the width and spacing of the metal lines at the boundary of the metal layer map, so as to meet the preset width and the preset spacing of the metal lines. With the adoption of the optimizing method provided by the embodiment of the invention, the turning in the metal layer map is reduced, and the metal layer map can be uniform in density distribution; the optics proximity correction and modification area required by the metal layer map can be optimized, the data volume in the optics proximity correction and modification and the modification time can be reduced, the manufacturability of a chip is improved, and the manufacturing cost of the chip is saved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

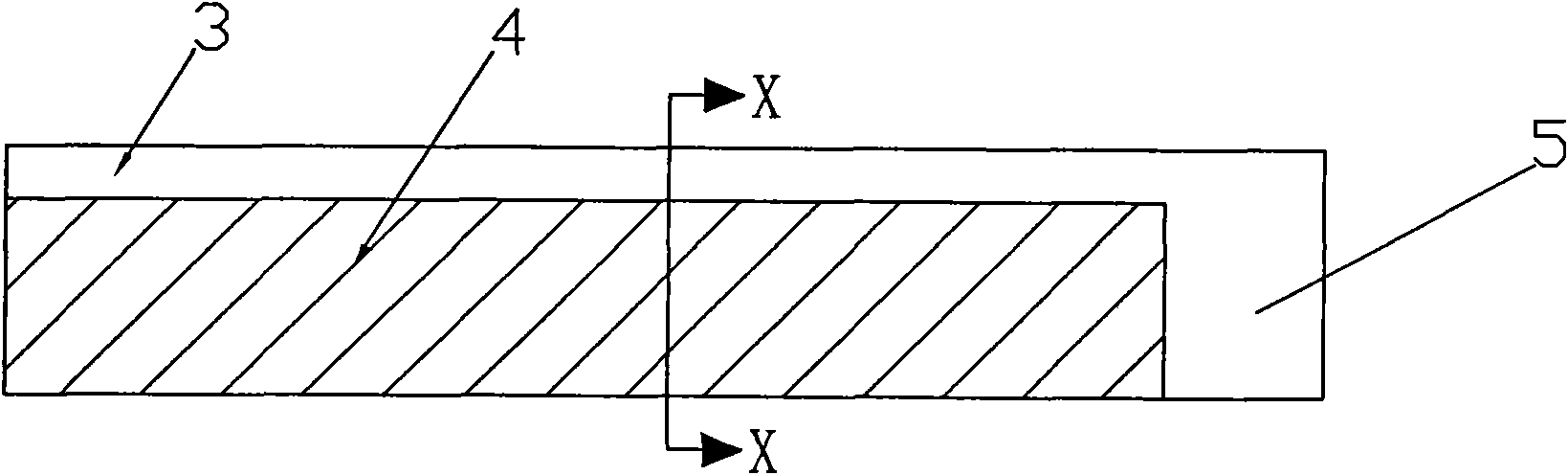

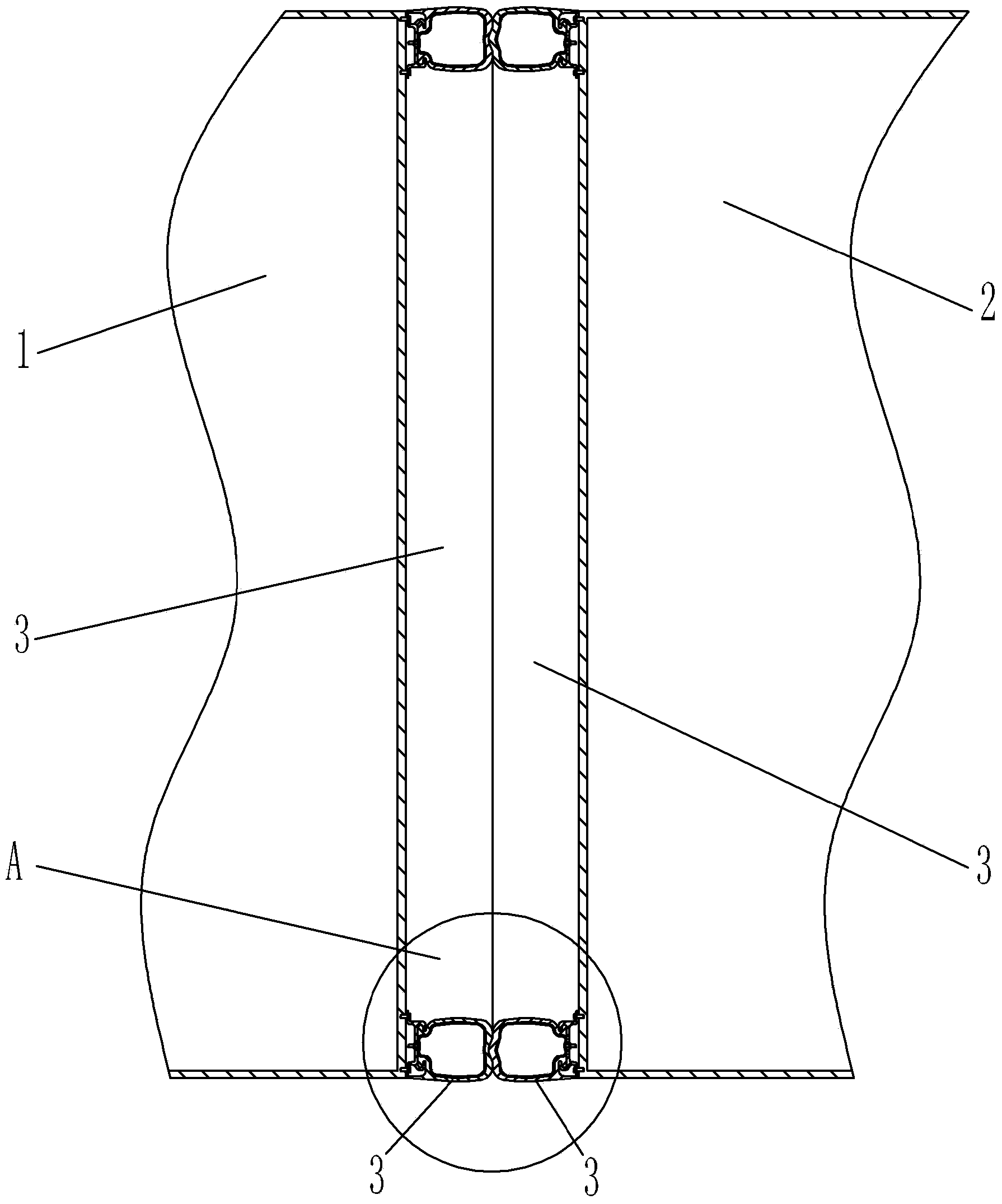

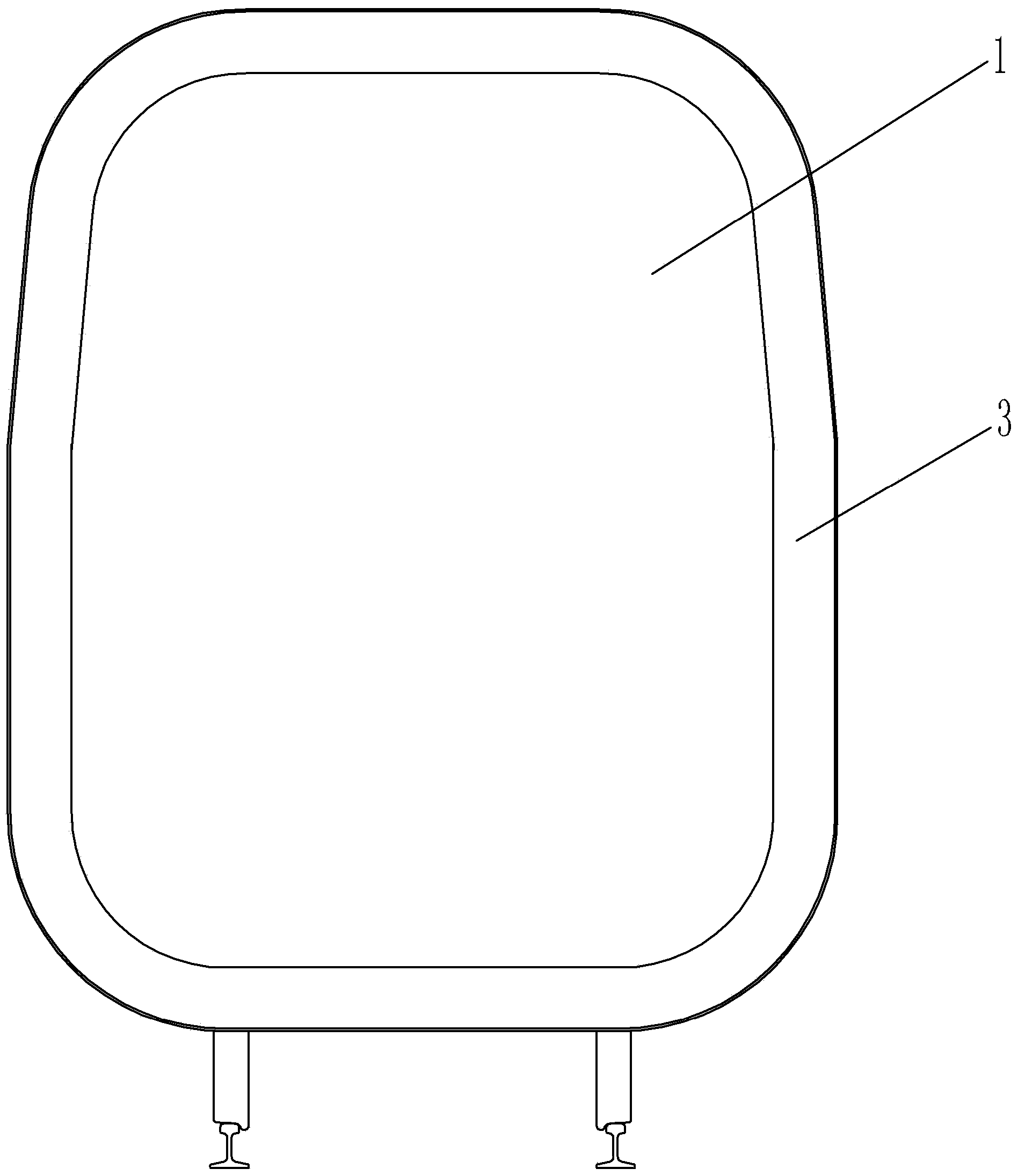

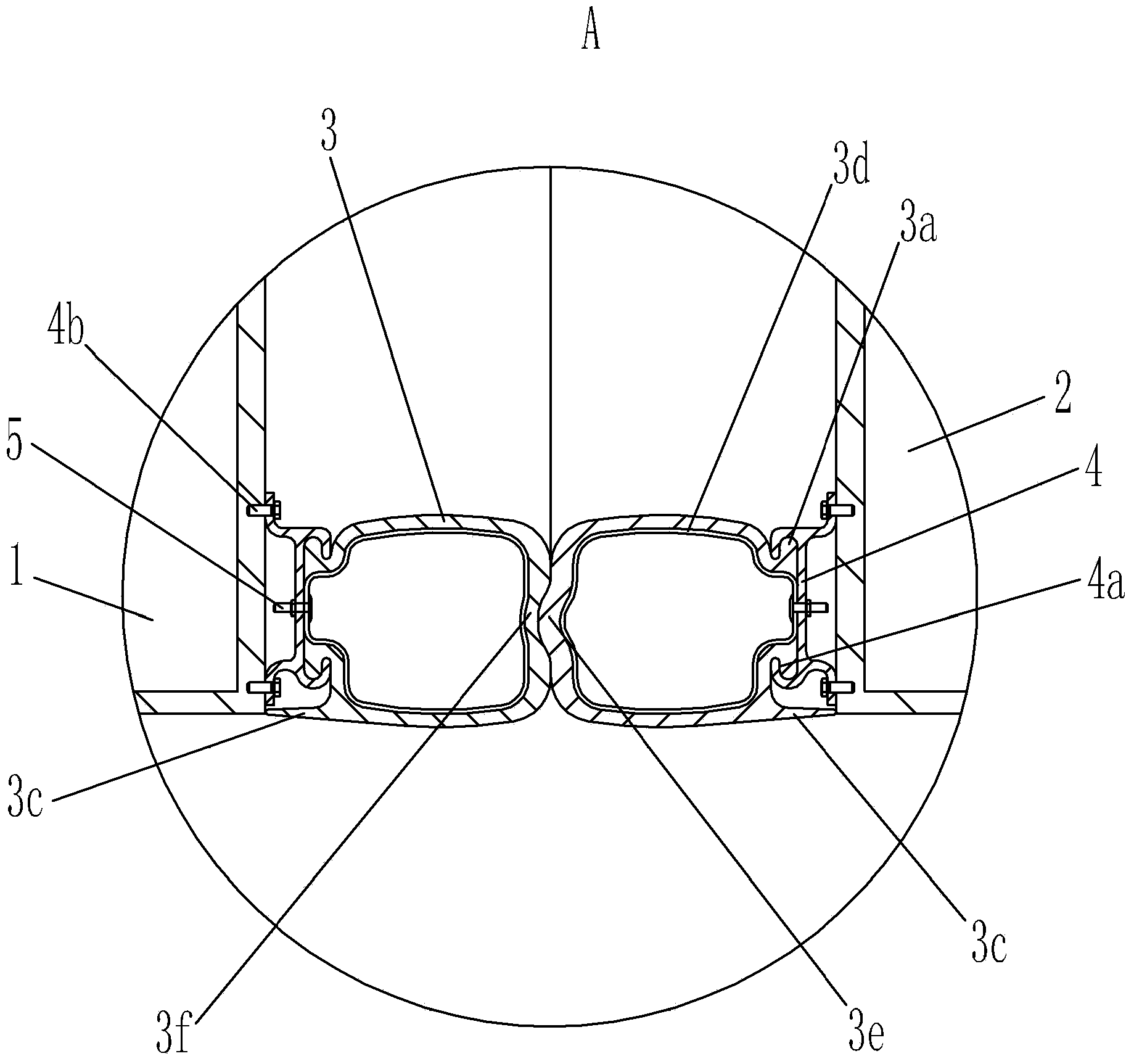

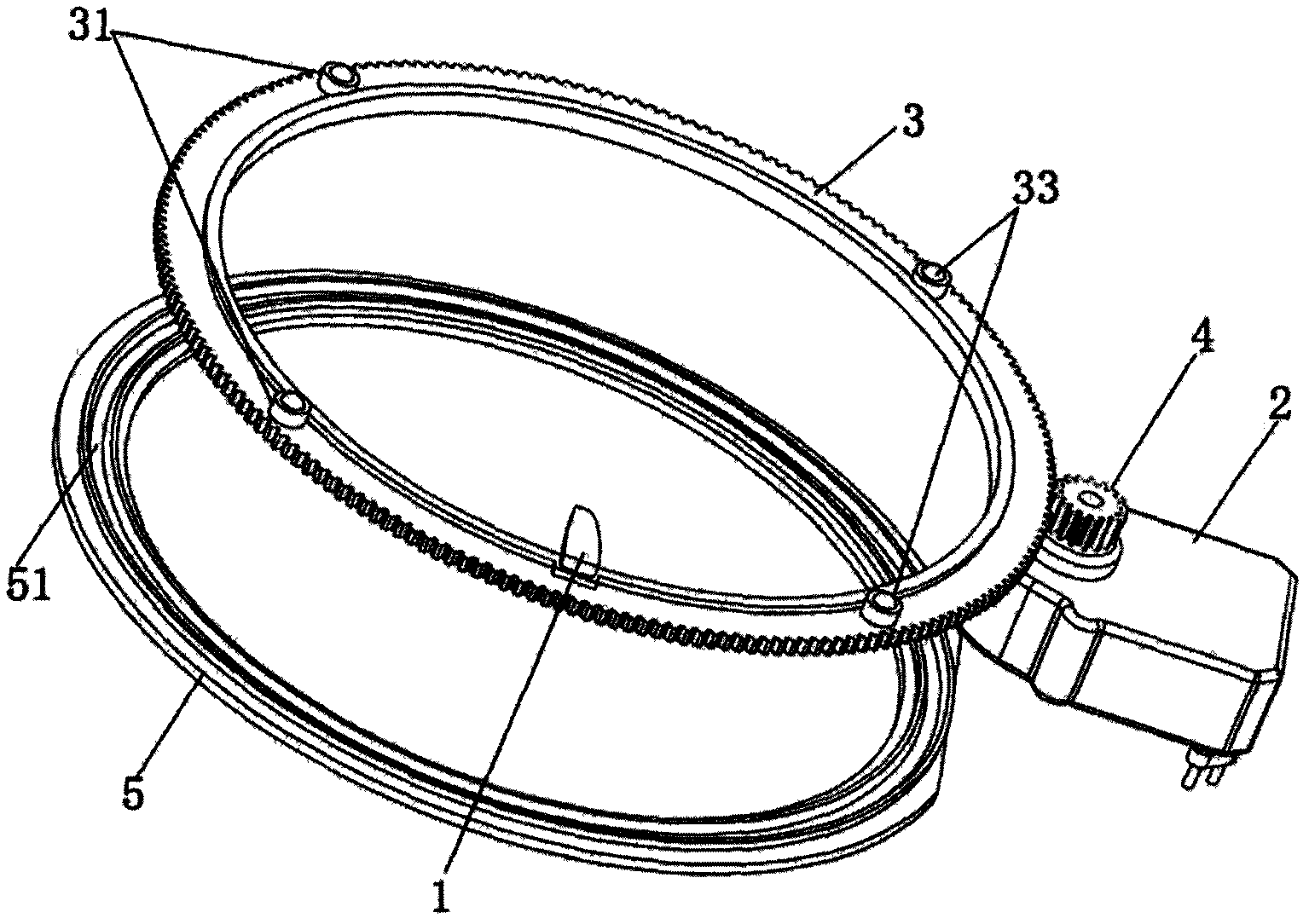

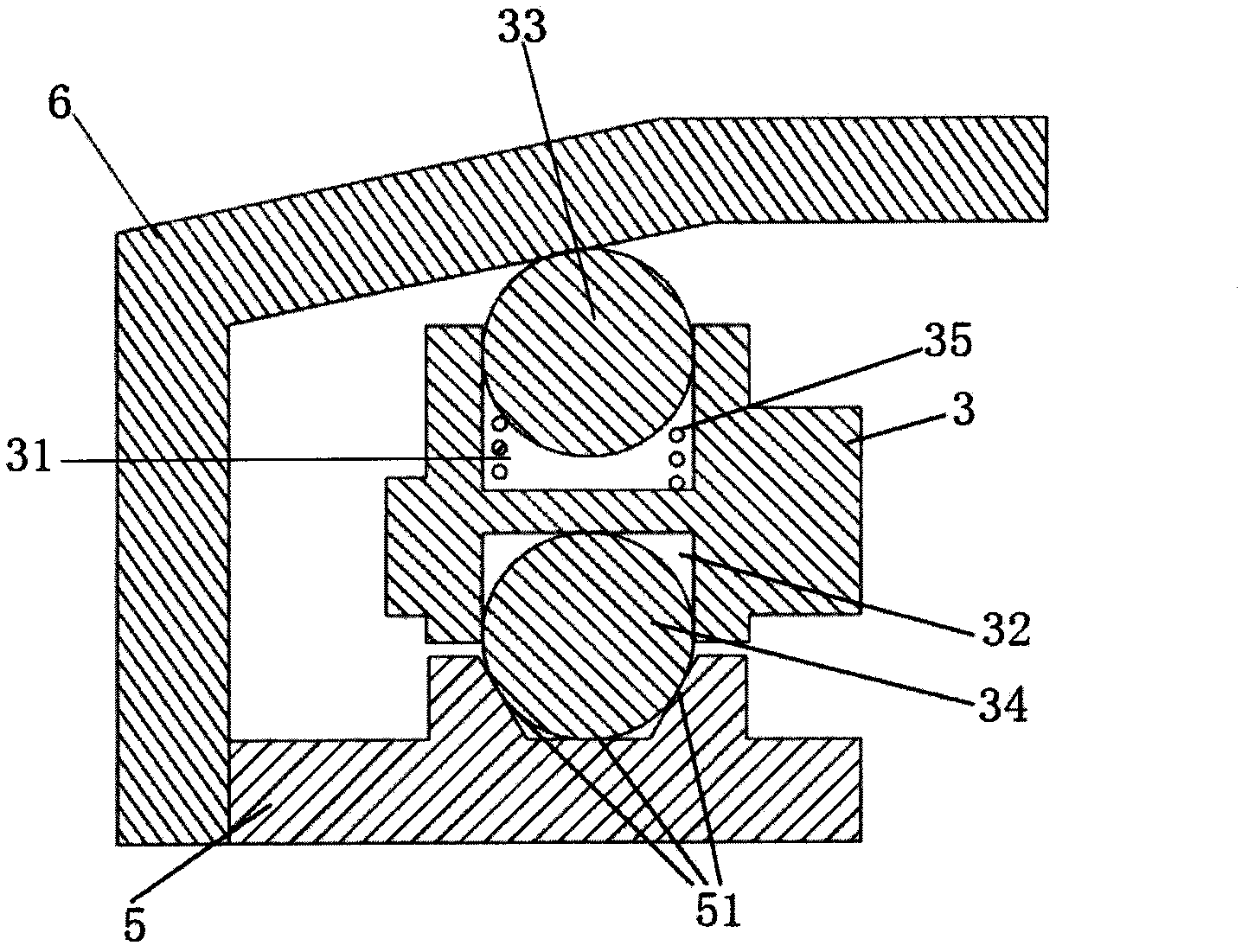

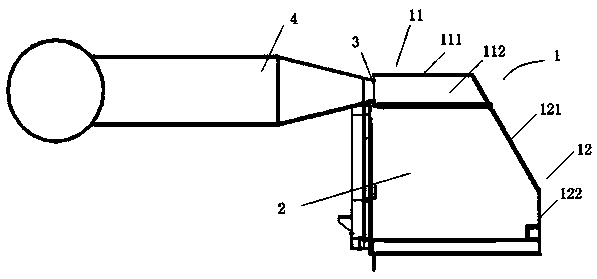

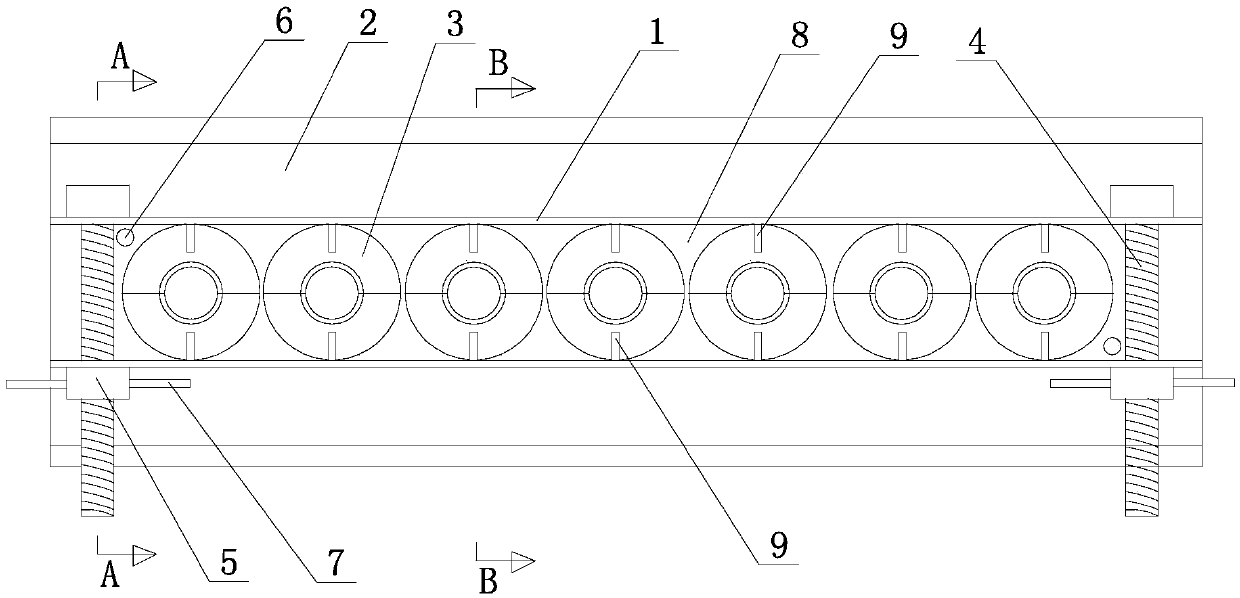

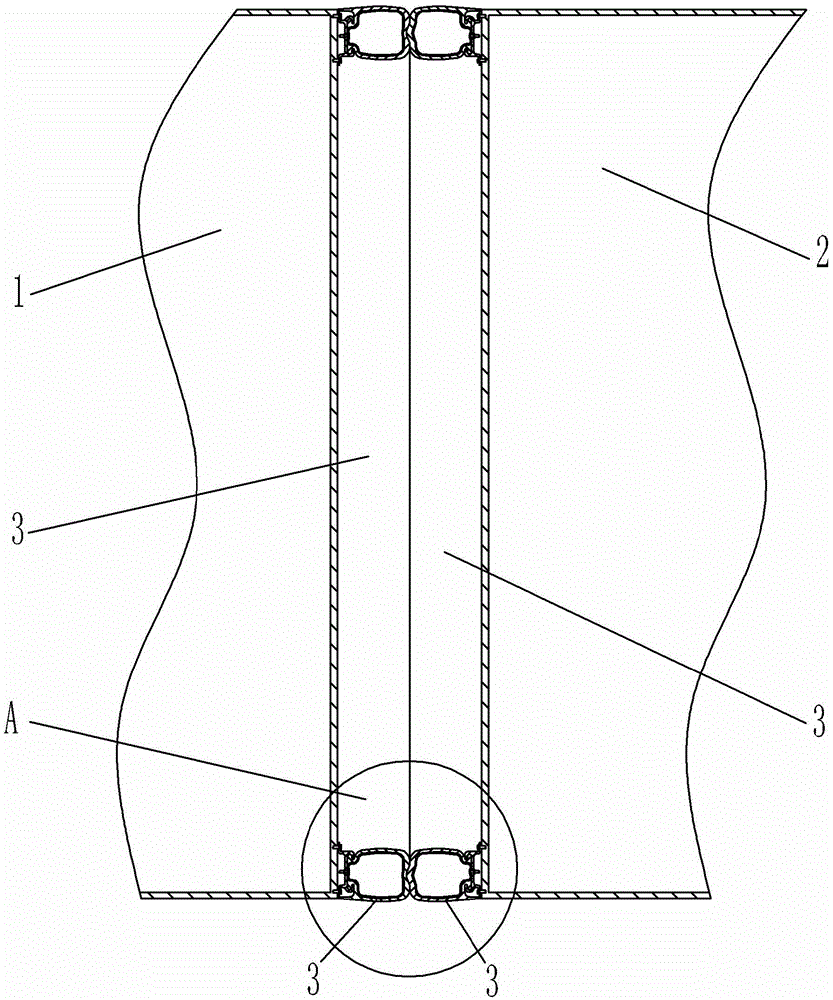

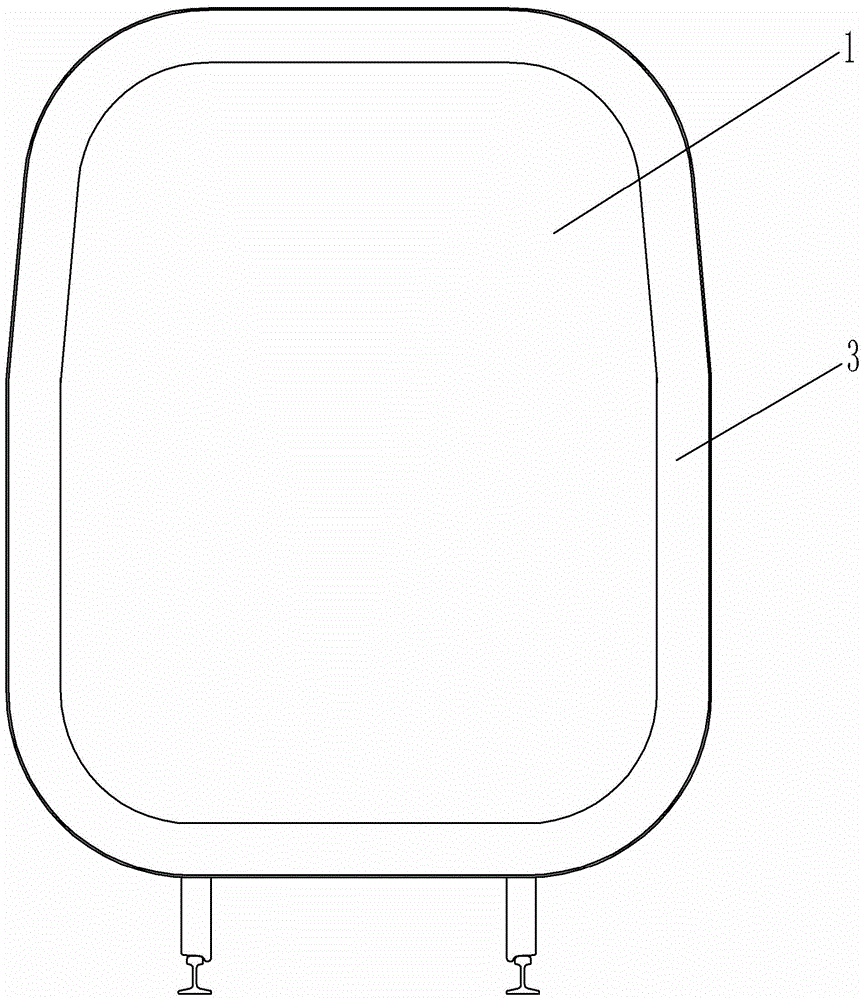

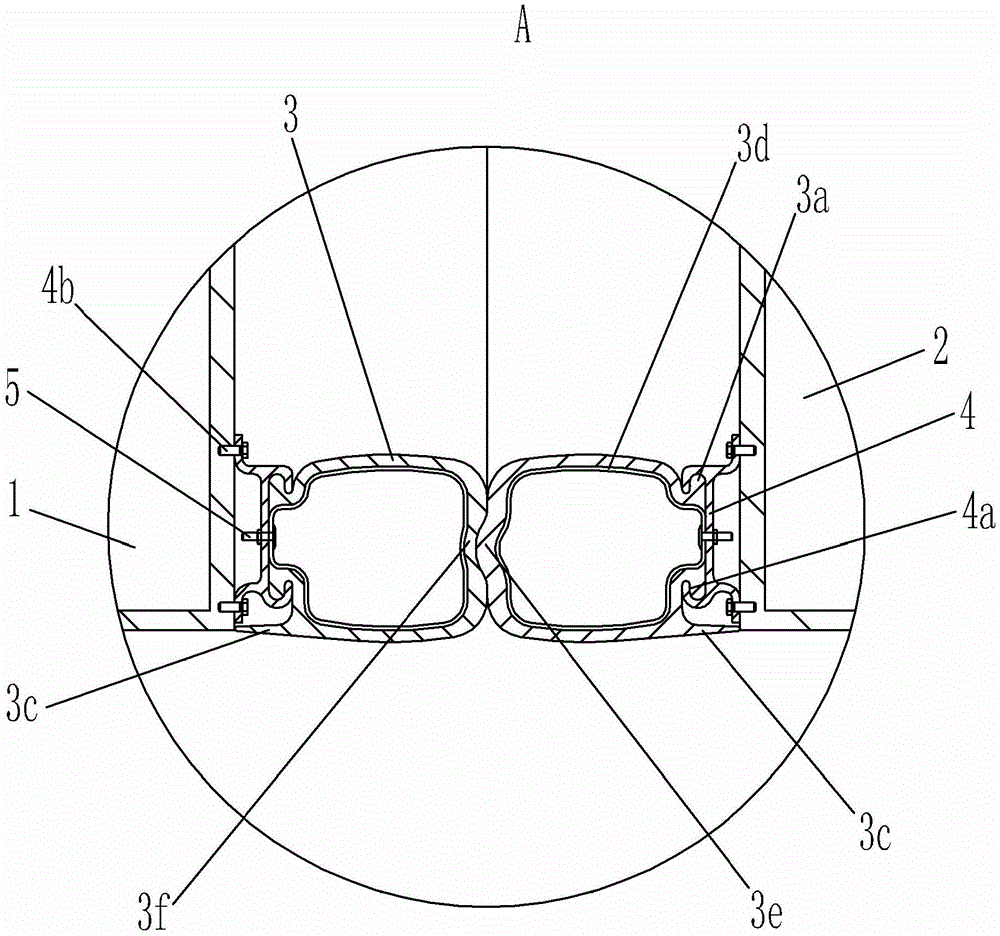

Inflatable type outer windscreen of motor train unit

ActiveCN103863344AStrong curve passing abilityGood air tightnessAxle-box lubricationRailway bodiesAir tightnessEngineering

The invention discloses an inflatable type outer windscreen of a motor train unit. The inflatable type outer windscreen of the motor train unit is characterized in that the periphery of the end face of a front car (1) is fixedly connected with an inflatable integral-ring-shaped rubber air bag (3), the periphery of the end face of a rear car (2) is also fixedly connected with an inflatable integral-ring-shaped rubber air bag (3), and the opposite surfaces of the two inflatable rubber air bags (3) are tightly attached to each other. The inflatable type outer windscreen of the motor train unit has good air tightness, heat-shielding performance, sound insulation performance and rainproof performance, small aerodynamic resistance and good curve passage capacity, and can provide a safer and more comfortable walking-through environment for passengers, and provide more effective protection for car flexible connection devices.

Owner:张建华

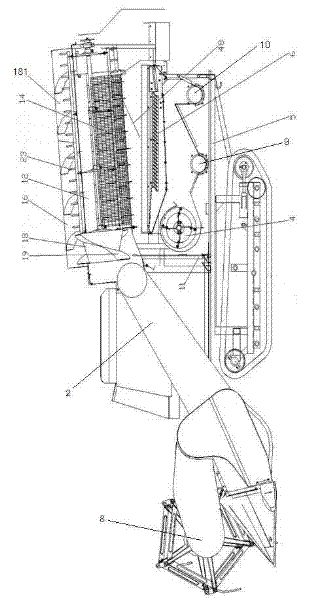

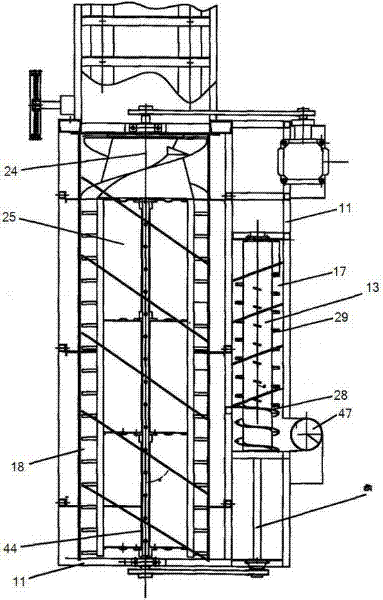

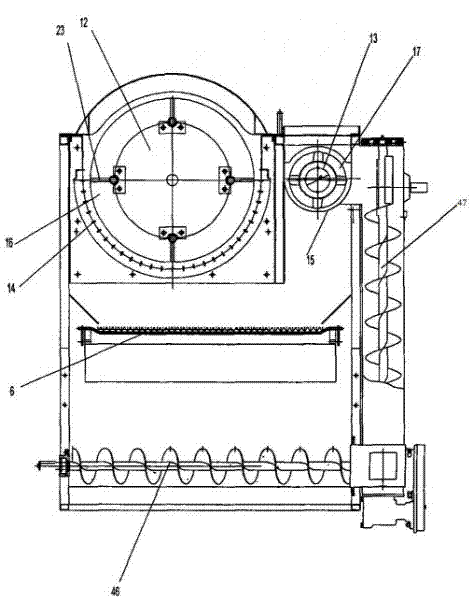

Threshing device of harvester

The invention relates to a harvester, in particular to a threshing device of a harvester. According to the technical scheme, the threshing device of the harvester comprises an underframe, a threshing frame, a main threshing mechanism, a rethreshing mechanism, a separation, cleaning and vibration screen and an impurity lifting screw, wherein the threshing frame is fixed on the underframe, both the main threshing mechanism and the rethreshing mechanism are connected to the threshing frame and disposed along the travelling direction of the harvester, the separation, cleaning and vibration screen is fixedly connected to the threshing frame and positioned between the underframe and the main threshing and rethreshing mechanisms, and the impurity lifting screw is disposed between the position below the rear end of the separation, cleaning and vibration screen and the rethreshing mechanism. The main threshing mechanism comprises a main threshing roller, a large concave screen and a main roller cover, wherein the main threshing roller is hinged to the threshing frame, the large concave screen is fixed to the threshing frame and encloses the main threshing roller, and the main roller cover covers an opening of the large concave screen. The main threshing roller is slantingly disposed along the advancing direction of the harvester. A corner between the main threshing roller and a conveying chute of the threshing device compared with the prior art is reduced, so that conveying of crops is smooth, and the shortages of the prior art are made up.

Owner:ZHONGJI SOUTHERN MACHINERY

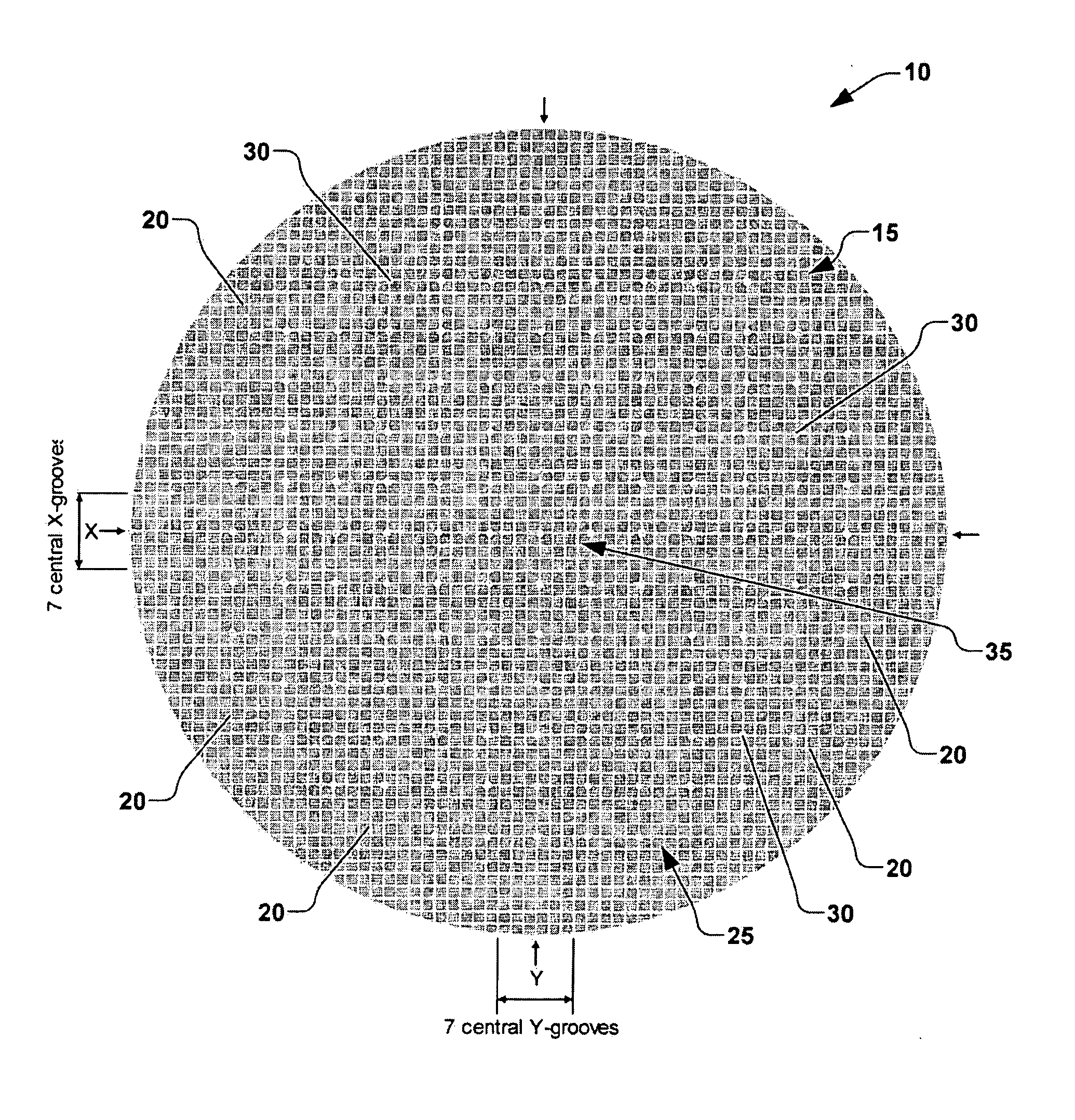

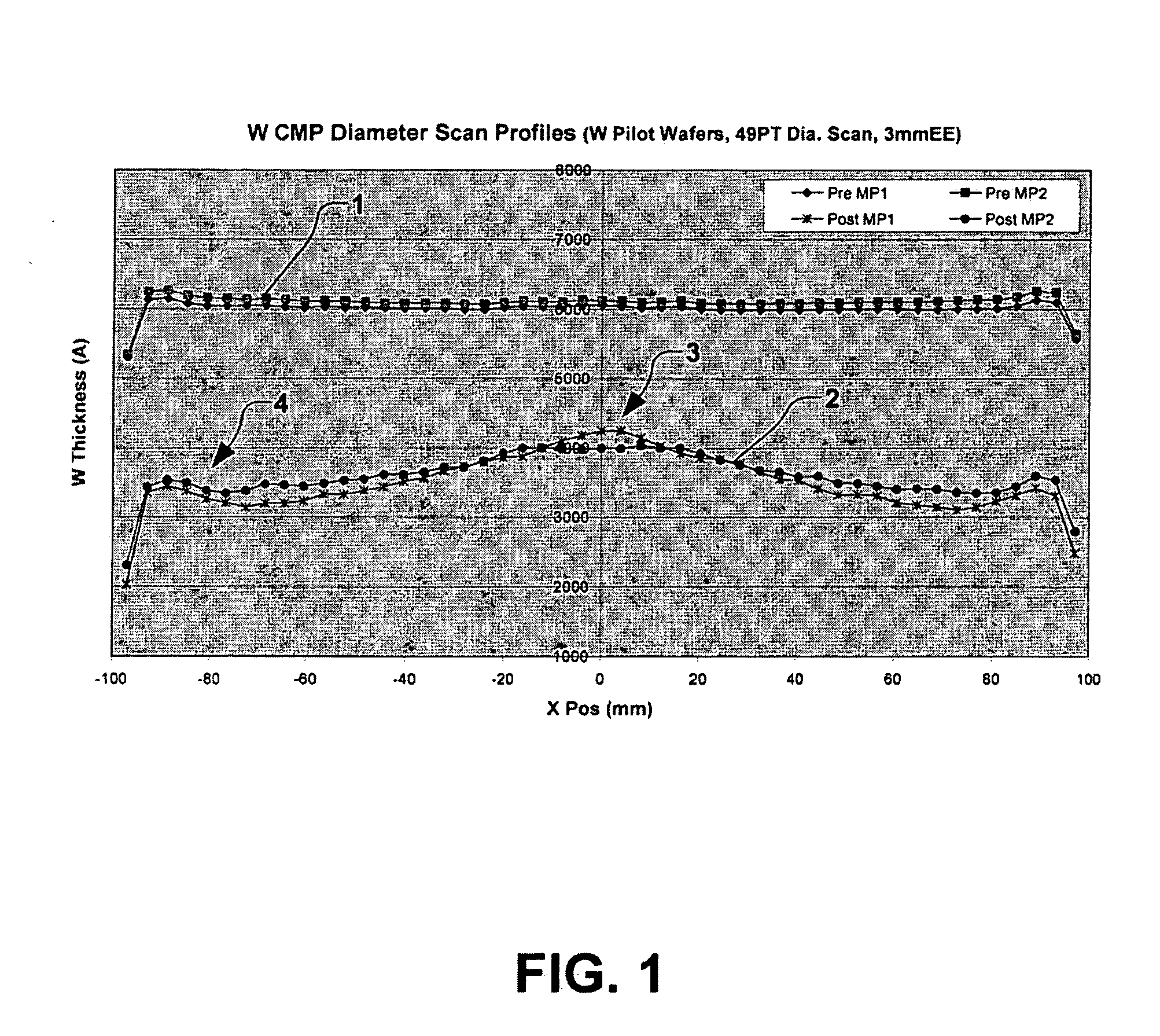

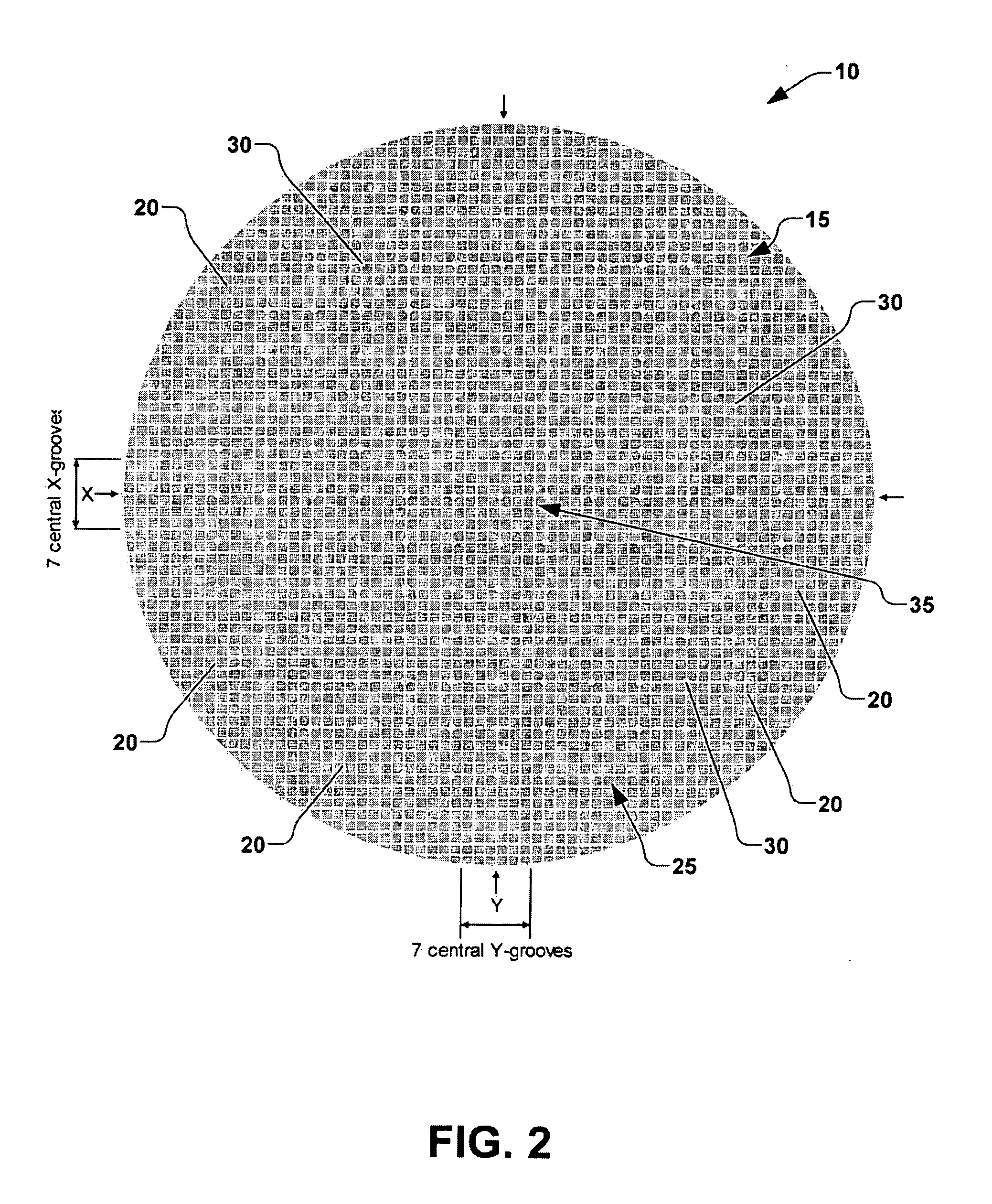

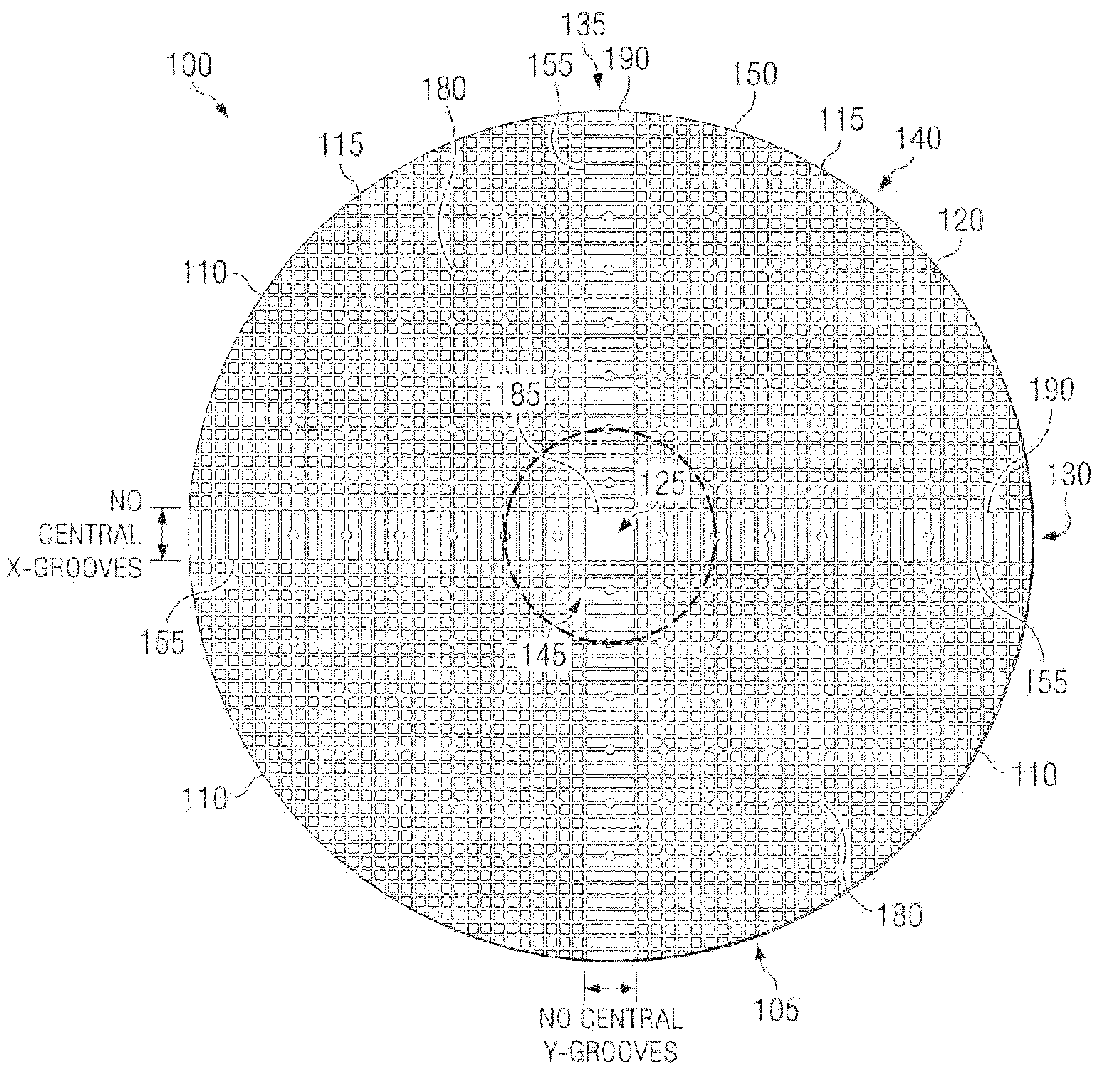

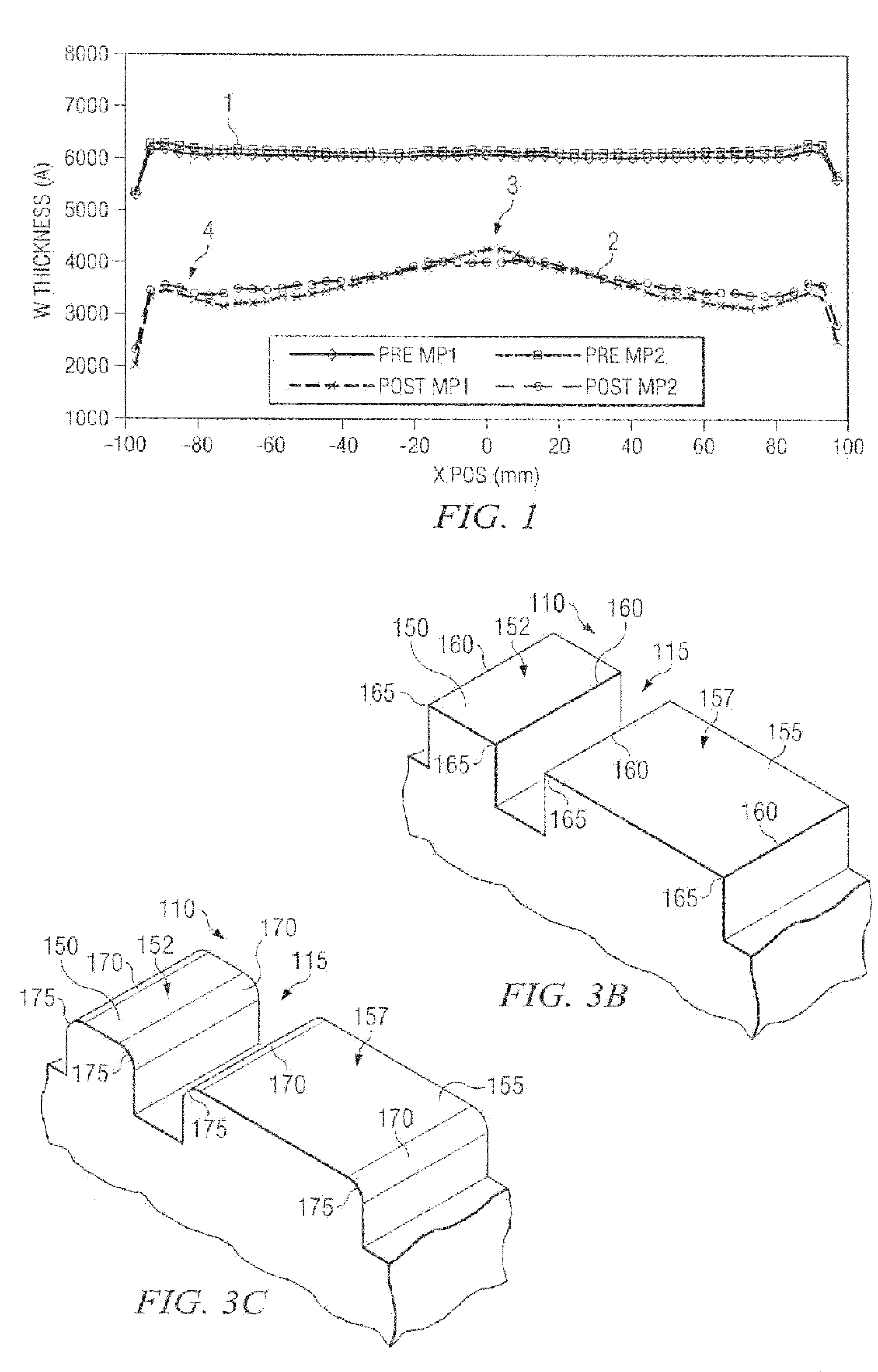

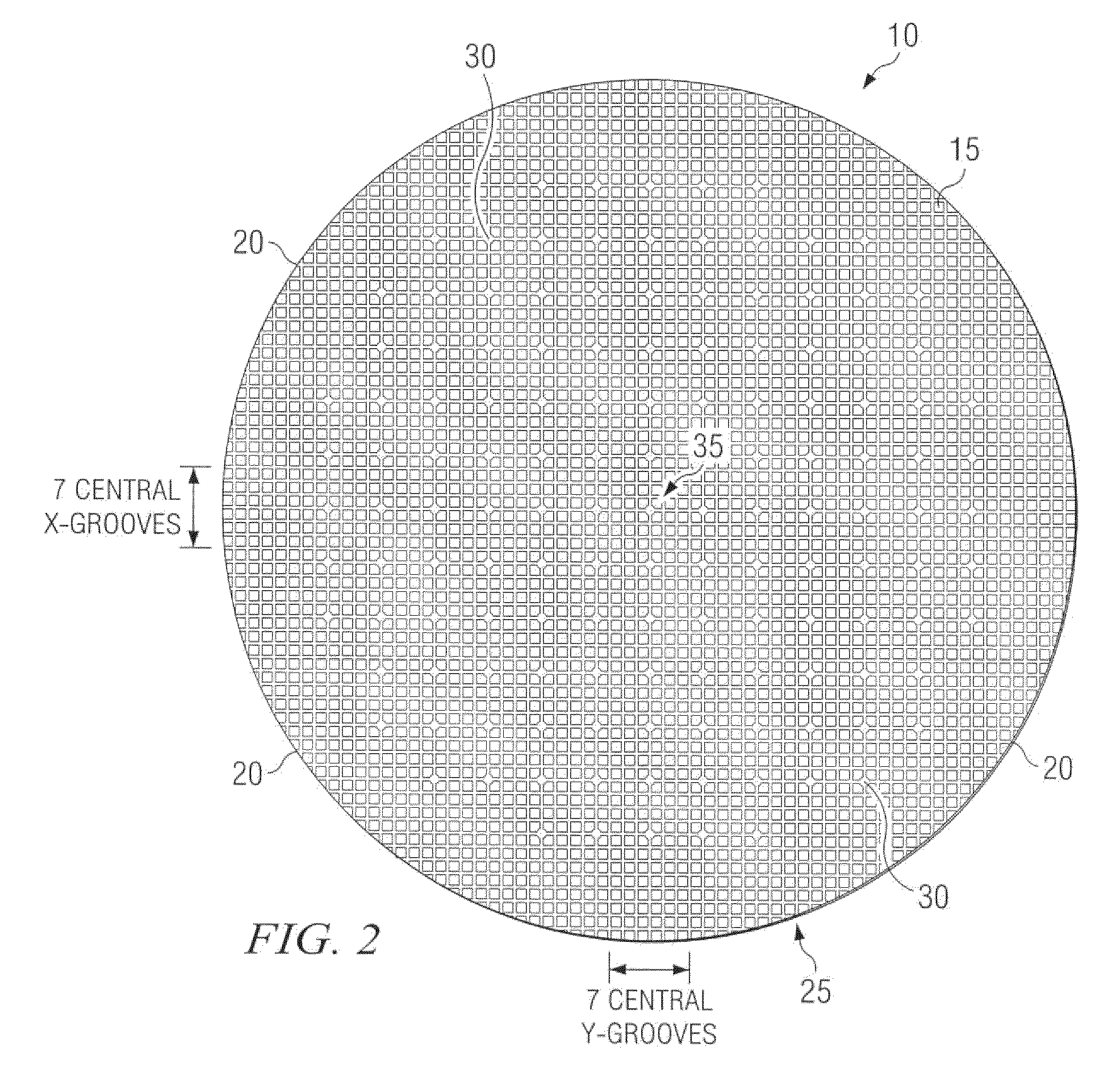

Chemical mechanical polishing pad having improved groove pattern

ActiveUS20080160890A1Greater mechanical and chemical polishingIncrease surface areaRevolution surface grinding machinesFlexible-parts wheelsEngineering

A chemical mechanical polishing pad and method for chemical-mechanical polishing is provided, wherein the polishing pad has a plurality of first mesas and one or more second mesas defined on a surface thereof. The plurality of first mesas are generally distributed about the surface of the polishing pad, wherein each of the plurality of first mesas has a first surface area associated therewith. The one or more second mesas are associated with a center region of the polishing pad, wherein each of the one or more second mesas has a second surface area associated therewith. The second surface area is at least twice the first surface area.

Owner:TEXAS INSTR INC

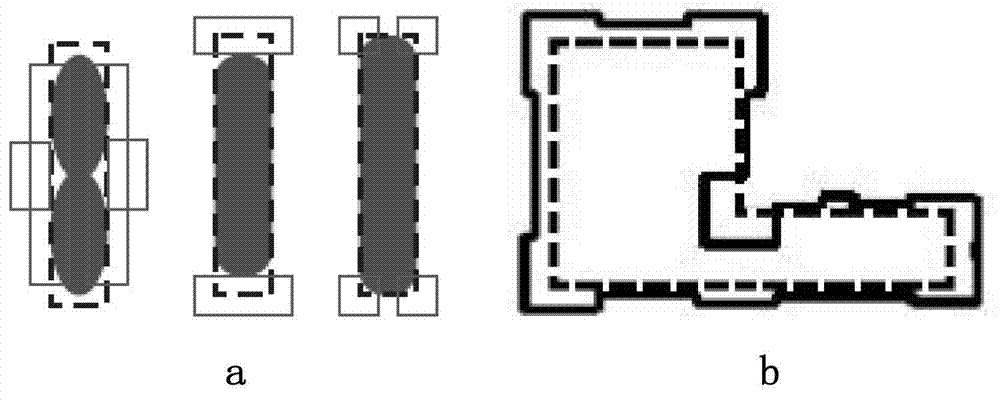

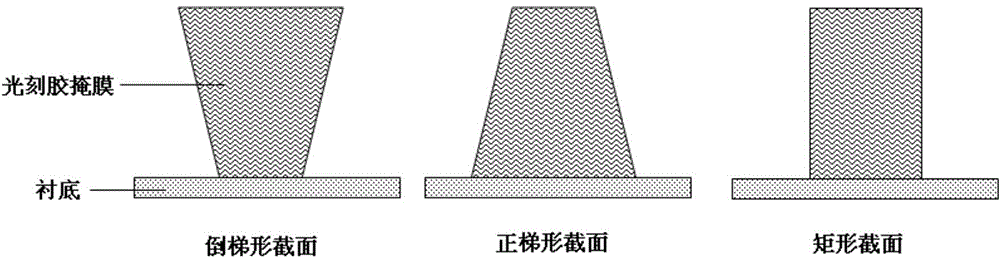

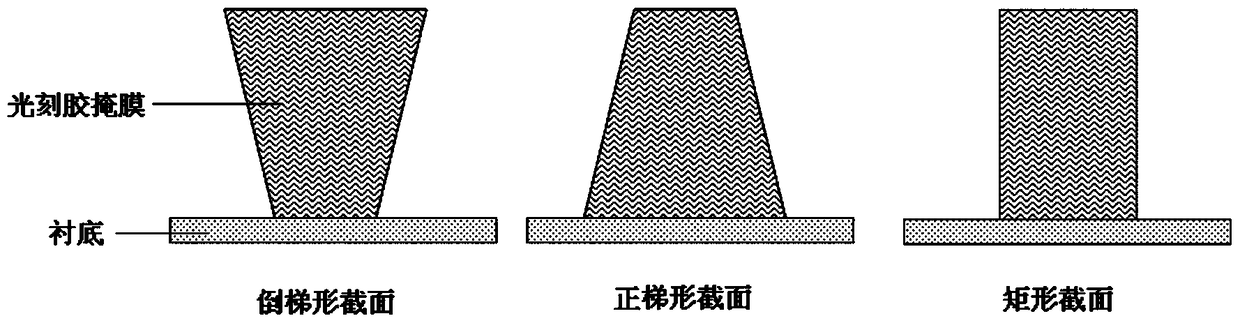

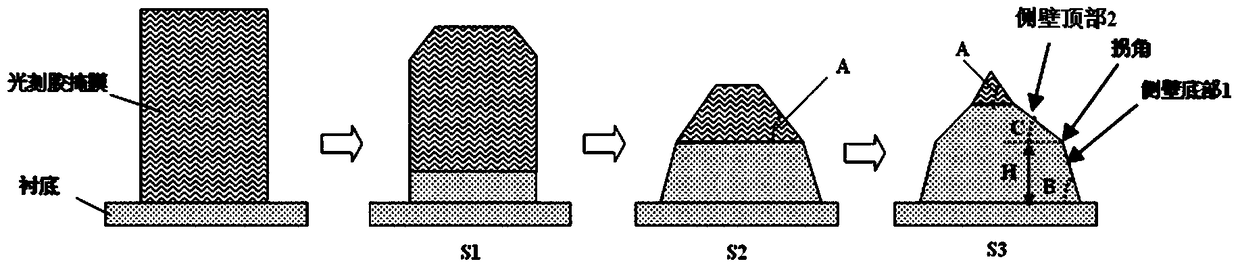

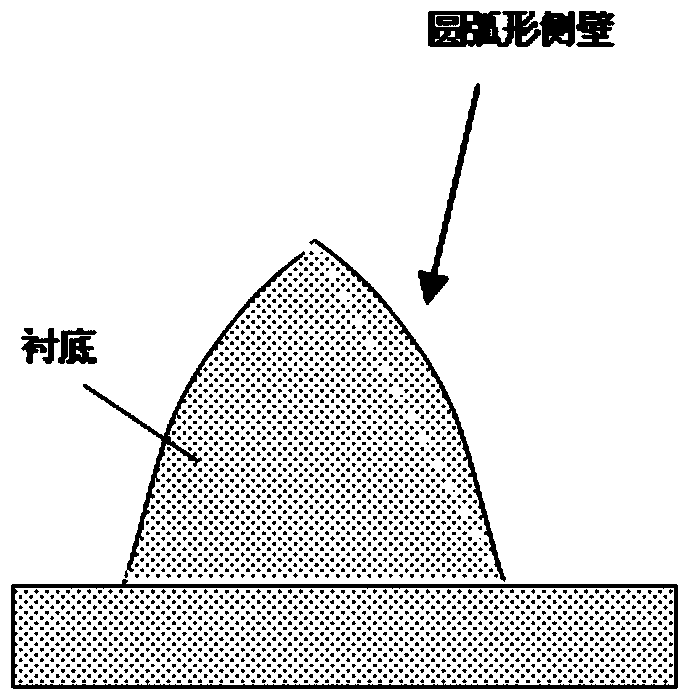

Etching mask group and substrate etching method applying same

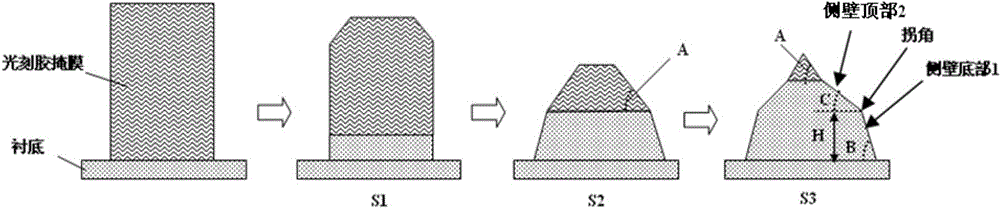

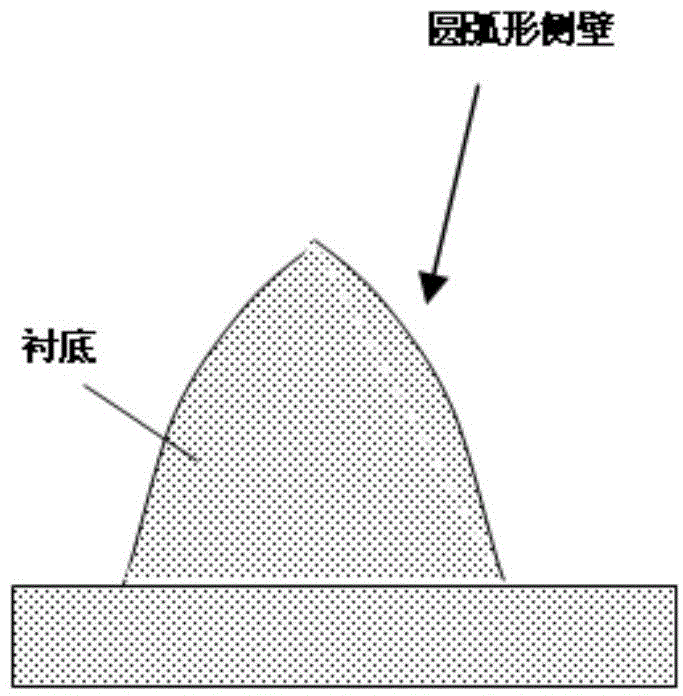

ActiveCN105655231ASlow down lateral shrinkageReduce cornersSemiconductor/solid-state device manufacturingEtching selectivityPhotoresist

The invention provides an etching mask group and a substrate etching method applying the same. The etching mask group comprises a first mask layer made of a photoresist material, and a second mask layer made of a material capable of improving an etching selectivity ratio relative to a substrate, wherein the first mask layer is arranged on the surface of the substrate, the second mask layer is arranged on the first mask layer; and the widths of the bottom portions of respective patterns of first mask layer and the second mask layer are arranged in such a way that the inclination angle of a preset connecting line between the first mask layer and the second mask layer is consistent with a fixed inclination angle of the first mask layer. The etching mask group provided by the invention can realize the purpose of improving the pattern morphology of the substrate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

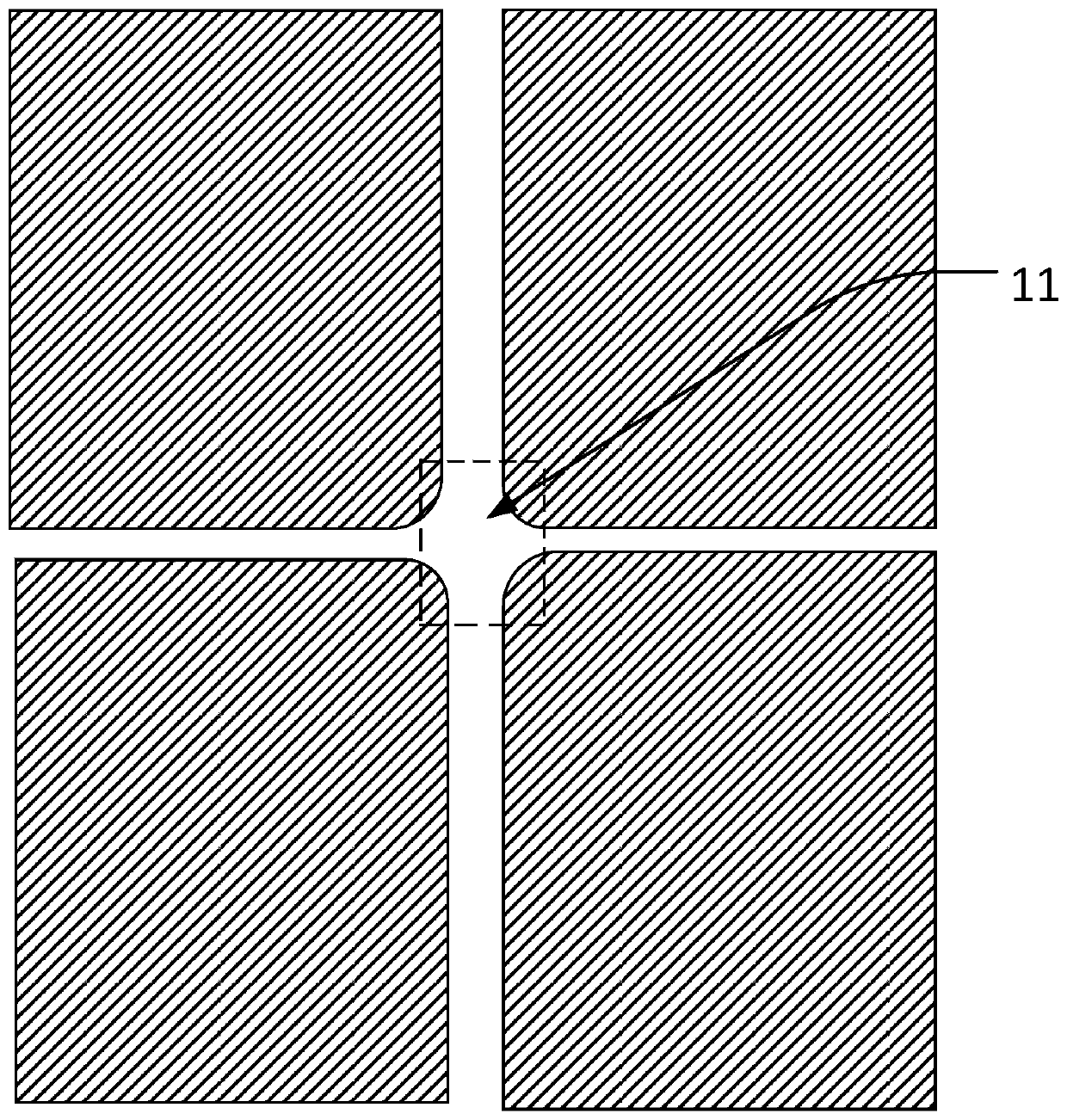

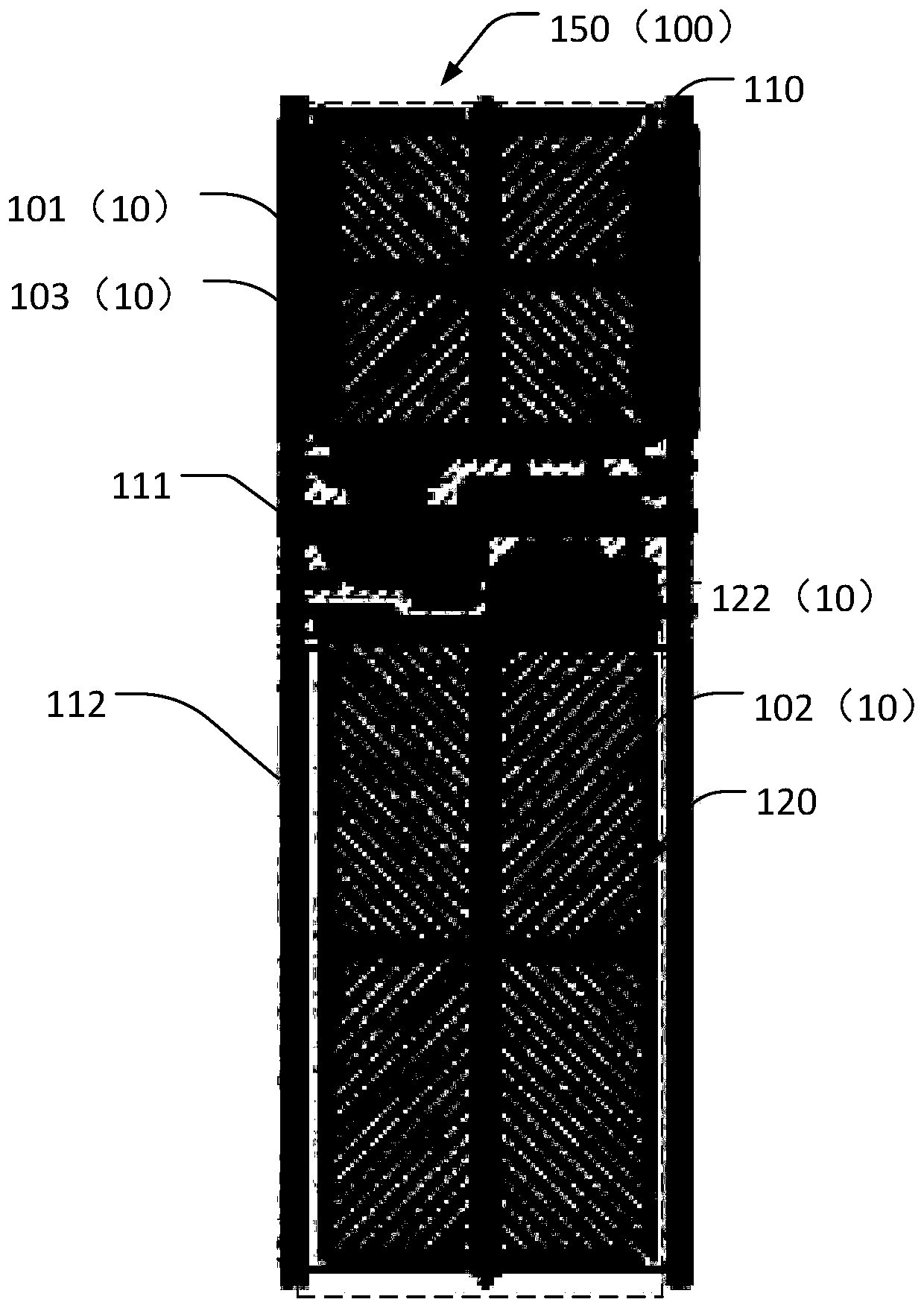

Array substrate

The invention provides an array substrate, which comprises a plurality of sub-pixels and a first metal layer, wherein the plurality of sub-pixels are in array arrangement, and each sub-pixel is divided into a main area and a secondary area; in the main area, the first metal layer is provided with first longitudinal lines and a first lateral line; each longitudinal-row sub-pixel corresponds to at least one first longitudinal line; the first lateral line is arranged on one side, which faces the secondary area, of the main area, and all first longitudinal lines are vertically connected to the first lateral line; in the secondary area, the first metal layer is provided with second longitudinal lines and a second lateral line, wherein each longitudinal-row sub-pixel corresponds to one second longitudinal line; the second lateral line is arranged on one side, which faces the main area, of the secondary area; and all second longitudinal lines are vertically connected to the second lateral line. The array substrate aims to reduce intersections and corners in a pixel area through the reduction of the lateral line of a first common electrode, and the problems of light leakage, poor contrastratio and the like of the pixel under a dark state can be effectively eliminated.

Owner:SUZHOU CHINA STAR OPTOELECTRONICS TECH CO LTD

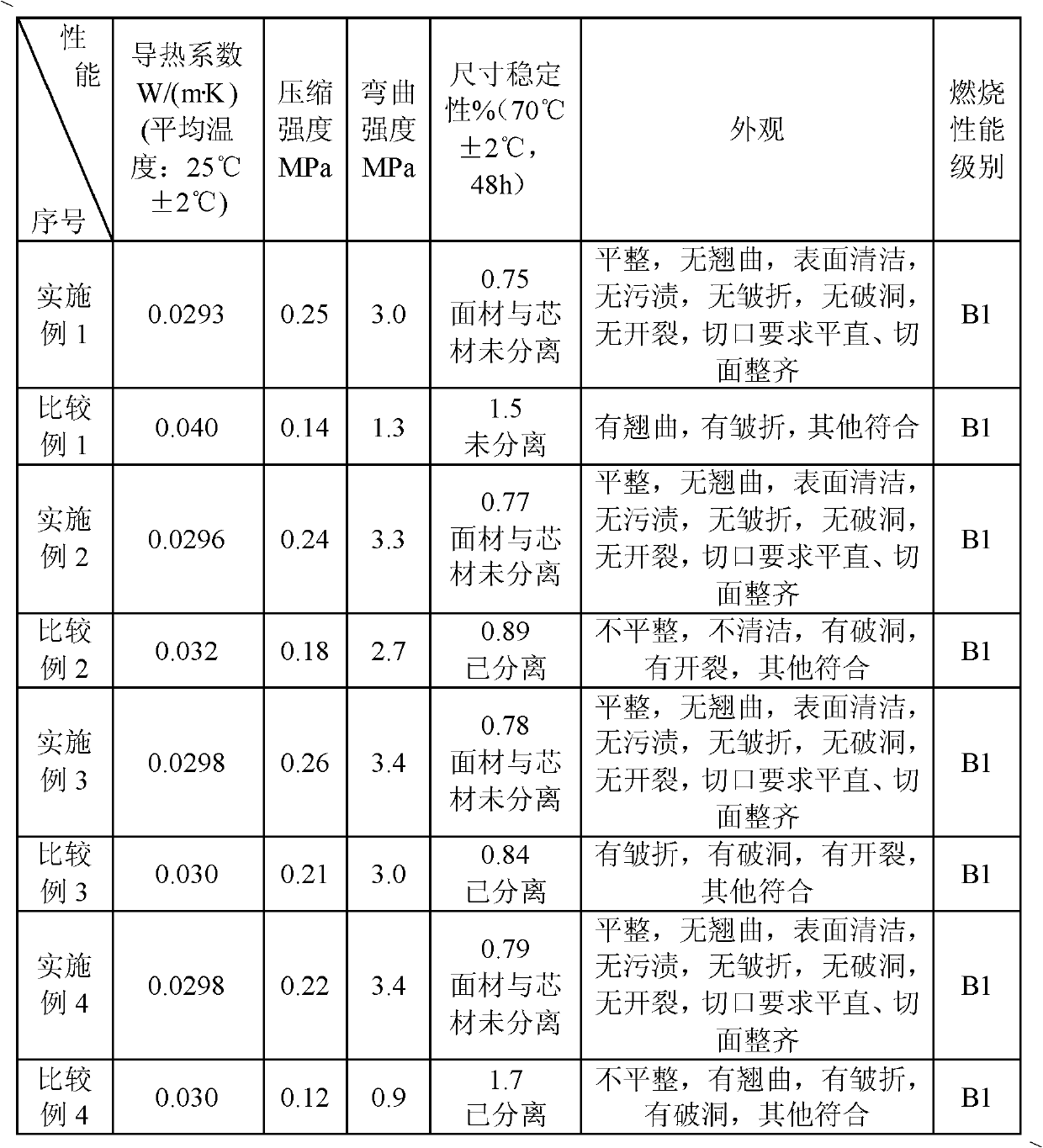

Preparation method of high energy-saving type modified environment-friendly phenolic fireproof insulation board

InactiveCN103289307AReduce cornersImproves Strength and ToughnessSurface-active agentsPhenol formaldehyde resin

The invention provides a preparation method of a high energy-saving type modified environment-friendly phenolic fireproof insulation board. The method comprises the following steps of: mixing and evenly stirring leftover and waste materials of the phenolic resin fireproof insulation board, waste rubber powder, expandable phenolic resin, modifying agents, a surface active agent and a foaming agent; then, adding a composite curing agent into the mixture, stirring the mixture and the agent, and pouring the obtained mixture into a mould to obtain the phenolic resin fireproof insulation board. By adopting the double modifying agents, the method can alleviate environment pollution caused by the waste rubber and the leftover and waste materials of the phenolic resin fireproof insulation board, reduce energy consumed by the preparation of the phenolic resin fireproof insulation board, improve the strength and the toughness of the phenolic insulation board, reduce the brittleness of the phenolic insulation board and lower the industrial cost, is beneficial to improving economic benefits, and meets the construction demand of a building outer wall (specifically an outer wall insulation system).

Owner:营口象圆新材料工程技术有限公司

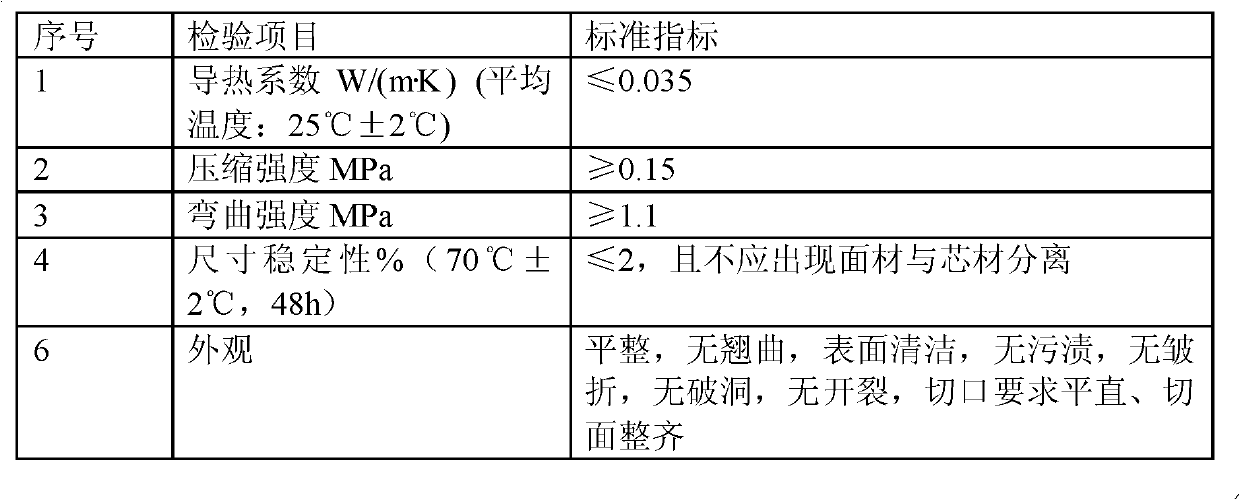

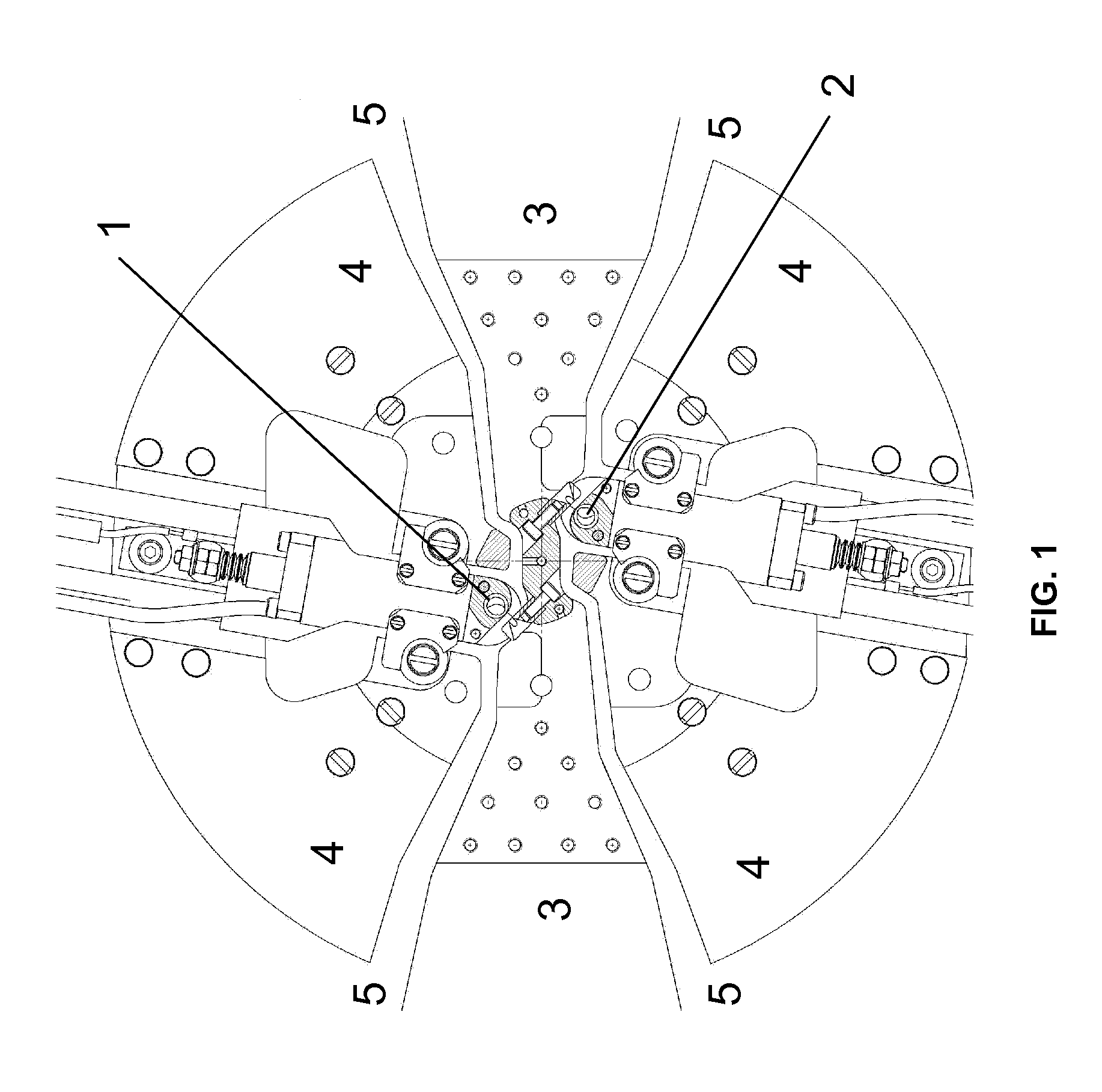

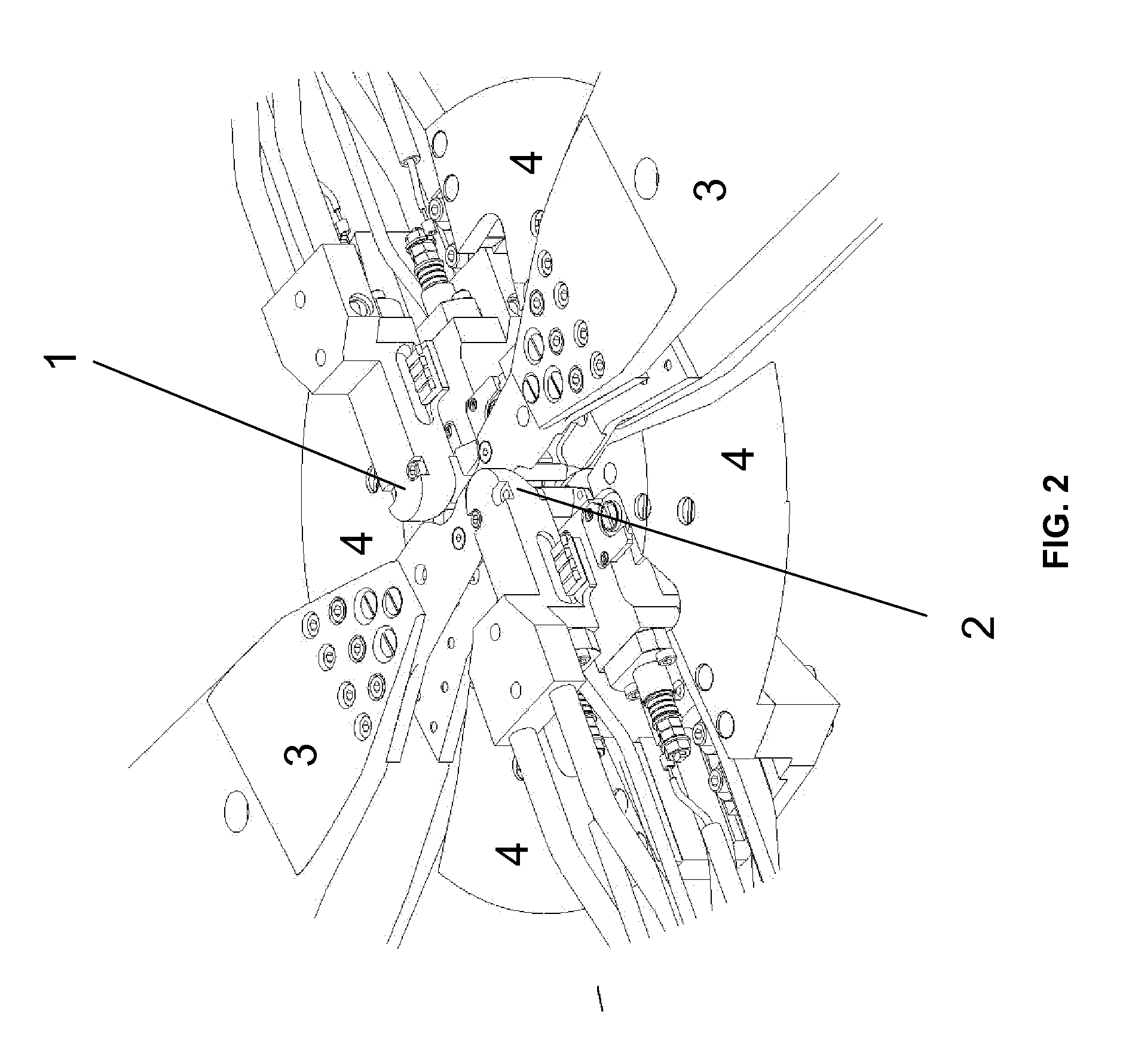

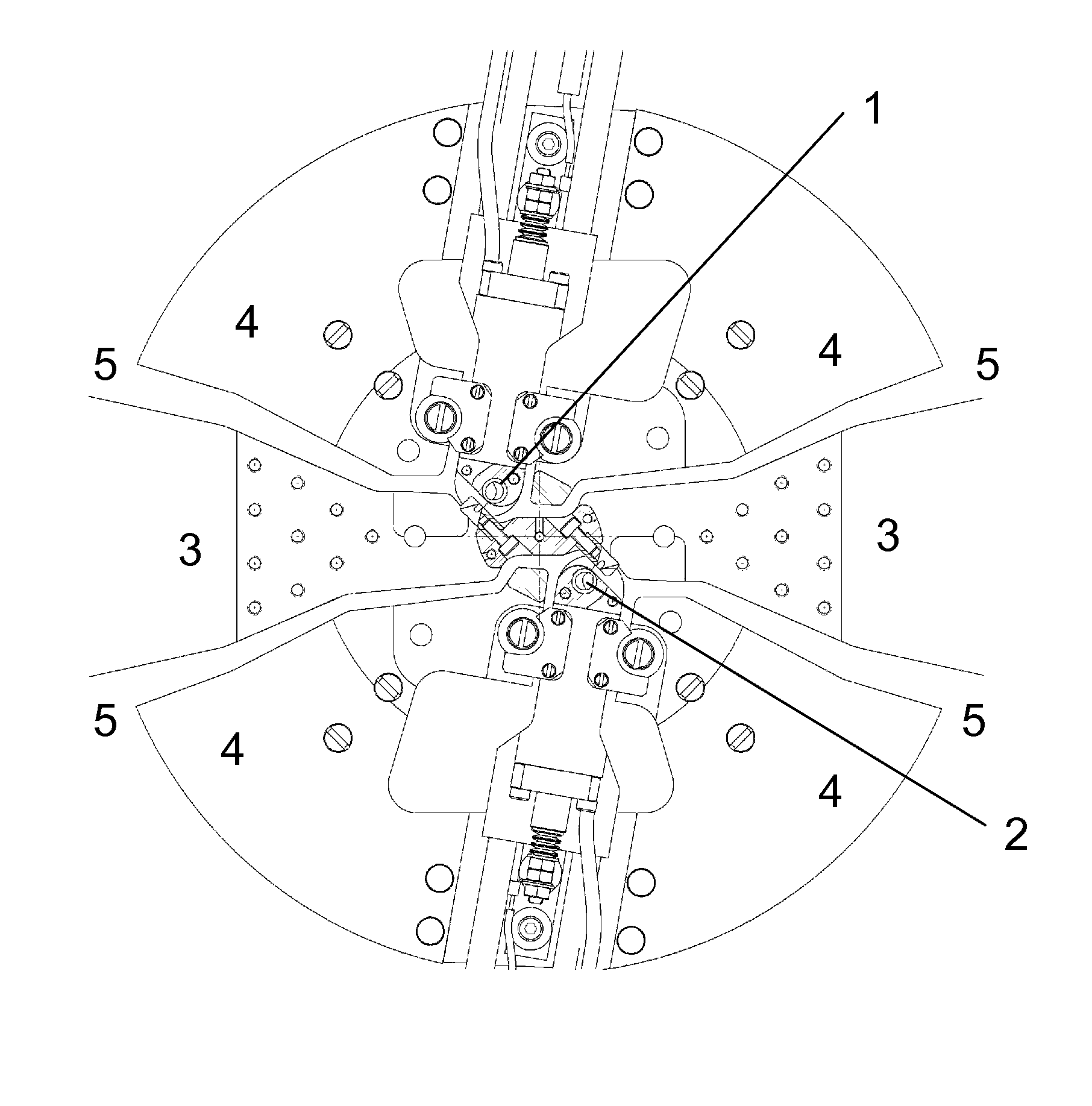

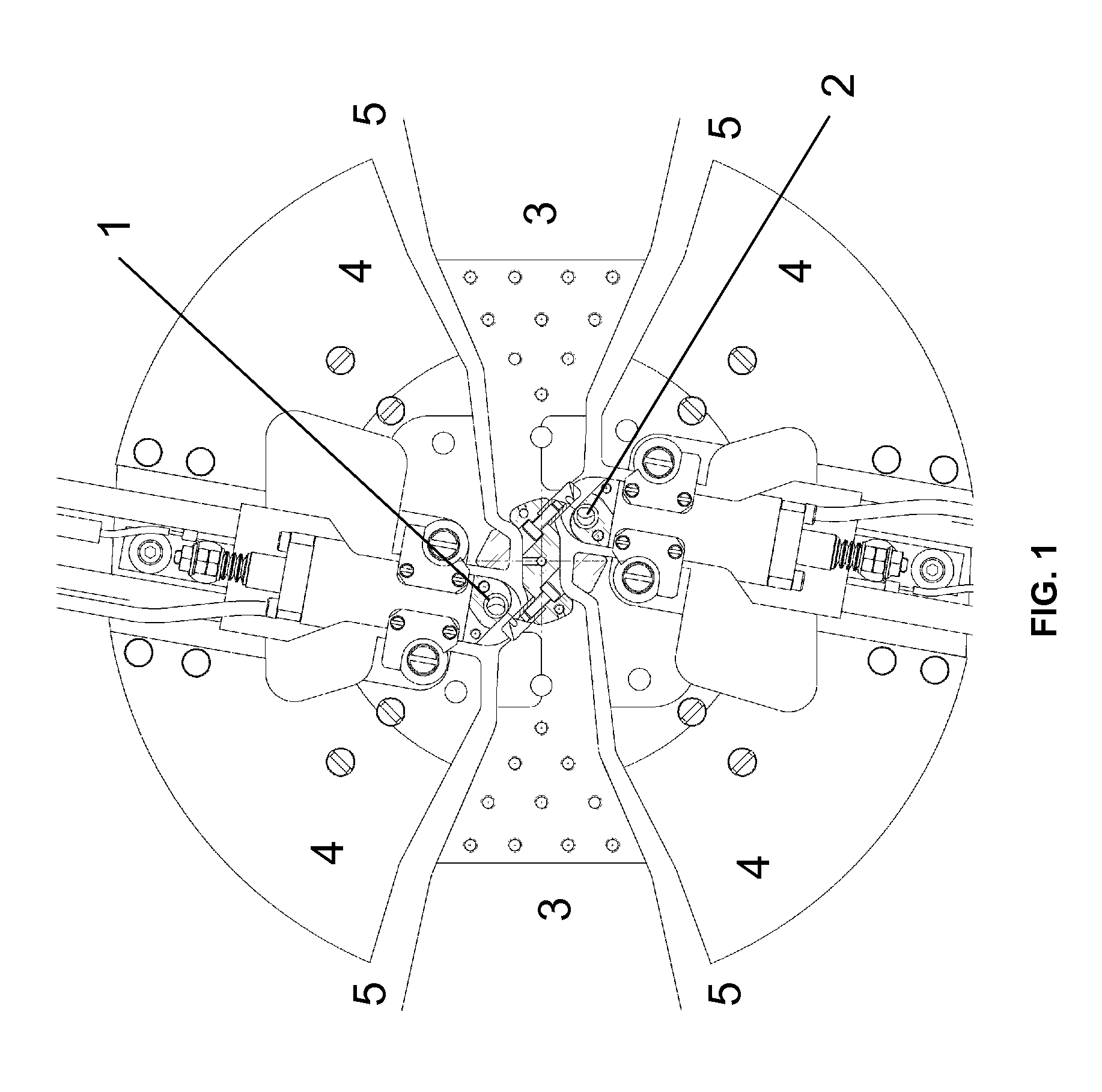

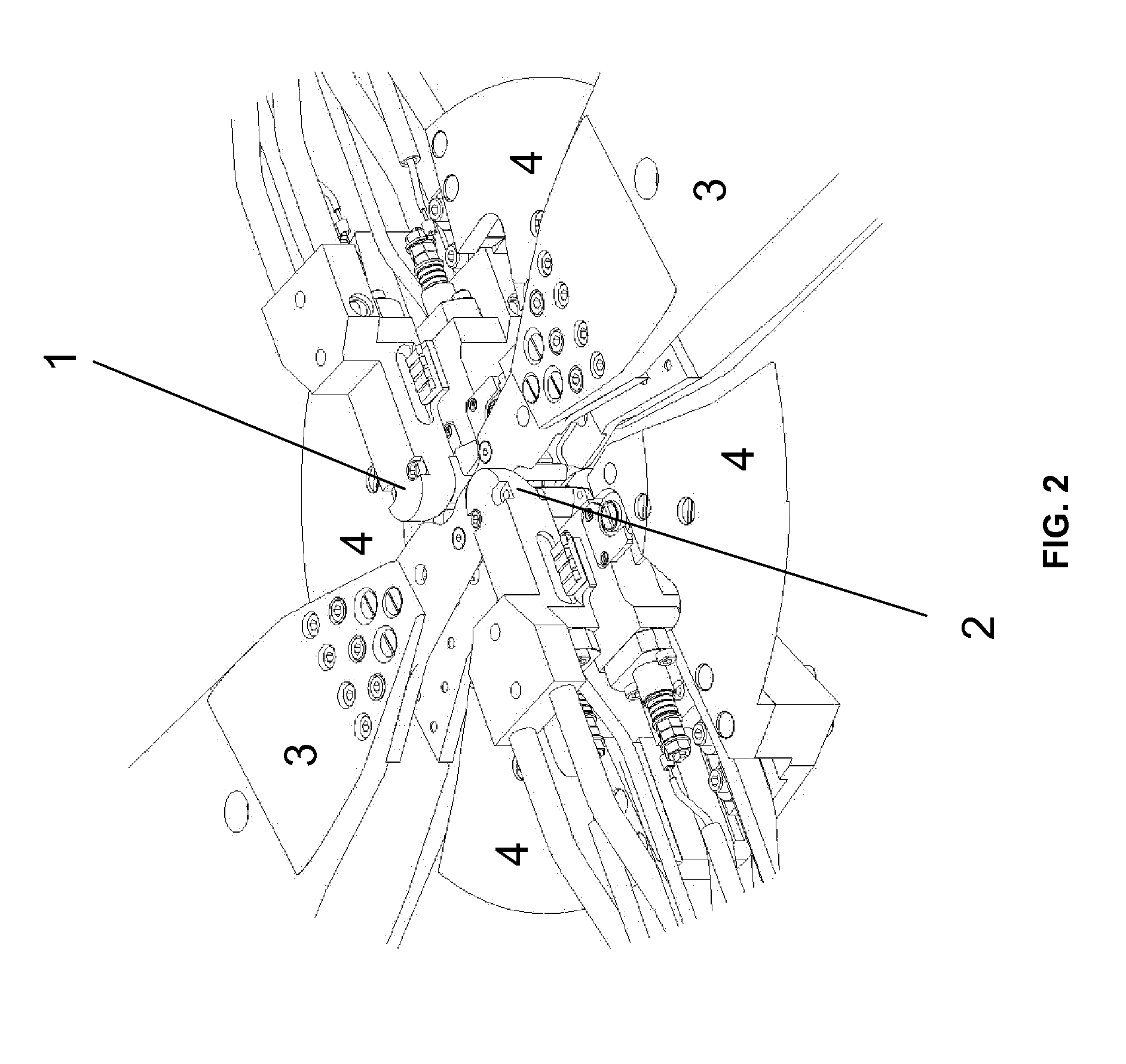

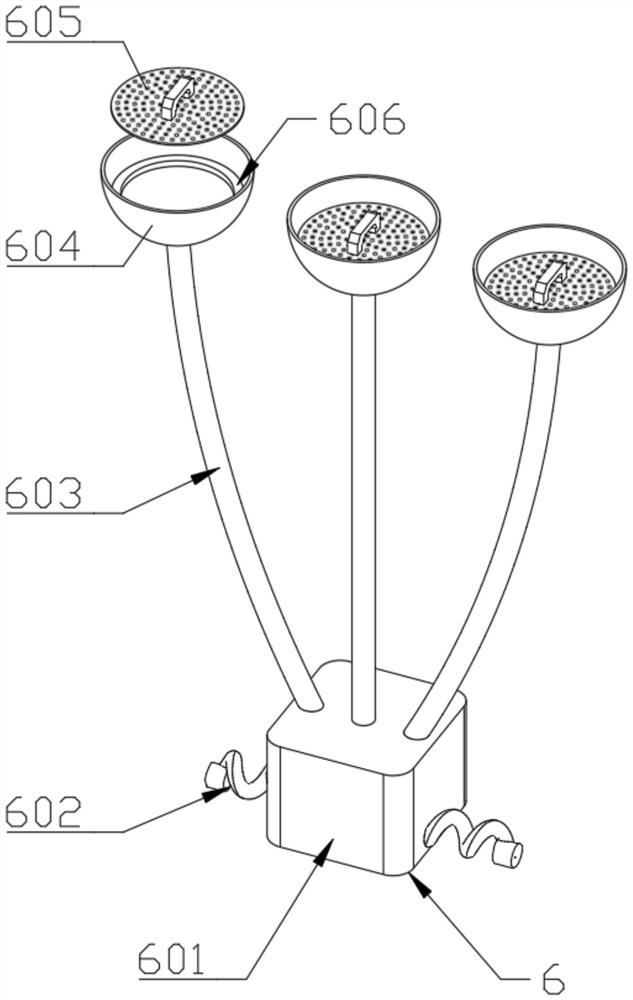

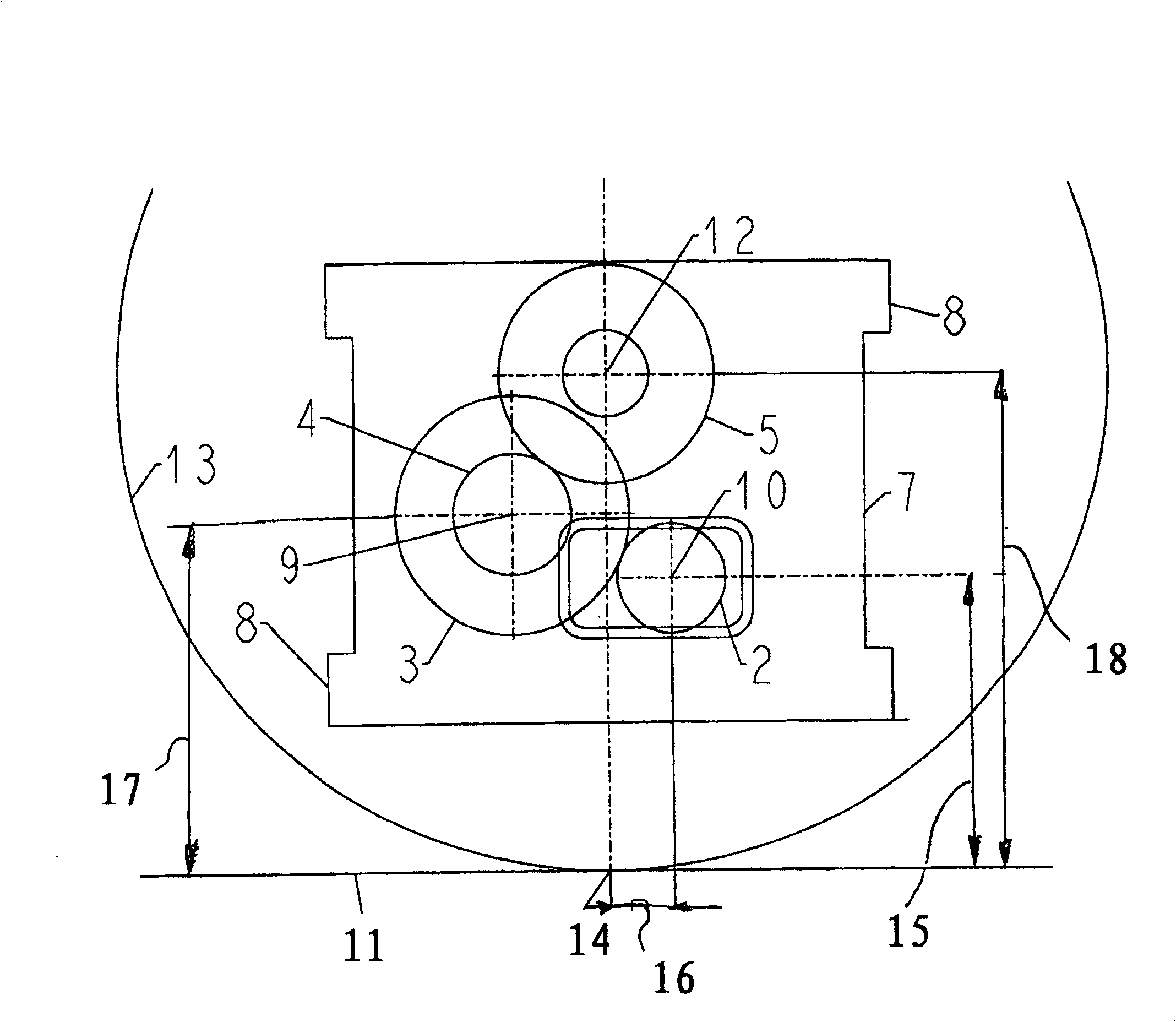

Twin Internal Ion Source For Particle Beam Production With A Cyclotron

ActiveUS20110068717A1Avoid particle lossIncrease distanceTransit-time tubesMagnetic resonance acceleratorsParticle beamParticle loss

The present invention relates to a cyclotron including two internal ion sources for the production of the same particles. The second ion source can be used as a spare ion source which strongly increases the uptime and the reliability of the cyclotron and reduces the maintenance interventions. Advantageously, the cyclotron is further characterized by an optimized close geometry of the different elements within the central region of the cyclotron. The cyclotron of the invention may be further characterized by an adaptation and optimization of the shape of first and second internal ion source to avoid particle losses during the first turn of acceleration. The cyclotron may be further characterized by an adaptation and optimization of the shape of the counter-Dee electrode assembly and possibly the Dee-electrode assembly in order to improve the acceleration field in-between the gaps.

Owner:ION BEAM APPL

Twin internal ion source for particle beam production with a cyclotron

ActiveUS8324841B2Avoid particle lossesParticle losses during the first turn of acceleration are minimizedTransit-time tubesMagnetic resonance acceleratorsParticle beamParticle loss

Owner:ION BEAM APPL

Chemical mechanical polishing pad having improved groove pattern

ActiveUS8002611B2Greater mechanical and chemical polishingIncrease surface areaRevolution surface grinding machinesAbrasion apparatusEngineering

A chemical mechanical polishing pad and method for chemical-mechanical polishing is provided, wherein the polishing pad has a plurality of first mesas and one or more second mesas defined on a surface thereof. The plurality of first mesas are generally distributed about the surface of the polishing pad, wherein each of the plurality of first mesas has a first surface area associated therewith. The one or more second mesas are associated with a center region of the polishing pad, wherein each of the one or more second mesas has a second surface area associated therewith. The second surface area is at least twice the first surface area.

Owner:TEXAS INSTR INC

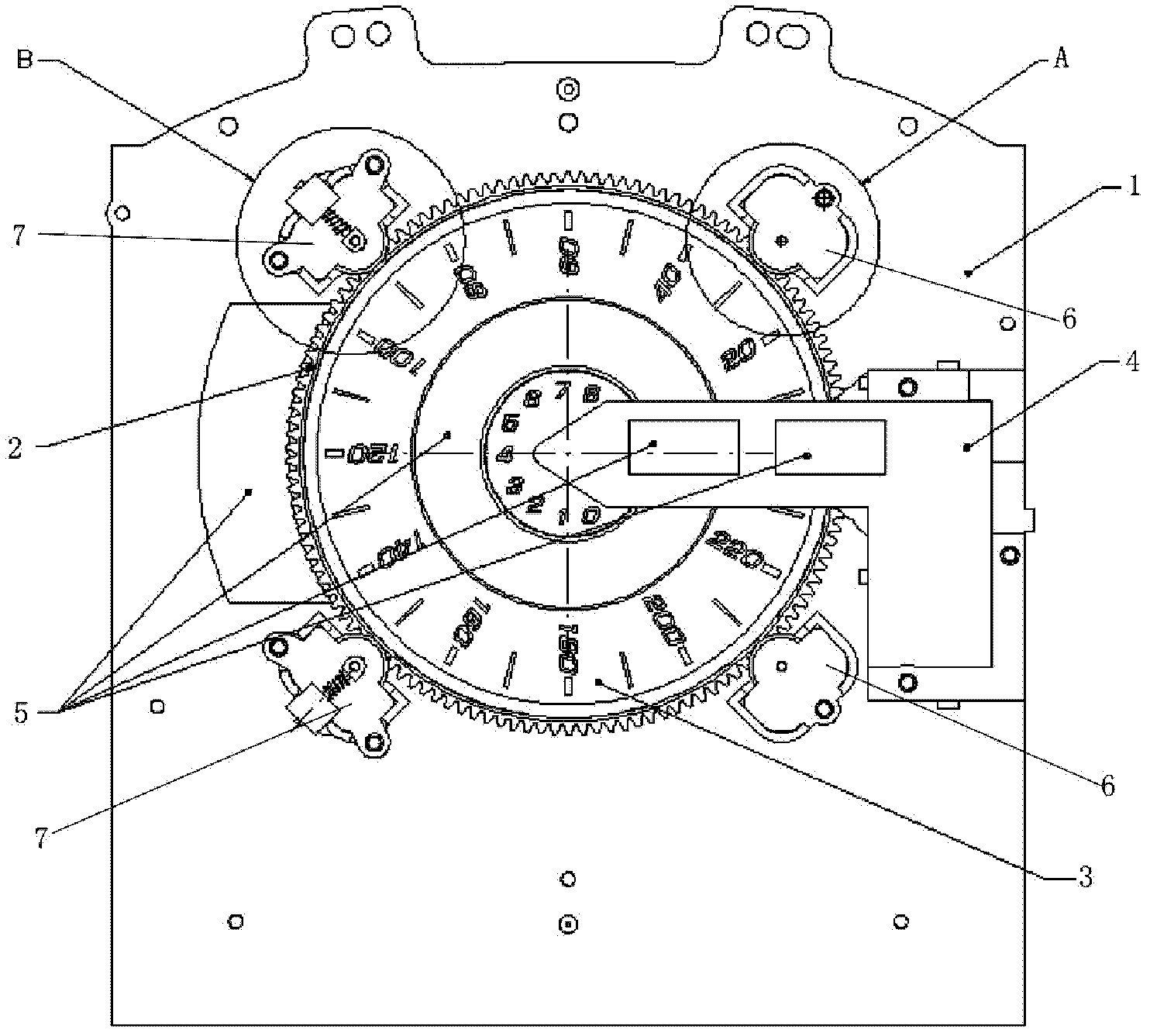

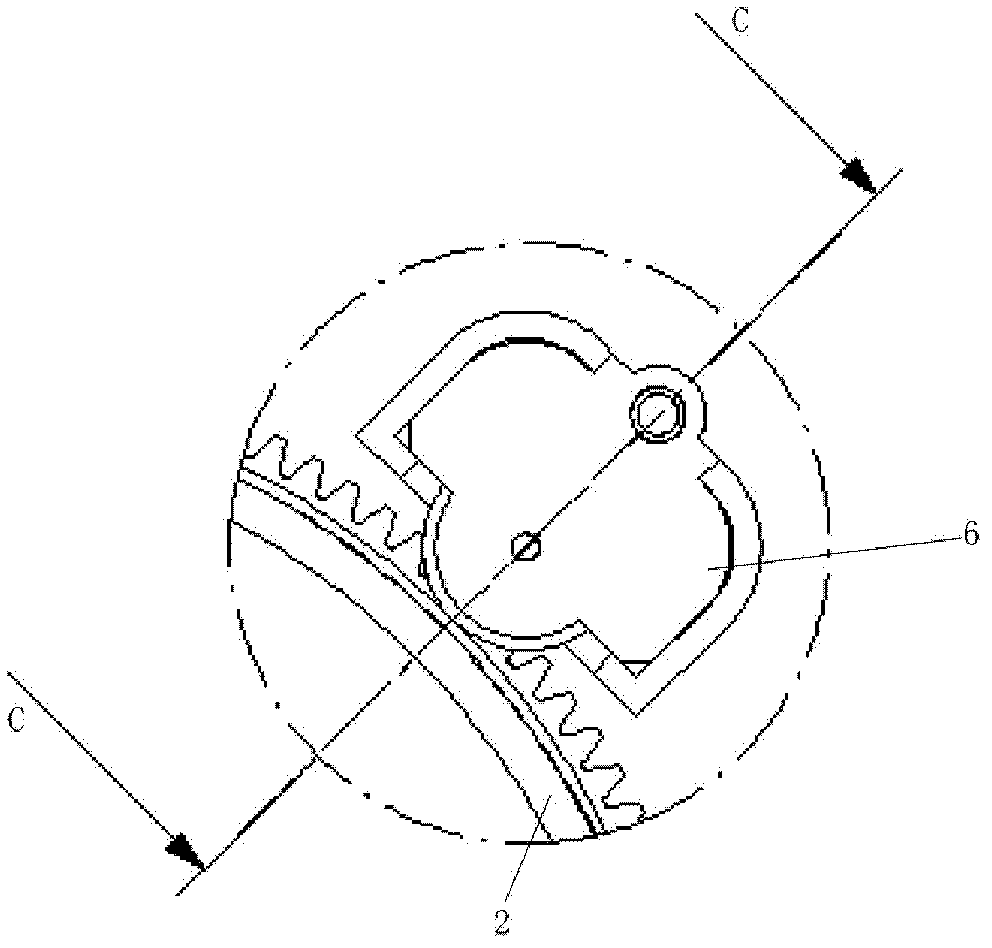

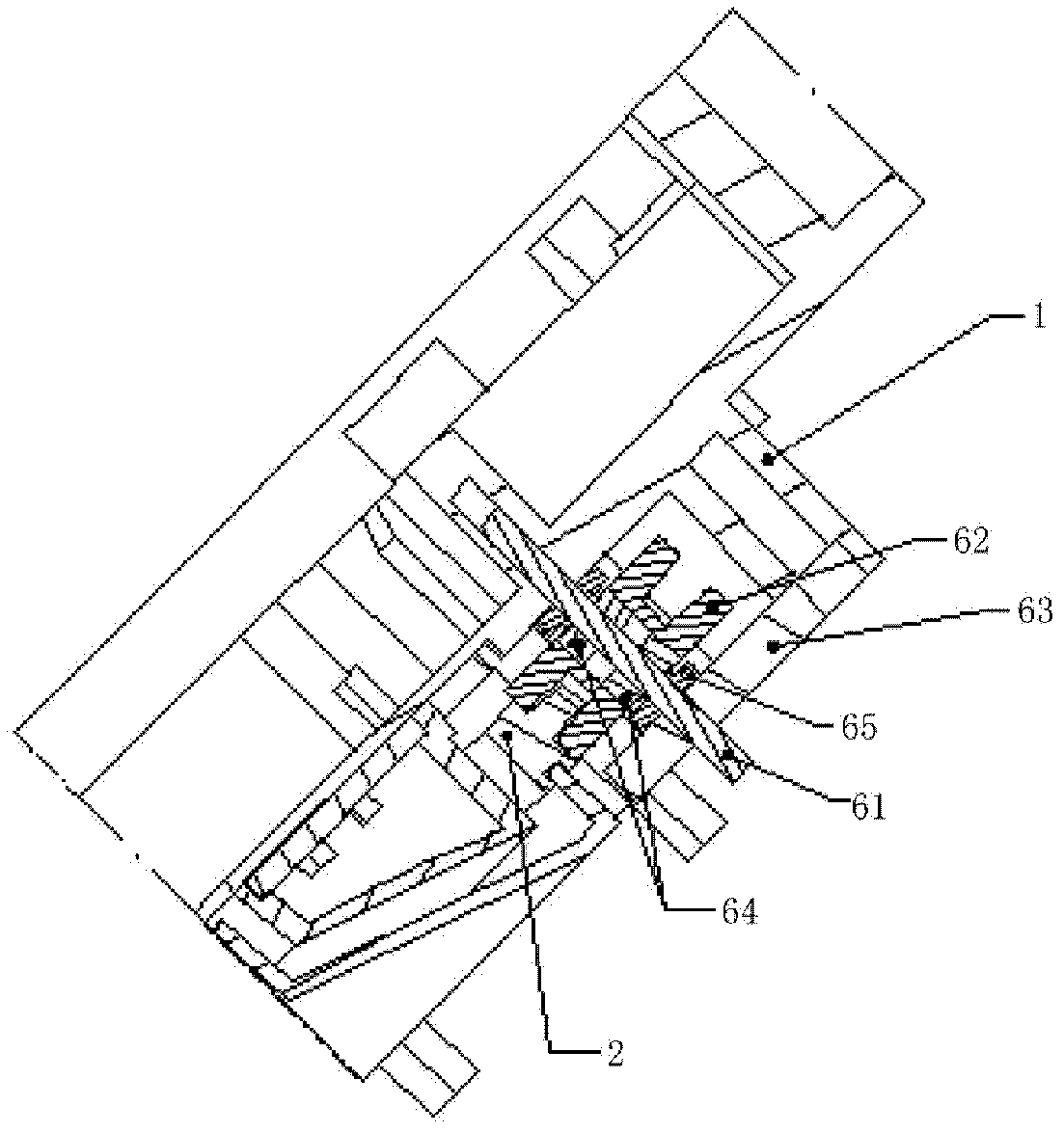

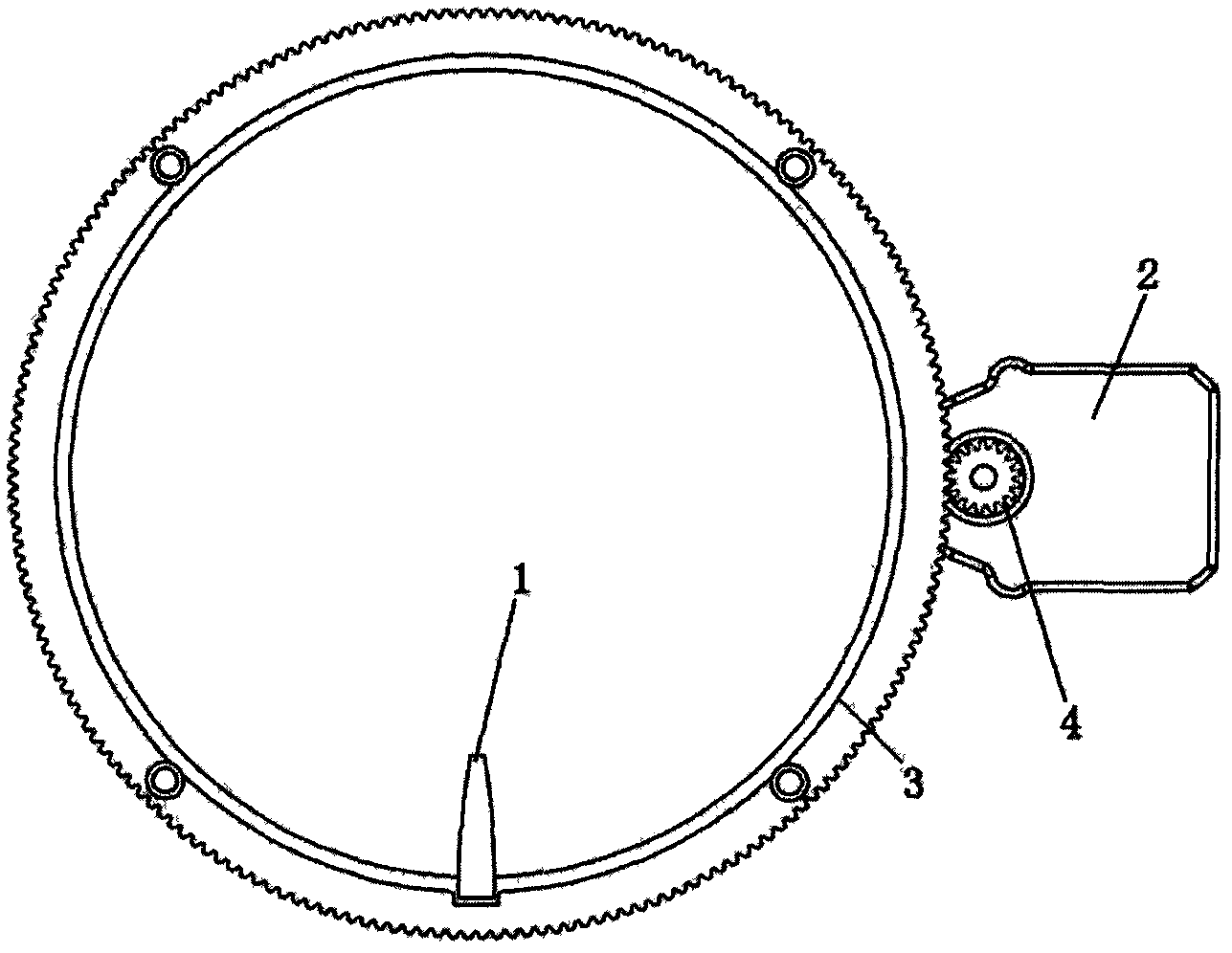

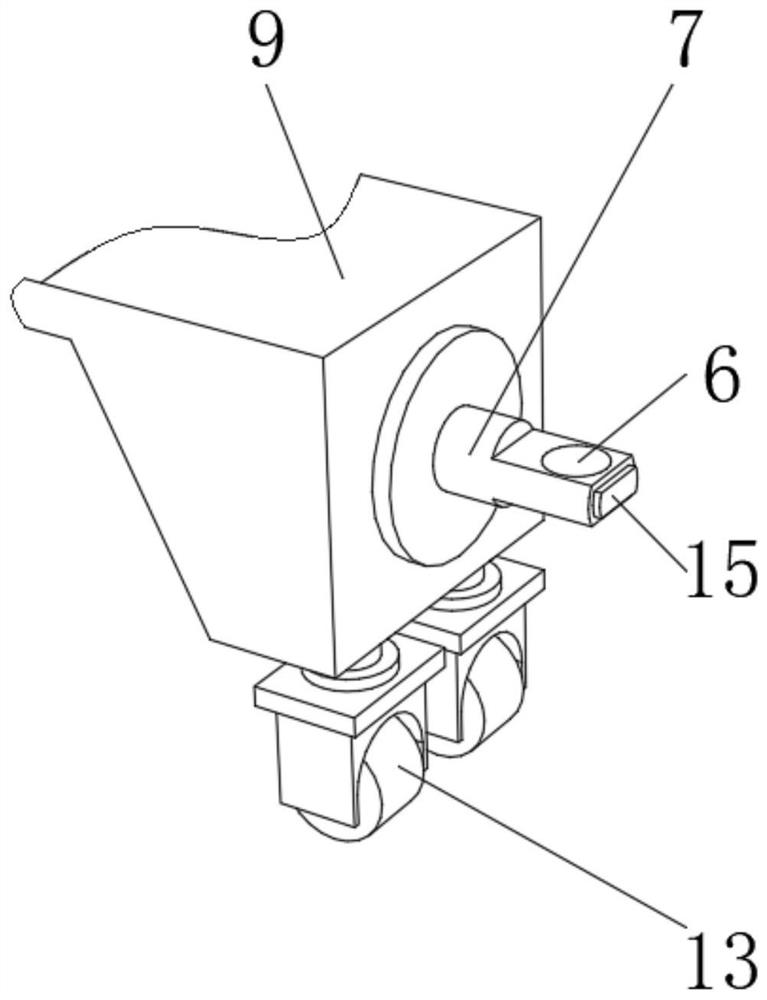

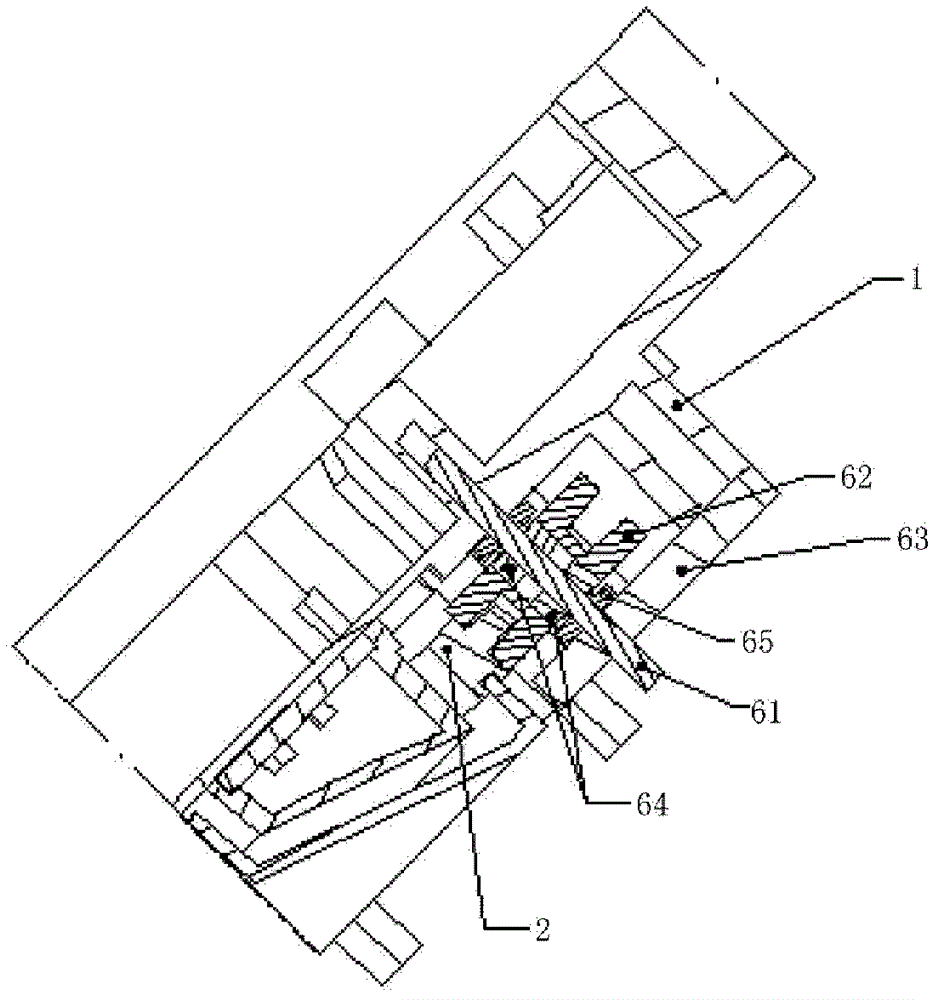

Support structure for DIG (Display In Gauge) automobile instrument rotational dial

The invention discloses a support structure for a DIG (Display In Gauge) automobile instrument rotational dial. The support structure comprises an instrument seat and a dial; the dial is circular; a gap is arranged between the dial surface and the instrument seat; at least three pulleys are arranged on the instrument seat; and the pulleys are uniformly distributed along the circumferential direction and tangential to the excircle of the dial. Teeth are continuously arranged on the outer circumference of the dial. Pulley support frames with the same number as the pulleys are fixedly arranged on the instrument seat, and the pulleys are respectively arranged in one pulley support frame through pulley shafts. At least one pulley shaft is connected with the pulley support frame, on which the pulley shaft is, through an elastic floating mechanism. The pulleys are in point contact with the excircle of the dial, so that the frictional resistance is less, therefore the load driven by a motor can be reduced, and the reliability of a motion mechanism is increased; the elastic floating mechanism offsets at least one pulley to the circle centre direction of the dial, so that the stable rotation of the dial can be supported, therefore the gap and jitter between the dial and each pulley in the rotation process are eliminated. A pointer is fixed, and a display screen is fixedly arranged in the instrument seat and can be observed through a central window of the dial.

Owner:YANFENG VISTEON ELECTRONICS TECH (SHANGHAI) CO LTD

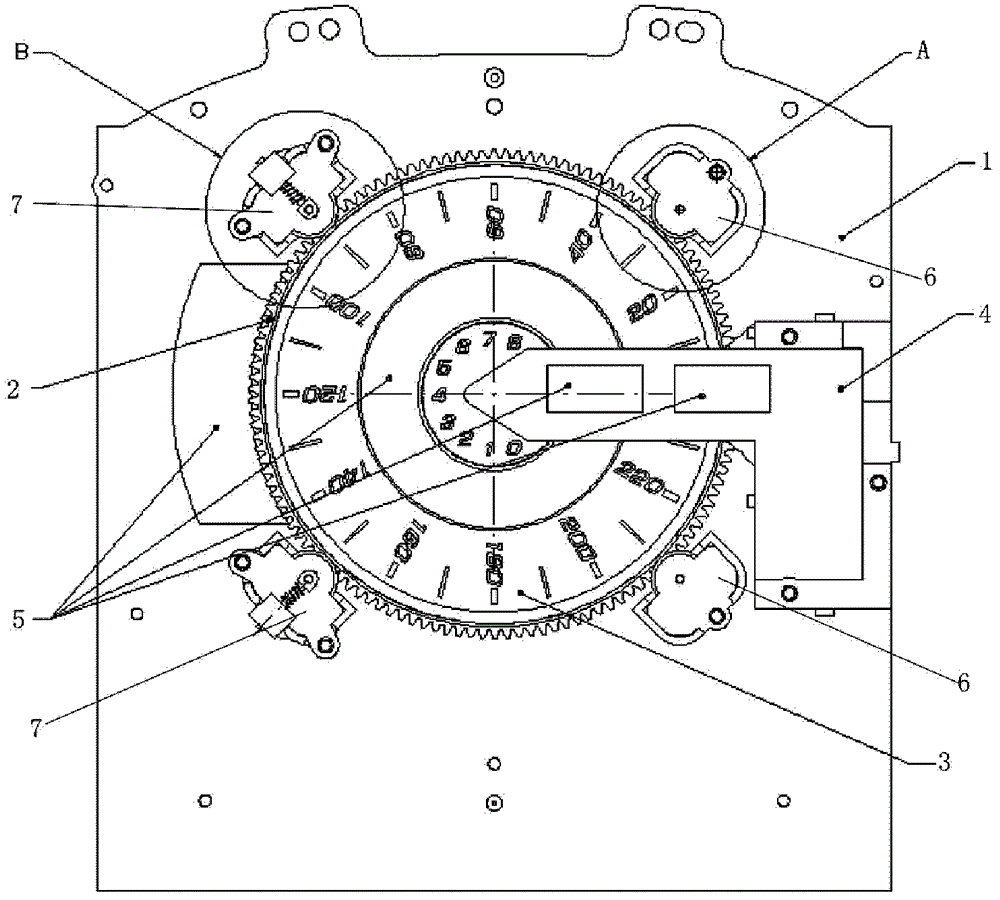

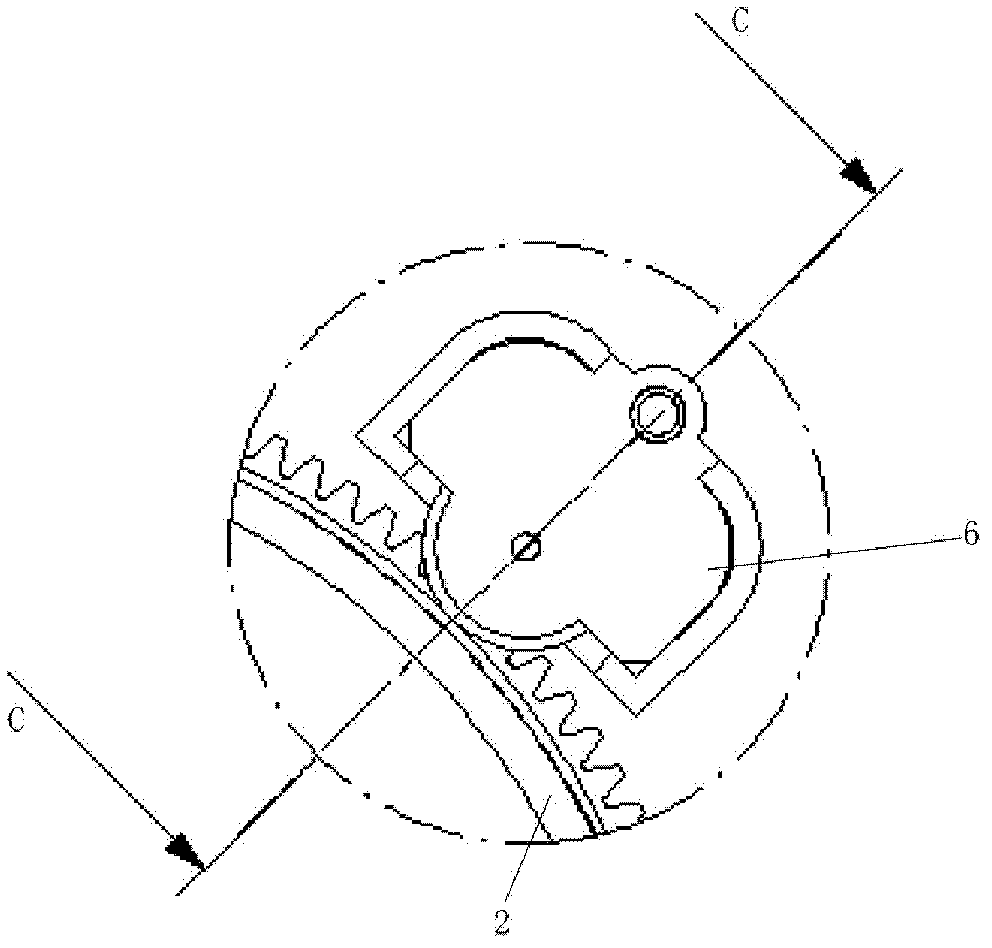

Annular pointer motion structure for automobile meter

ActiveCN102837611AReduce cornersImprove light uniformityIndication apparatusVehicle componentsDashboardRolling resistance

Owner:YANFENG VISTEON AUTOMOTIVE ELECTRONICS

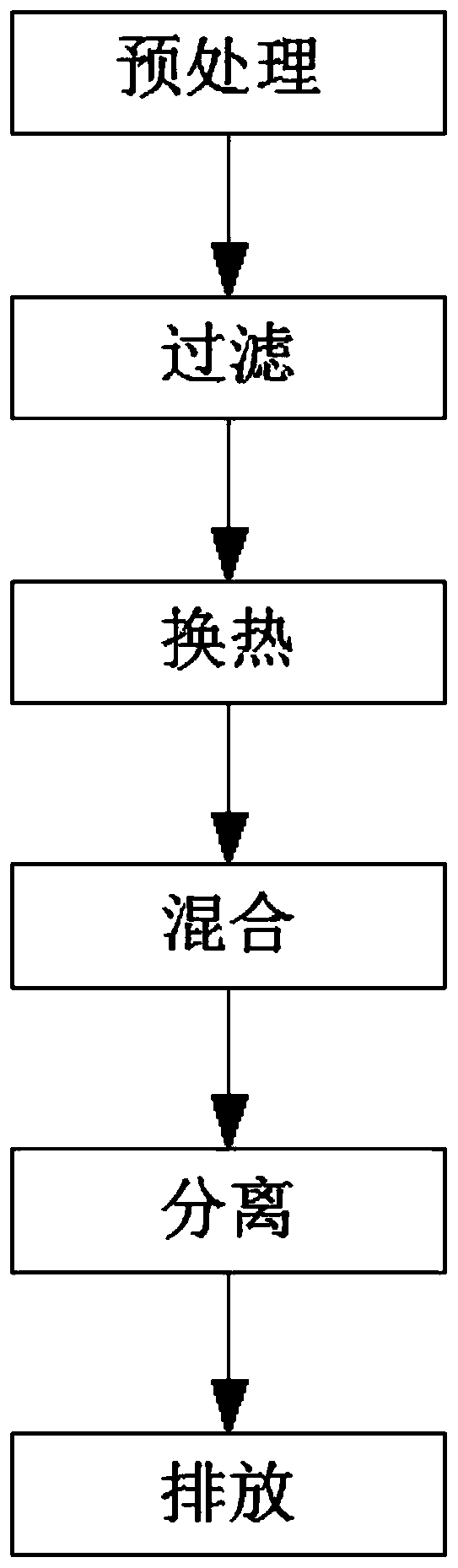

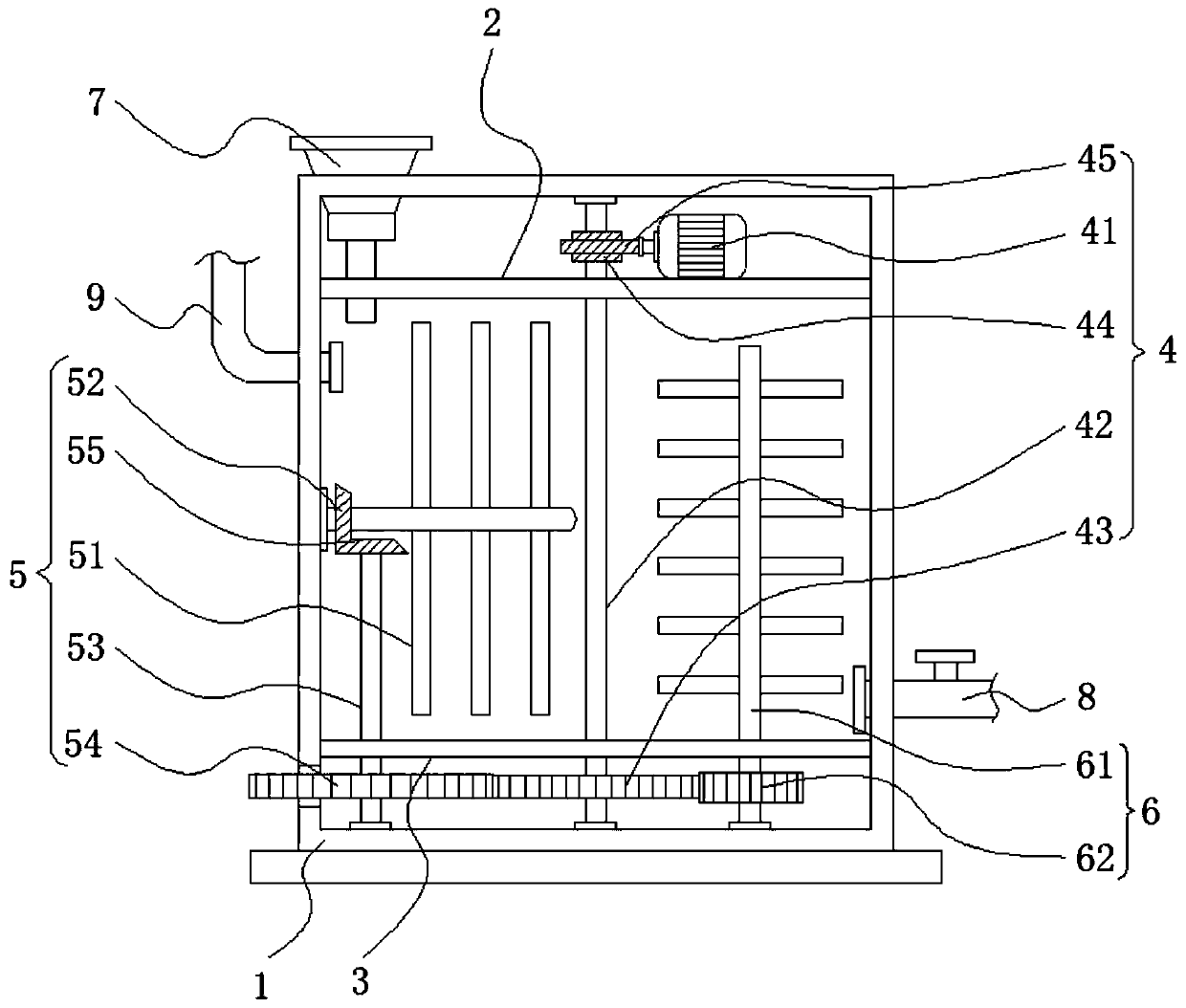

Treatment process and mixing equipment for coal cracking produced sewage

InactiveCN110330146AImprove functionalityEasy to handleWater contaminantsTreatment involving filtrationSocial benefitsEmission standard

The invention provides a treatment process and mixing equipment for coal cracking produced sewage. The treatment process for the coal cracking produced sewage comprises the following step: S1, pretreatment: discharging the sewage to be treated into a treatment tank inside a treatment box through a sewage pipe. By adopting the treatment process and mixing equipment for the coal cracking produced sewage disclosed by the invention, tar in the sewage can be quickly treated, and phenolic compounds in the sewage can be treated, thereby realizing standard sewage discharge, avoiding environmental pollution, being more environmentally-friendly and energy-saving, achieving green circulation and improving economic efficiency; the treatment process and mixing equipment have strong environmental protection performances, make relative contributions to environmental protection, and play active and important roles in the aspects of environment protection, energy conservation and emission reduction andthe like while realizing better economic and social benefits. Wastewater is recycled after meeting national emission standards and the wastewater discharge basically achieves zero emission and real green and environmental protection.

Owner:内蒙古蓝色火宴科技环保股份公司

Production technology for circular-truncated-cone-shaped elevation concrete block for floor slab

ActiveCN106863581AExtended service lifeReduce investmentMouldsBuilding material handlingFloor slabResonance

The invention discloses a production technology for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The production technology comprises the steps of the preparing stage, the pouring stage, vibration forming, connecting piece setting, forming form removal and the like. According to the production technology for the circular-truncated-cone-shaped elevation concrete block for the floor slab, vibration waves can be formed between ring plates and clamping plates under the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, in other words, an operator can finish demoulding with small knocking force, labor force input is reduced, and the demoulding efficiency is greatly improved; and meanwhile, knocking on a die is reduced, and accordingly the service life of the die is prolonged; the distance between connecting columns and wedge-shaped blocks is 81%-84% of the length of ring plate bevels; and resonance is most easily generated between the ring plates and between the ring plates and the clamping plates, and the demoulding efficiency is the highest in the resonance state. Equal-height blocks manufactured through the method can be used for wood templates and steel templates, corresponding technologies can be adopted for the two different templates, and high universality is achieved; and the demoulding operation is conducted according to the set sequence, and the superior product rate of products can be increased to 90% or above.

Owner:CHINA MCC5 GROUP CORP

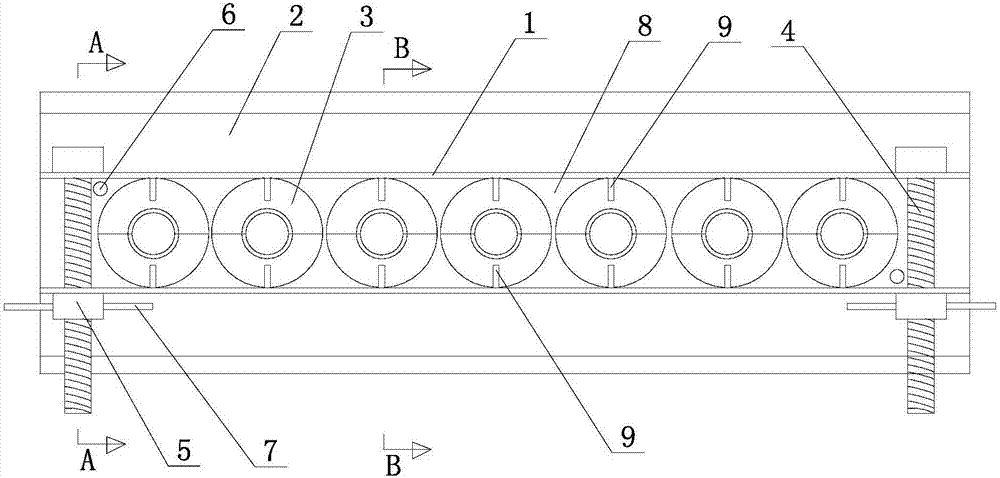

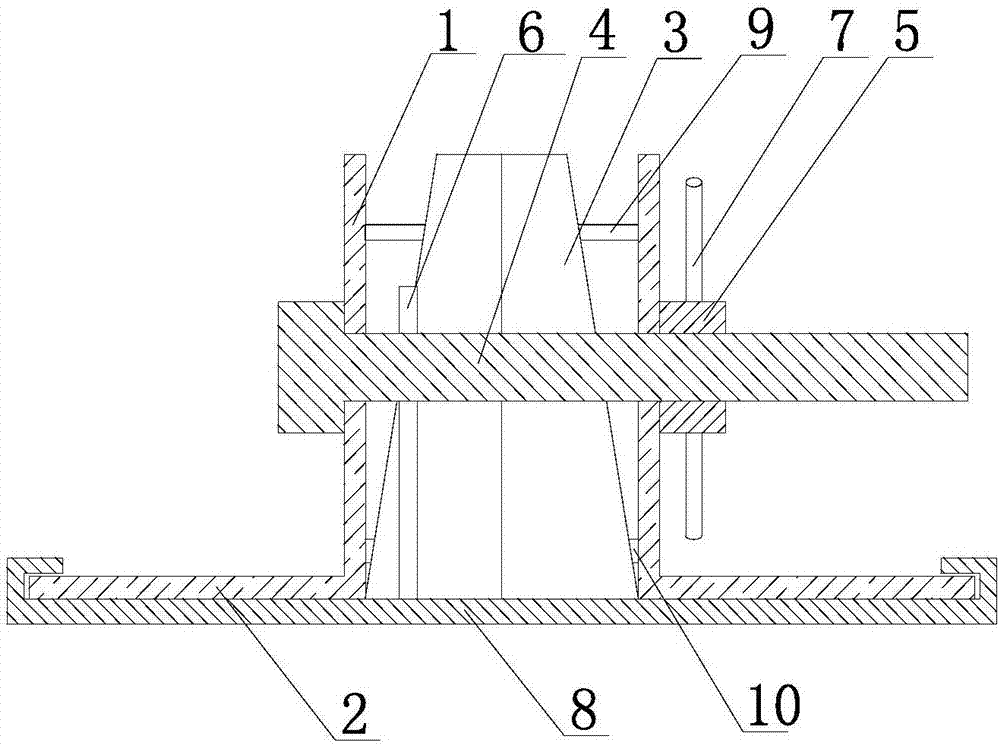

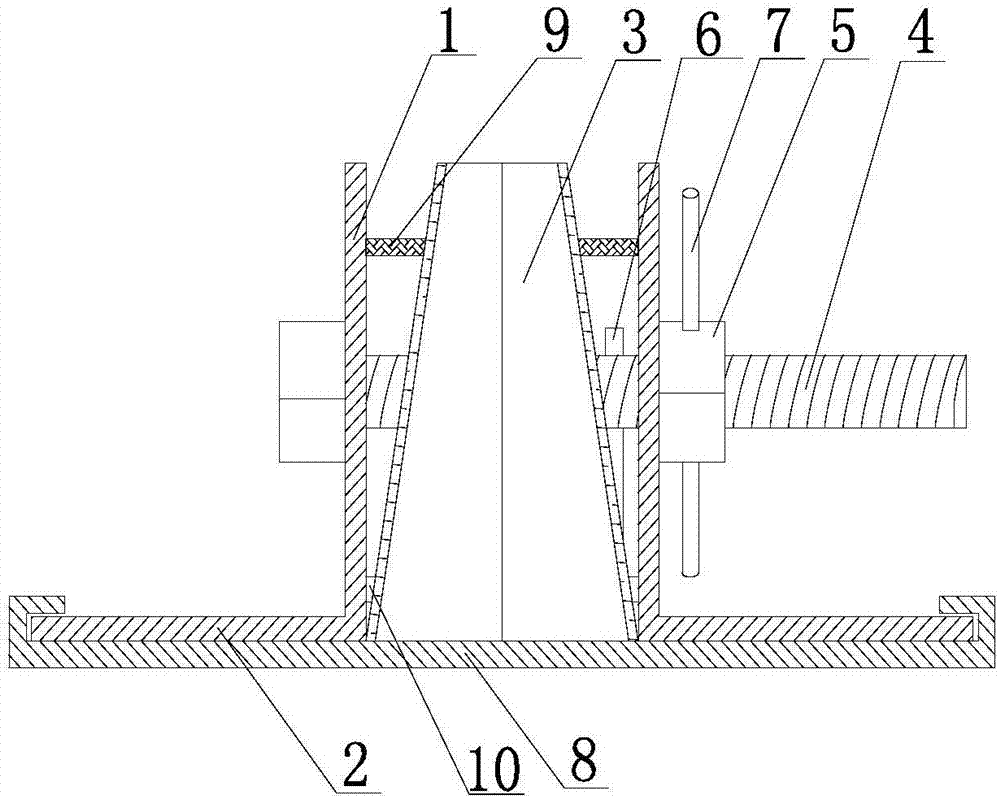

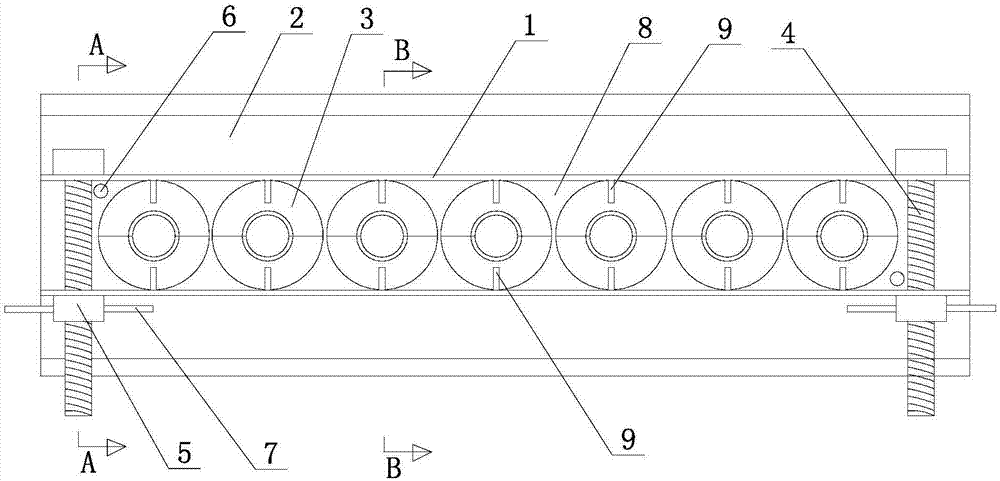

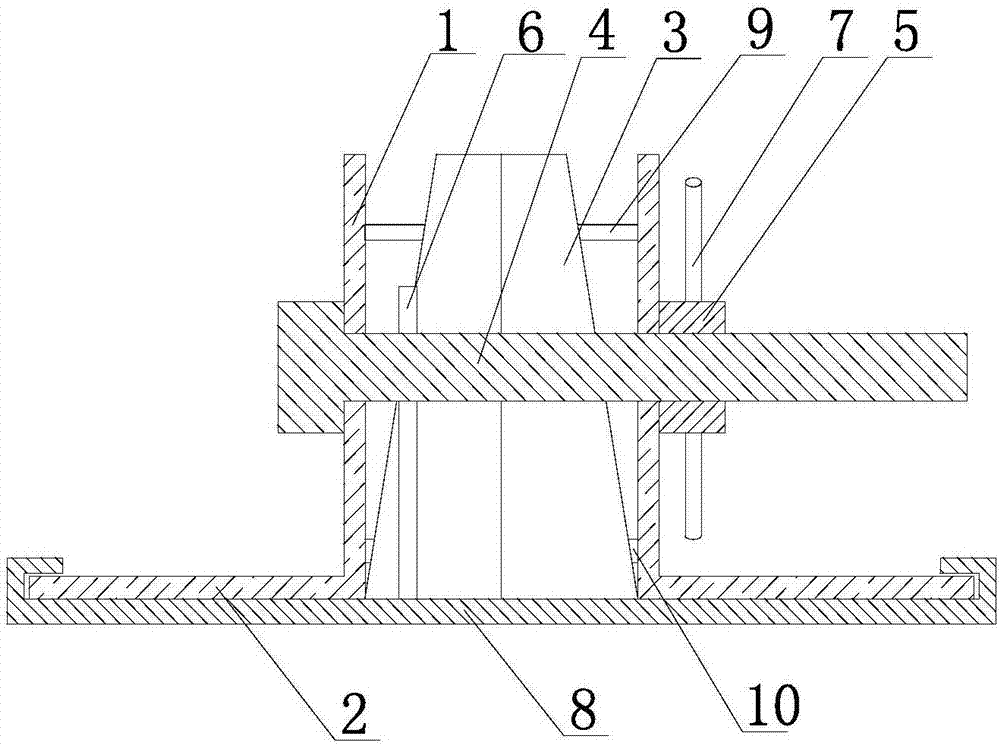

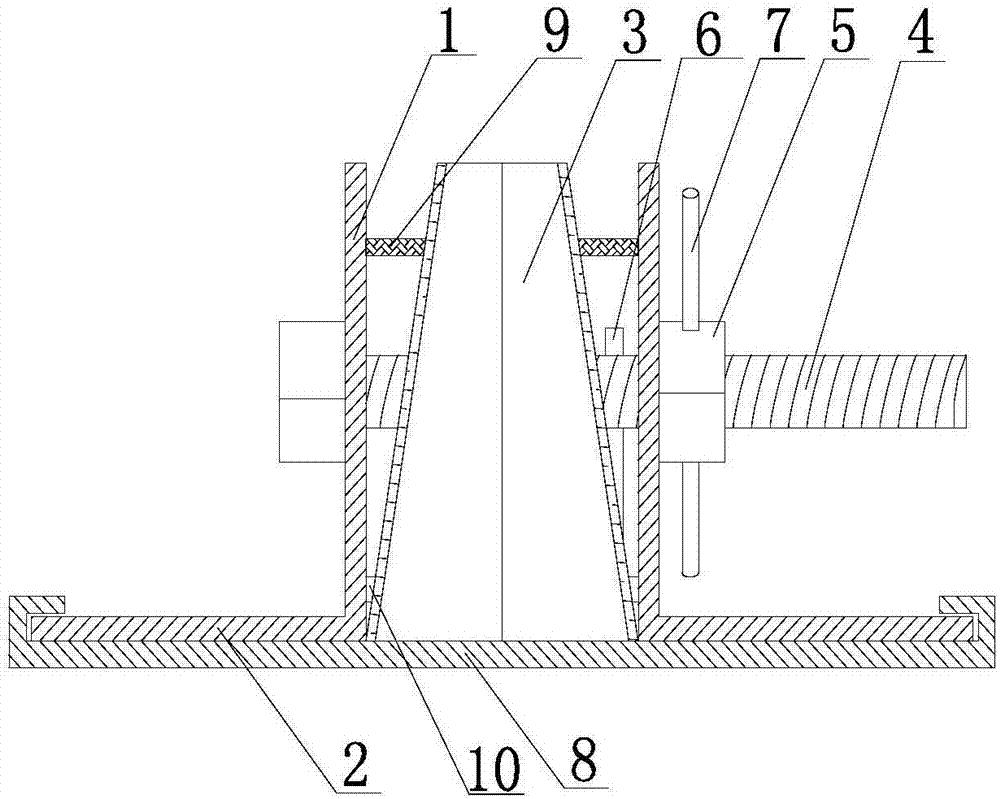

Forming device for circular-truncated-cone-shaped elevation concrete block for floor slab

ActiveCN106863580AImprove protectionIncrease widthMouldsBuilding material handlingFloor slabEngineering

The invention discloses a forming device for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The forming device comprises two parallel clamping plates. A plurality of half circular truncated cone ring plates are arranged on the opposite sides of the clamping plates. The ring plates are paired between the two clamping plates to form a circular-truncated-cone-shaped die. A bed board on the side opposite to the corresponding ring plate is vertically arranged at the bottom of each clamping plate, and the two clamping plates are connected through at least two sets of paired bolts and nuts. According to the forming device, cavities can be formed between the clamping plates and the ring plates through a two-point connecting structure, when the clamping plates are knocked, vibration waves can be formed between the ring plates and the clamping plates through the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, and in other words, an operator can finish demoulding with small knocking force; and the labor force input is reduced, the demoulding efficiency is greatly improved, knocking on the die is reduced, and accordingly the service life of the die is prolonged.

Owner:CHINA MCC5 GROUP CORP

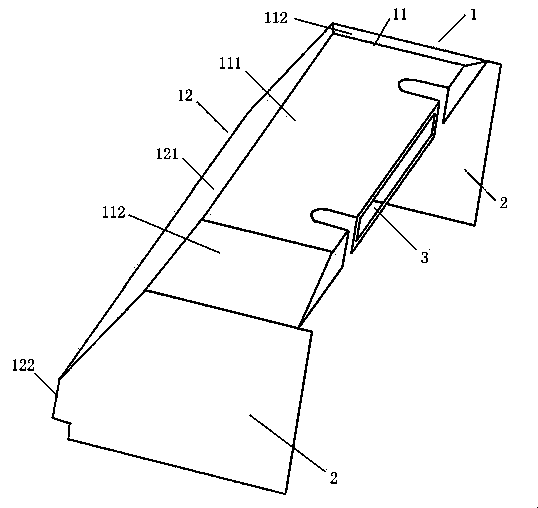

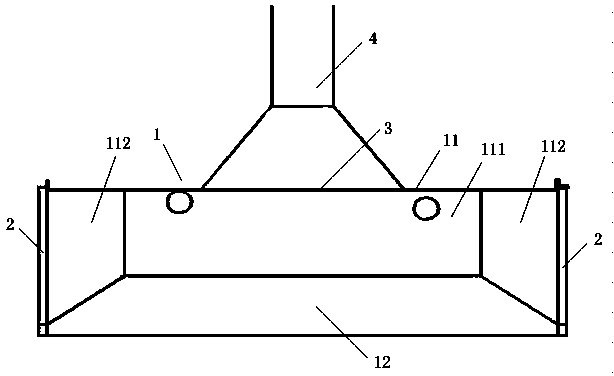

Furnace door dust collection hood

ActiveCN103836985APrevent spillageImprove collection effectWaste heat treatmentEngineeringThermal radiation

The invention discloses a furnace door dust collection hood which comprises a top hood, side baffles and a rectangular air port, wherein the top hood is used for blocking smoke and changing the movement direction of the smoke, the side baffles are used for preventing smoke on two sides from overflowing, and the rectangular air port is used for collecting the smoke. The top hood comprises an upper guide plate and a sloping baffle, the upper guide plate is composed of a top cover and a side sloping cover, the side baffles comprise a left side baffle and a right side baffle, and the rectangular air port is formed in the top end inside the furnace door dust collection hood; under the guide function of the top hood and the side baffles and the function of negative pressure of a smoke discharge pipeline, the smoke intensively reaches the position of the rectangular air port in the same direction, rotates by 90 degrees and is sucked into the smoke discharge pipeline. The furnace door dust collection hood is capable of effectively preventing the smoke in front of a furnace from overflowing, reducing thermal radiation and energy waste, strengthening collecting ability of the smoke, and reducing secondary pollution, the occupied area, the investment cost and working burdens of a draught fan.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

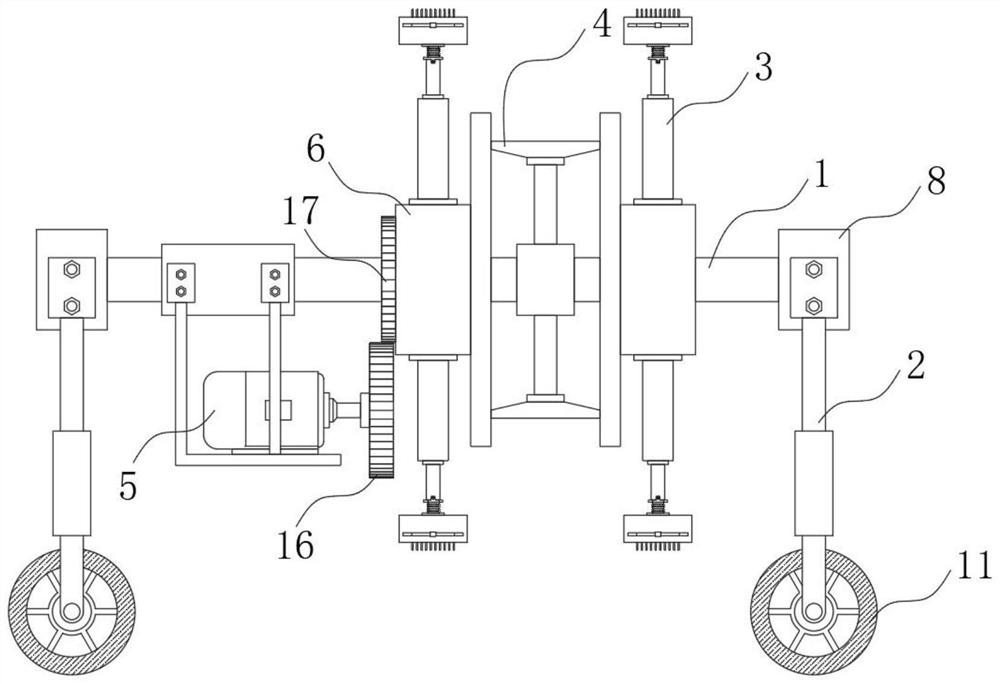

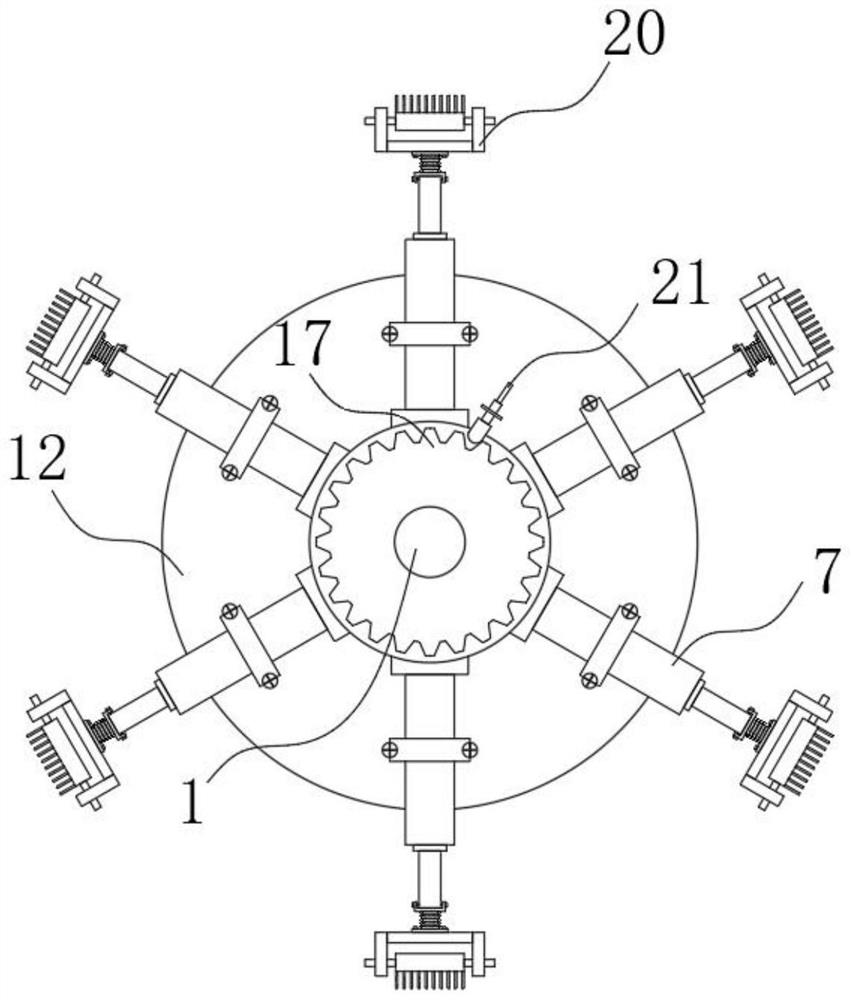

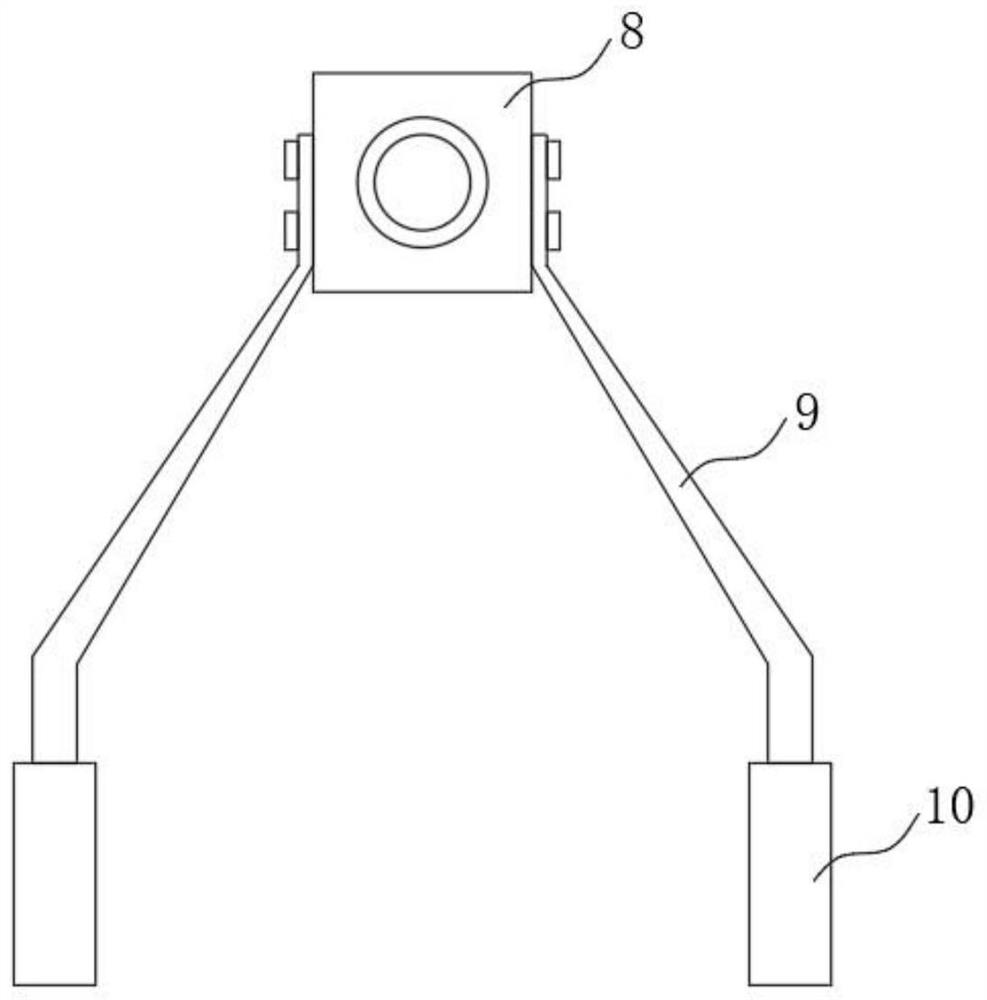

Urban underground pipeline repairing device

ActiveCN112354989AChange lengthEasy to realize matching installation and fixingHollow article cleaningReciprocating motionElectric machinery

The invention belongs to the technical field of pipeline repairing, and particularly relates to an urban underground pipeline repairing device. The device comprises a horizontally-arranged supportingrod, wherein moving mechanisms are arranged at the two ends of the supporting rod, two annular sweeping mechanisms are rotationally connected to the supporting rod, the two annular sweeping mechanismscan rotate reversely through transmission of a transmission mechanism, and a motor for driving one annular sweeping mechanism is fixedly mounted on the supporting rod. The annular sweeping mechanismcomprises a sleeve rotationally connected to the supporting rod in a sleeving manner and sweeping pieces distributed on the periphery of the sleeve, and an adjusting chamber used for adjusting the lengths of the sweeping pieces is formed in the sleeve. According to the urban underground pipeline repairing device, because permanent magnet blocks are embedded in brush heads, when the permanent magnet blocks located on the two annular sweeping mechanisms move to the corresponding positions, the two brush heads get close to or get away from each other in the axial direction of the supporting rod,the brush heads can reciprocate along the axis of the pipeline in the process of rotating around the inner wall of the pipeline in the axial direction of the supporting rod, multi-angle sweeping of the brush head on the inner wall of the pipeline is implemented, and the sweeping effect is improved.

Owner:上海誉帆环境建设有限公司

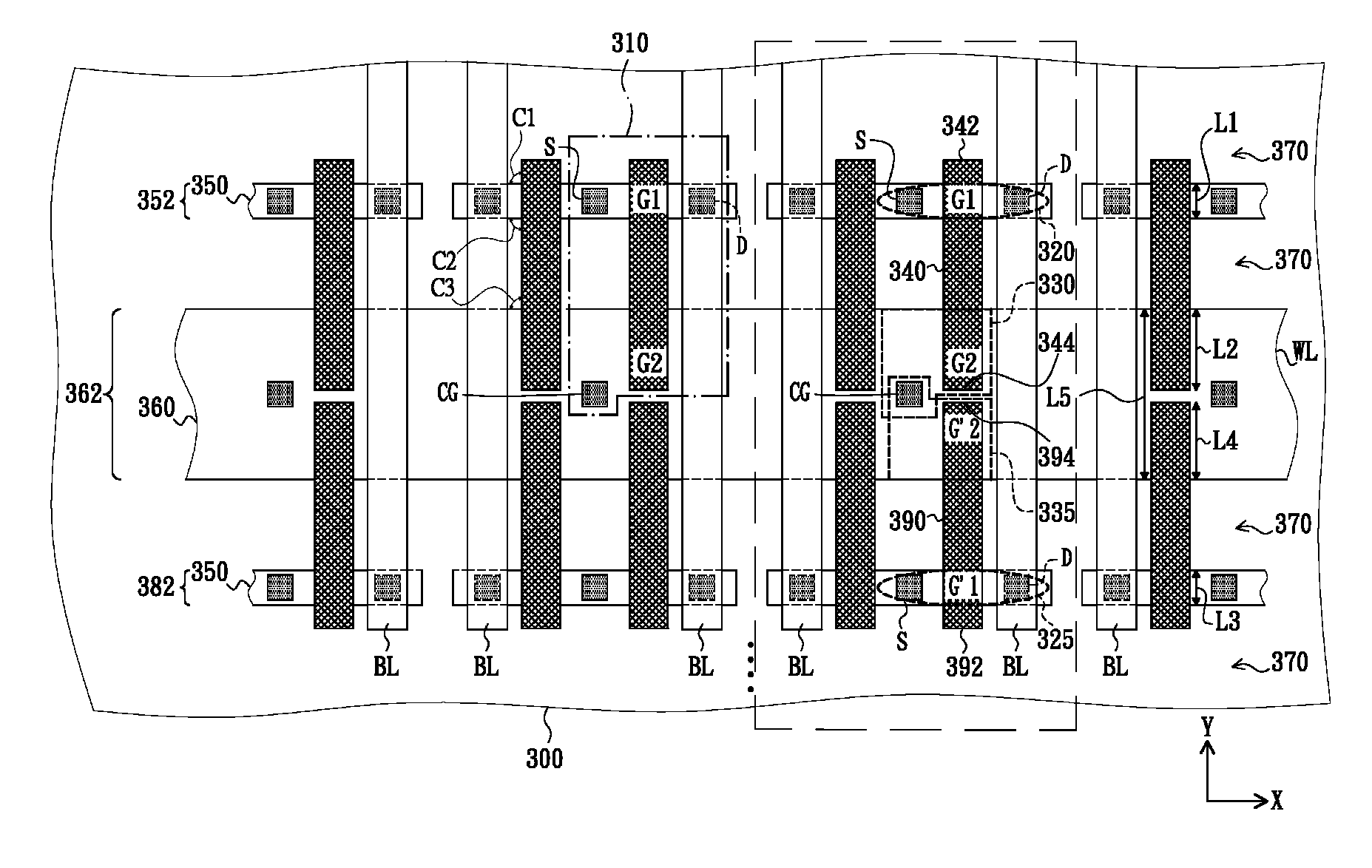

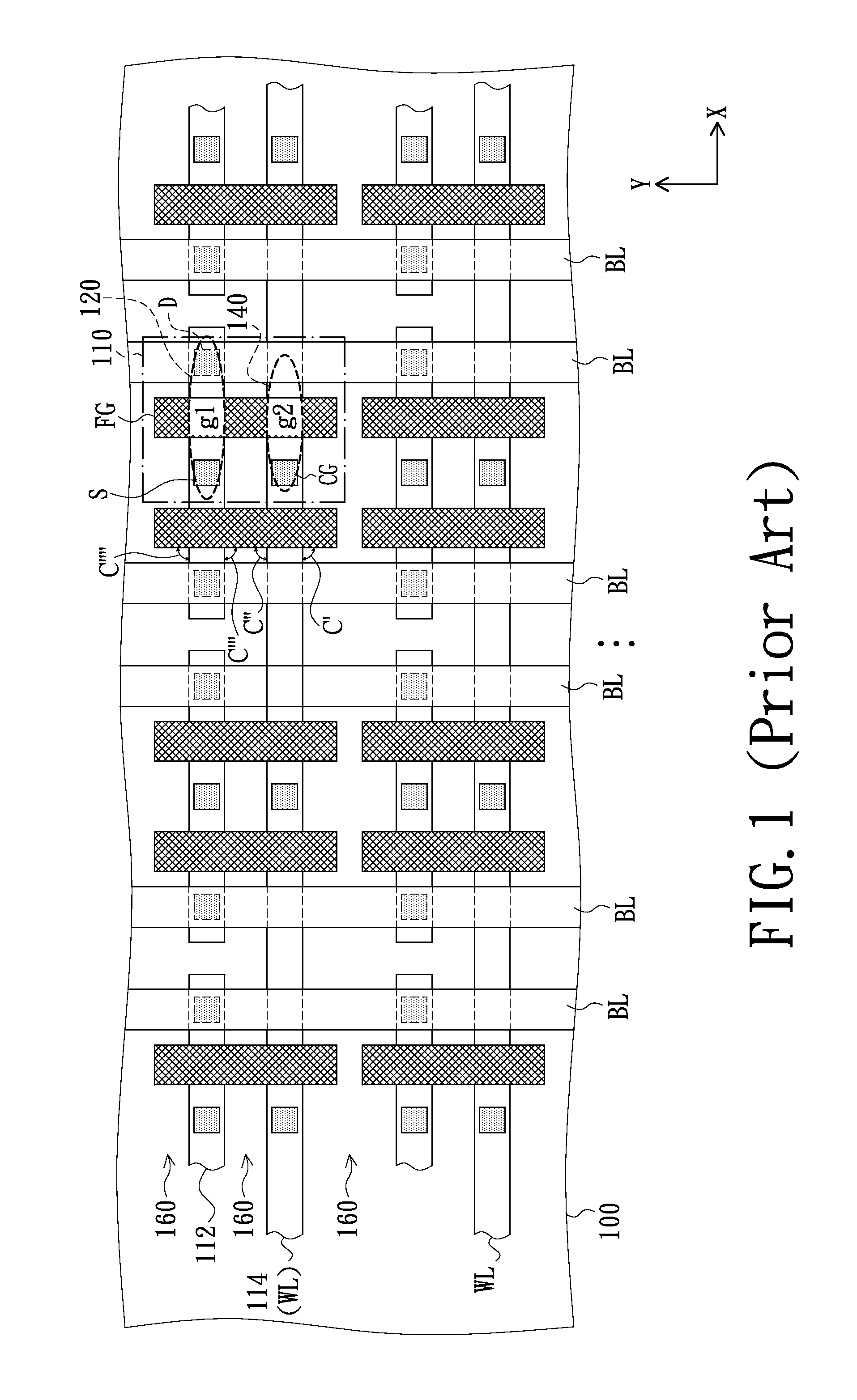

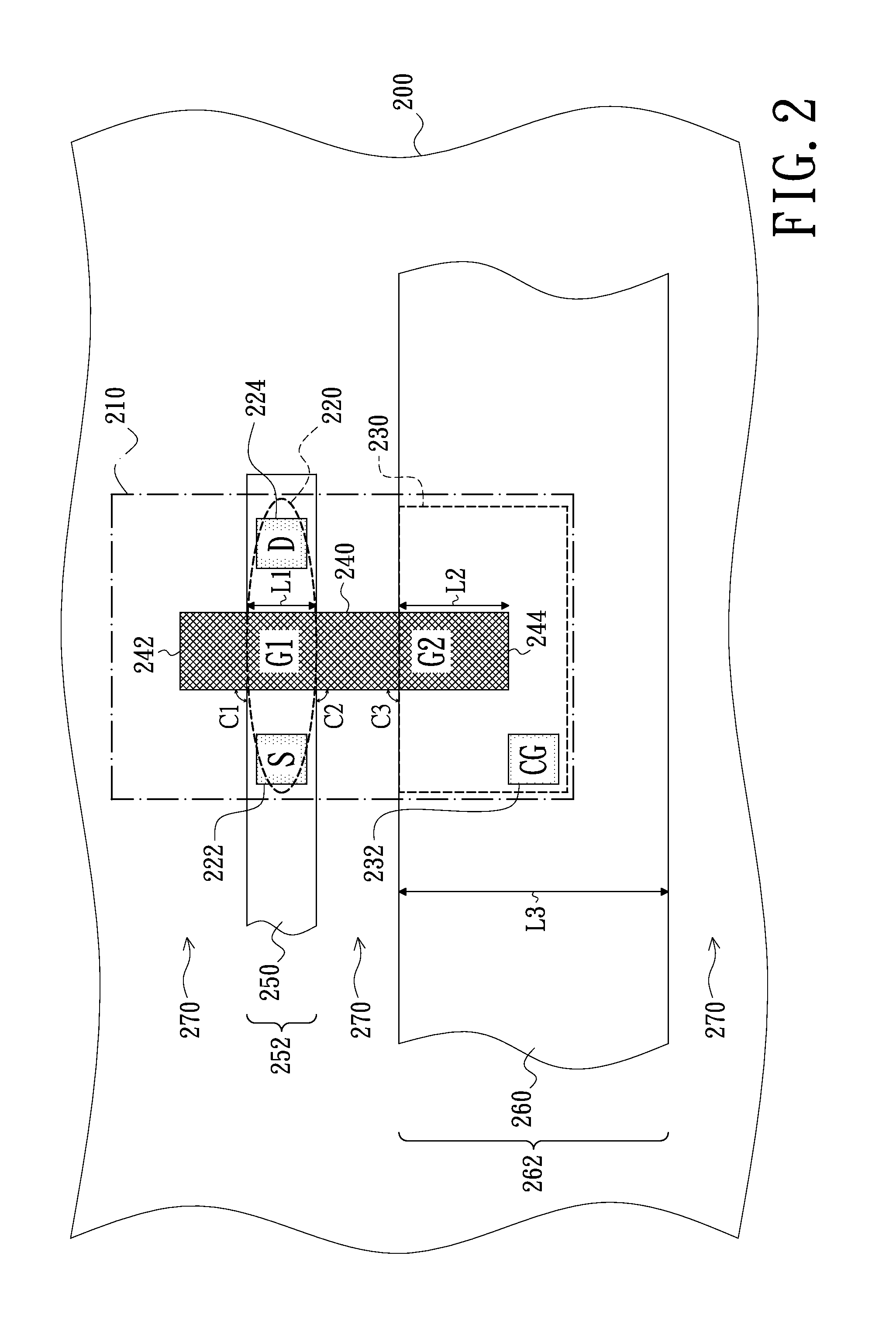

Layout structure of non-volatile memory device

ActiveUS8362535B2Reduce leakage currentEnhanced couplingTransistorSolid-state devicesElectrical conductorEngineering

A non-volatile memory cell includes a semiconductor substrate with isolation structures formed therein and thereby transistor region and capacitor region are defined therein. A conductor is disposed over the isolation structures, the transistor region and a first-type doped well disposed in the capacitor region. The conductor includes a capacitor portion disposed over the first-type doped well, a transistor portion disposed over the transistor region, a first edge disposed over the isolation structure at a side of the transistor region, and an opposite second edge disposed over the first-type doped well. Two first ion doped wells are disposed in the transistor region and respectively at two sides of the transistor portion, and constitutes a transistor with the transistor portion. A second ion doped region is disposed in the capacitor region excluding the conductor and constitutes a capacitor with the capacitor portion.

Owner:UNITED MICROELECTRONICS CORP

A Production Technology of Concrete Block with Concrete Concrete Block with Concrete Elevation for Floor Slab

The invention discloses a production technology for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The production technology comprises the steps of the preparing stage, the pouring stage, vibration forming, connecting piece setting, forming form removal and the like. According to the production technology for the circular-truncated-cone-shaped elevation concrete block for the floor slab, vibration waves can be formed between ring plates and clamping plates under the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, in other words, an operator can finish demoulding with small knocking force, labor force input is reduced, and the demoulding efficiency is greatly improved; and meanwhile, knocking on a die is reduced, and accordingly the service life of the die is prolonged; the distance between connecting columns and wedge-shaped blocks is 81%-84% of the length of ring plate bevels; and resonance is most easily generated between the ring plates and between the ring plates and the clamping plates, and the demoulding efficiency is the highest in the resonance state. Equal-height blocks manufactured through the method can be used for wood templates and steel templates, corresponding technologies can be adopted for the two different templates, and high universality is achieved; and the demoulding operation is conducted according to the set sequence, and the superior product rate of products can be increased to 90% or above.

Owner:CHINA MCC5 GROUP CORP

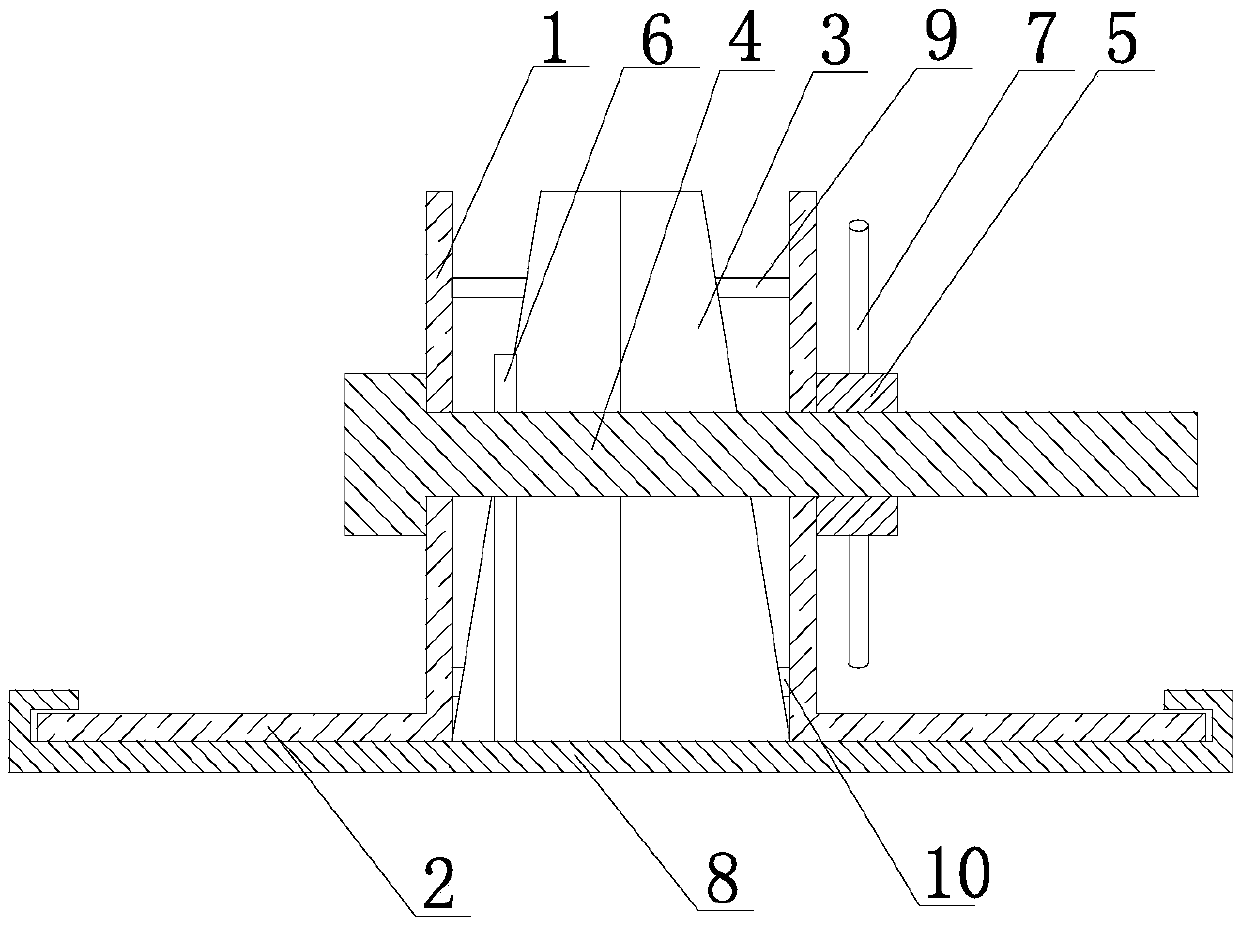

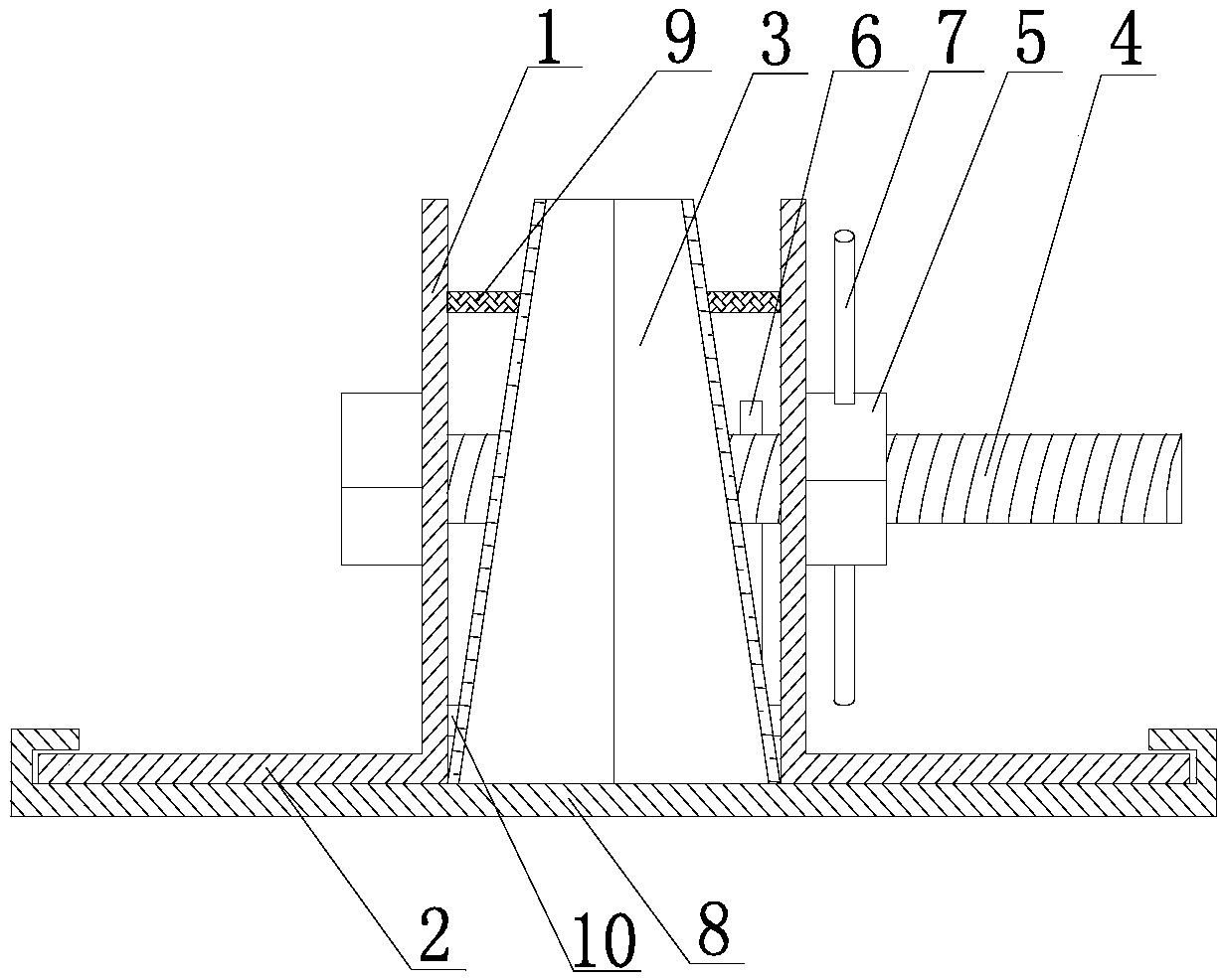

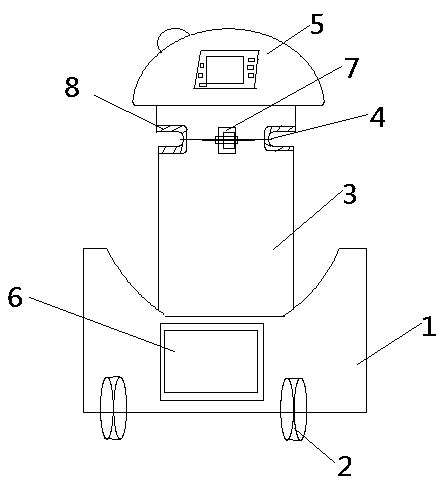

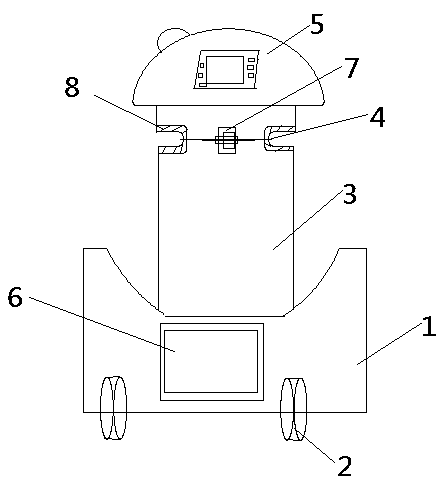

Vacuum circuit breaker overhaul frame

The invention discloses a vacuum circuit breaker maintenance frame. The vacuum circuit breaker maintenance frame comprises a machine body, a tool box and rotating wheels; a base is arranged at the lower end of the machine body; rotating wheels are mounted on two sides of the lower end of the base; a motor is mounted at the lower end of the middle of the base; the output end of the motor is connected with a ball screw; limiting rods are arranged on the left side and the right side of the ball screw; a sliding table is arranged at the upper end of the base; the tool box is installed on the upperside of the left end of the sliding table; a door opening is formed in the end, away from the tool box, of the sliding table; and a first step is arranged on the lower side of the right end of the door opening. The vacuum circuit breaker maintenance frame is simple in structure; a reciprocating screw rod structure is arranged between the ball screw rod and the sliding table so as to drive the ball screw rod to rotate through rotation of the motor, then the sliding table on the ball screw rod can slide up and down along with the ball screw rod, and therefore stable operation of the device canbe increased, the danger coefficient of climbing overhauling of workers is reduced, and meanwhile the overhauling difficulty is lowered.

Owner:泰州亿丰达电器有限公司

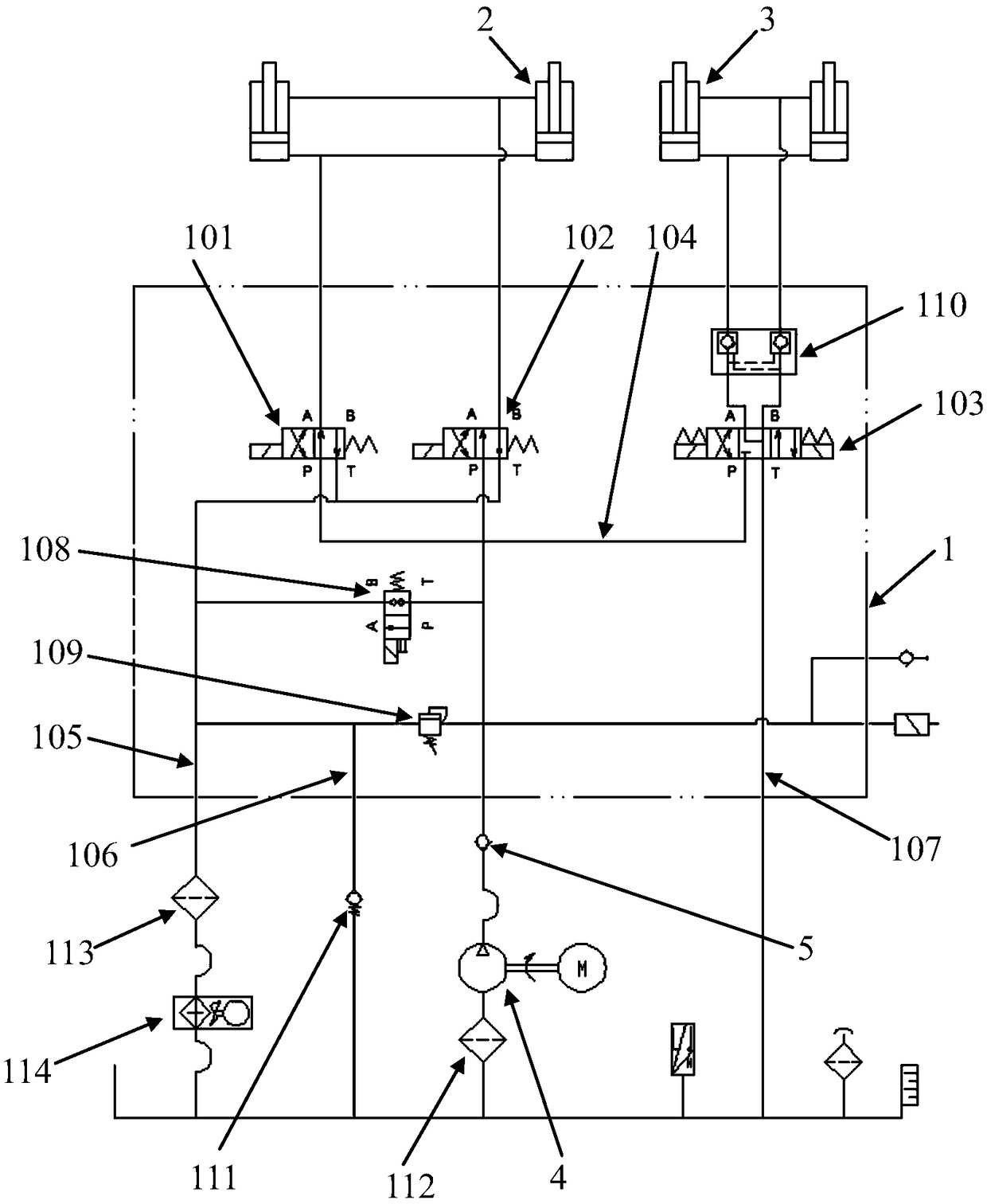

Hydraulic valve set for garbage compression

InactiveCN109356891AAvoid damageExtended service lifeServomotor componentsServomotorsEngineeringMechanical engineering

The invention provides a hydraulic valve set for garbage compression. The hydraulic valve set for garbage compression comprises a first two-position four-way electromagnetic valve, a second two-position four-way electromagnetic valve, a three-position four-way electromagnetic valve, an oil inlet, a first oil outlet and a second oil outlet; a P oil port of the first two-position four-way electromagnetic valve, a P oil port of the second two-position four-way electromagnetic valve and a P oil port of the three-position four-way electromagnetic valve communicate to the oil inlet; a T oil port ofthe first two-position four-way electromagnetic valve and a T oil port of the second two-position four-way electromagnetic valve communicate to the first oil outlet; a T oil port of the three-positionfour-way electromagnetic valve communicates to the second oil outlet; and a two-position two-way electromagnetic valve and an overflow valve are arranged between the oil inlet and the oil outlet in parallel. The hydraulic valve set can realize idling startup, uses the two-position two-way electromagnetic valve for unloading, reduces the impact force during reversing of hydraulic oil, and meanwhile, achieves longer service life.

Owner:扬州海纳尔液压设备有限公司

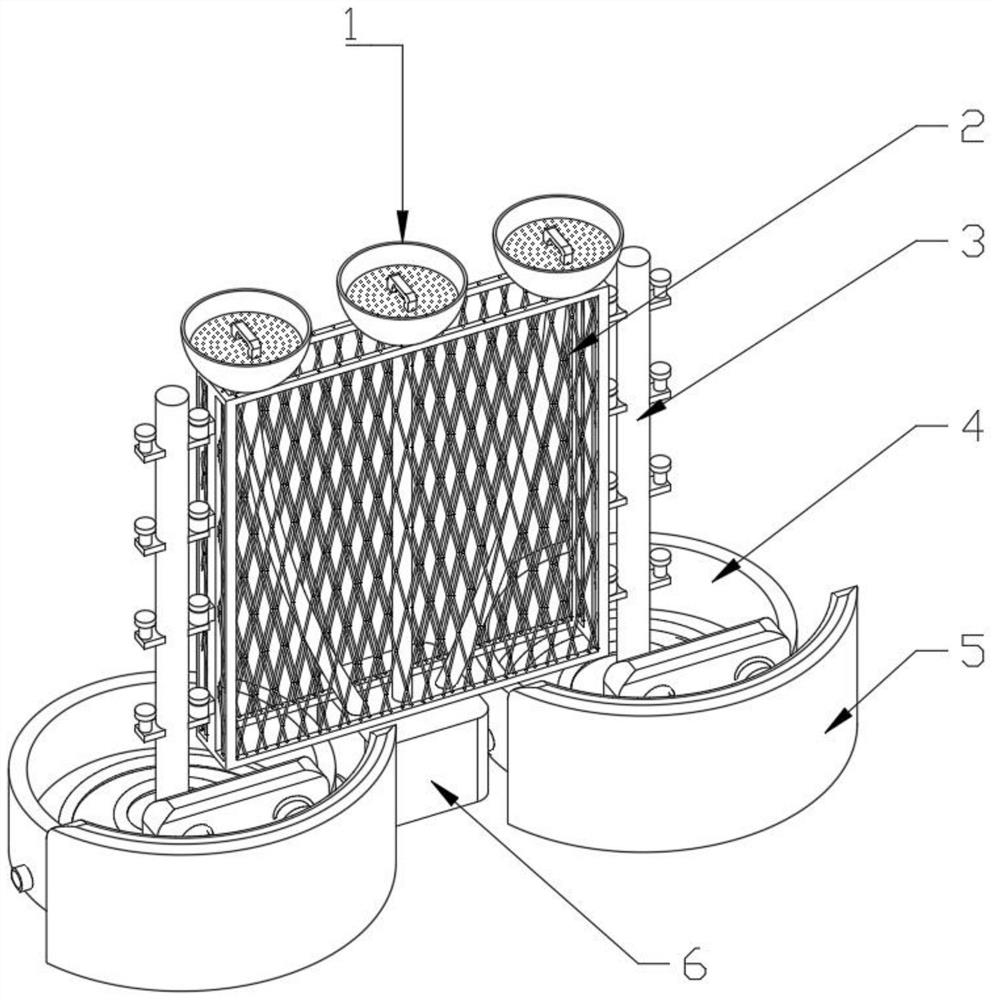

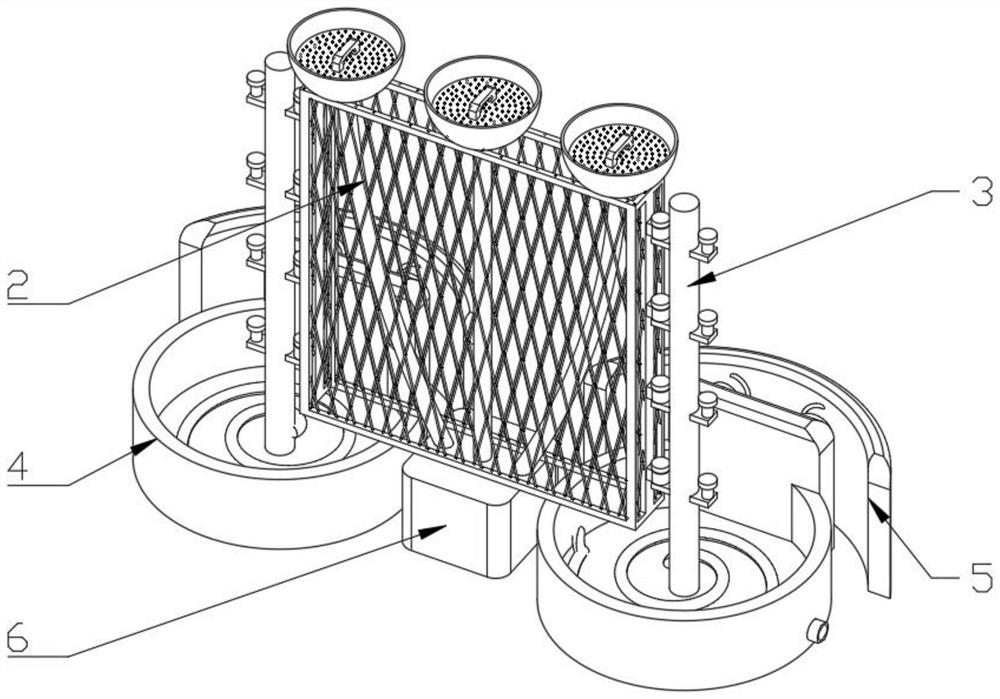

A guardrail structure for climbing greenery

ActiveCN108643092BImprove the protective effectEasy to viewNoise reduction constructionRoadway safety arrangementsWater storage tankAgricultural engineering

The invention provides a guardrail structure used for climber greening. The structure comprises planting weight boxes and a water storage tank. The planting weight boxes are arranged on the bottom side of a guardrail body. Water inlets are symmetrically formed in the bottom ends of the side walls of the planting weight boxes. Supporting columns are welded and fixed to the middle positions of the inner sides of the planting weight boxes. Climbing protection nets are rotationally connected to the outer walls of the supporting columns through hinges. The water storage tank is fixed to the bottomsides of the climbing protection nets through bolts. Three water collection covers are welded and fixed to the top sides of the climbing protection nets. Output pipelines are symmetrically arranged onthe two sides of the bottom end of the water storage tank. Anti-collision boards are further arranged on the outer side walls of the planting weight boxes. A fixed board is welded and fixed to the outer wall on one side of each planting weight box. The guardrail structure used for climber greening is provided with the climbing protection nets arranged in two layers, the two layers of climbing protection nets are spaced at 25 centimeters, through design of the double-layer protection nets, on the one hand, the protection capacity is improved, and on the other hand, climbing of plants is further facilitated.

Owner:临沂鹏泰新型建材合伙企业(有限合伙)

A kind of mask set for etching and substrate etching method using the same

ActiveCN105655231BPlay a protective effectSlow down lateral shrinkageSemiconductor/solid-state device manufacturingTopographyPhotoresist

The etching mask set provided by the present invention and the substrate etching method using the same include the first mask layer made of photoresist material, and the material that can improve the etching selectivity ratio relative to the substrate making a second mask layer, wherein the first mask layer is disposed on the surface of the substrate; the second mask layer is disposed on the first mask layer; the respective patterns of the first mask layer and the second mask layer The width of the bottom is set such that: the inclination angle of the preset connection line between the first mask layer and the second mask layer is consistent with the fixed inclination angle of the first mask layer. The mask set for etching provided by the present invention can achieve the purpose of improving the figure topography of the substrate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Support structure for DIG (Display In Gauge) automobile instrument rotational dial

Owner:YANFENG VISTEON ELECTRONICS TECH (SHANGHAI) CO LTD

A kind of processing technology of battery cover protective sleeve

The invention relates to the technical field of battery cover protective sleeves, in particular to a processing technology for a battery cover protective sleeve. The processing technology includes the following steps that firstly, a thin film is prepared; secondly, an ink layer is printed and dried; thirdly, a removable adhesive layer is printed and dried; fourthly, a positioning hole is punched; fifthly, the thin film is put into a mold; sixthly, silicon rubber is put into the mold; seventhly, the mold is closed, and forming is achieved; eighthly, a semi-finished product attached to the silicon rubber is taken out; ninthly, the semi-finished product is cooled, and the silicon rubber is taken down; and finally, the outline is punched. The battery cover protective sleeve manufactured through the processing technology has the advantages of being small in thickness, stable in outline size and good in toughness and strength, and therefore the battery cover protective sleeve can be tightly matched with a battery and a battery machine case, and light leakage of the battery cover protective sleeve can be avoided. The processing technology for the battery cover protective sleeve has the characteristics of being simple, low in production cost and suitable for large-scale production.

Owner:DONGGUAN SINCO ELECTRONICS

An inflatable outer windshield for an EMU

ActiveCN103863344BImprove air tightnessExcellent rainproof and windproof performanceAxle-box lubricationRailway bodiesEngineeringAir tightness

The invention discloses an inflatable type outer windscreen of a motor train unit. The inflatable type outer windscreen of the motor train unit is characterized in that the periphery of the end face of a front car (1) is fixedly connected with an inflatable integral-ring-shaped rubber air bag (3), the periphery of the end face of a rear car (2) is also fixedly connected with an inflatable integral-ring-shaped rubber air bag (3), and the opposite surfaces of the two inflatable rubber air bags (3) are tightly attached to each other. The inflatable type outer windscreen of the motor train unit has good air tightness, heat-shielding performance, sound insulation performance and rainproof performance, small aerodynamic resistance and good curve passage capacity, and can provide a safer and more comfortable walking-through environment for passengers, and provide more effective protection for car flexible connection devices.

Owner:张建华

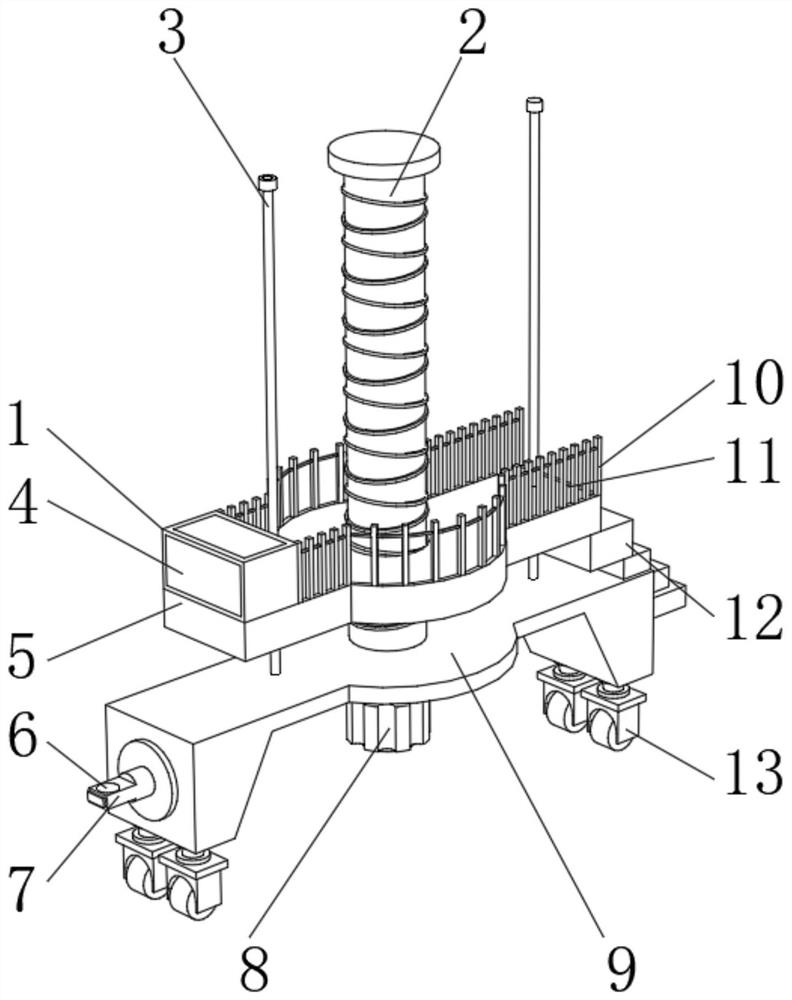

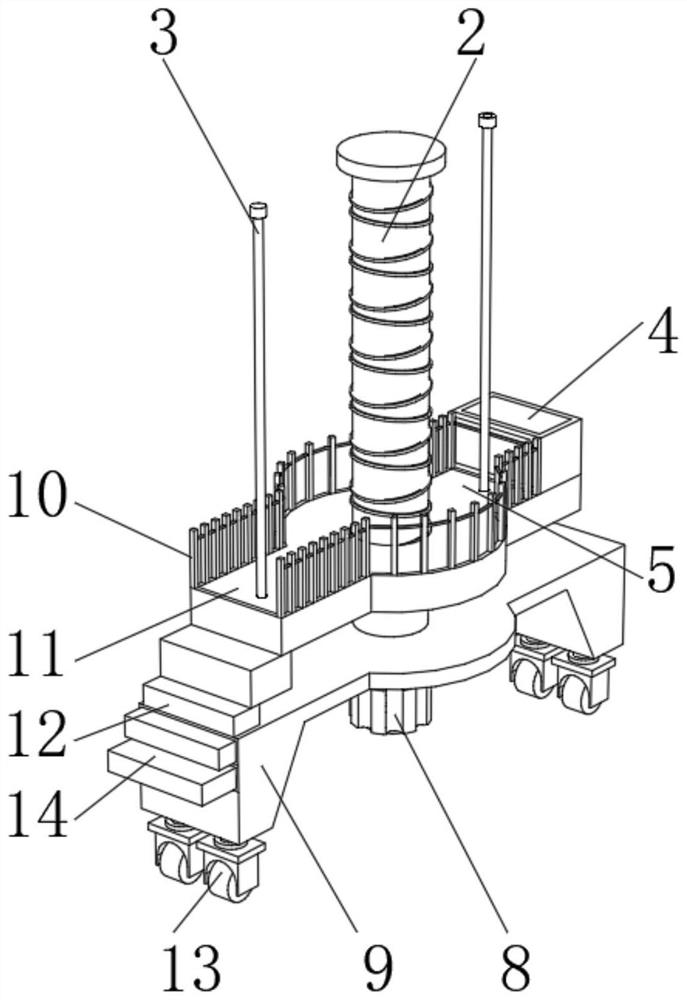

A pay-off device and working method used in the process of wire and cable construction

The invention discloses a paying-off device for wire / cable construction. The paying-off device comprises a base, trundles, a wire post, a wire / cable, a limiting device and a control device. The trundles are arranged below the base, the paying-off end of the wire / cable is arranged on the wire post, the limiting device is arranged on the wire post, and the control device is arranged on the base. The control device is internally provided with an input mechanism, a drive mechanism, an alarm device, a power supply device and a control mechanism, and the input mechanism, the drive mechanism, the alarm device and the power supply device are connected with the control mechanism. Manual paying-off is replaced with the paying-off device, and due to the facts that the paying-off end of the wire / cable on a wire / cable frame is fixed to the wire post and the control device controls the paying-off device to pull the wire / cable to an appointed position, the workloads of wire / cable constructors are relieved, the problem that paying-off is difficult is solved well, automation is achieved for wire / cable construction, and the demands of a construction team can be met better.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

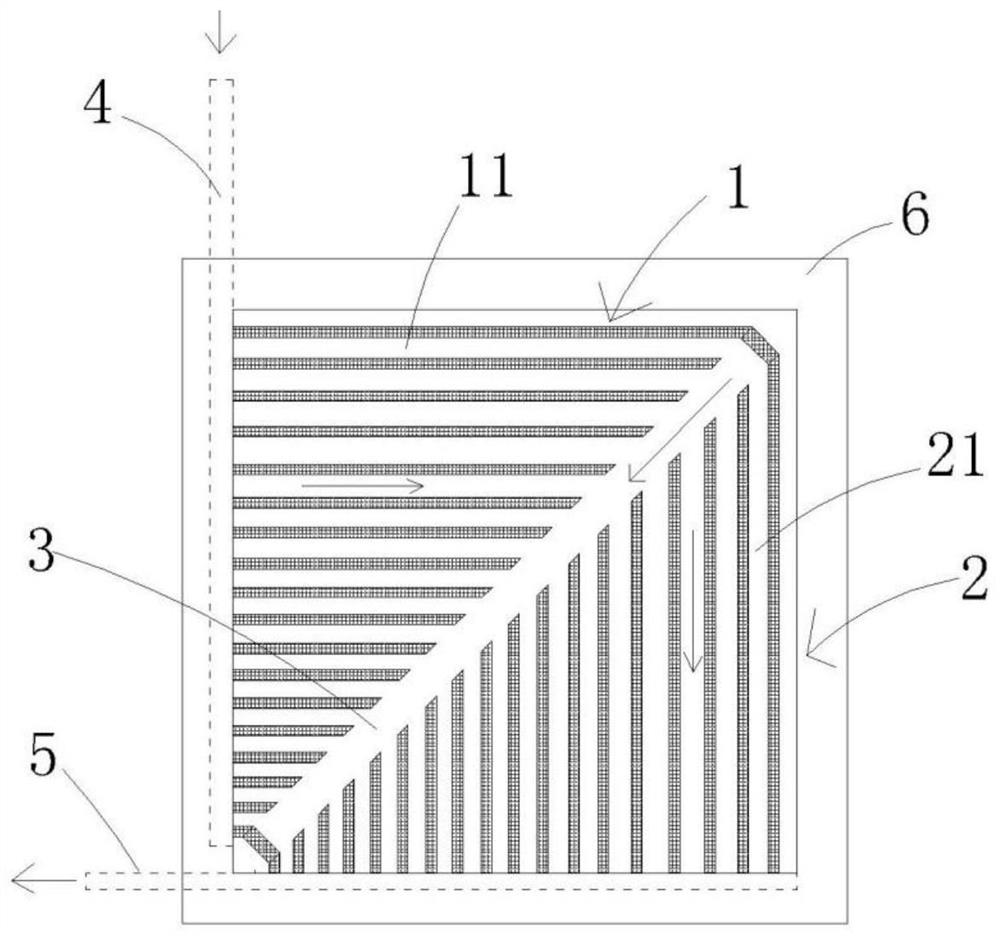

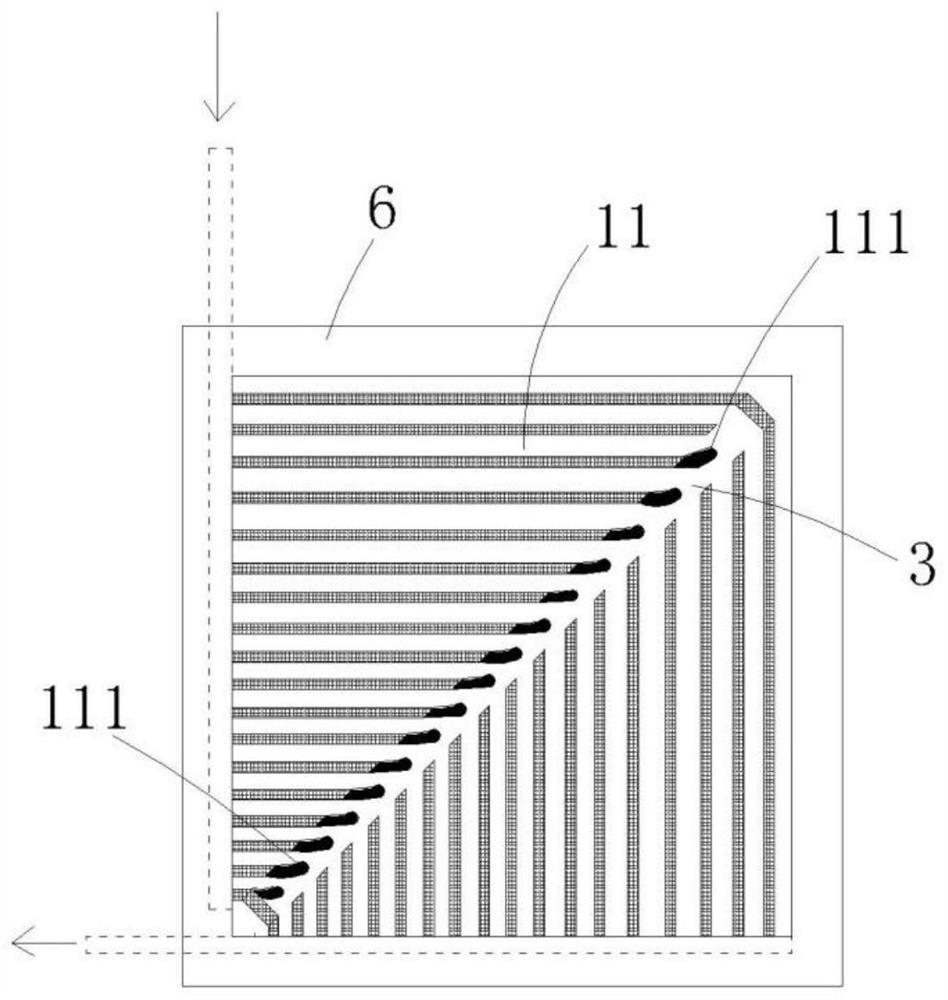

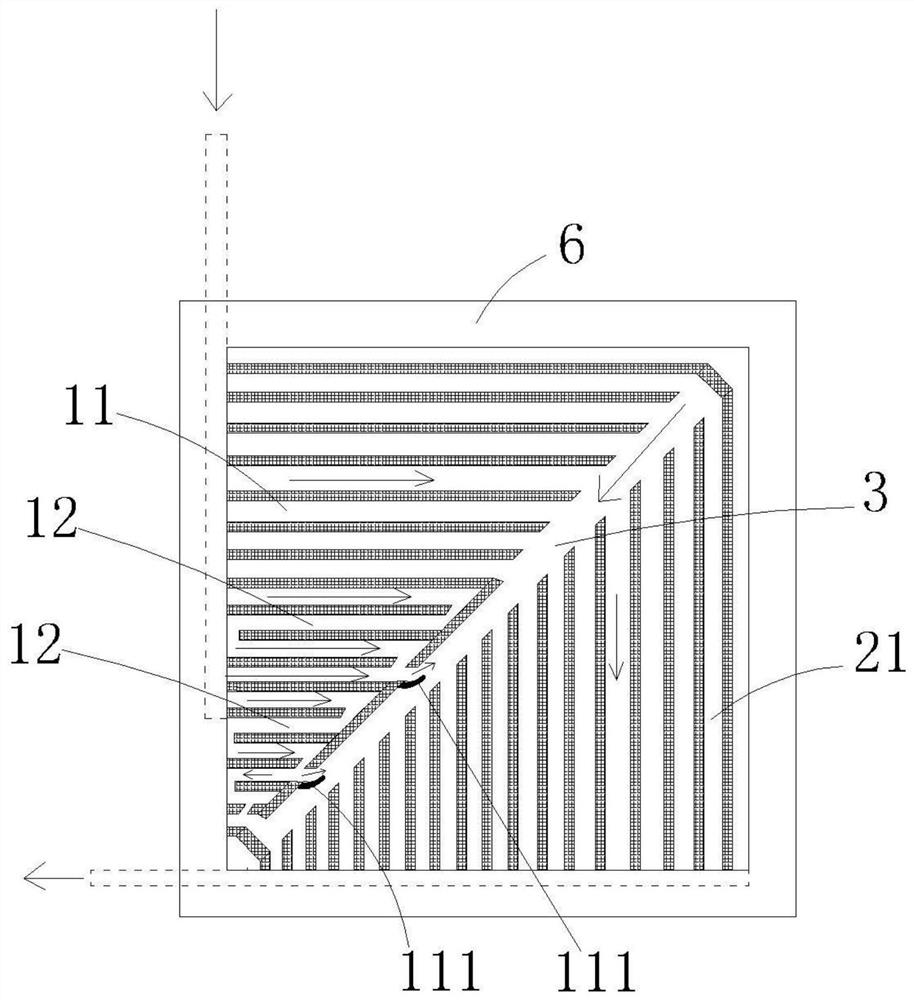

Fuel cell runner structure, flow field plate and fuel cell

InactiveCN111682238AAchieving Concentration ComplementaryAvoid floodingFinal product manufactureCollectors/separatorsFuel cellsMechanical engineering

The invention provides a fuel cell flow channel structure, a flow field plate and a fuel cell, which are used for solving the problems of flow channel water accumulation and poor cell stability of thefuel cell in the prior art. The fuel cell flow channel structure comprises an upper triangular area and a lower triangular area; the upper triangular area is provided with plurality of horizontal flow channels, and in every two vertically adjacent horizontal flow channels, length of the upper horizontal flow channel is larger than that of the lower horizontal flow channel; the lower triangular area is provided with a plurality of vertical flow channels; the vertical flow channels and the horizontal flow channels correspond to one another to form L-shaped flow channels, and the longer verticalflow channels correspond to the longer horizontal flow channels; each horizontal flow channel and one end far away from the lower triangular area are respectively communicated with an inlet pipeline;the ends, away from the upper triangular area, of the vertical flow channels communicate with an outlet pipeline; the fuel cell flow channel structure comprises an oblique angle flow channel which islocated between the upper triangular area and the lower triangular area, and the horizontal flow channels and the vertical flow channels are communicated with the oblique angle flow channel.

Owner:JIANGSU UNIV OF SCI & TECH

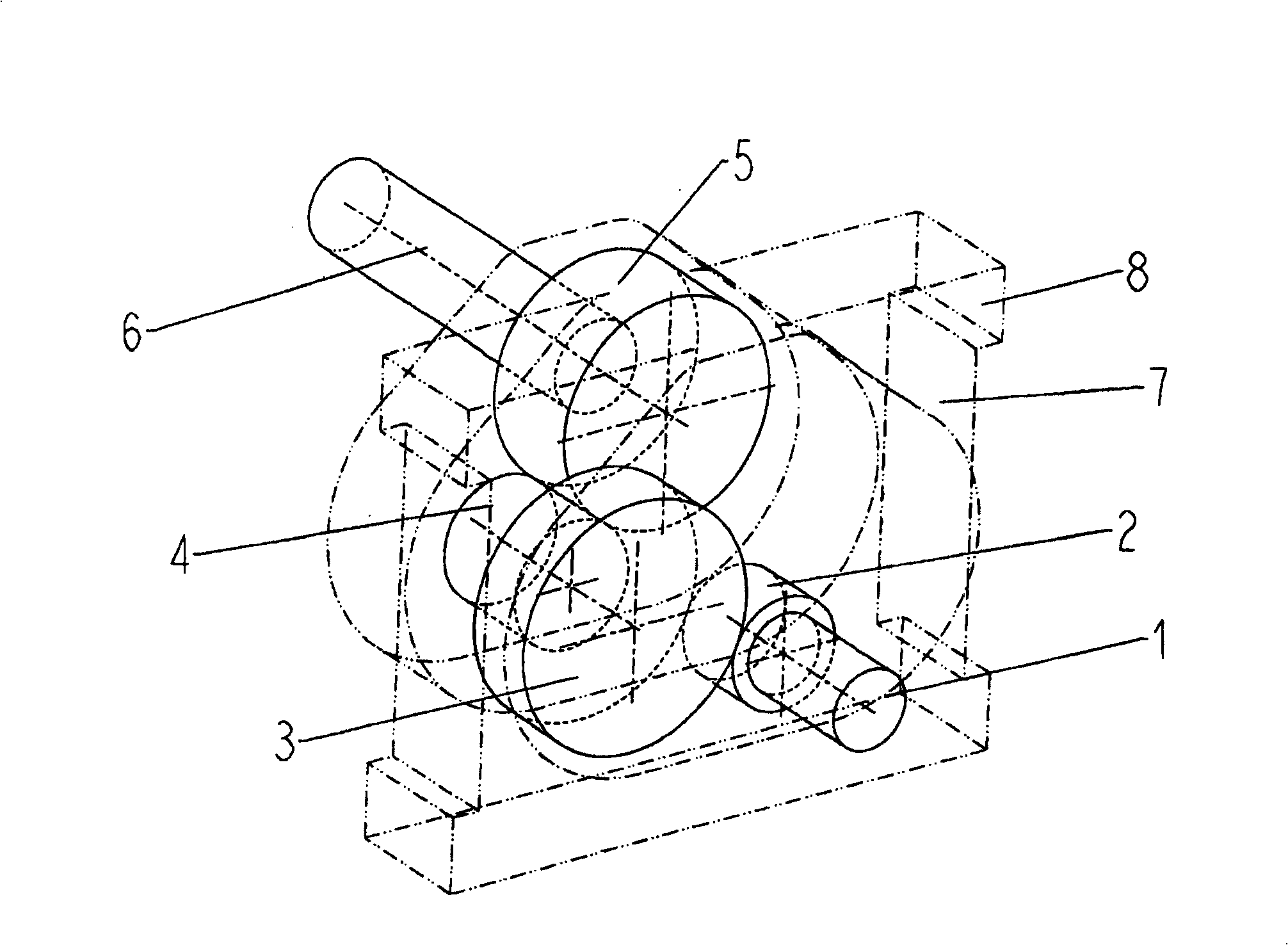

Portalachse

ActiveCN100430256CLarge transmission ratioTransmission ratio is smallControl devicesRotational axisPortal axle

The invention relates to a portal axle for low-platform vehicles. Said portal axle consists of a drive spur wheel (2) which interacts with a first counter spur wheel (3) which is rotationally fixed to a second counter spur wheel (4) which interacts with a driven spur wheel (5). The vertical distance of the rotational axis (10) of the drive spur wheel to the ground (11) is less than the vertical distance of the counter spur wheels (9, 4) to the ground (11).

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com