Forming device for circular-truncated-cone-shaped elevation concrete block for floor slab

A forming device and frustum-shaped technology, which is applied in the processing of building materials, molds, construction, etc., can solve the problems of easy breakage of elevation blocks and low yield, and achieve the effects of good protection, improved integrity, and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

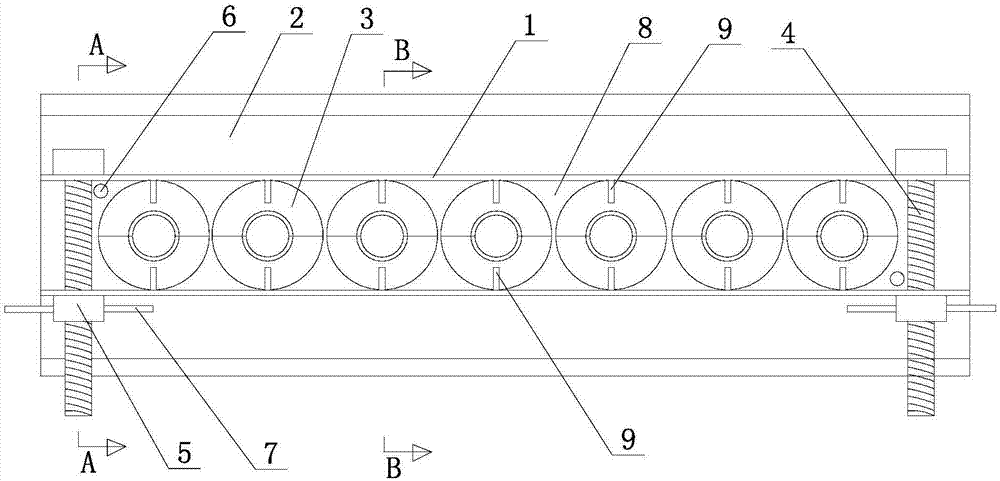

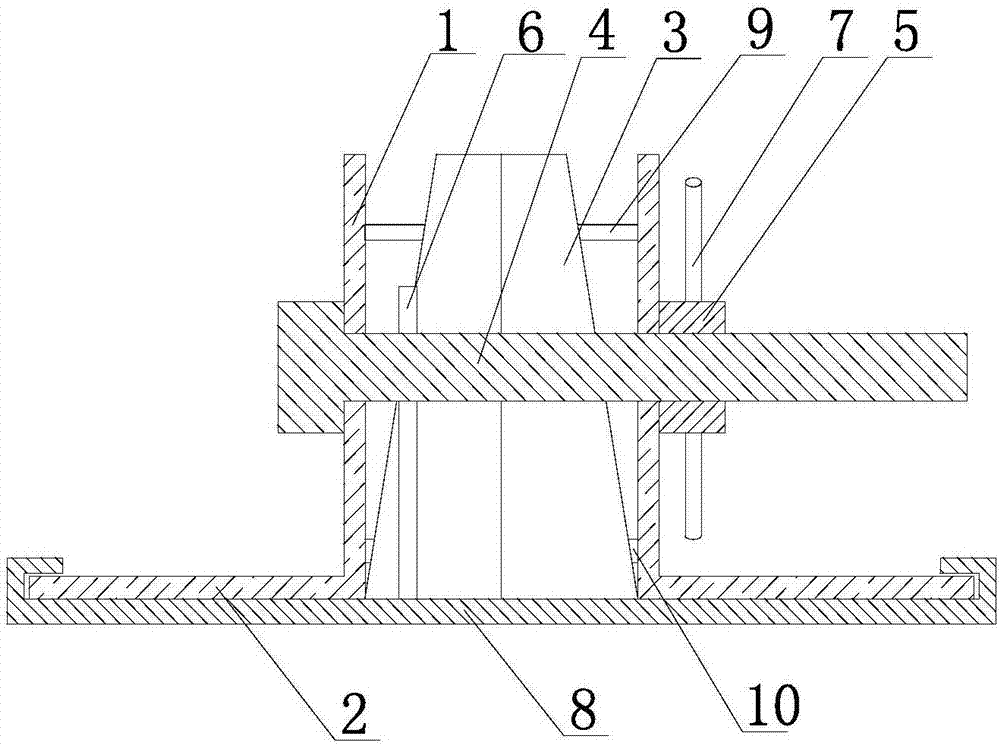

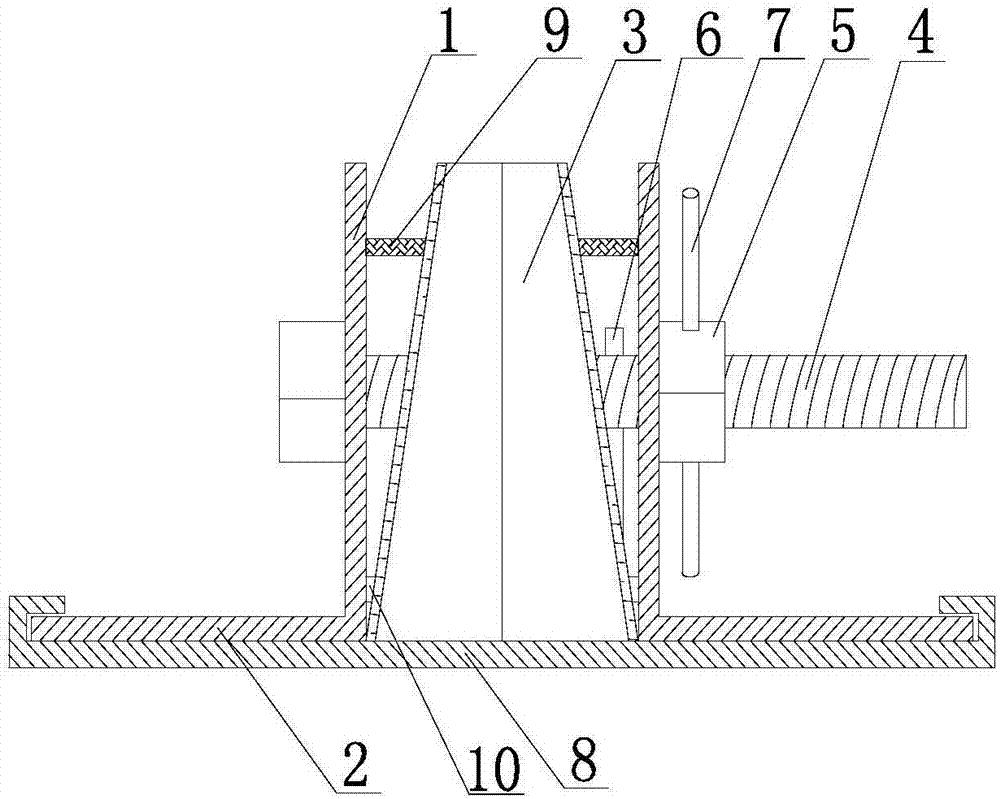

[0030] Such as Figures 1 to 3 As shown, the present invention is a forming device for a conical concrete block with a conical height of floor slabs. 3. Pair between two splints 1 to form a frustum-shaped mold. The upper side wall of the semi-circular frustum-shaped ring plate 3 is connected with the splint 1 through the connecting column 9, and the lower side wall of the semi-circular frustum-shaped ring plate 3 is connected with the wedge-shaped block 10. The splint 1 is connected, the distance between the connecting column 9 and the wedge block 10 is 81% to 84% of the length of the slope of the ring plate 3, and the bottom of each splint 1 is vertically provided with a plank 2 on the opposite side of the ring plate 3, The two splints 1 are connected by at least two sets of paired bolts 4 and nuts 5. The splint 1 and the plank 2 in this embodiment are made of triangular steel, and the vertical uniformity of the triangular steel can be used to realize the verticality of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com