Furnace door dust collection hood

A technology for dust collecting hoods and furnace doors, which is applied in the direction of furnaces, furnace components, waste heat treatment, etc., can solve the problems of increased flue gas processing capacity, reduce flue gas processing capacity, solve the problem of excessive floor space and investment, The effect of preventing smoke from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

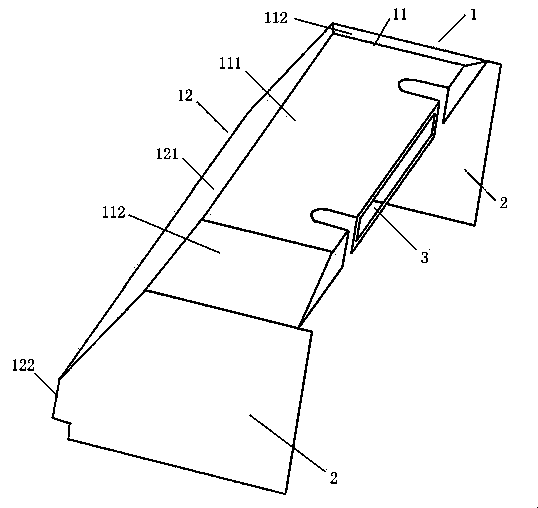

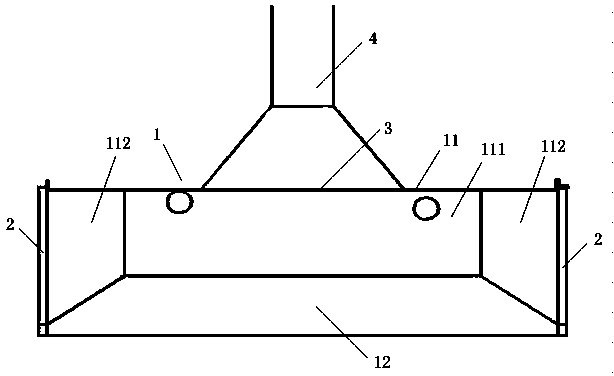

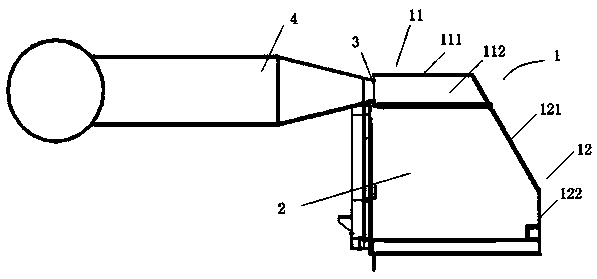

[0040] see Figure 1 to Figure 3 , The present invention provides a furnace door dust collecting cover, which is mainly composed of a top cover 1, a side baffle plate 2, and a rectangular tuyere 3, with a length of 8560 mm and a width of 2765 mm. Under the guidance of the top cover 1 and side baffles 2 and the negative pressure of the smoke exhaust pipe 4, the smoke concentrates in the same direction and reaches the rectangular tuyere 3, turns 90° and is sucked into the smoke exhaust pipe 4.

[0041] 1. The top cover 1 is used to block smoke and change the direction of smoke movement, and includes an upper guide plate 11 and an inclined baffle 12. The top cover 1 is in the shape of a trapezoid as a whole.

[0042] The upper guide plate 11 is composed of a rectangular top cover 111 and two right-angle trapezoidal side inclined covers 112 on the left and right. Wherein, the rectangular top cover 111 has a length of 5770mm and a width of 1542.8mm.

[0043] The inclined baffle 1...

Embodiment 2

[0055] The difference from Example 1 is that the furnace door dust collecting hood provided in Example 2 is mainly composed of a top cover 1, a side baffle 2, and a rectangular tuyere 3, with a length of 9416mm and a width of 3041.5mm.

[0056] Wherein, the top cover 1 includes an upper guide plate 11 and an inclined baffle plate 12, and the overall shape is trapezoidal. The upper guide plate 11 is composed of a rectangular top cover 111 and two right-angle trapezoidal side inclined covers 112 on the left and right. Wherein, the rectangular top cover 111 has a length of 6347 mm and a width of 1697.1 mm. The inclined baffle 12 is an inclined right-angle type baffle, and is composed of two parts: an inclined plate 121 and a right-angled plate 122 . Among them, the inclined plate 121 is directly connected with the upper end and the left and right ends of the upper guide plate 11. The height of the top cover 1 is 2689.5mm, the length of the upper bottom is 1697.1mm, the length of...

Embodiment 3

[0060] The difference from Example 1 is that the furnace door dust collecting hood provided in Example 3 is mainly composed of a top cover 1, side baffles 2, and a rectangular tuyere 3, with a length of 4708 mm and a width of 1520.75 mm.

[0061] Wherein, the top cover 1 includes an upper guide plate 11 and an inclined baffle plate 12, and the overall shape is trapezoidal. The upper guide plate 11 is composed of a rectangular top cover 111 and two right-angle trapezoidal side inclined covers 112 on the left and right. Wherein, the rectangular top cover 111 has a length of 3173.5mm and a width of 848.6mm. The inclined baffle 12 is an inclined right-angle type baffle, and is composed of two parts: an inclined plate 121 and a right-angled plate 122 . Among them, the inclined plate 121 is directly connected with the upper end and the left and right ends of the upper guide plate 11. The height of the top cover 1 is 1344.75mm, the length of the upper bottom is 848.55mm, the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com