Support structure for DIG (Display In Gauge) automobile instrument rotational dial

A support structure and automotive instrumentation technology, applied in the physical field, can solve the problems of large rotational friction, unstable rotation of the annular rail groove, and large motor drive load, etc., and achieve the effects of small frictional resistance, reduced bending angle, and reduced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

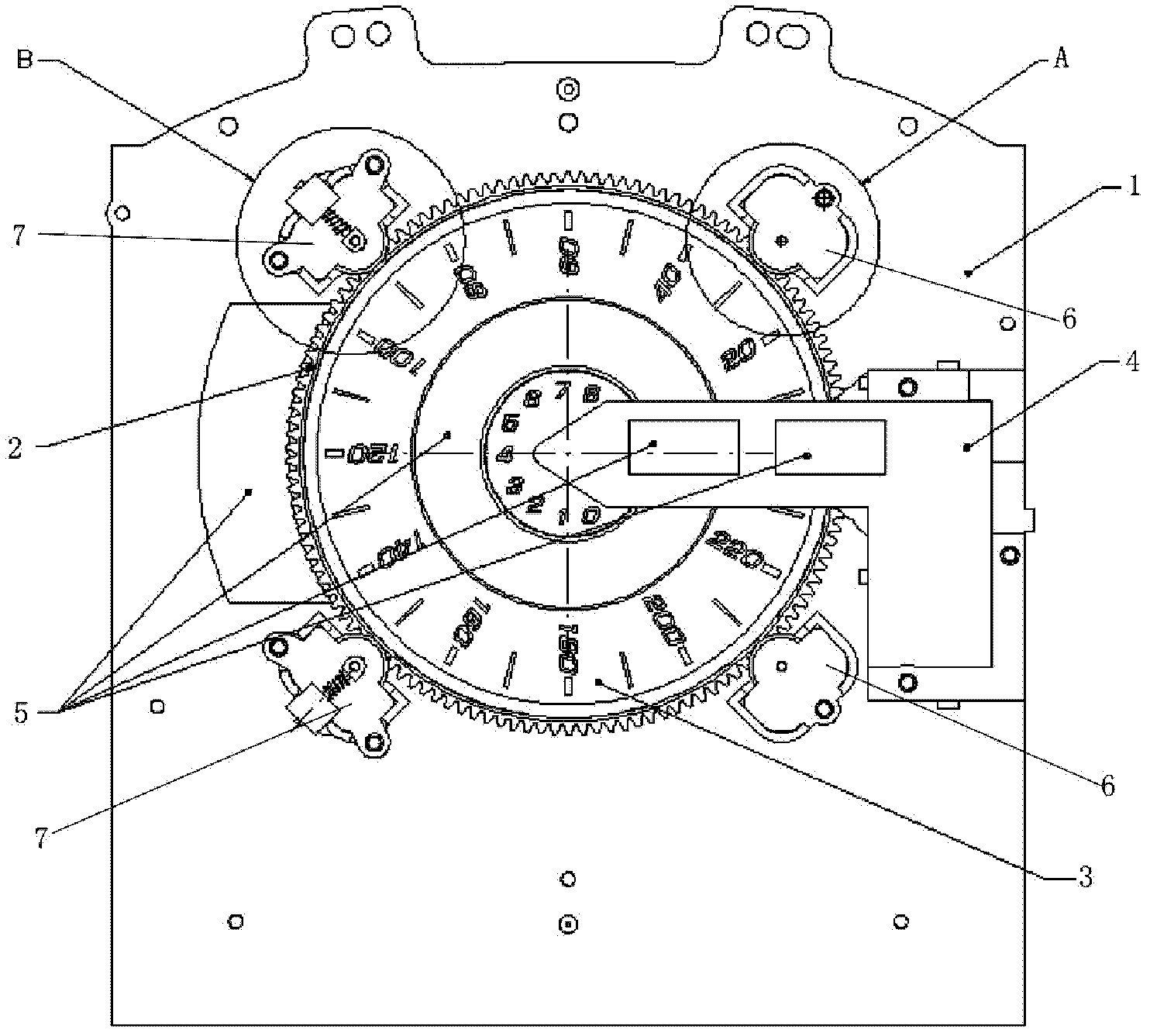

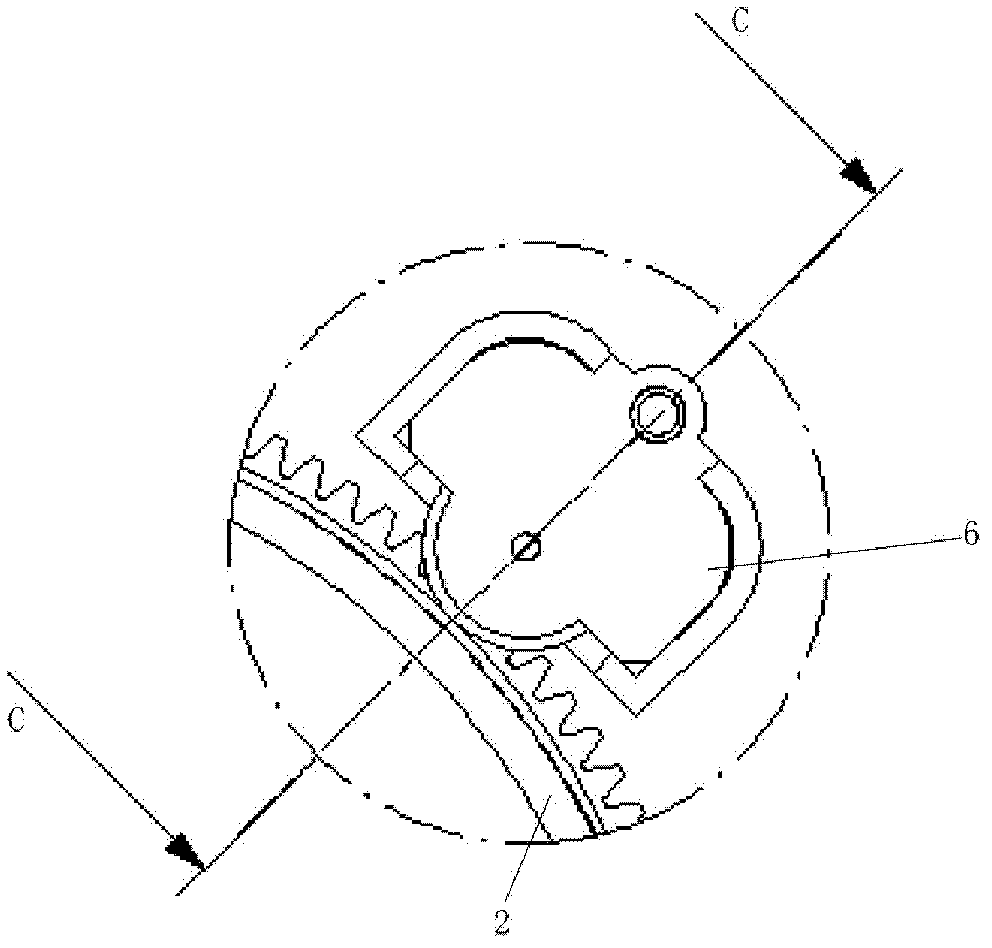

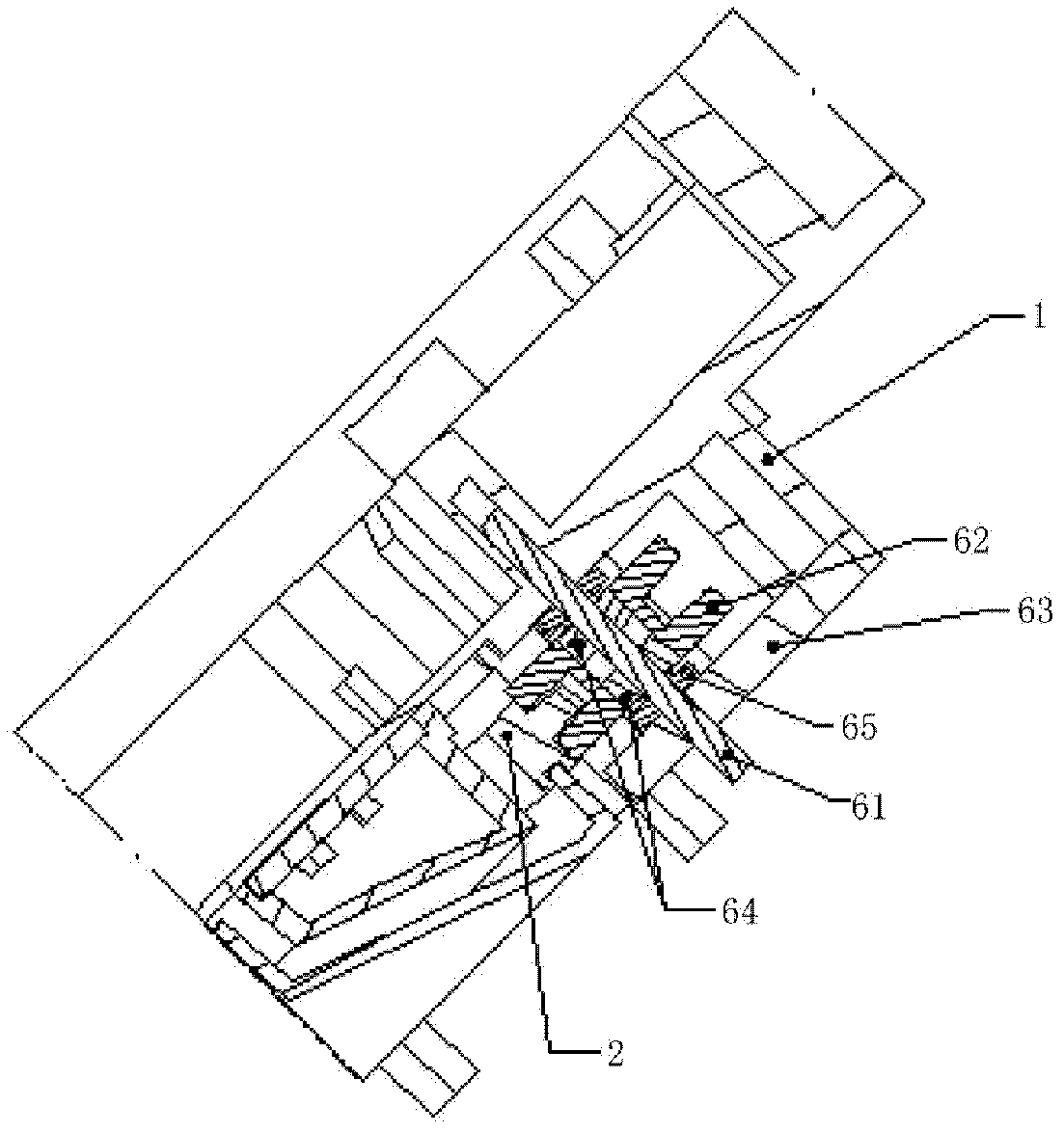

[0020] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the supporting structure of a DIG automobile instrument rotary dial of the present invention includes an instrument base 1 and a dial 3, and the dial 3 is arranged on the instrument base 1, wherein the dial 3 is circular, There is a gap between the plane of the dial 3 and the instrument base 1. The instrument base 1 is provided with two pulleys 62 and two pulleys 72. The pulleys 62 and the pulleys 72 are evenly distributed along the circumferential direction and are respectively connected to the outer circle of the dial 3. Tangent.

[0021] Further, teeth 2 are continuously provided on the outer circumference of the dial 3 .

[0022] Further, the instrument base 1 is provided with a motor (not shown in the figure), the output shaft of the motor is provided with a driving gear (not shown in the figure), and the driving gear and the dial 3 meshes.

[0023] Further, two pulley brackets 6 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com