Patents

Literature

33results about How to "Not easy to cause breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

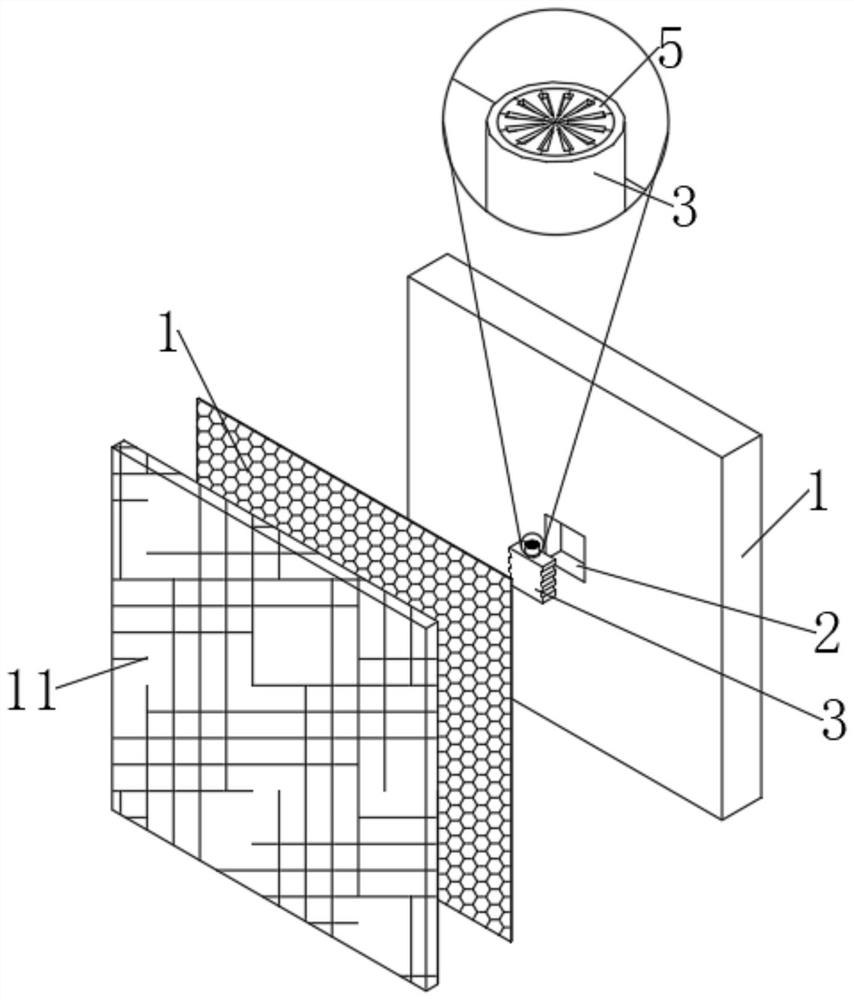

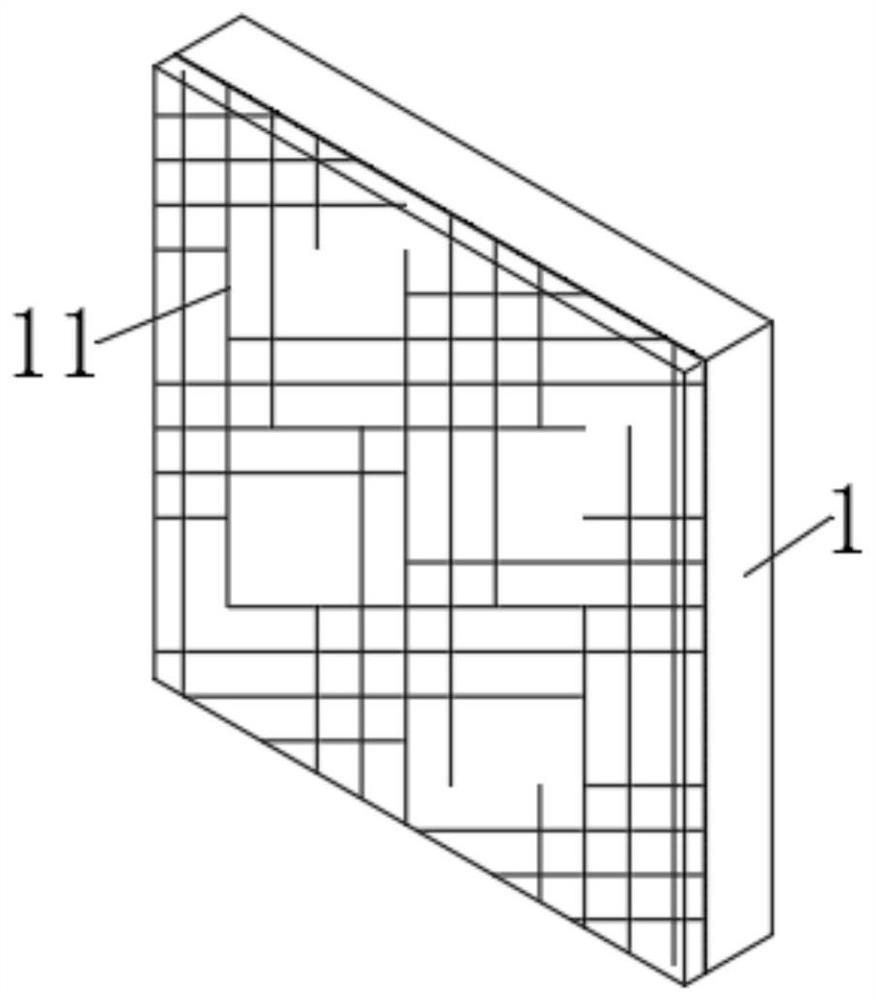

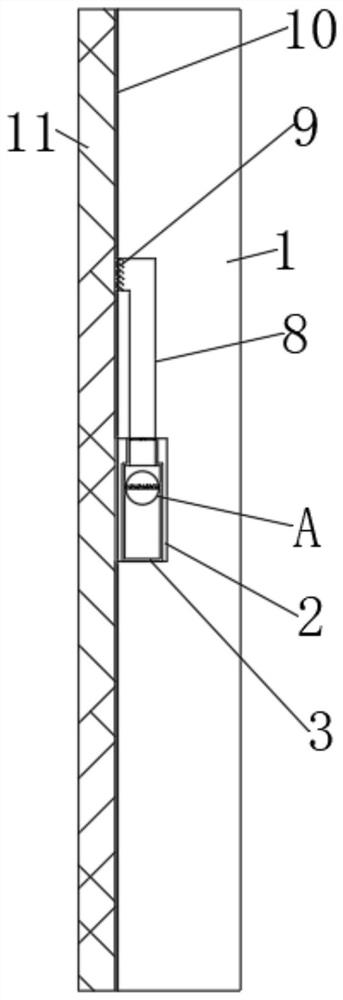

Supporting structure for composite anchor mesh steel bar support of deep well high-stress soft rock roadway and construction method thereof

InactiveCN106761811AImprove stabilityAvoid loose damageUnderground chambersTunnel liningSupporting systemShotcrete

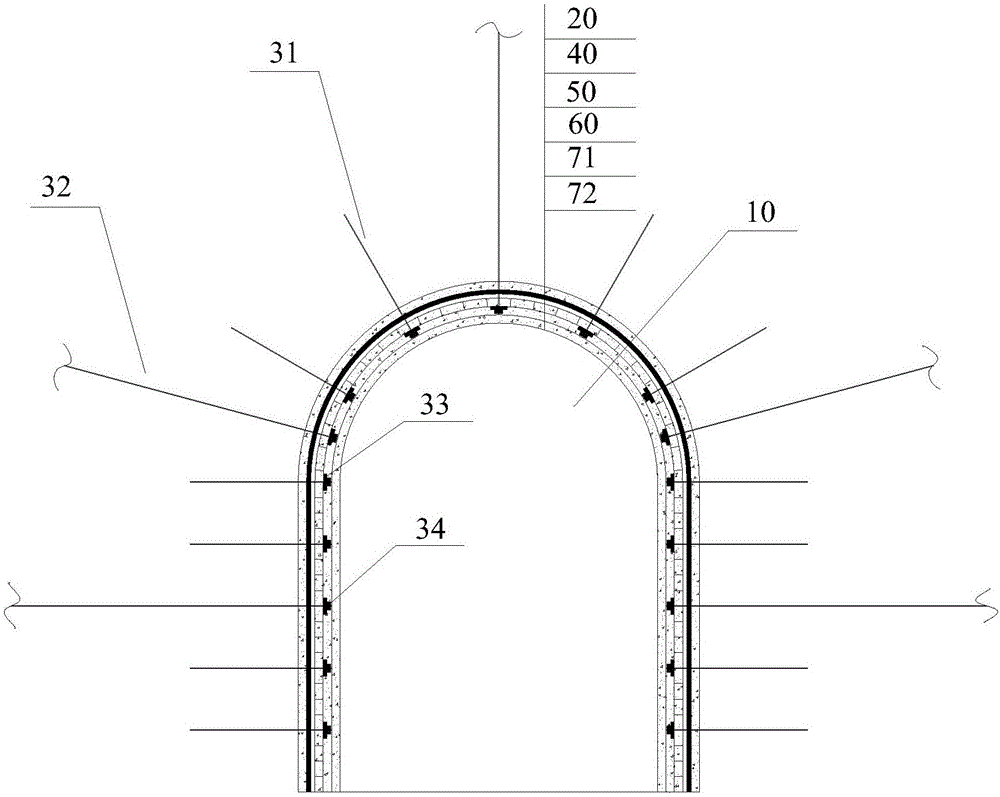

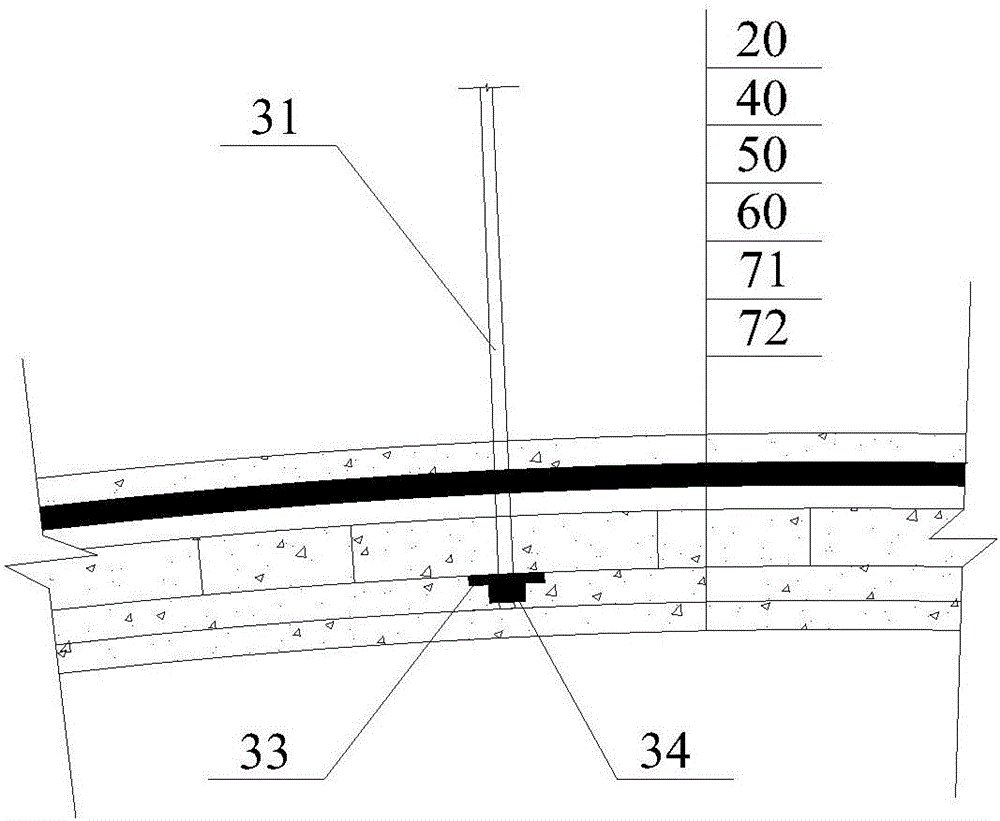

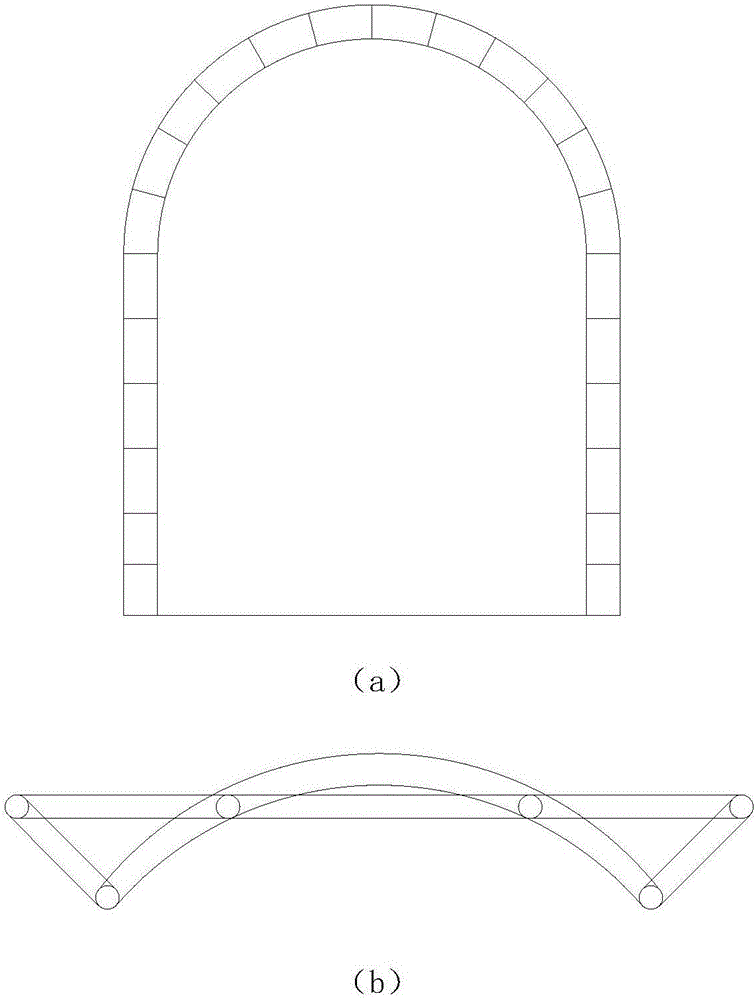

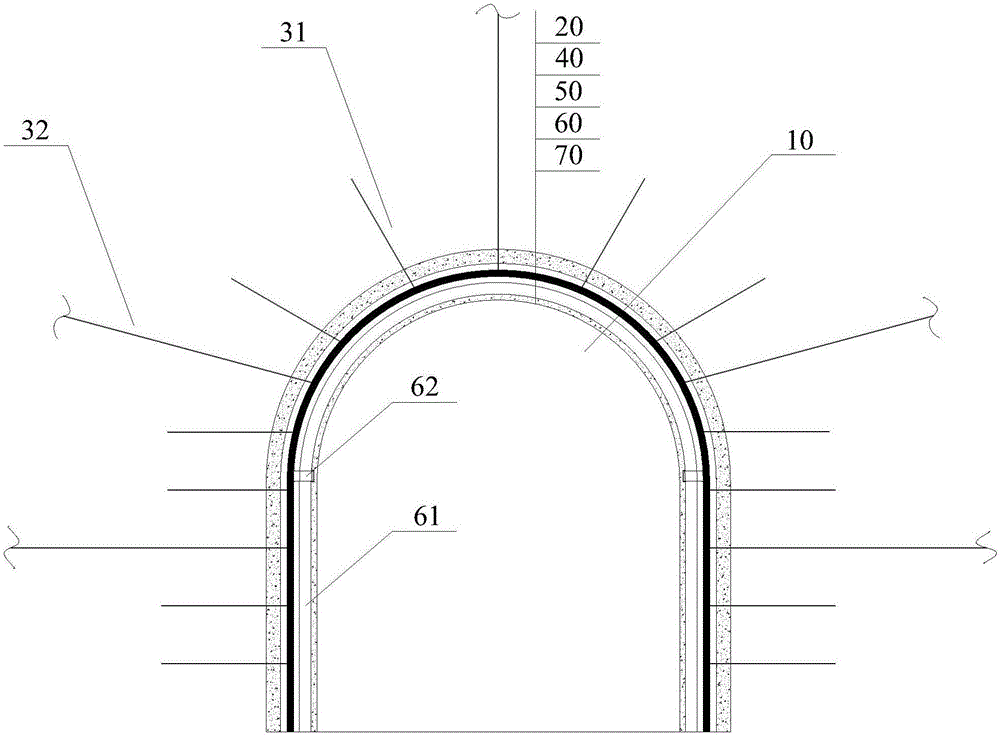

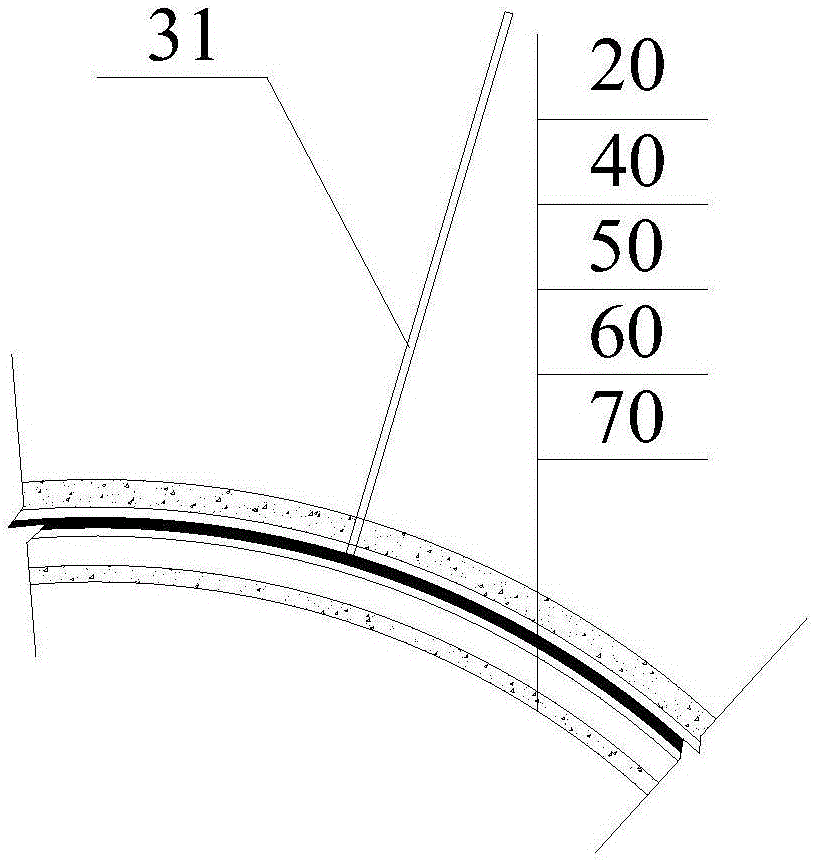

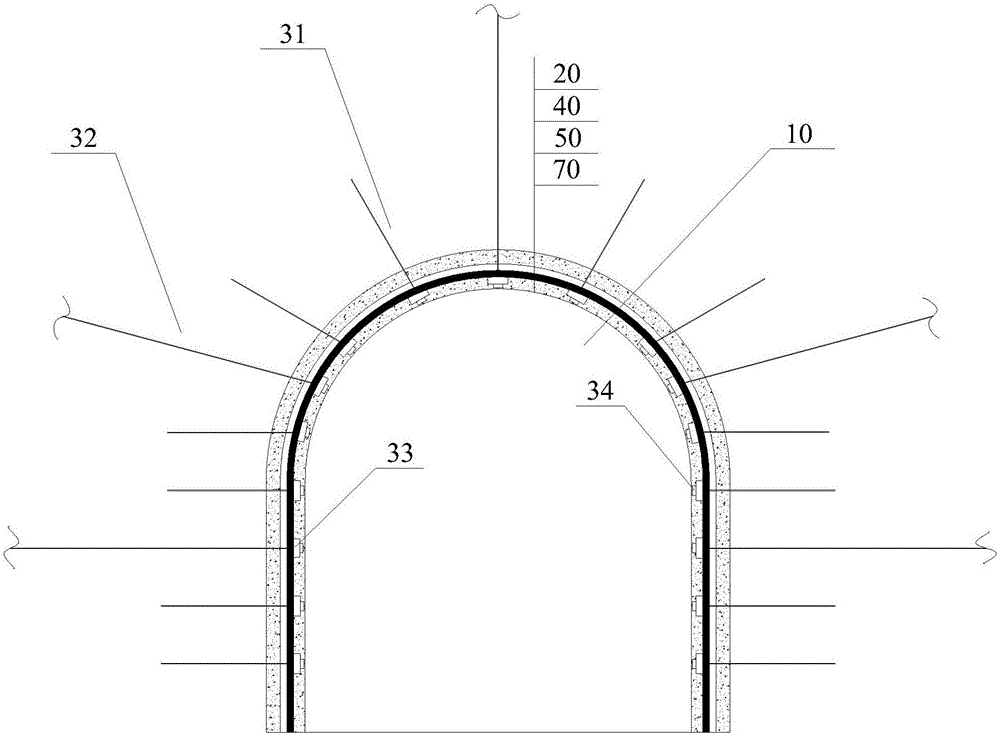

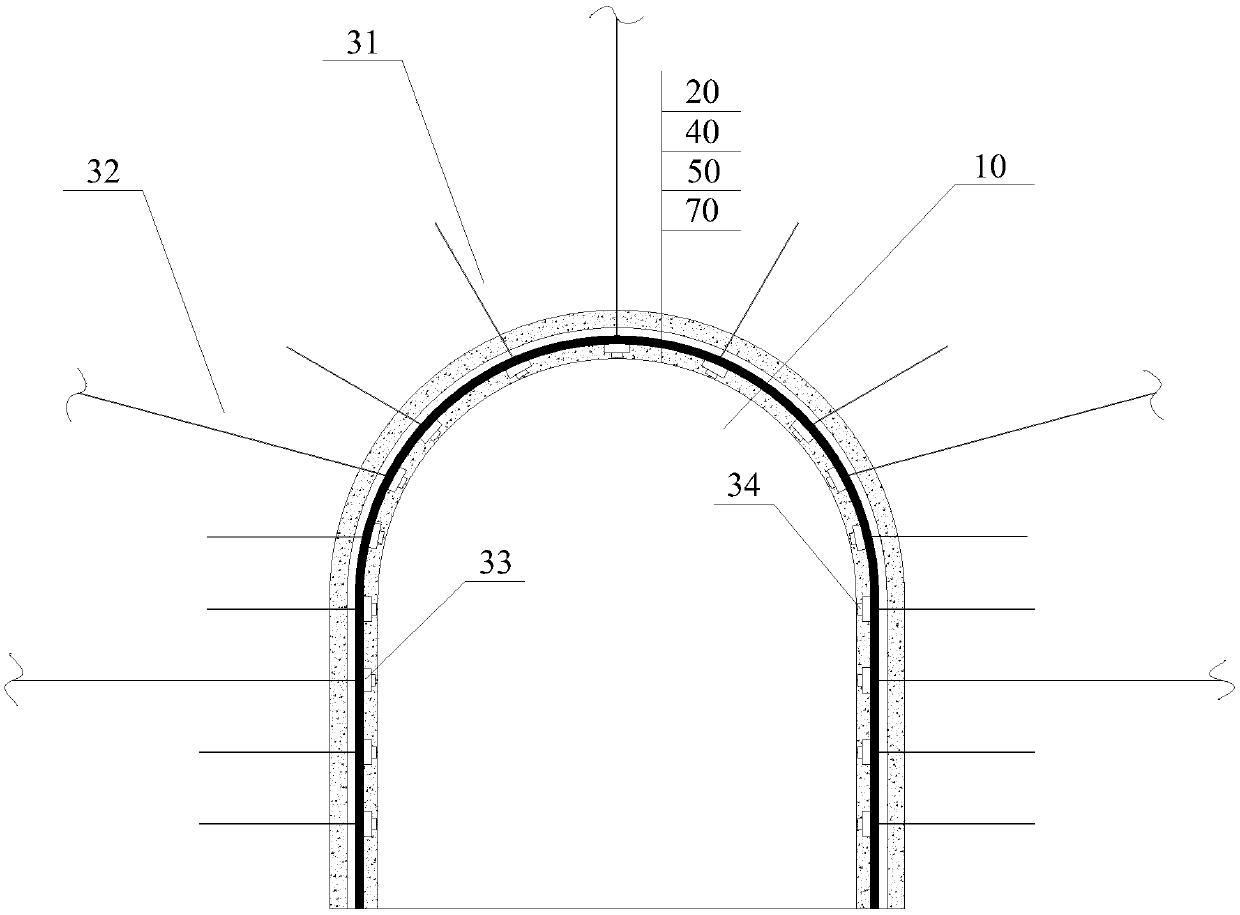

The invention provides a supporting structure for a composite anchor mesh steel bar support of a deep well high-stress soft rock roadway and a construction method thereof. Firstly, anchor rods and anchor ropes are stroke into the interior of surrounding rock, and the set length is exposed; then, steel bar meshes and polyester fiber meshes are laid and hung through the outward-exposing portion of the anchor rods and the anchor ropes, the steel bar meshes are closely attached to the surrounding rock to be laid, and the polyester fiber meshes are closely attached to the steel bar meshes to be laid; a steel bar mesh shell support is erected; the anchor rods and the anchor ropes pass through the steel bar meshes, the polyester fiber meshes and the steel bar mesh shell support in sequence and are fixed on the steel bar mesh shell support through trays and nuts; a first concrete shotcrete layer is poured to close the whole supporting structure, and initial supporting is finished; and finally, a second concrete shotcrete layer is poured, and second supporting is finished. Through initial supporting, the whole structure and the surrounding rock deforms jointly, the yielding effect is given play, and surrounding rock pressure is released, and then second supporting is conducted. Meanwhile, the flexibility and pressure releasing effects of the polyester fiber meshes are utilized, so that the surrounding rock pressure is evenly distributed in the whole supporting system.

Owner:ANHUI UNIV OF SCI & TECH

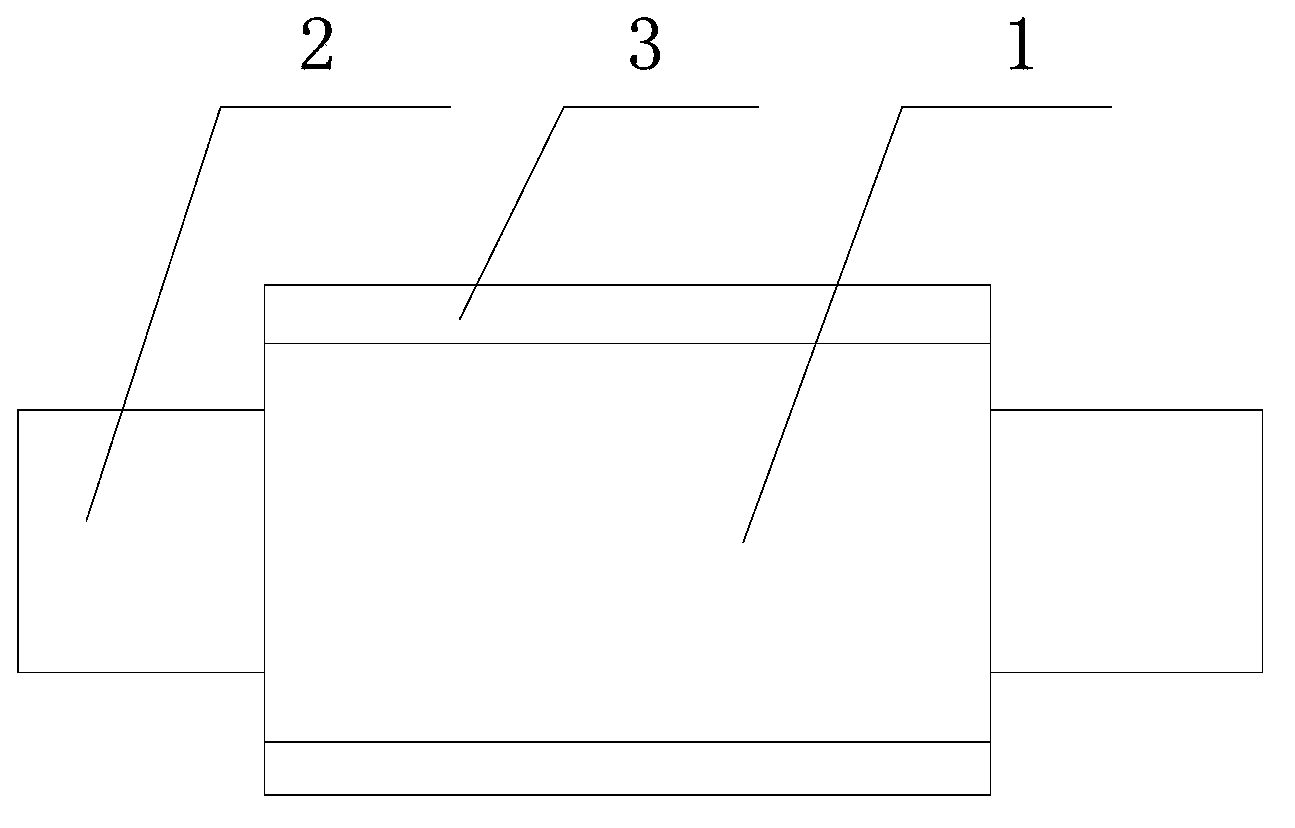

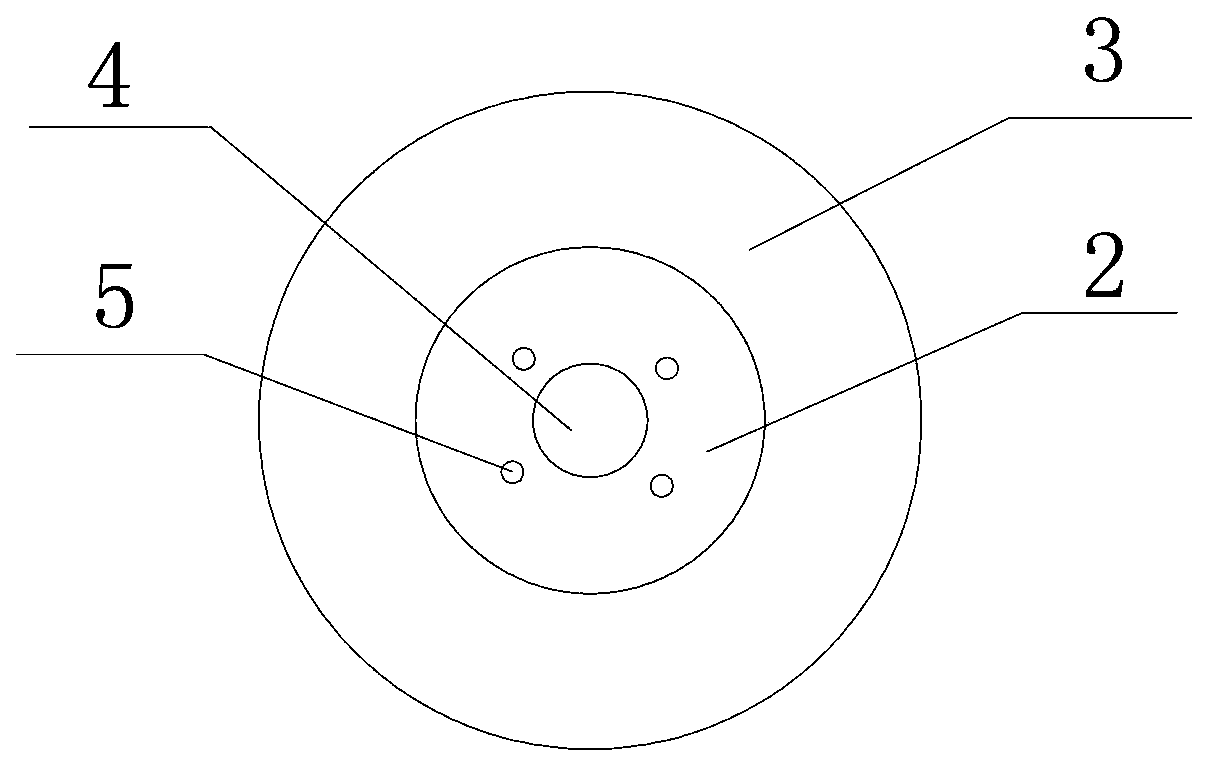

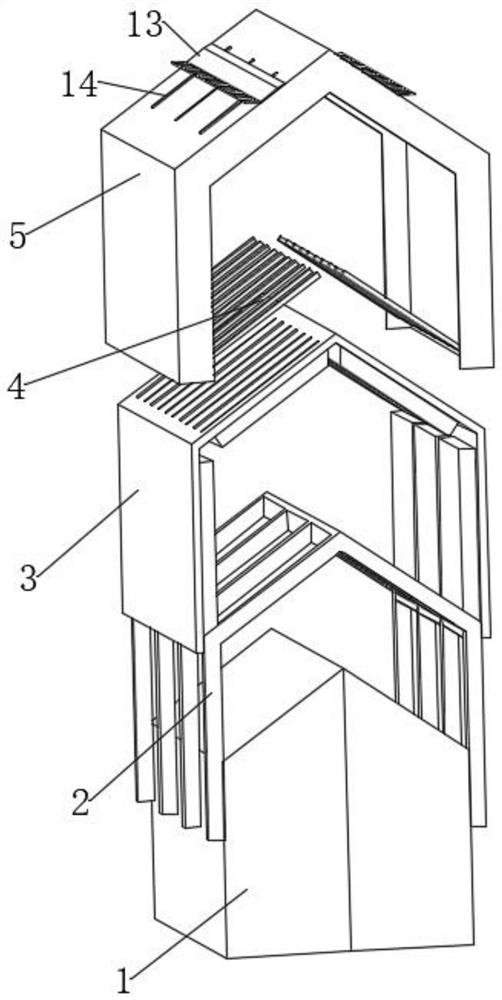

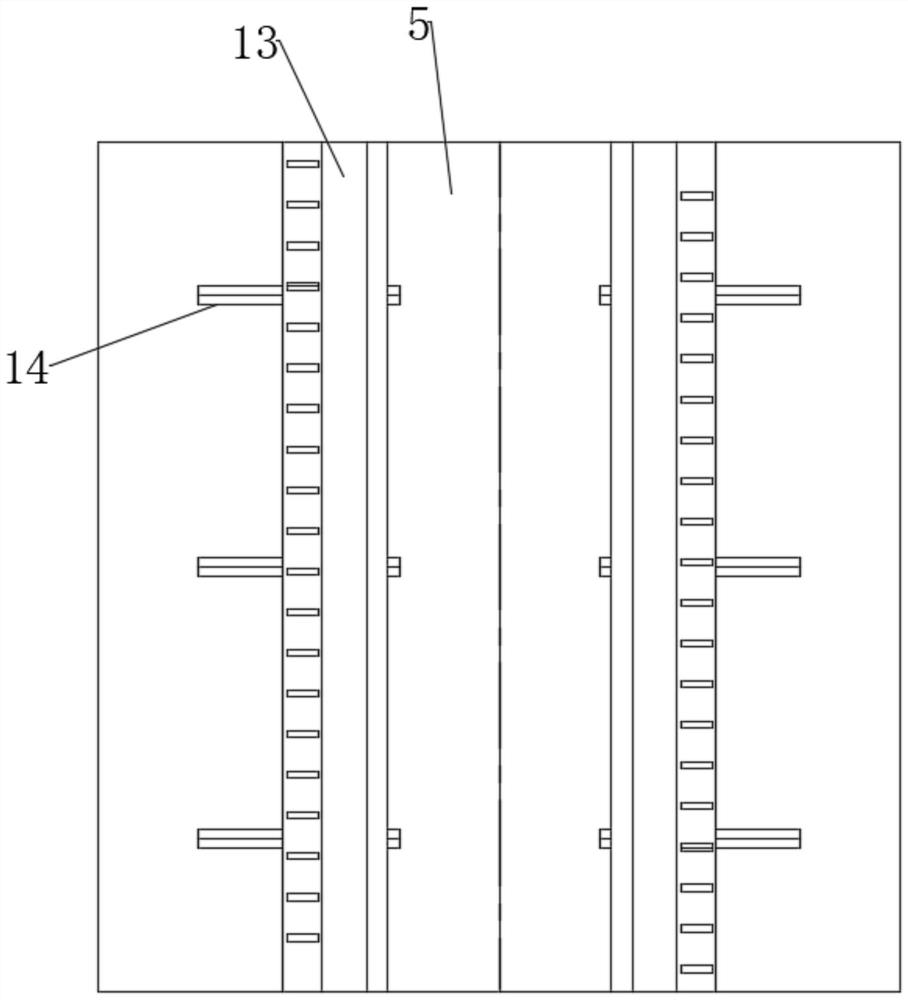

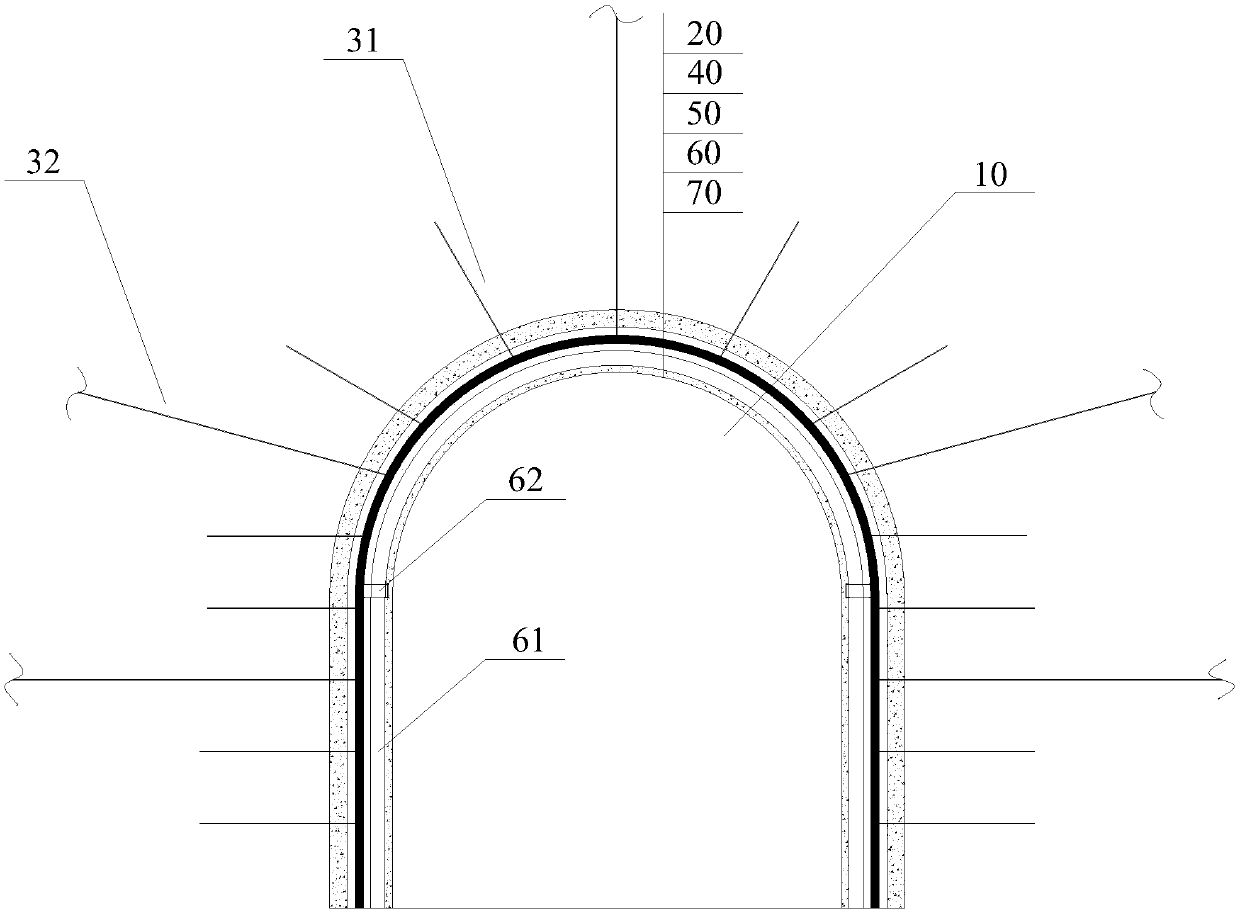

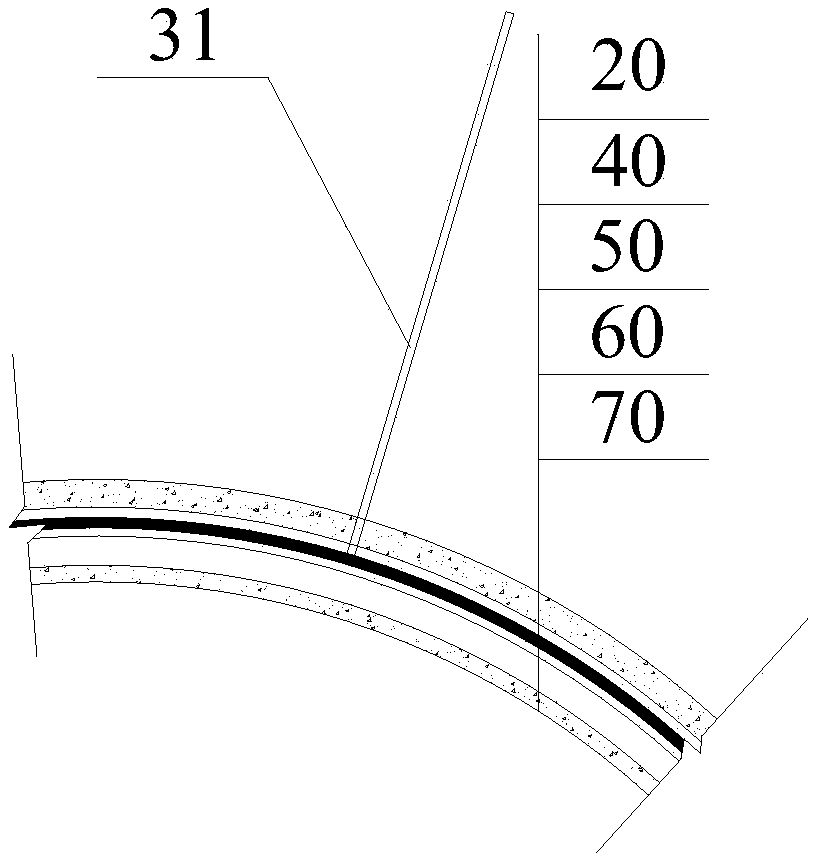

U-shaped steel reinforced composite anchor net support structure for high-stress soft rock tunnel of deep well and construction method thereof

ActiveCN106401605AStrong and stable supportStrong engineering practicabilityUnderground chambersTunnel liningPolyesterFiber

The invention provides an U-shaped steel reinforced composite anchor net support structure for a high-stress soft rock tunnel of a deep well and a construction method thereof. The construction method comprises the following steps of firstly, punching an anchor bolt and an anchor cable into a surrounding rock, supporting the surrounding rock, and exposing with setting lengths; then, sequentially paving and hanging a polyester fiber net and a reinforcement net on the exposing parts of the anchor bolt and the anchor cable, tightly paving the polyester fiber net onto the surrounding rock, tightly paving the reinforcement net onto the polyester fiber net, building an U-shaped steel bracket, enabling the anchor bolt and the anchor cable to sequentially penetrate through the polyester fiber net and the reinforcement net, and fixing on the reinforcement net by trays and screw caps; casting a concrete spray layer to seal the whole support structure. The construction method has the advantages that by using the U-shaped steel bracket, the reinforcement net and the polyester fiber net as skeletons, and forming a reinforced concrete sealing structure with the concrete spraying layer, the flexibility and pressure relief functions of the polyester fiber net are utilized, the pressure of the surrounding rock is uniformly distributed into the whole support system, and the active support property of the anchor bolt and anchor cable, and the passive support property of the reinforcement net and the U-shaped steel bracket are fully utilized.

Owner:ANHUI UNIV OF SCI & TECH

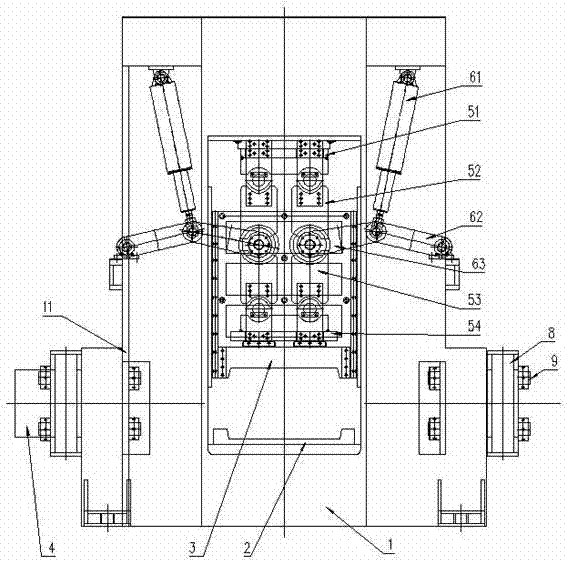

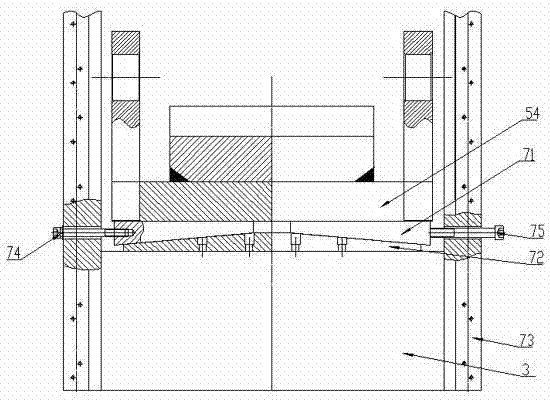

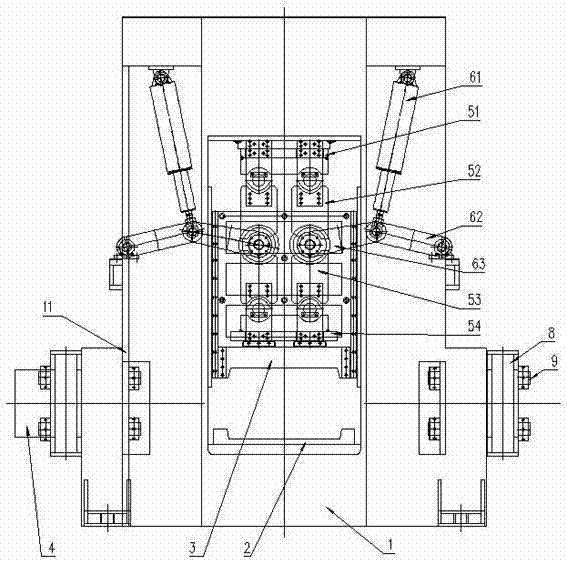

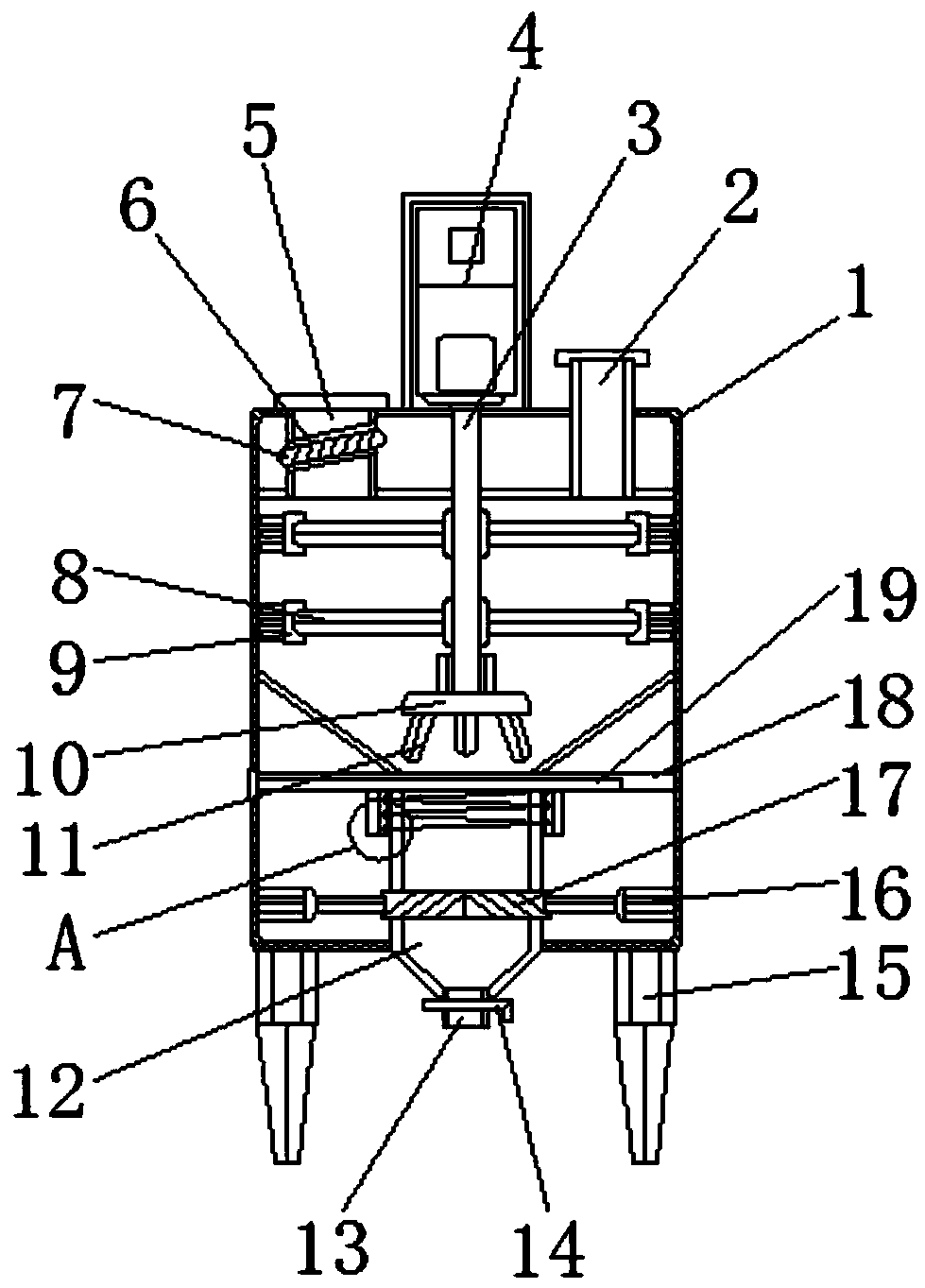

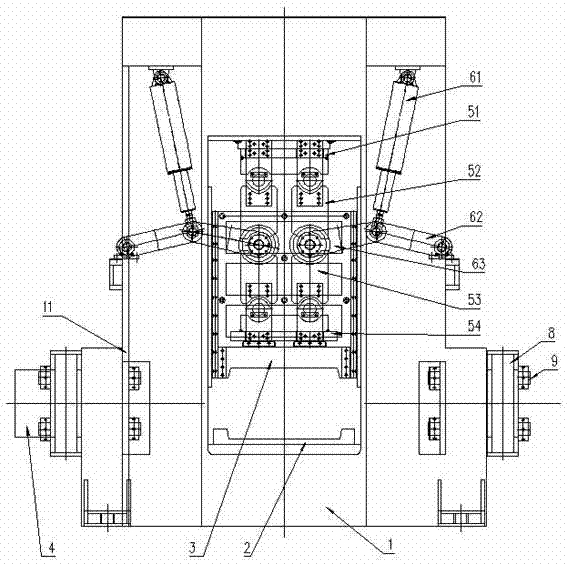

Toggle lever metal extruder

ActiveCN102343377AImprove mechanical performanceSlow and smooth working strokeHydraulic cylinderMechanical engineering

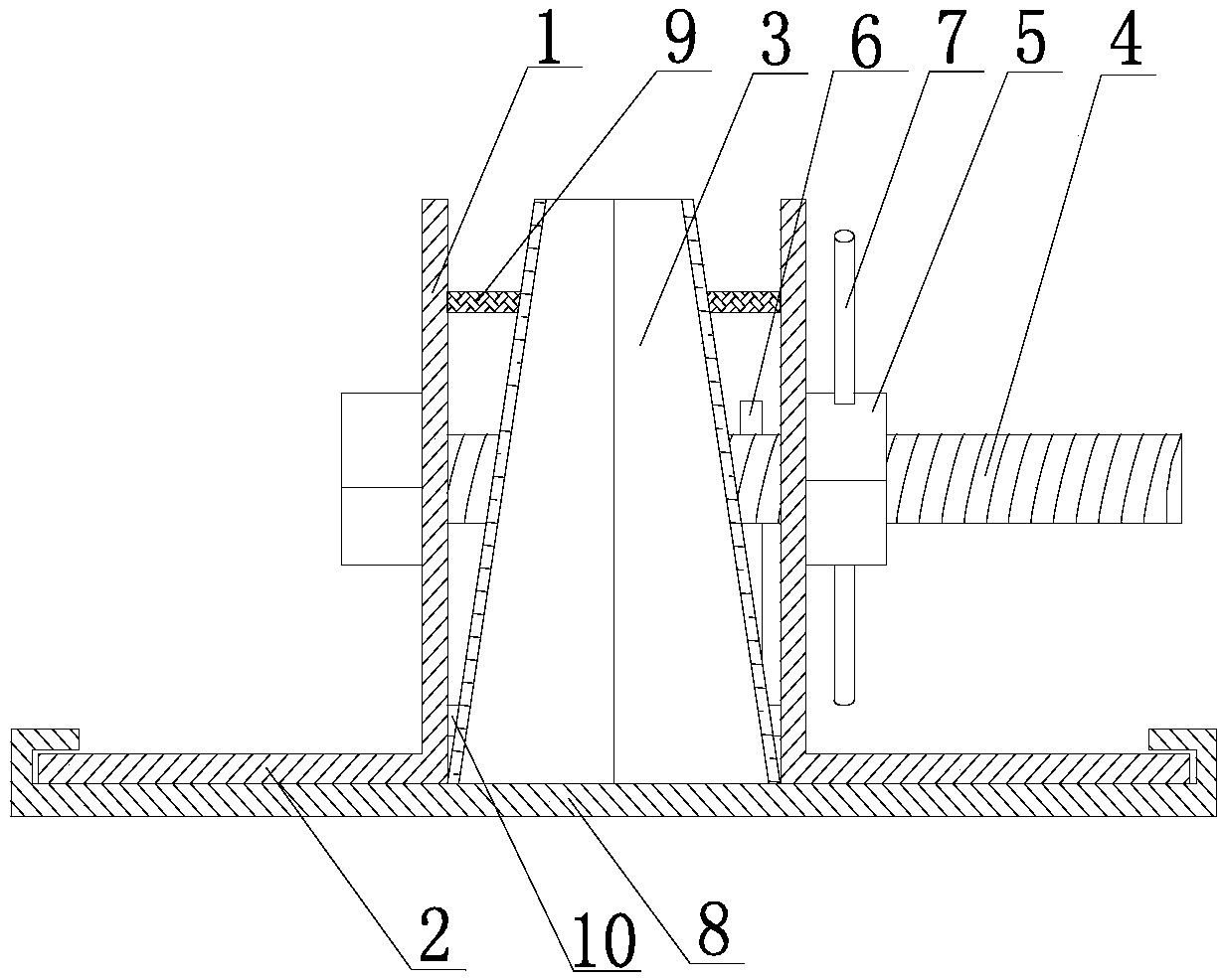

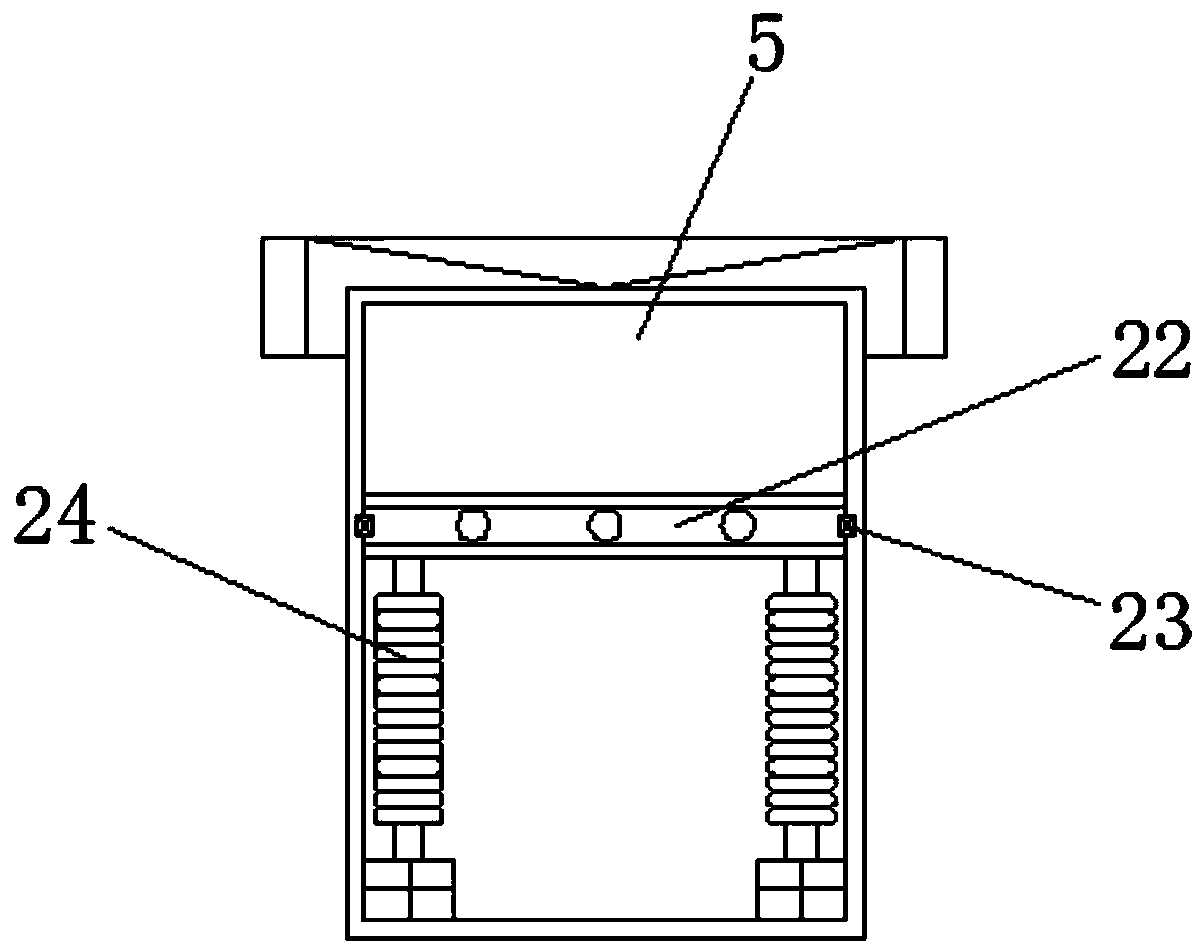

The invention discloses a toggle lever metal extruder, which comprises a framework-type rack and is creatively characterized in that a workbench is arranged at the lower part of the rack, a sliding block is arranged above the workbench and can reciprocate on the rack along a vertical direction, and two sides of the work bench are provided with lateral pressing cylinders; a toggle lever mechanism is arranged on the upper part of the rack and mainly comprises an upper support, an upper toggle lever, a lower toggle lever and a lower support; and a driving mechanism is arranged outside the togglelever mechanism and comprises a hydraulic cylinder, a first connecting lever and a second connecting lever. A hydraulic cylinder and the lateral pressing cylinder act to drive an upper die, a left male die and a right male die to move to a lower die on the workbench for pressing. The driving mechanism drives the toggle lever mechanism to move the sliding block, the sliding block is fast in a return downward trip, and a working stroke is slow and stable; in addition, in the working stroke, the stamping pressure has long duration, the pressing efficiency is high, the stress bearing effect of the rack is good, so that the installed power is reduced and the production cost is lowered.

Owner:NANTONG RUNDE MECHANICAL TECH

Interpenetrating polymer networks wide temperature band damping adhesive and its preparation method

InactiveCN1400270AGood adhesionAvoid breakingPolyureas/polyurethane adhesivesPolyesterPolymer science

The present invention discloses an interpenetrating network wide-temp. band damping adhesion agent, is made of the glue formed from polyurethane prepolymer and polyacrylate copolymer, polyurethane solidifying agent and polyacrylate solidifying agent. Its preparation method includes: (1). synthesizing polyester; (2). synthesizing polyurethane prepolymer; (3). synthesizing polyurethane solidifying agent; (4). synthesizing polyacrylate copolymer; (5). synthesizing polyacrylate solidifying agent; and (6). uniformly mixing polyurethane prepolymer and polyacrylate copolymer to obtain glue. Said invention can forcedly mix the obtained two component adhesive to form the alloy of interpenetrating neetwork polymer, i.e. interpenetrating network wide-temp. band damping adhesion agent which can mave vibration energy.

Owner:ZHEJIANG UNIV +1

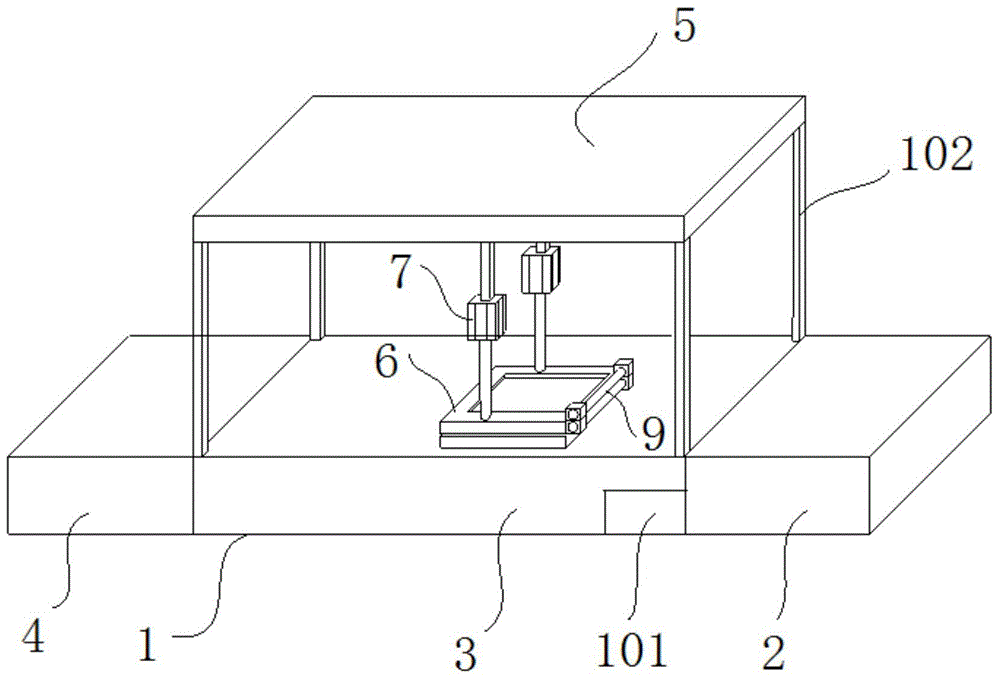

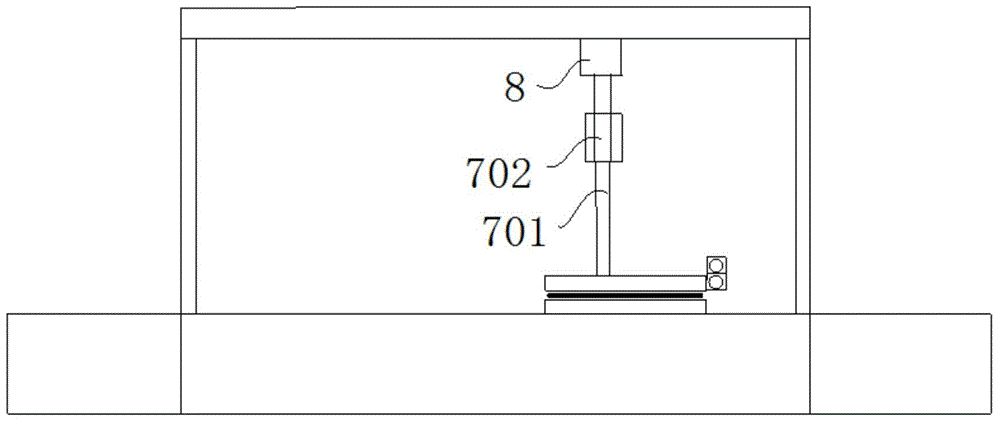

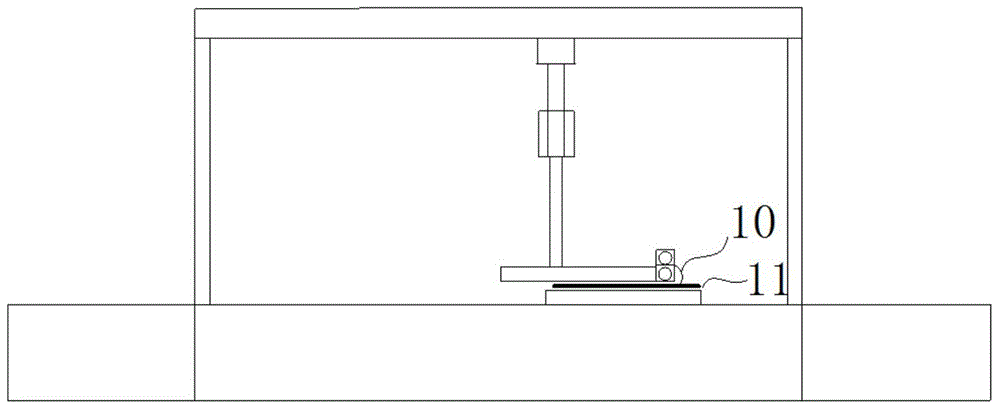

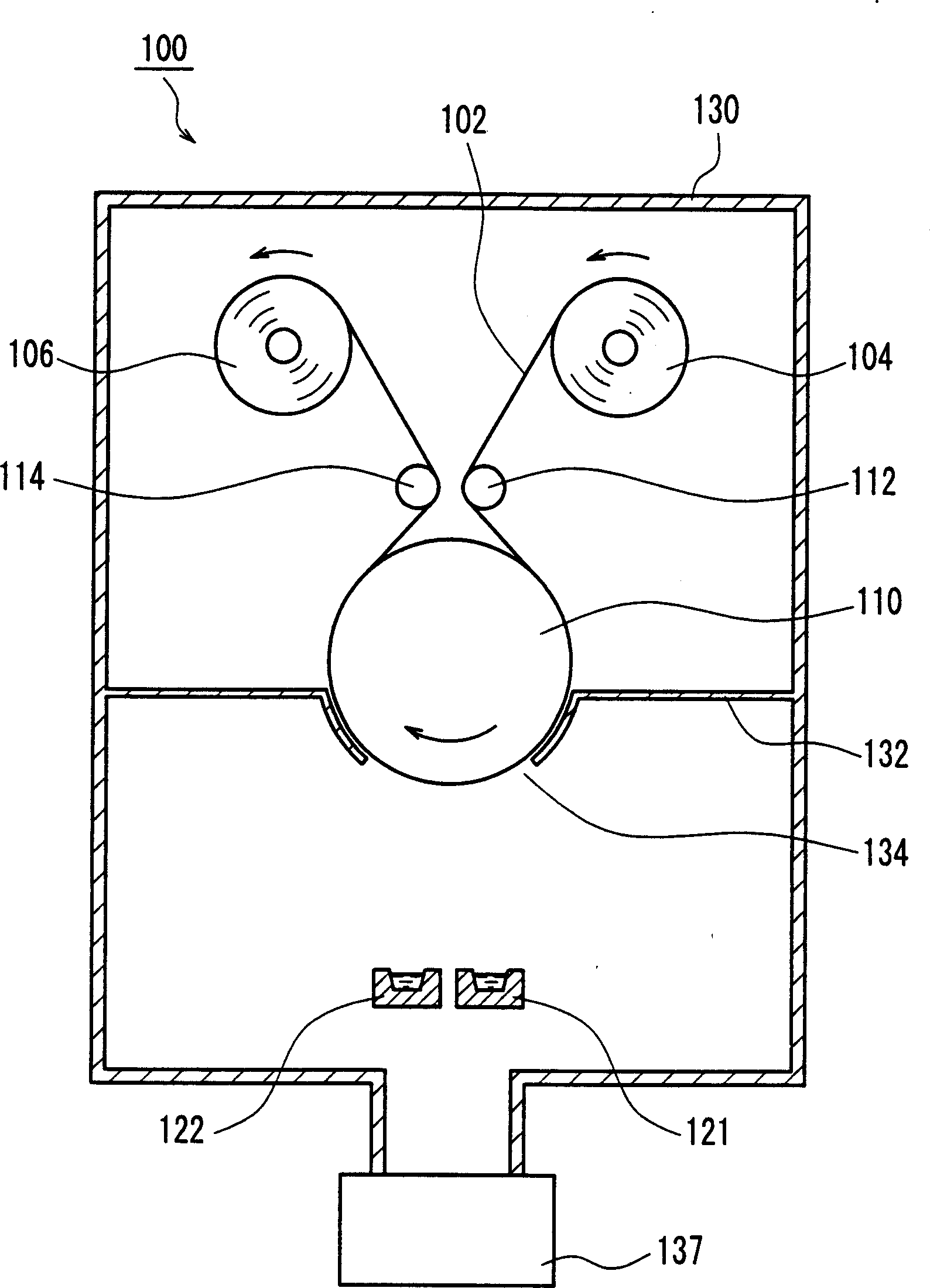

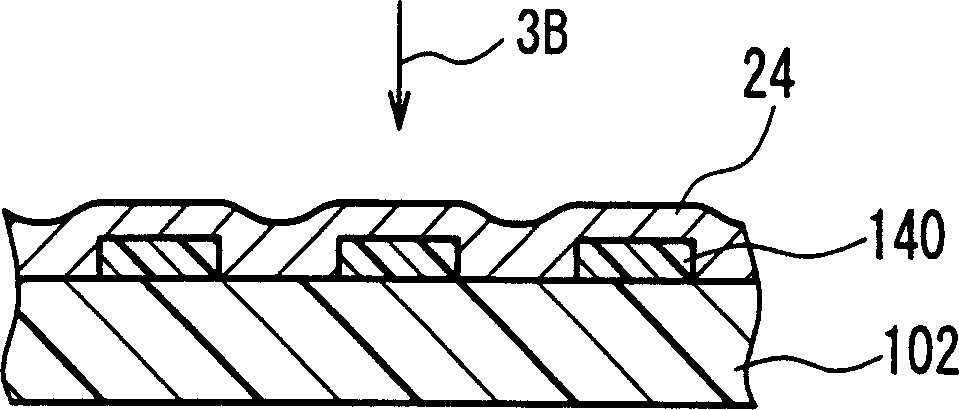

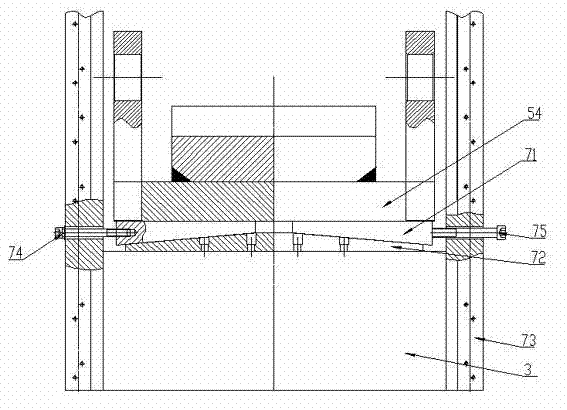

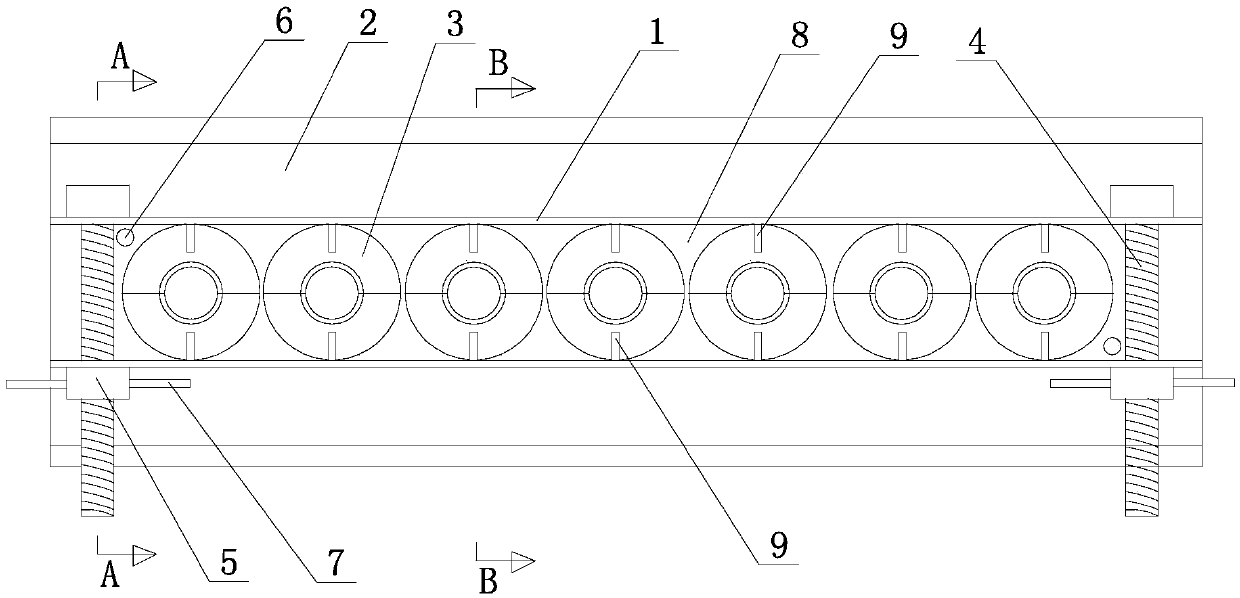

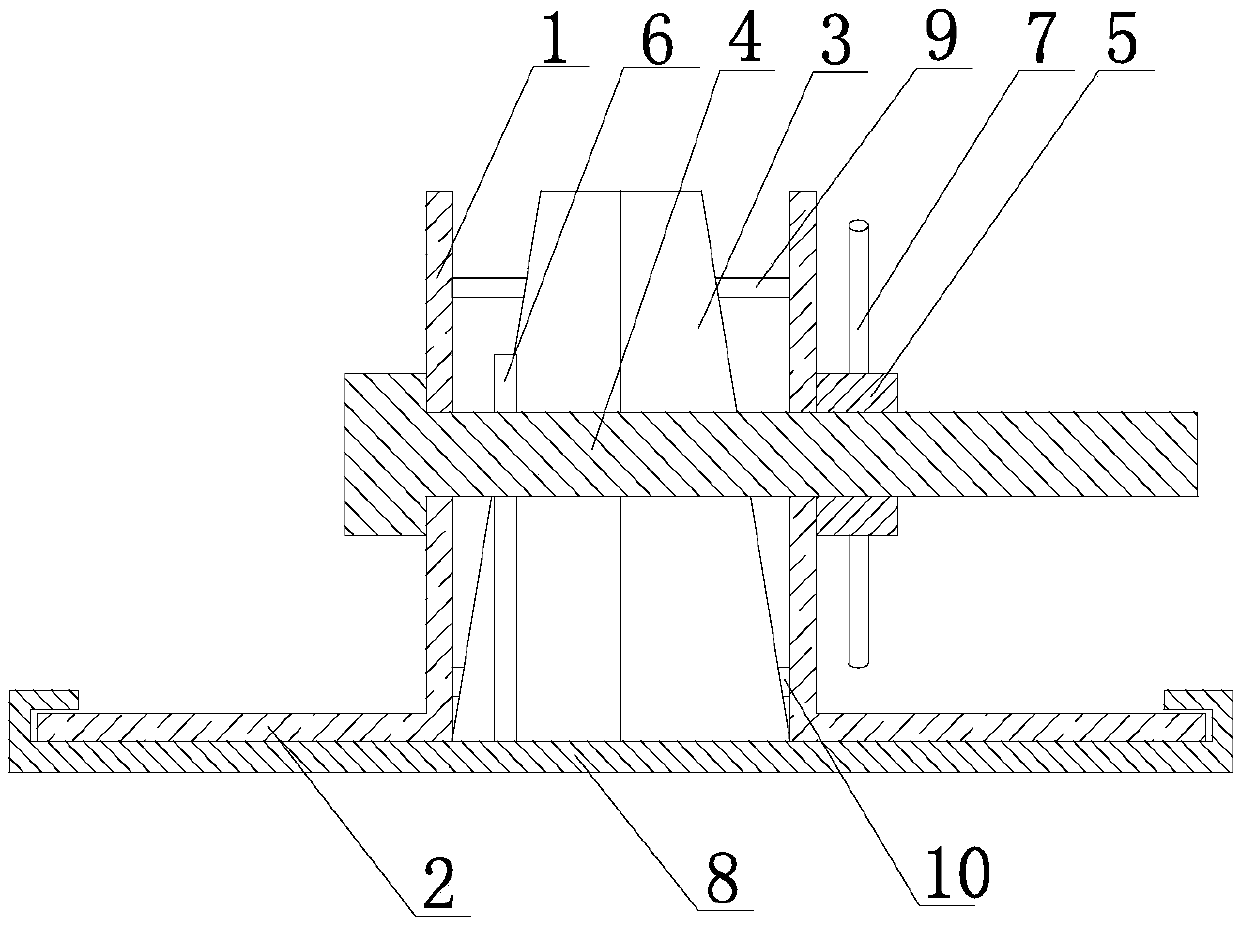

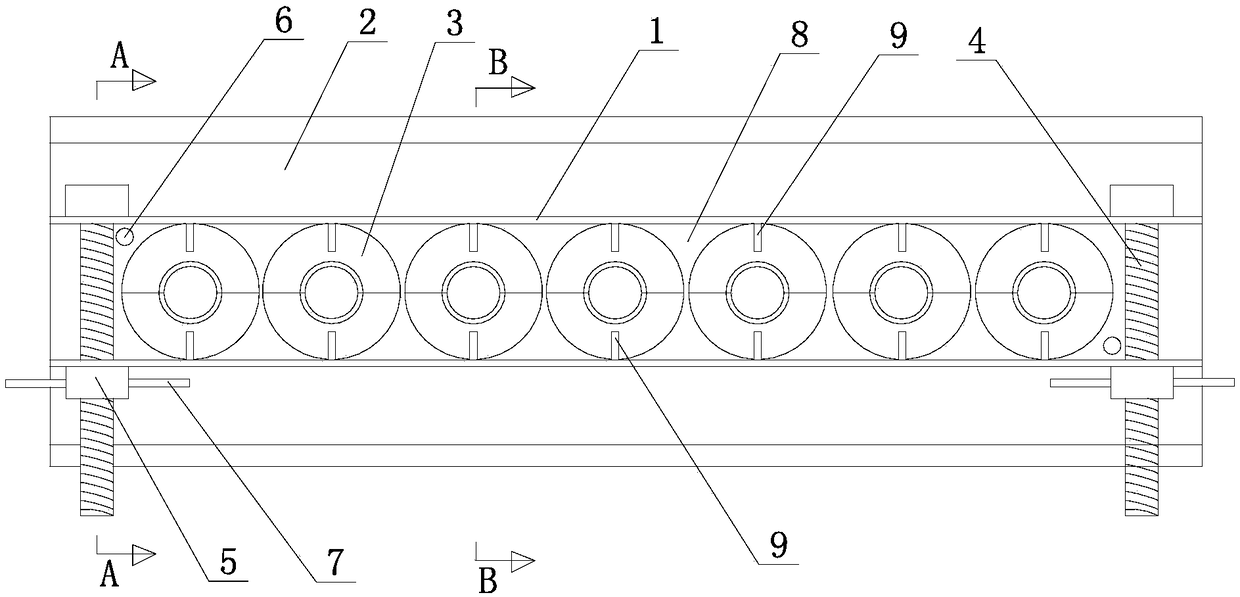

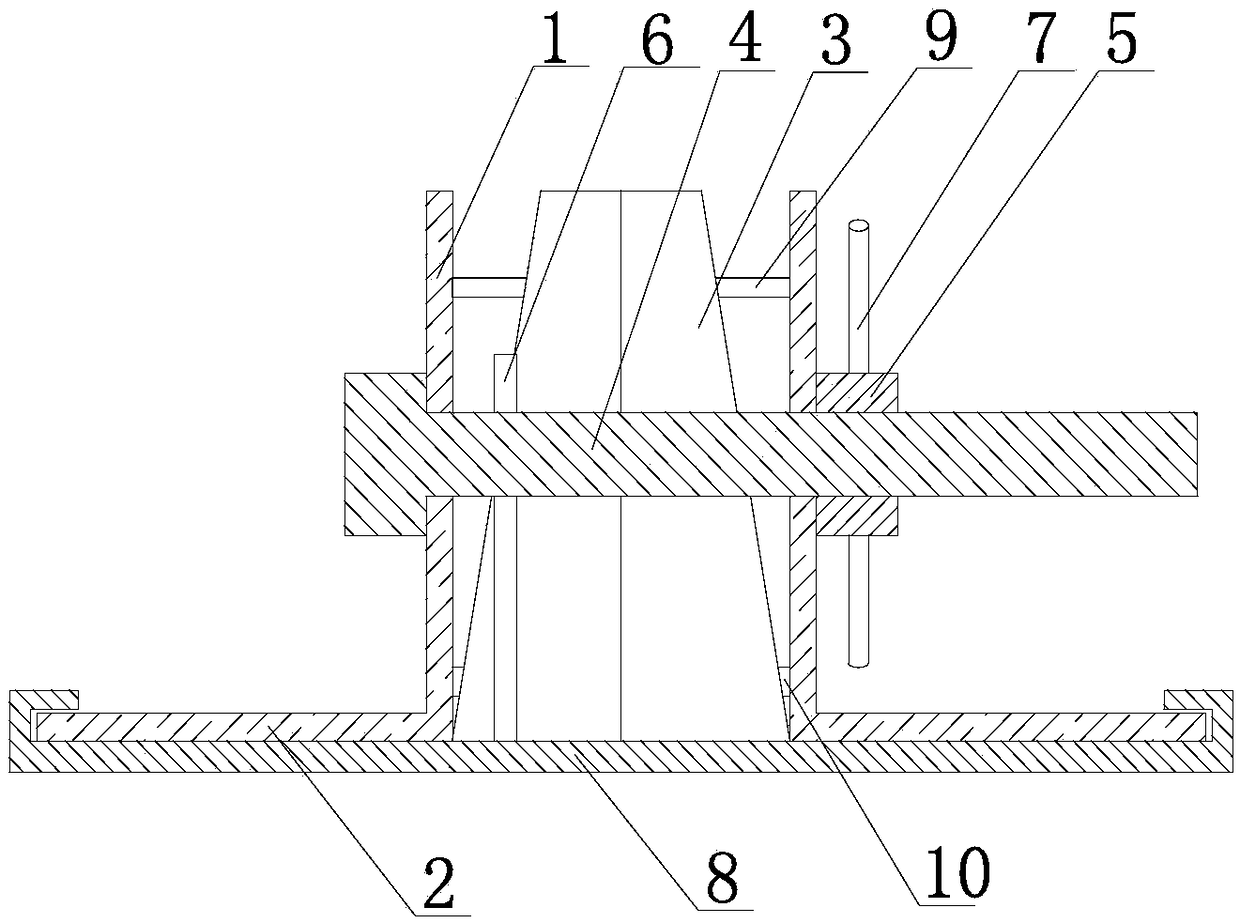

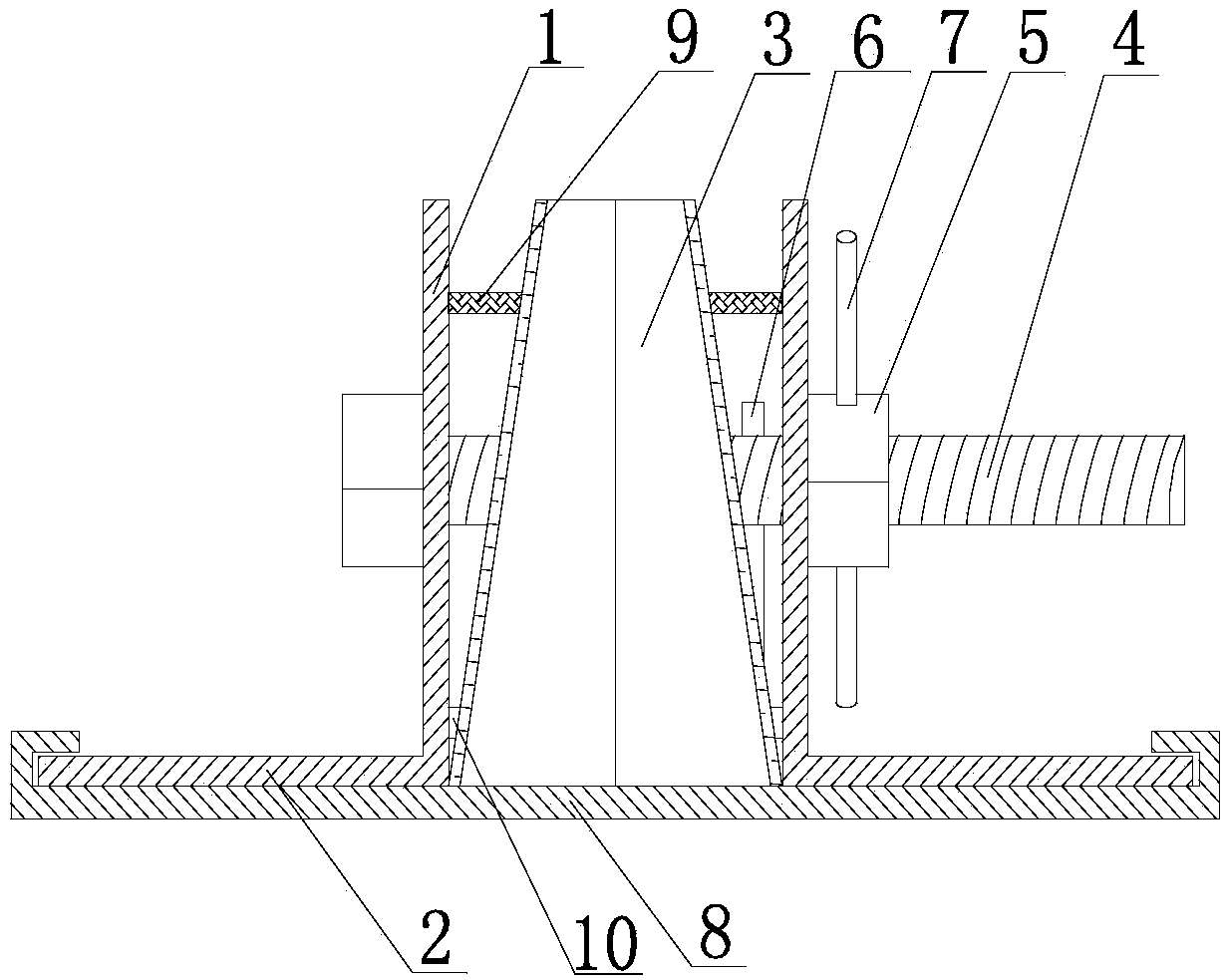

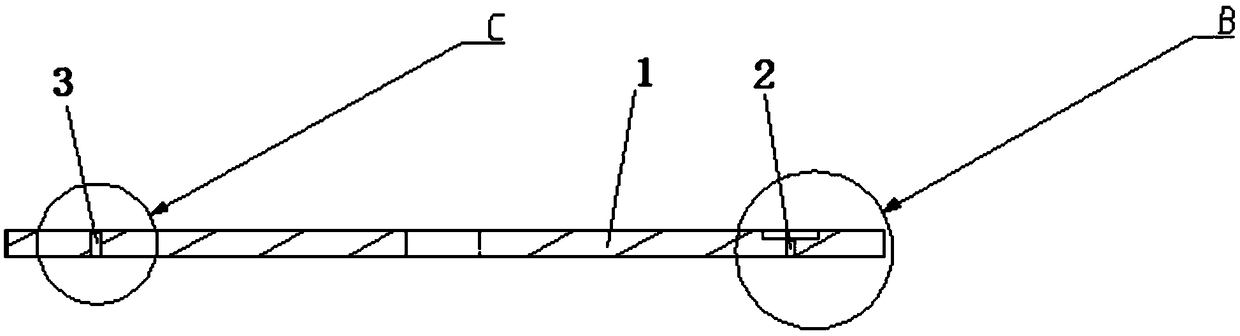

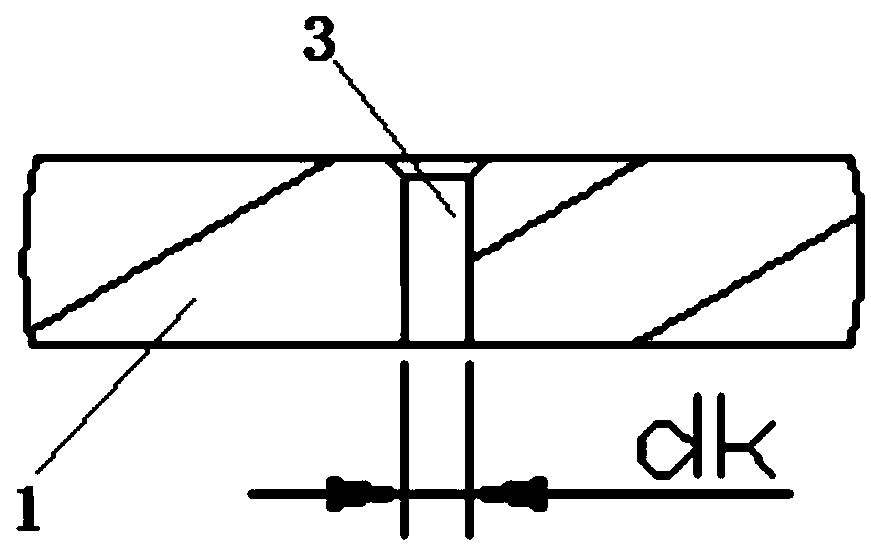

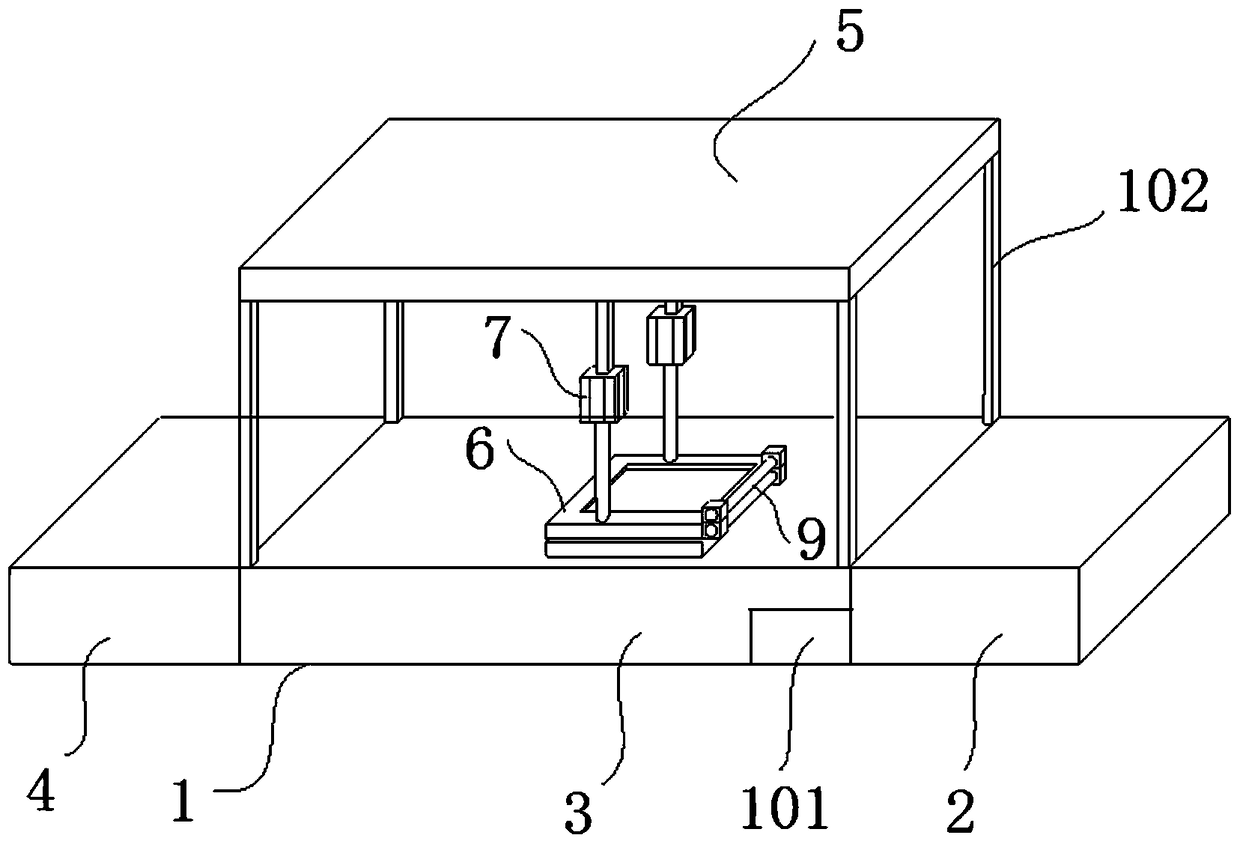

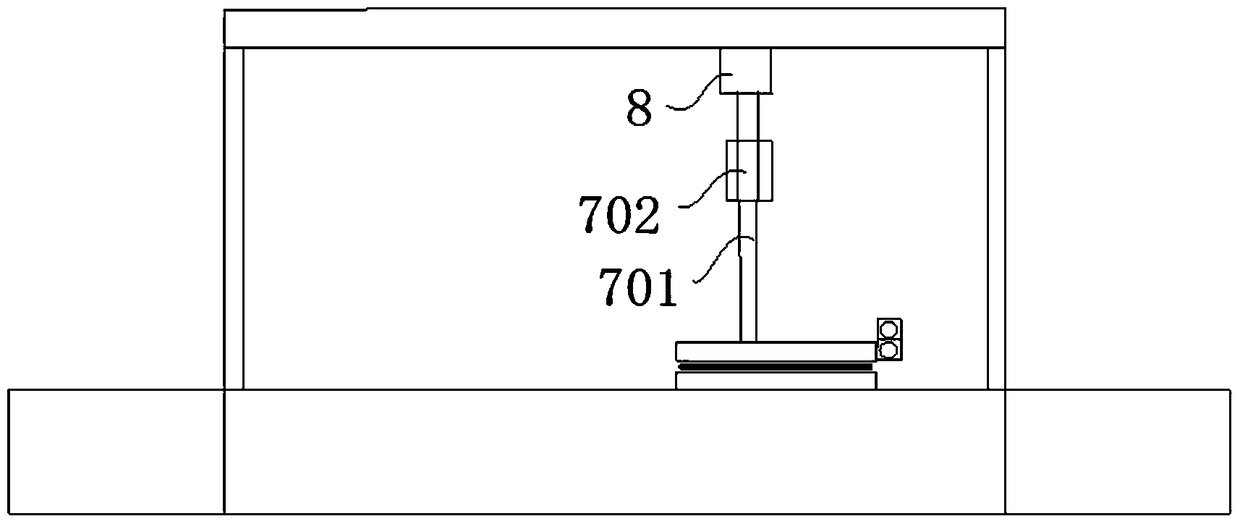

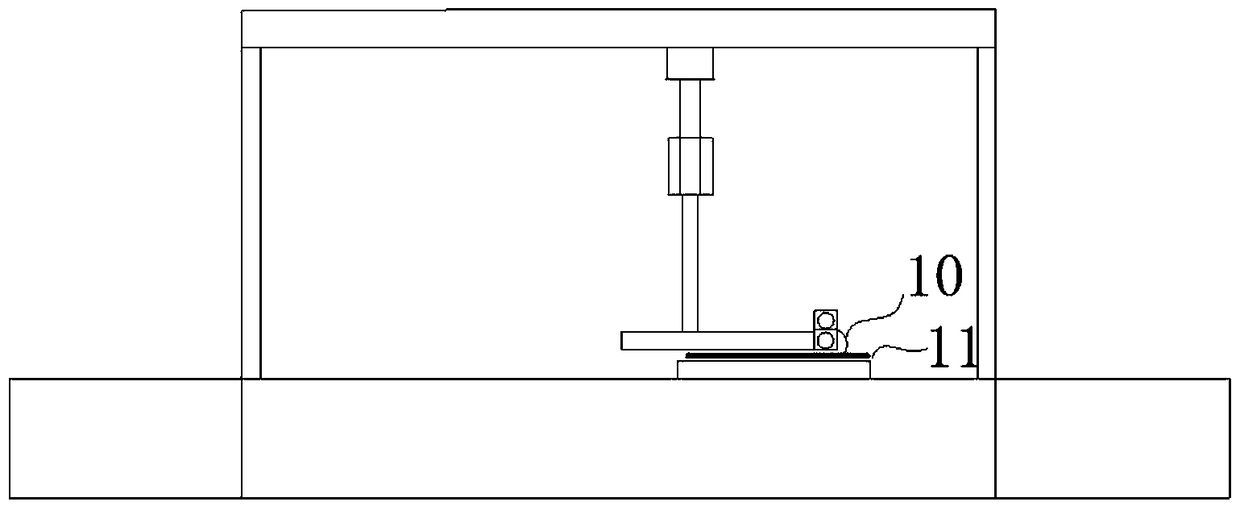

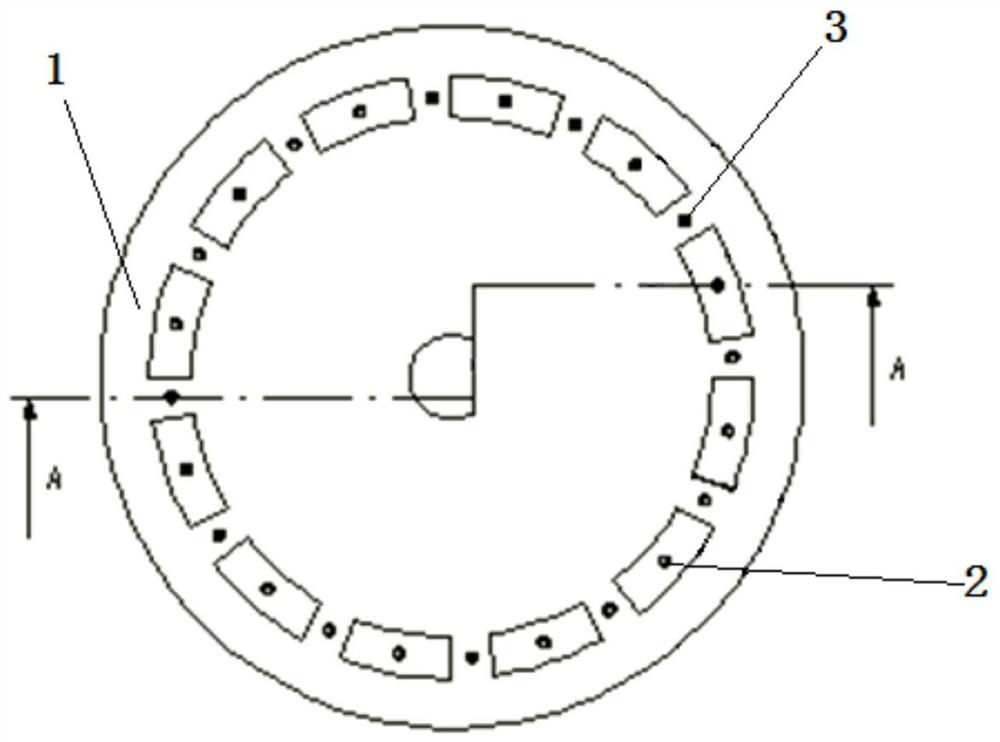

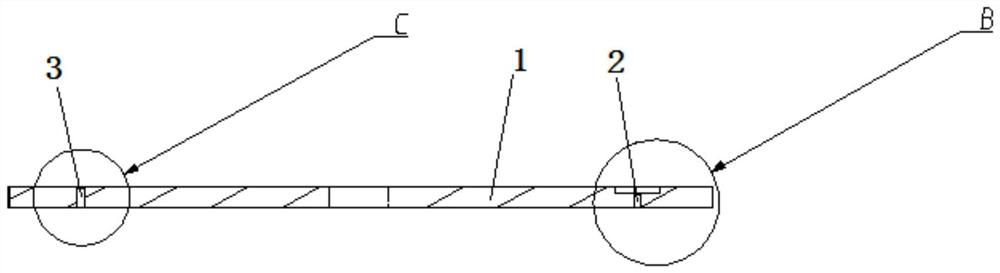

Semi-automatic polarizer stripping device for liquid crystal display panel

ActiveCN104808382AEffective peelingAchieve strippingLamination ancillary operationsLaminationLiquid-crystal displayEngineering

The invention discloses a semi-automatic polarizer stripping device for a liquid crystal display panel. The semi-automatic polarizer stripping device comprises a base, a first conveyor, a stripping platform, a second conveyor, a support plate, a heating plate and a clamping device. According to the semi-automatic polarizer stripping device, as the first conveyor and the second conveyor are arranged, the liquid crystal display panel can be automatically conveyed onto the stripping platform for stripping a polarizer, and the liquid crystal display panel stripped is conveyed out from the stripping platform, so that the processing efficiency is improved, and the labor cost is reduced; as the heating plate is arranged, the polarizer can be heated, and the stripping strength of the polarizer is reduced; a first roll shaft and a second roll shaft are driven by a first motor and a second motor to rotate for realizing the stripping of the polarizer on the liquid crystal display panel, so that the stress on the polarizer is relatively uniform, and the polarizer is unlikely to be fractured. The device can effectively strip the polarizer, and is good in stripping effect, high in work efficiency, low in processing cost and convenient and quick in operation.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

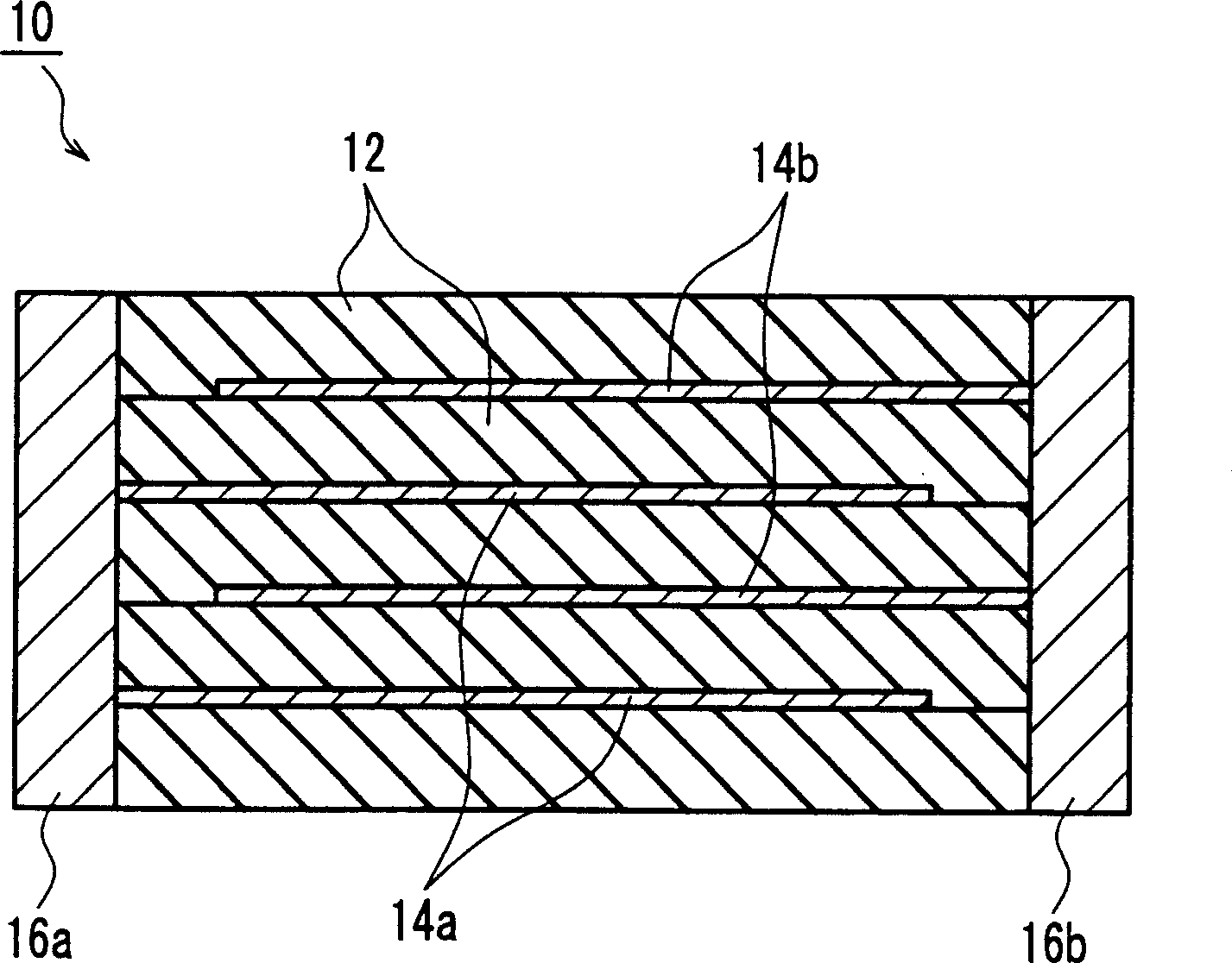

Ceramic laminated body and its manufacturing method

InactiveCN1497628ANot easy to cause breakageFixed capacitor electrodesLayered product treatmentMetallurgyMaterials science

A ceramic layered product 10 includes a plurality of ceramic layers 12 including a metallic element and a plurality of metal layers 14a, 14b, each of which is arranged between the ceramic layers 12. The metallic layers 14a, 14b include at least one element selected from the group consisting of Ni, Cu, Ag, and Pd in a total content of not less than 50 atm % as a main component, and at least one element selected from the metallic elements of the ceramic layers 12 in a content of not less than 1 atm % and less than 50 atm % as an additive component. This ceramic layered product can be less susceptible to fracture in the metal layers caused by firing.

Owner:PANASONIC CORP

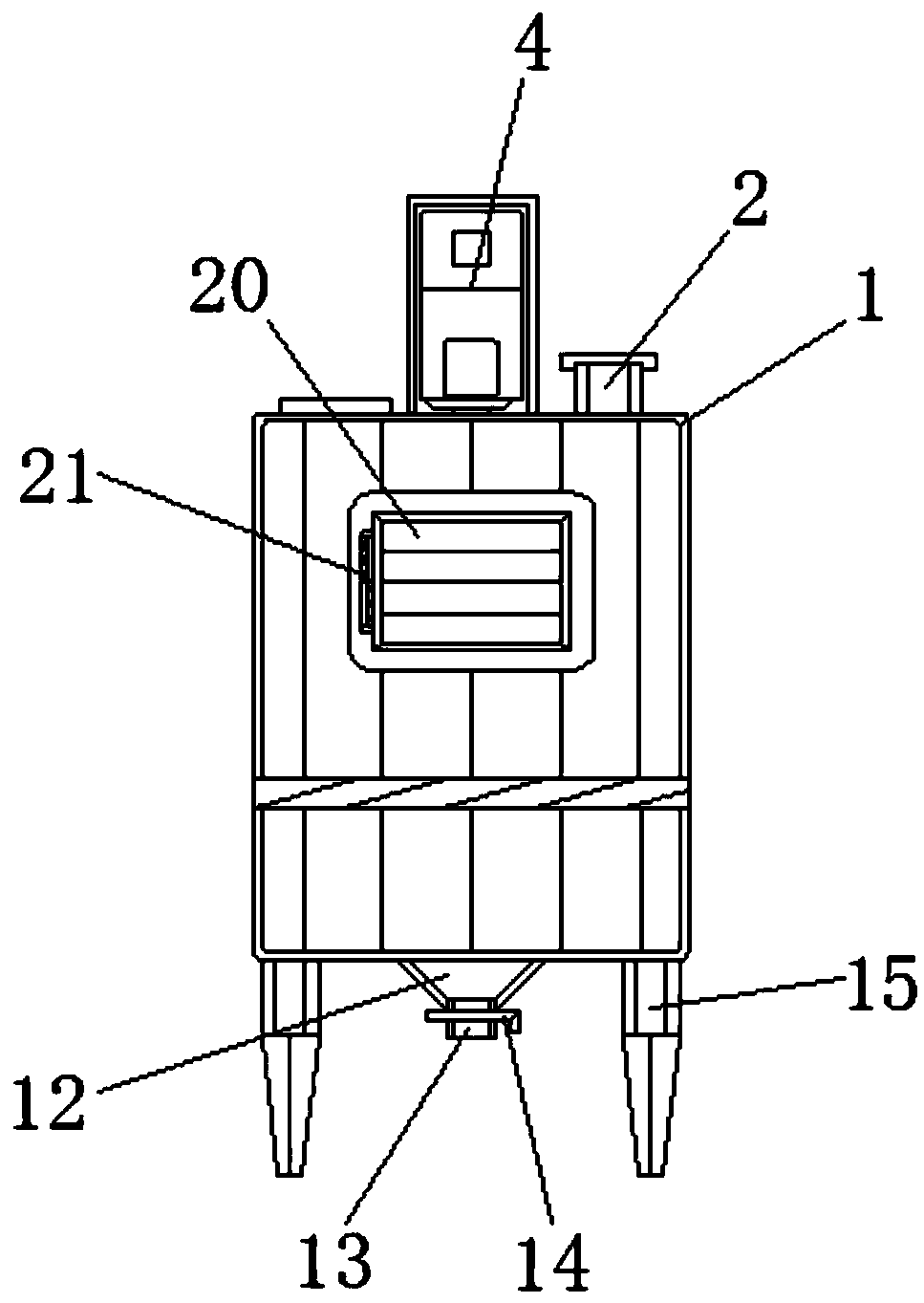

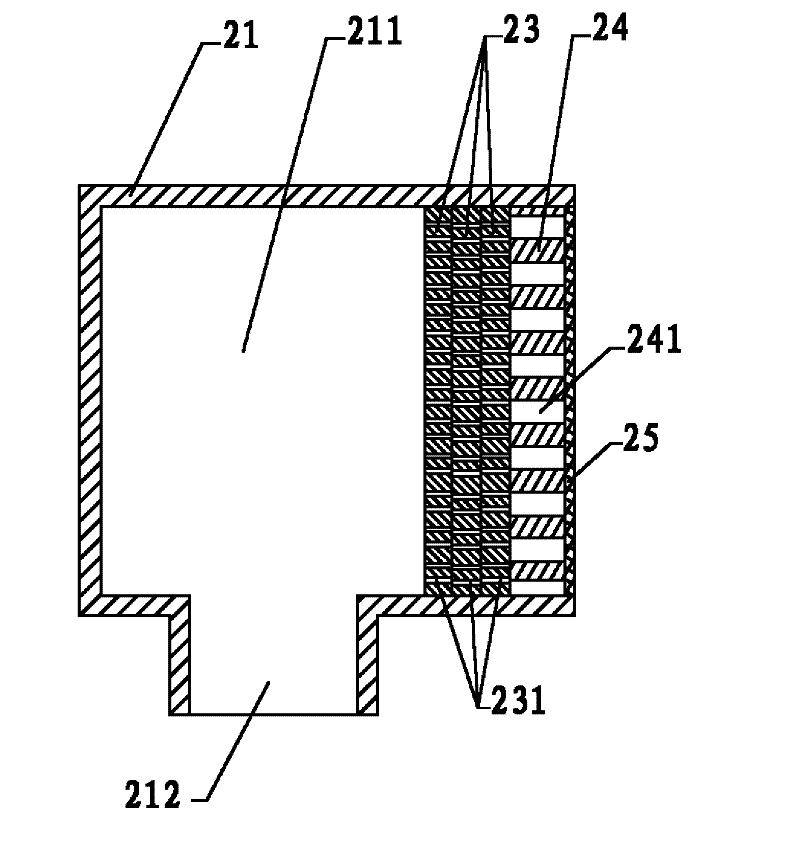

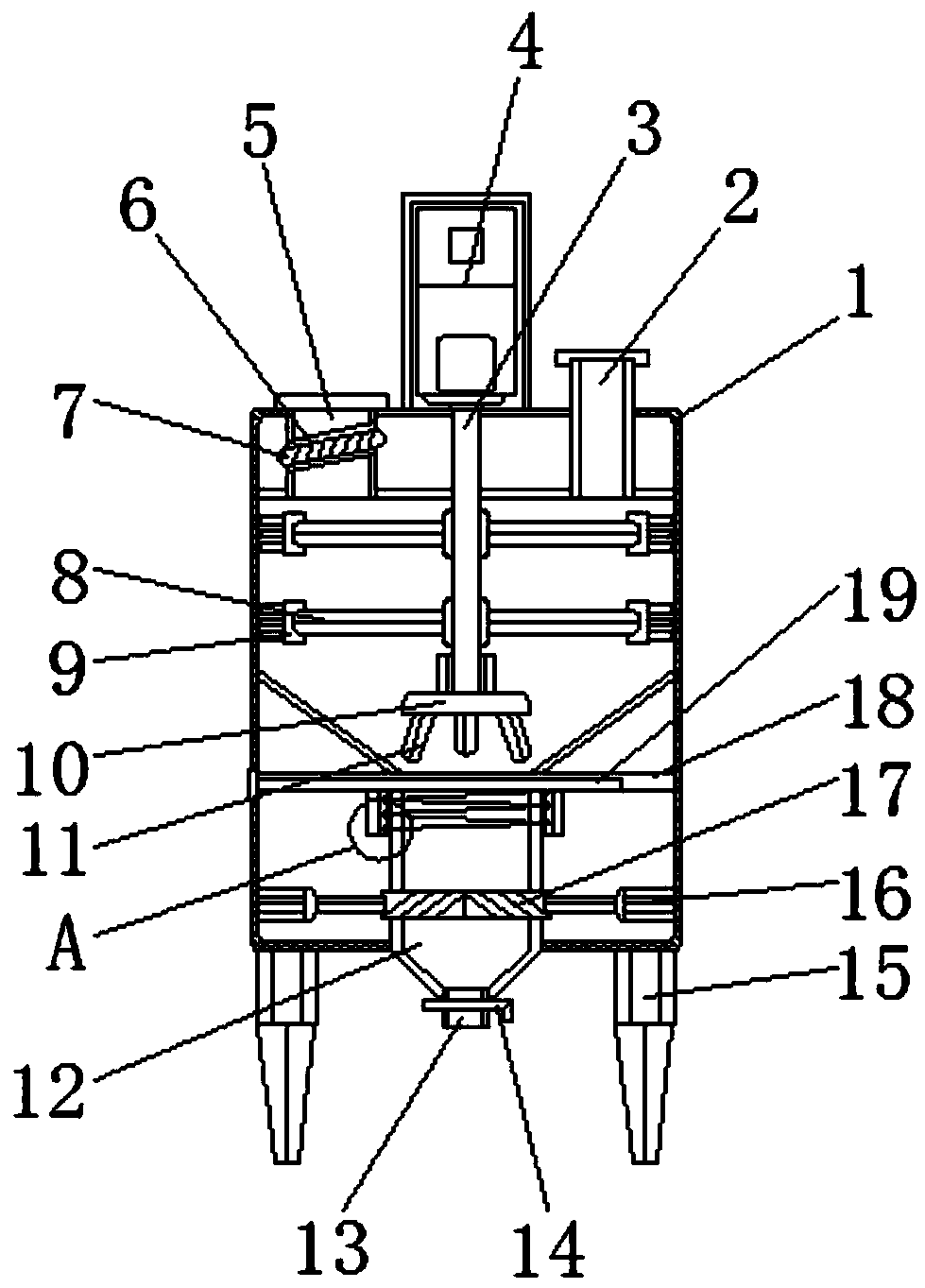

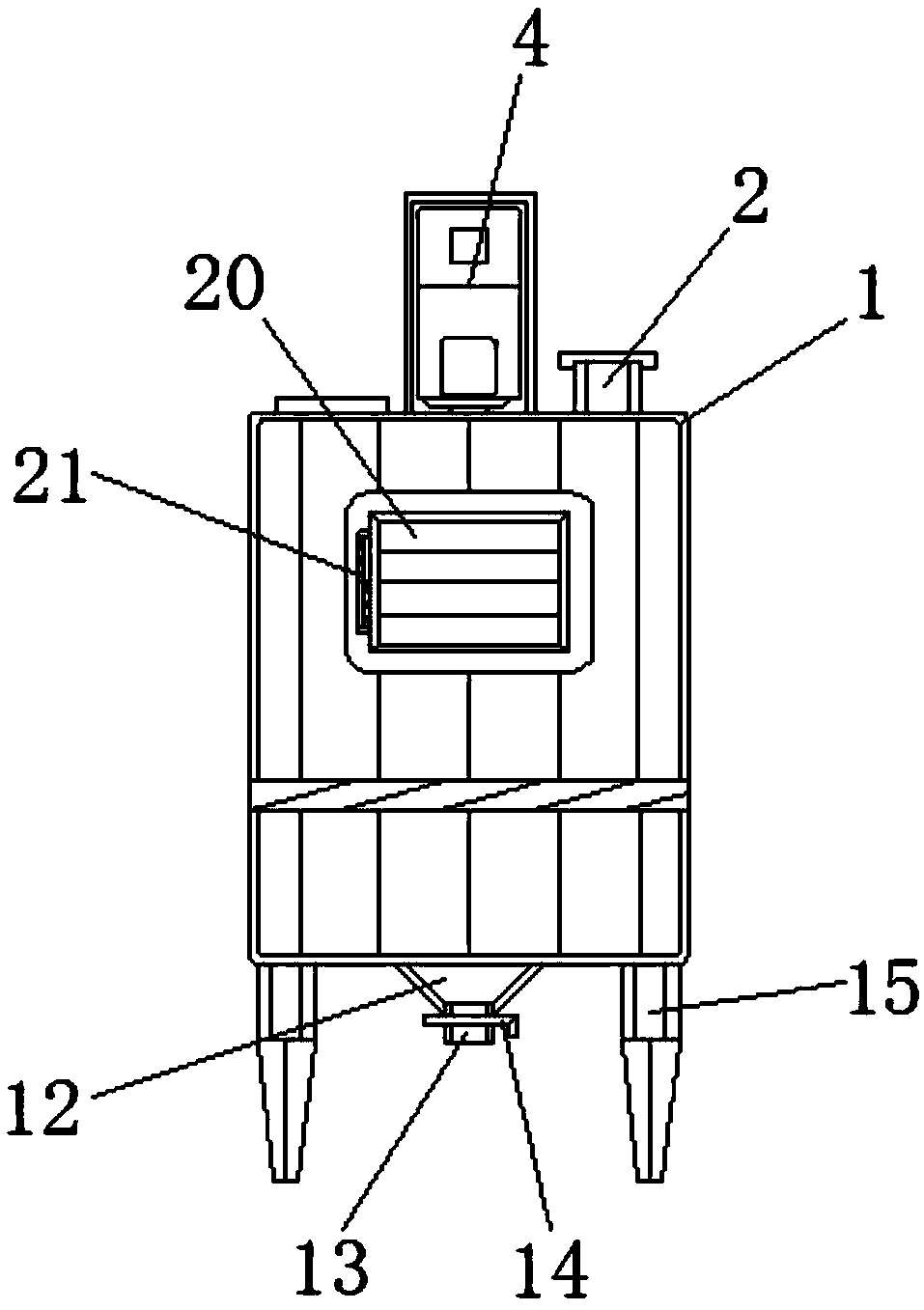

Electrode slurry automatic preparation equipment with fast drying function for battery production

InactiveCN109603619AExcellent preparation workHomogenizedElectrode manufacturing processesRotary stirring mixersElectricityBiochemical engineering

The invention relates to electrode slurry automatic preparation equipment with fast drying function for battery production. The equipment includes a main body, an electric heating wire and a screen. Awater inlet penetrates the top of the main body, a rotating shaft penetrates the middle at the top of the main body, a motor is movably disposed at the top of the rotating shaft, and the outer wall of the rotating shaft is connected to stirring rods. The invention has the beneficial effects that: the screen, springs, a feed inlet, the main body, a storage cylinder and a partition board are disposed, and the screen and the feed inlet compose an elastic structure through the springs, when the equipment carries out preparation operation on electrode slurry, charging is needed on the inner side,through the distribution function of the feed inlet and the main body, material can enter vertically at one step, thus saving time, and when the materials fall down to the screen, by means of the gravity of the materials themselves and the relative effect of the springs at the screen bottom, the screen can better perform homogenizing treatment on the materials, and the equipment can have excellentworking effect of electrode slurry preparation.

Owner:方玩霞

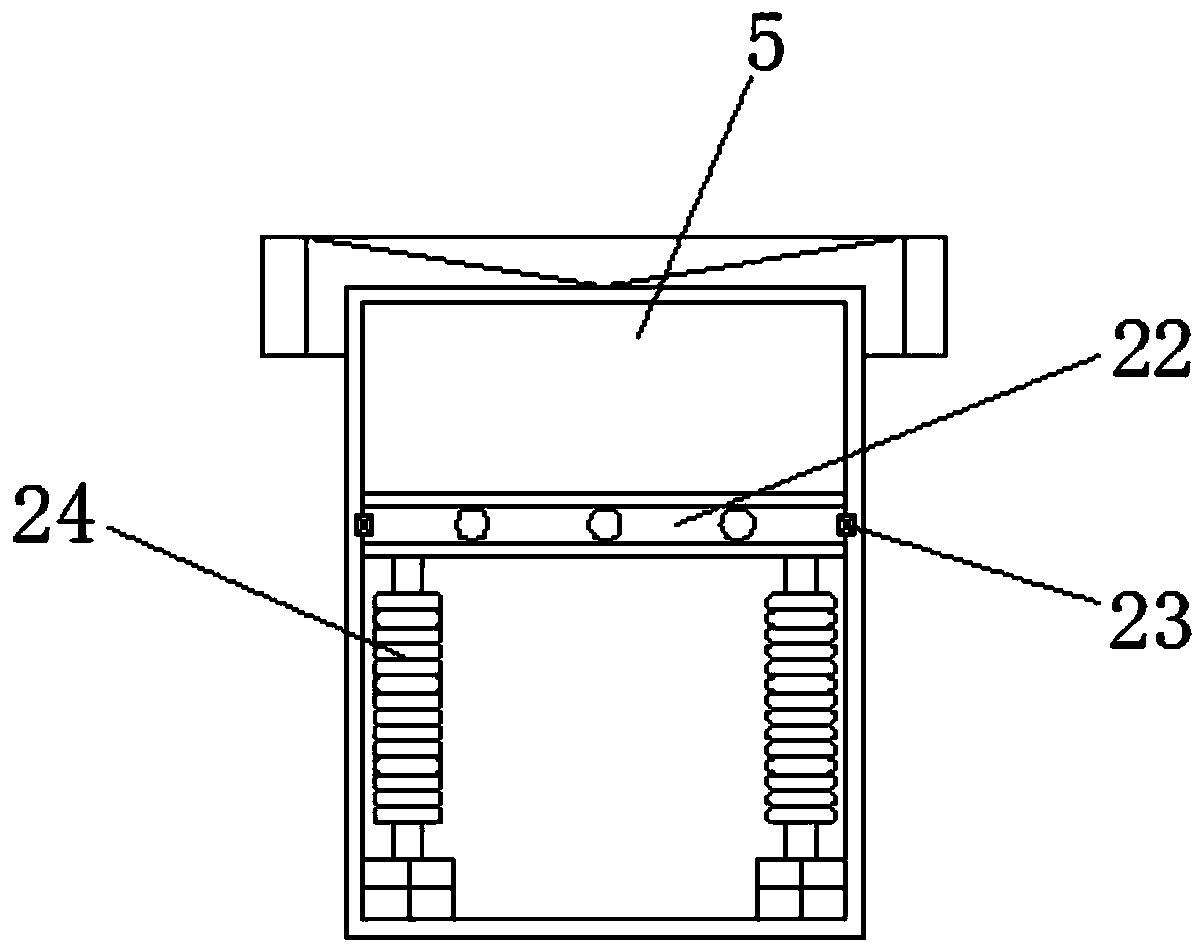

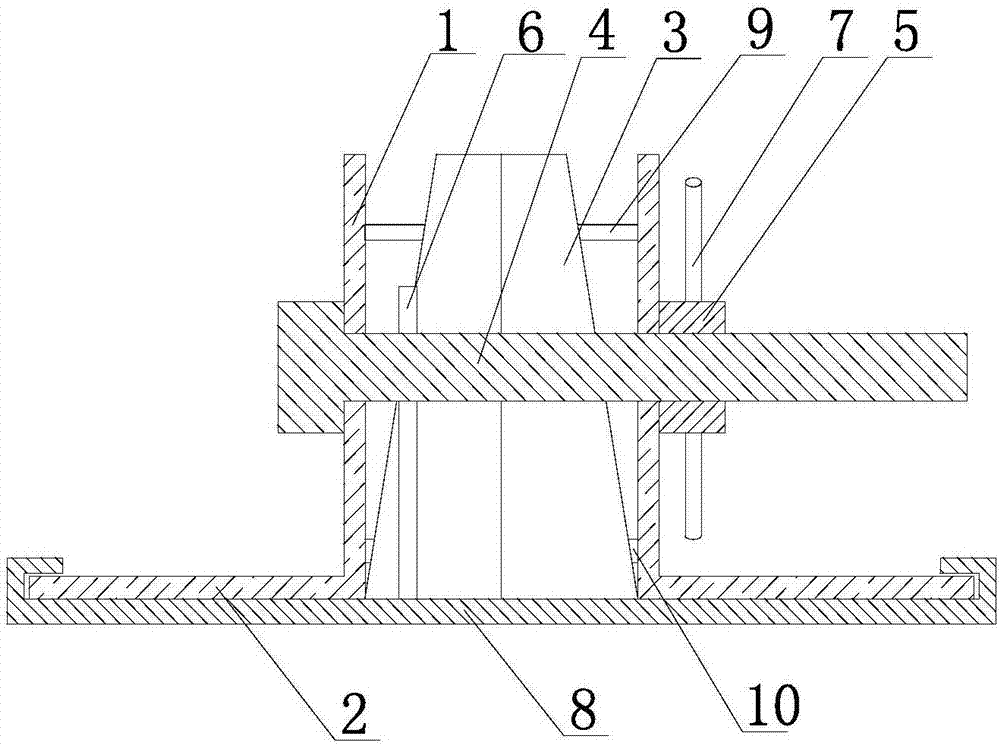

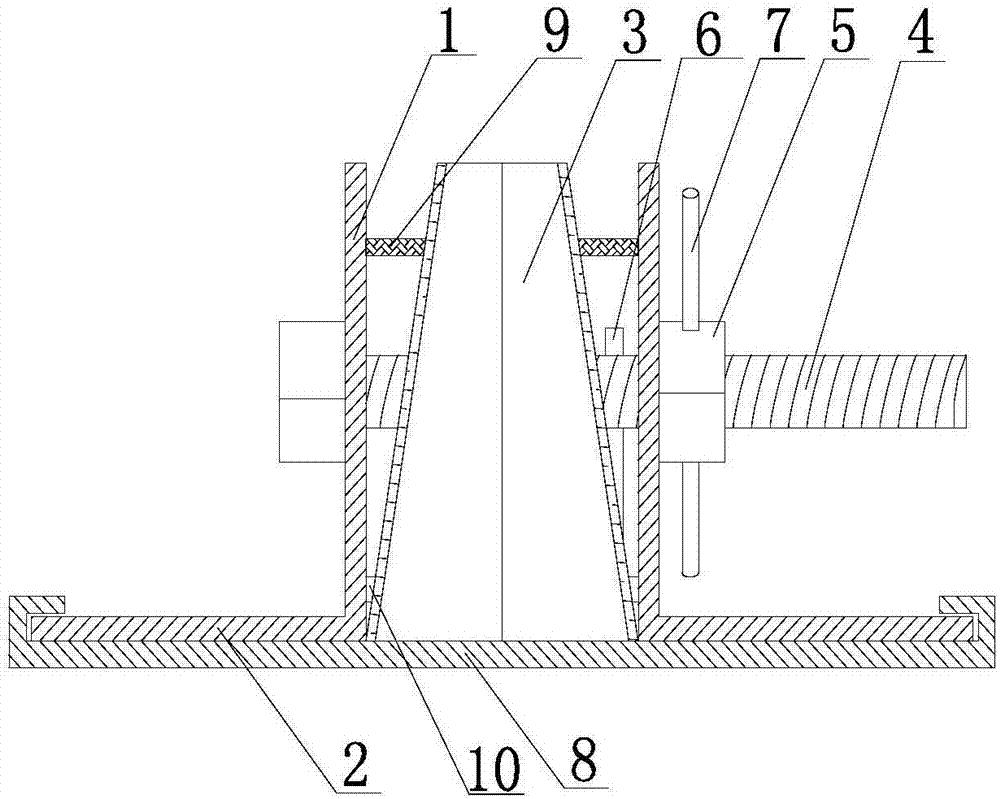

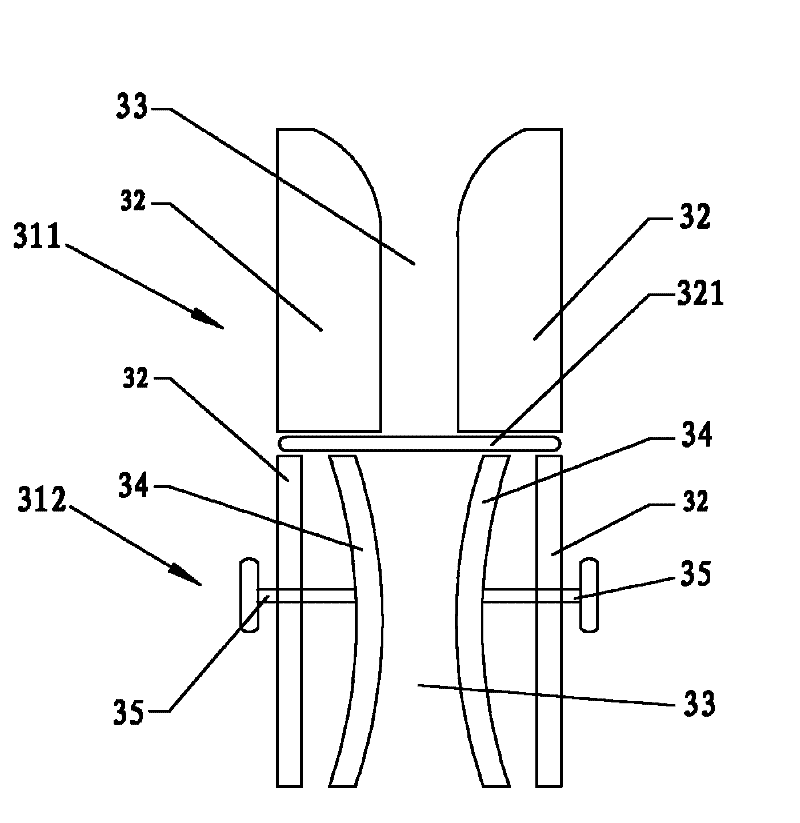

Production technology for circular-truncated-cone-shaped elevation concrete block for floor slab

ActiveCN106863581AExtended service lifeReduce investmentMouldsBuilding material handlingFloor slabResonance

The invention discloses a production technology for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The production technology comprises the steps of the preparing stage, the pouring stage, vibration forming, connecting piece setting, forming form removal and the like. According to the production technology for the circular-truncated-cone-shaped elevation concrete block for the floor slab, vibration waves can be formed between ring plates and clamping plates under the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, in other words, an operator can finish demoulding with small knocking force, labor force input is reduced, and the demoulding efficiency is greatly improved; and meanwhile, knocking on a die is reduced, and accordingly the service life of the die is prolonged; the distance between connecting columns and wedge-shaped blocks is 81%-84% of the length of ring plate bevels; and resonance is most easily generated between the ring plates and between the ring plates and the clamping plates, and the demoulding efficiency is the highest in the resonance state. Equal-height blocks manufactured through the method can be used for wood templates and steel templates, corresponding technologies can be adopted for the two different templates, and high universality is achieved; and the demoulding operation is conducted according to the set sequence, and the superior product rate of products can be increased to 90% or above.

Owner:CHINA MCC5 GROUP CORP

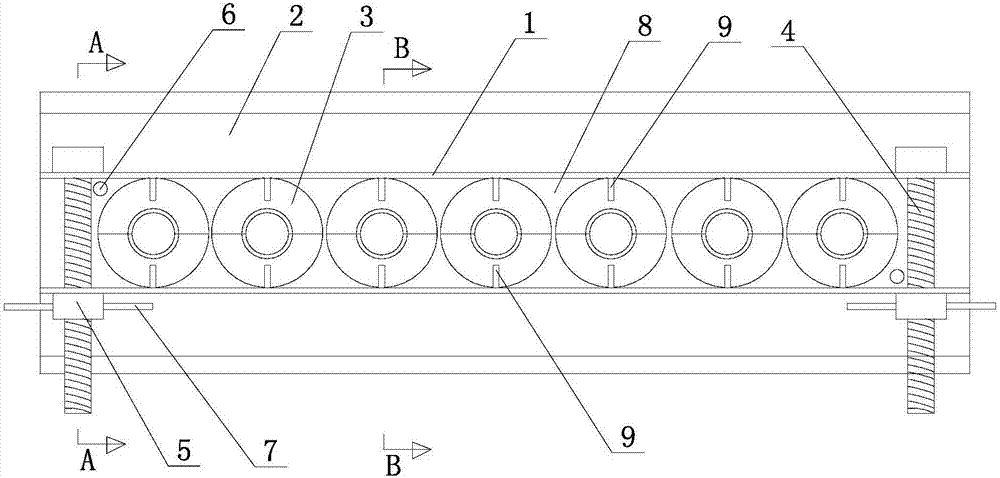

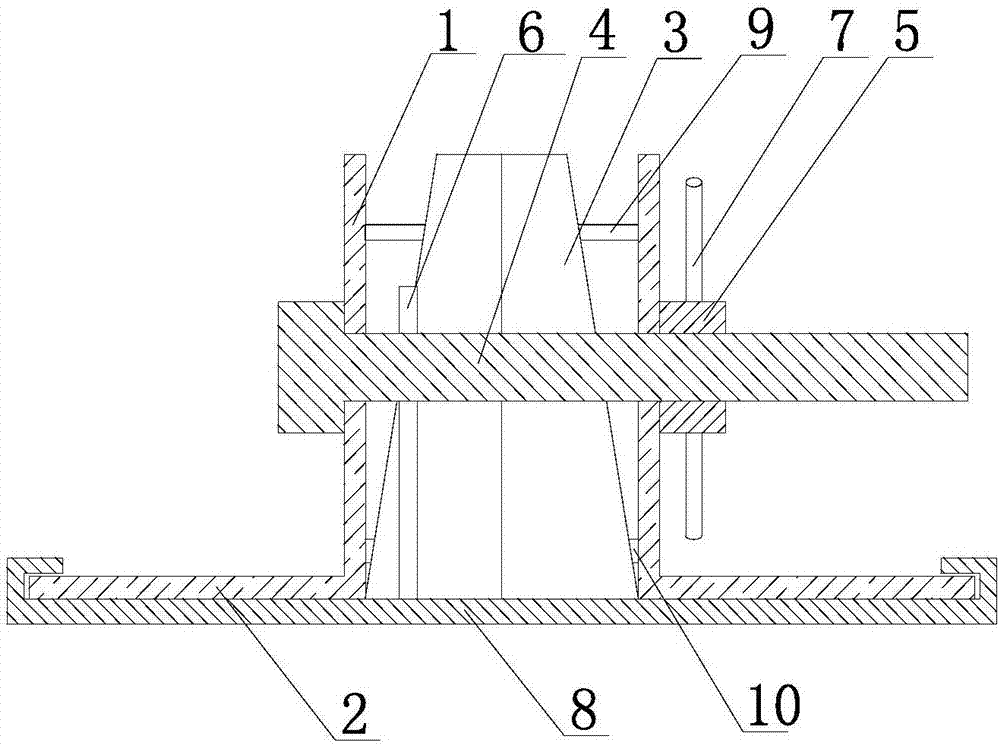

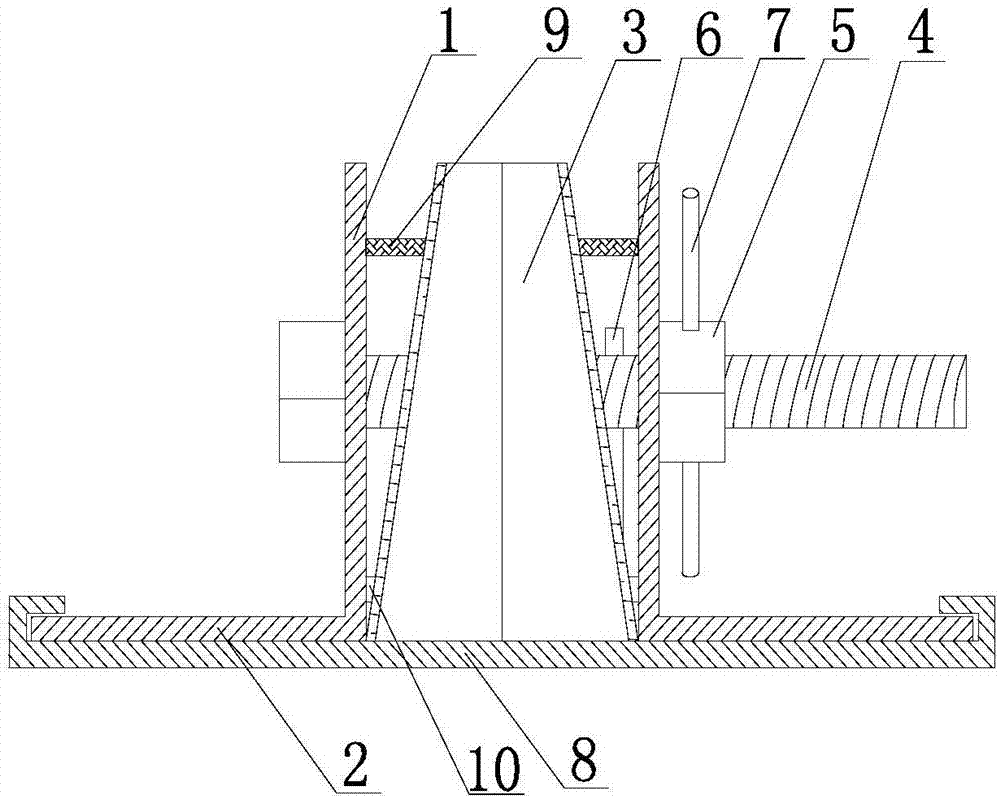

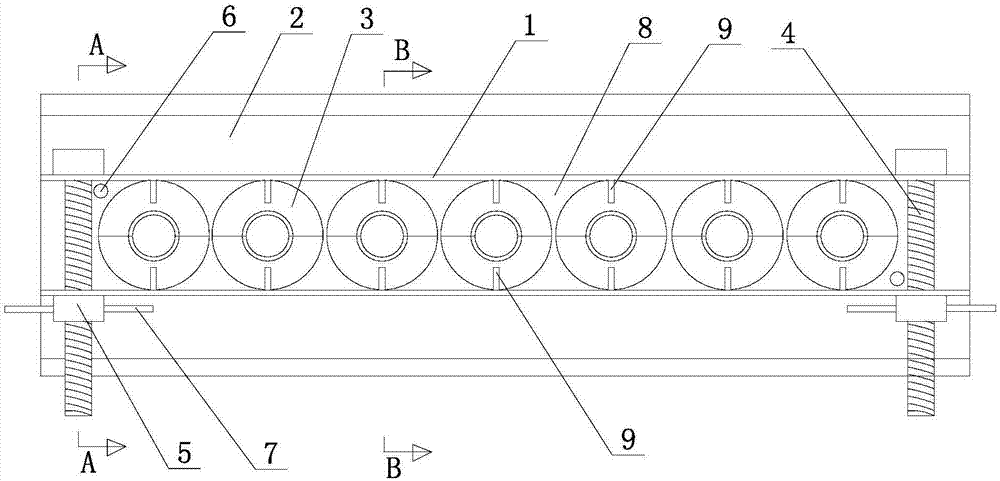

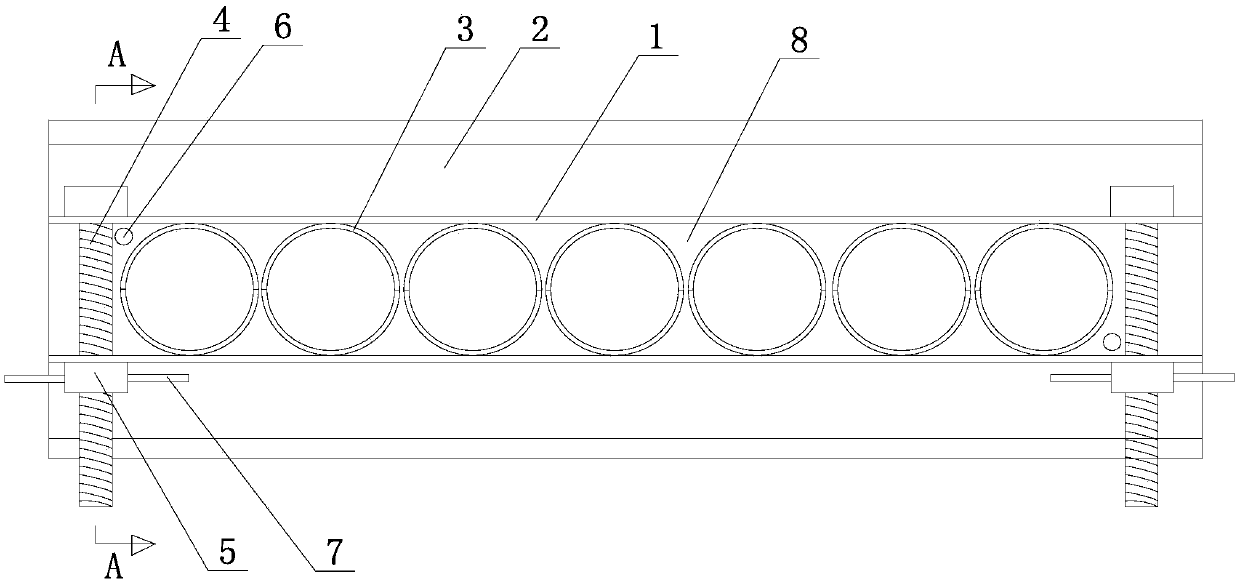

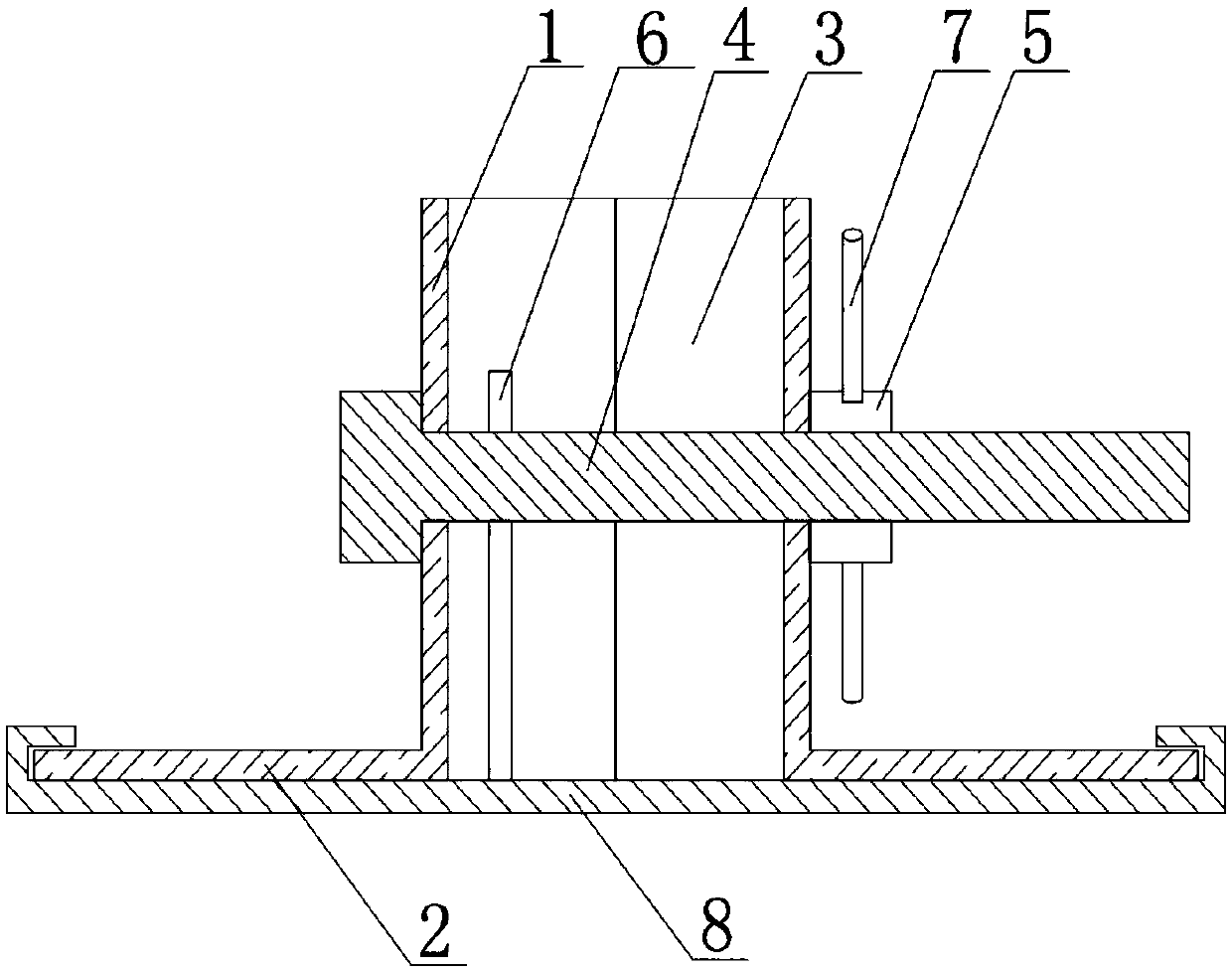

Forming device for circular-truncated-cone-shaped elevation concrete block for floor slab

ActiveCN106863580AImprove protectionIncrease widthMouldsBuilding material handlingFloor slabEngineering

The invention discloses a forming device for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The forming device comprises two parallel clamping plates. A plurality of half circular truncated cone ring plates are arranged on the opposite sides of the clamping plates. The ring plates are paired between the two clamping plates to form a circular-truncated-cone-shaped die. A bed board on the side opposite to the corresponding ring plate is vertically arranged at the bottom of each clamping plate, and the two clamping plates are connected through at least two sets of paired bolts and nuts. According to the forming device, cavities can be formed between the clamping plates and the ring plates through a two-point connecting structure, when the clamping plates are knocked, vibration waves can be formed between the ring plates and the clamping plates through the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, and in other words, an operator can finish demoulding with small knocking force; and the labor force input is reduced, the demoulding efficiency is greatly improved, knocking on the die is reduced, and accordingly the service life of the die is prolonged.

Owner:CHINA MCC5 GROUP CORP

Manufacturing method of hot-work die steel

InactiveCN111020152ANot easy to break steelImprove segregationFurnace typesHeat treatment furnacesMold testingPolishing

The invention discloses a manufacturing method of hot-work die steel. The method is characterized by including the steps: blank forging, annealing, mechanical roughening, finish machining forming, quenching, high-temperature tempering, fitter trimming, polishing, mold assembling and mold testing; and the hot-work die steel is one of 5H12, H13 and 8418. According to the method, water-bath cyclic quenching treatment is adopted to transform a massive lamellar structure of the steel into a uniform and fine structure, and the steel is not liable to break. The effects of rapid heating and cyclic treatment are fully utilized, heating is rapidly performed, a large number of austenite crystal nuclei are generated, and fine grains appear and are obtained; and the faster the process is carried out, the greater the temperature difference is, and the better the obtained refining effect is.

Owner:雷晓芳

Toggle lever metal extruder

ActiveCN102343377BImprove mechanical performanceSlow and smooth working strokeHydraulic cylinderMechanical engineering

The invention discloses a toggle lever metal extruder, which comprises a framework-type rack and is creatively characterized in that a workbench is arranged at the lower part of the rack, a sliding block is arranged above the workbench and can reciprocate on the rack along a vertical direction, and two sides of the work bench are provided with lateral pressing cylinders; a toggle lever mechanism is arranged on the upper part of the rack and mainly comprises an upper support, an upper toggle lever, a lower toggle lever and a lower support; and a driving mechanism is arranged outside the toggle lever mechanism and comprises a hydraulic cylinder, a first connecting lever and a second connecting lever. A hydraulic cylinder and the lateral pressing cylinder act to drive an upper die, a left male die and a right male die to move to a lower die on the workbench for pressing. The driving mechanism drives the toggle lever mechanism to move the sliding block, the sliding block is fast in a return downward trip, and a working stroke is slow and stable; in addition, in the working stroke, the stamping pressure has long duration, the pressing efficiency is high, the stress bearing effect of the rack is good, so that the installed power is reduced and the production cost is lowered.

Owner:NANTONG RUNDE MECHANICAL TECH

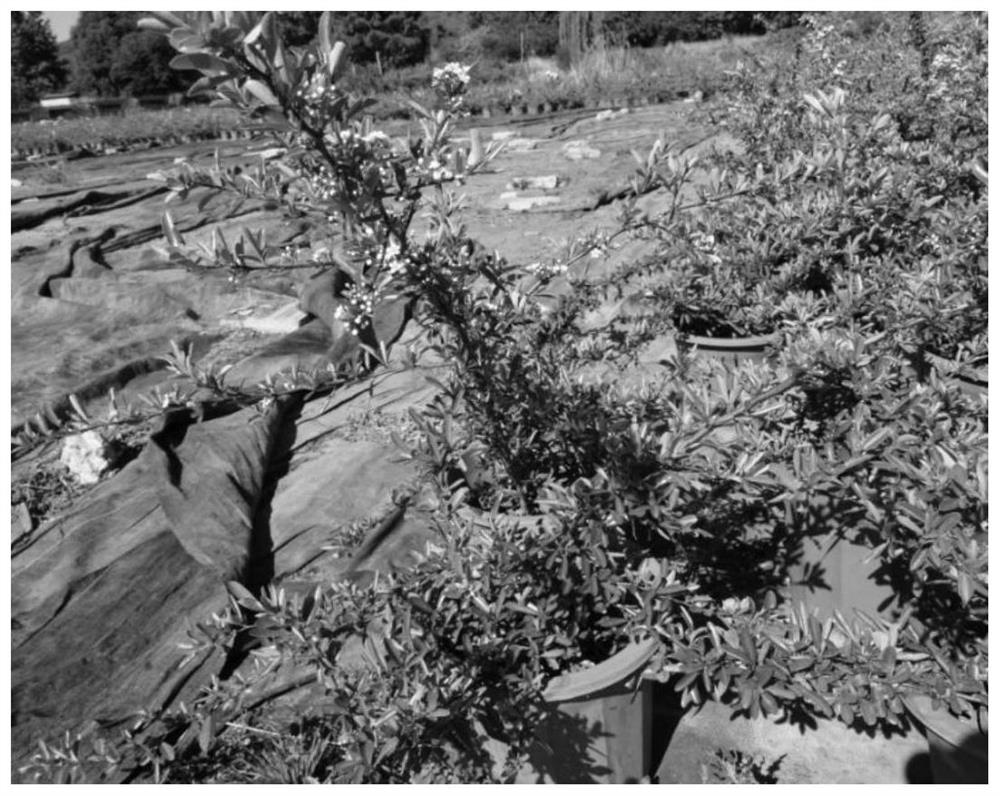

Pyracantha fortuneana bonsai modeling method

ActiveCN112075313AFast Climbing PruningGrow fastFlowers cultivationHorticulture methodsPyracantha coccineaPlantlet

The invention provides a pyracantha fortuneana bonsai modeling method, and belongs to the technical field of bonsai modeling. The method comprises the steps that pyracantha fortuneana sowing seedlingswith the tree age of 2-3 years are used as pyracantha fortuneana seedlings to be modeled for first modeling, cultivation continues to be conducted for 2-4 years after first modeling, and sacrificialbranches are reserved for trunk thickening; trimming and secondary modeling are carried out on lateral branches of the pyracantha fortuneana seedlings while trunk thickening is carried out; and the pyracantha fortuneana sowing seedlings with the tree age of 2-3 years grow fast, the tree form is full, and pyracantha fortuneana bonsai climbing, binding, trimming and forming are fast. The modeling method can be carried out in spring and summer, branches grow vigorously in spring, and modeling is easy; trunk climbing and binding can be formed at a time, and other branches can be formed after beinggradually trimmed; and according to the modeling method, pyracantha fortuneana plants can be planted in a cultivation pot before being formed, are adjusted according to environmental conditions, arelight and convenient, can be moved, do not easily cause flowerpot cracking, are transplanted into a purple sand pot and a porcelain pot or a pottery pot for maintenance after being modeled and shaped,and are convenient to popularize in a large range.

Owner:丽江恒玉花卉有限公司 +1

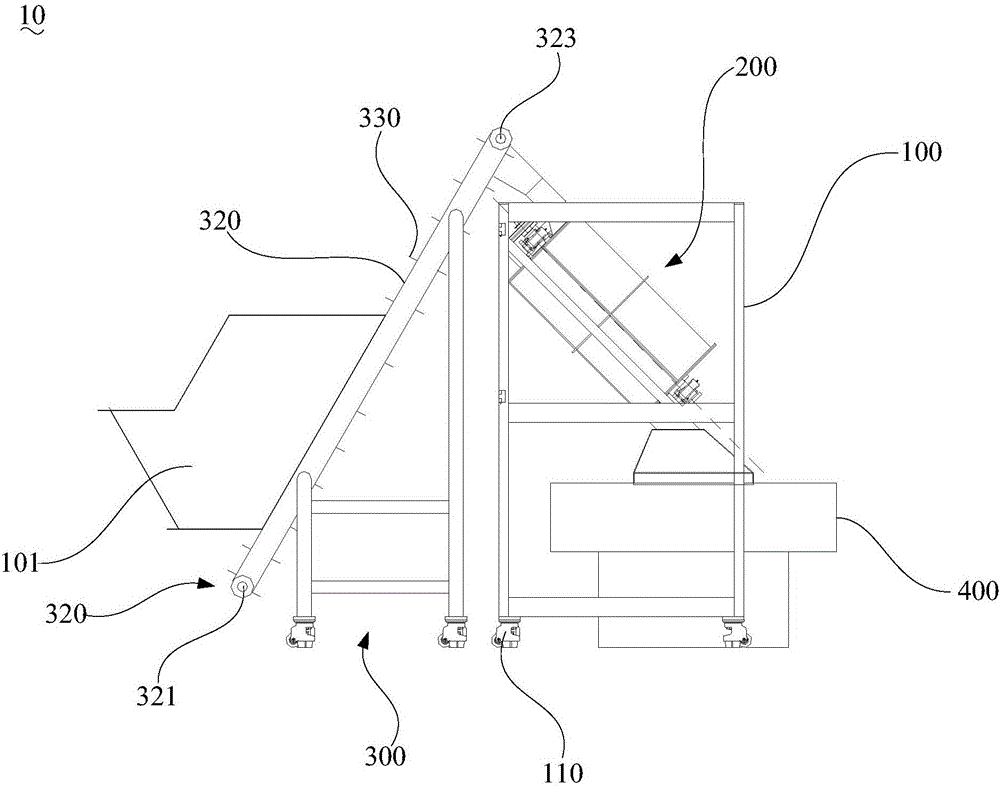

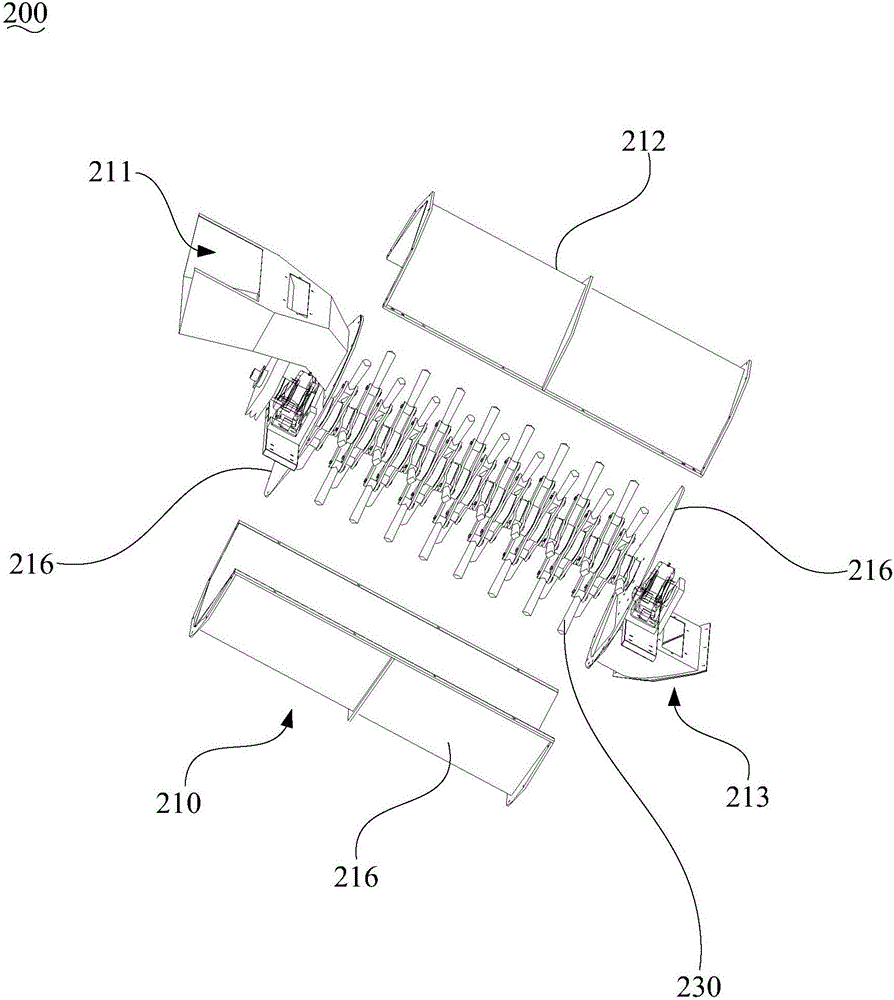

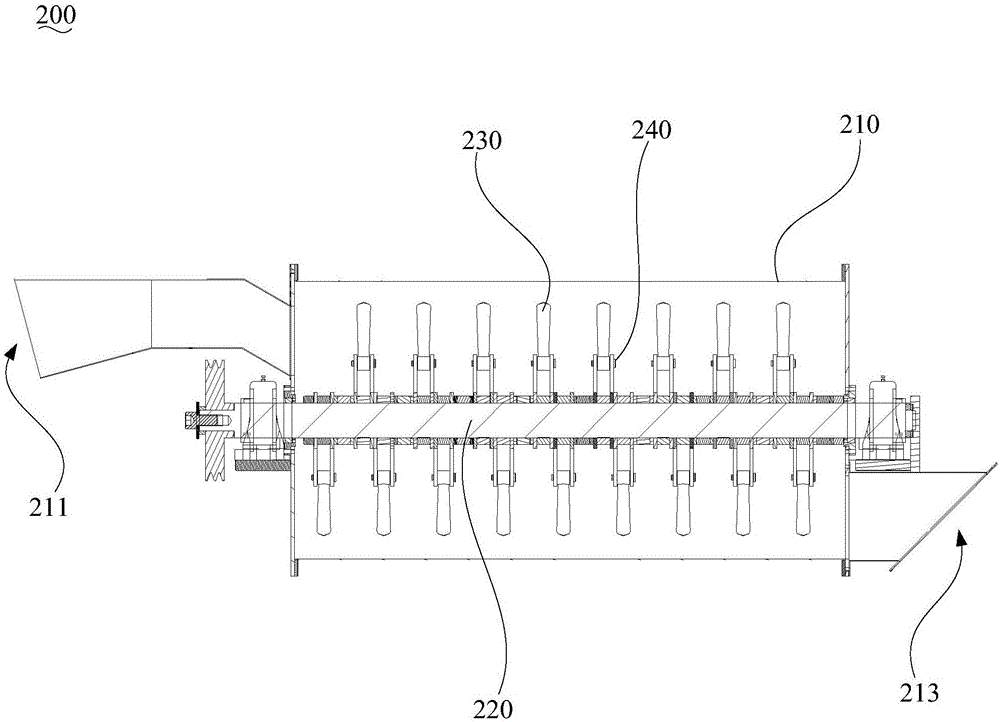

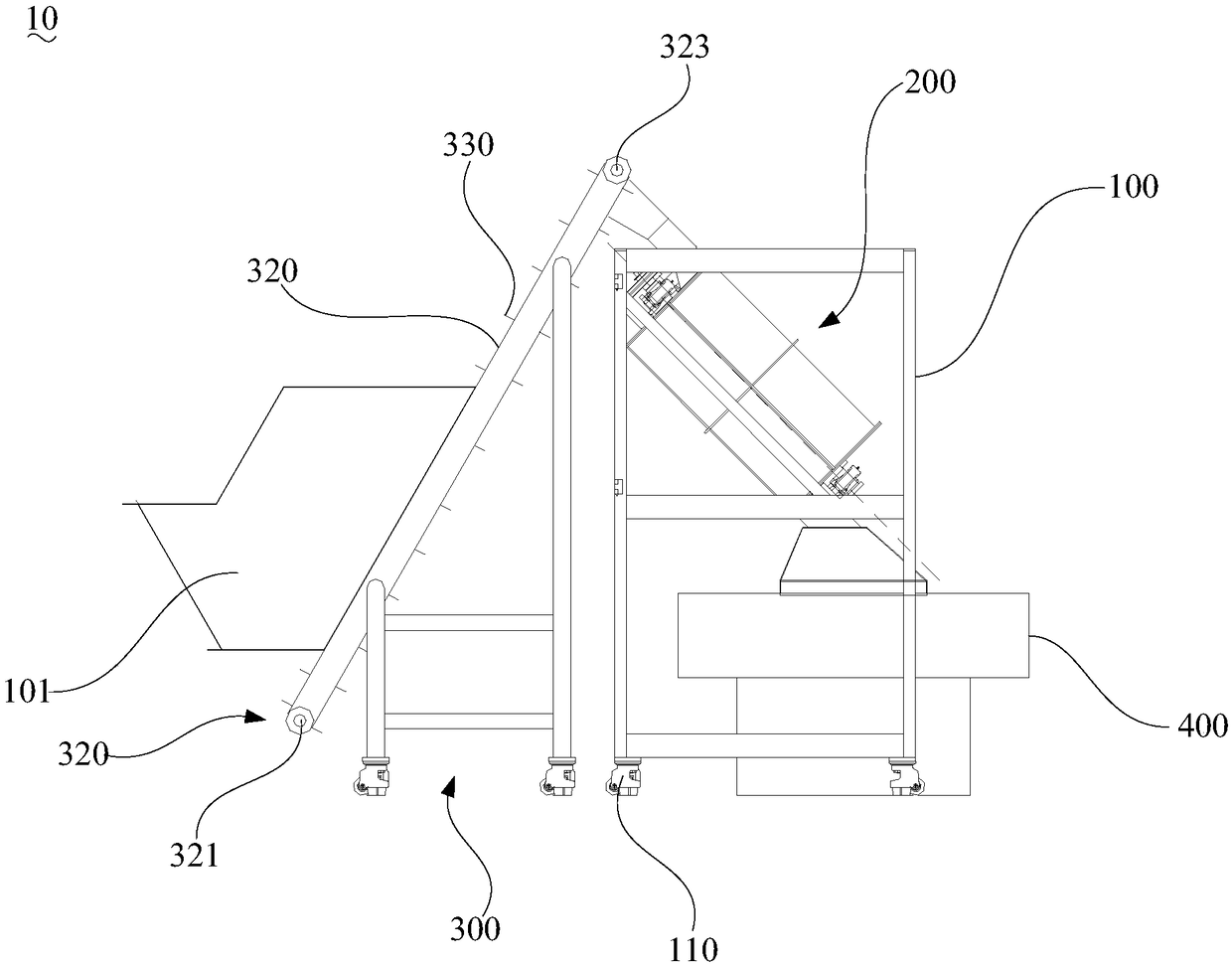

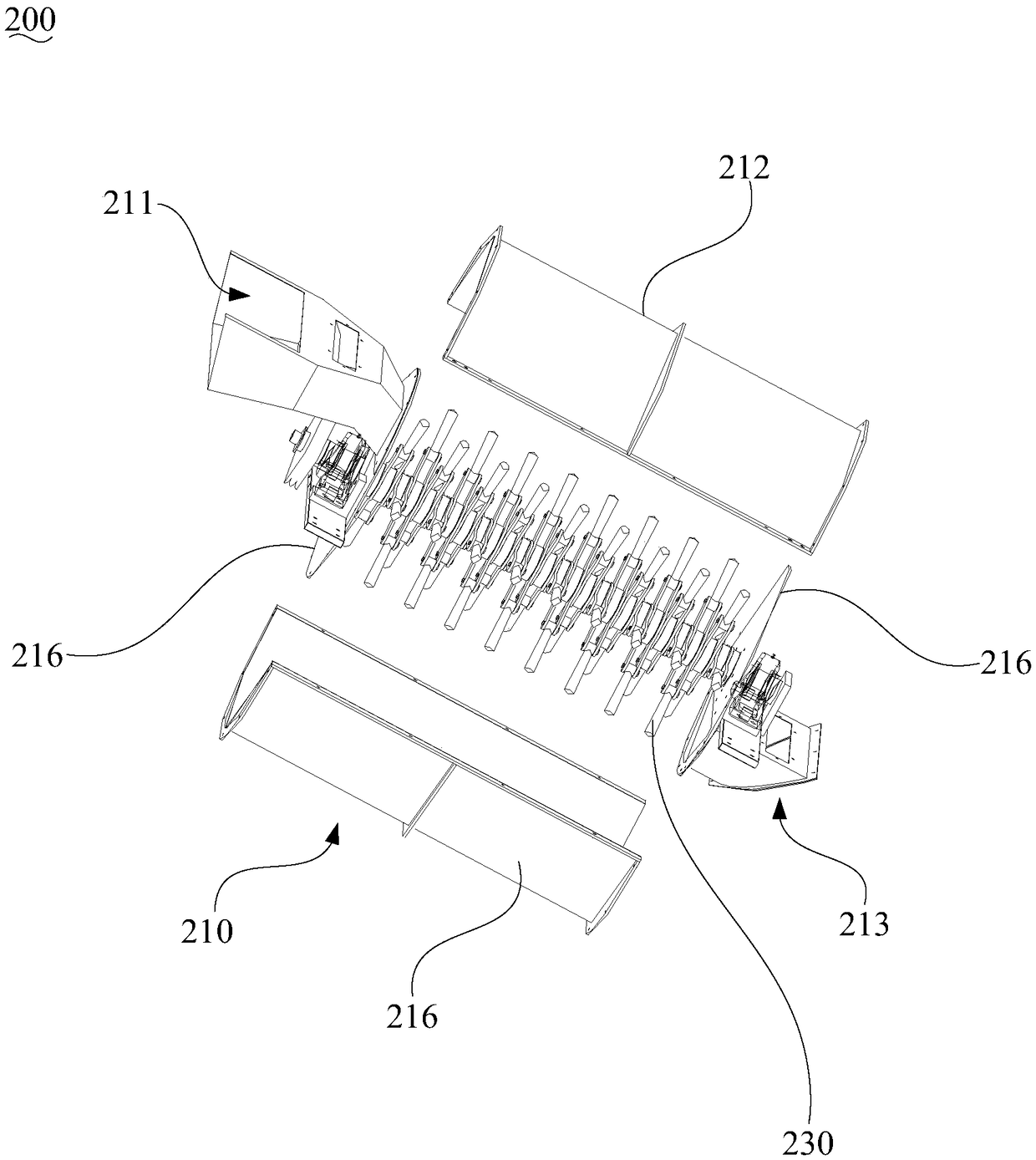

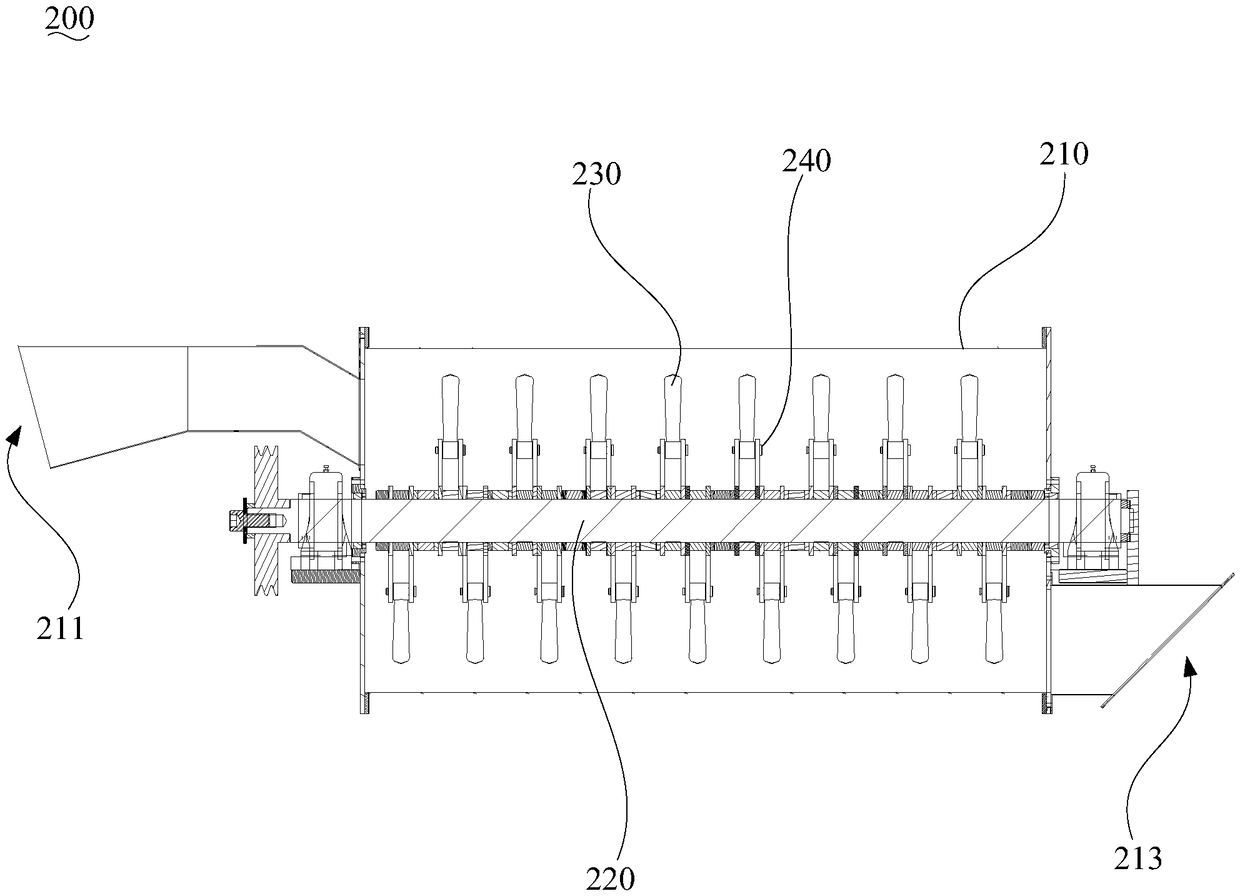

Cut tobacco recovery device and waste cigarette crushing mechanism thereof

The invention relates to a cut tobacco recovery device and a waste cigarette crushing mechanism thereof. The waste cigarette crushing mechanism comprises a shell, a rotary shaft and a soft rod. The soft rod comprises a rigid base body and a flexible covering layer covering the surface of the base body. One end of the soft rod is installed on the rotary shaft, and the rotary shaft can drive the soft rod to rotate in a containing cavity of the shell. When cut tobacco is recovered, waste cigarettes enter the shell through a feed port, and the rotary shaft rotates to drive the soft rod to beat the waste cigarettes in the containing cavity. Due to the fact that the surface of the soft rod is provided with the flexible covering layer, the soft rod and the waste cigarettes are in flexible contact. The waste cigarettes are crushed through the soft rod by means of friction and vibration. Thus, compared with a cutting or grinding mode adopted for traditional equipment, the cut tobacco is not likely to be broken when the waste cigarettes are crushed through the crushing mechanism, the integrity of the cut tobacco can be better kept, and then the finally recovered cut tobacco is good in integrity through the cut tobacco recovery device.

Owner:CHANGDE RUIHUA MFG

A Production Technology of Concrete Block with Concrete Concrete Block with Concrete Elevation for Floor Slab

The invention discloses a production technology for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The production technology comprises the steps of the preparing stage, the pouring stage, vibration forming, connecting piece setting, forming form removal and the like. According to the production technology for the circular-truncated-cone-shaped elevation concrete block for the floor slab, vibration waves can be formed between ring plates and clamping plates under the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, in other words, an operator can finish demoulding with small knocking force, labor force input is reduced, and the demoulding efficiency is greatly improved; and meanwhile, knocking on a die is reduced, and accordingly the service life of the die is prolonged; the distance between connecting columns and wedge-shaped blocks is 81%-84% of the length of ring plate bevels; and resonance is most easily generated between the ring plates and between the ring plates and the clamping plates, and the demoulding efficiency is the highest in the resonance state. Equal-height blocks manufactured through the method can be used for wood templates and steel templates, corresponding technologies can be adopted for the two different templates, and high universality is achieved; and the demoulding operation is conducted according to the set sequence, and the superior product rate of products can be increased to 90% or above.

Owner:CHINA MCC5 GROUP CORP

Processing method for enhancing fluffiness of white duck down

InactiveCN110735327AEfficient coatingEasy to cleanBiochemical fibre treatmentLiquid repellent fibresBiotechnologySodium sulfate

The invention discloses a processing method for enhancing fluffiness of white duck down. The method includes the following steps: mixing ferric chloride hexahydrate, ferrous sulfate heptahydrate and water, heating and stirring, adding ammonia water, stirring uniformly, adding humic acid and whey protein, stirring continuously, adding mercaptoethanol, stirring continuously, removing mercaptoethanol, cooling, filtering, washing to neutrality, and drying the mixture to obtain prefabricated materials; washing white duck down, drying, adding the prefabricated materials, coconut oil hydroxyethyl sodium sulfonate, laurel essential oil, sodium dodecyl sulfate and water, uniformly mixing, dipping, filtering and washing the mixture to obtain pretreated white duck down; and drying the pretreated white duck down, spraying a down finishing agent in the drying process, and sterilizing to obtain the white duck down with high fluffiness.

Owner:六安市皖西羽绒有限公司

Tobacco recycling device and its waste smoke crushing mechanism

The invention relates to a cut tobacco recovery device and a waste cigarette crushing mechanism thereof. The waste cigarette crushing mechanism comprises a shell, a rotary shaft and a soft rod. The soft rod comprises a rigid base body and a flexible covering layer covering the surface of the base body. One end of the soft rod is installed on the rotary shaft, and the rotary shaft can drive the soft rod to rotate in a containing cavity of the shell. When cut tobacco is recovered, waste cigarettes enter the shell through a feed port, and the rotary shaft rotates to drive the soft rod to beat the waste cigarettes in the containing cavity. Due to the fact that the surface of the soft rod is provided with the flexible covering layer, the soft rod and the waste cigarettes are in flexible contact. The waste cigarettes are crushed through the soft rod by means of friction and vibration. Thus, compared with a cutting or grinding mode adopted for traditional equipment, the cut tobacco is not likely to be broken when the waste cigarettes are crushed through the crushing mechanism, the integrity of the cut tobacco can be better kept, and then the finally recovered cut tobacco is good in integrity through the cut tobacco recovery device.

Owner:CHANGDE RUIHUA MFG

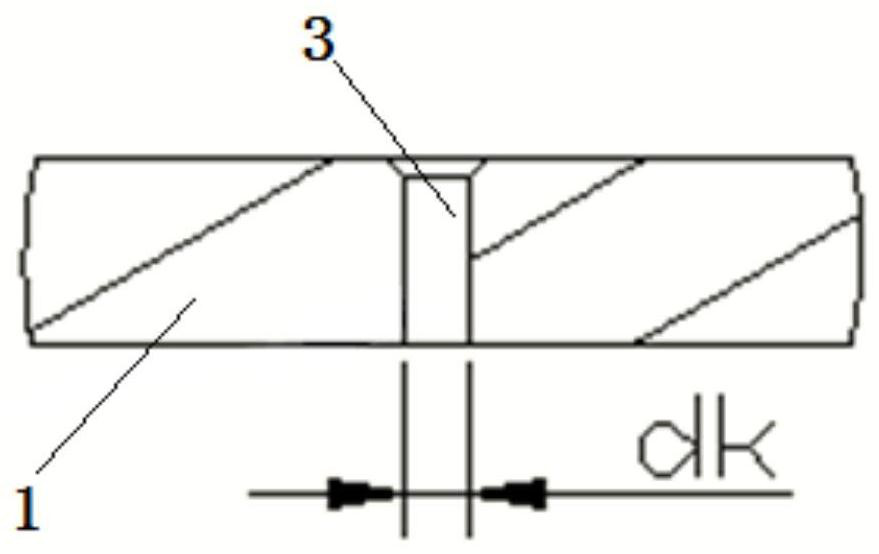

Novel roller

InactiveCN103658187AExtended service lifeReduce manufacturing costRollsMetal rolling arrangementsRolling millPulp and paper industry

The invention discloses a novel roller. The novel roller is provided with a roller core and a roller neck connected with the roller core. A roller body is arranged on the surface of the roller core in a sleeved mode. A threaded center hole is formed in the center of the roller neck, and at least two pin holes are formed around the threaded center hole in the roller neck. When being arranged on the roller core in the sleeved mode, the roller body can absorb impact force, and the roller can not be easily broken. The threaded center hole is used for hoisting of the roller and assembling of a rolling mill, the pin holes have the locating effect of turnbuckles, the service life is prolonged, and the production cost is saved.

Owner:JIANGSU DONGYE ROLL

Plant ecological building curtain wall for bottom-layer building

ActiveCN113615426ADifficult to contact directlyReduce corrosionWallsCultivating equipmentsDistilled waterZoology

The invention discloses a plant ecological building curtain wall for a bottom-layer building, and belongs to the field of ecological building curtain walls. According to the scheme, gas generated through pheromone volatilization can be discharged to the position of landscape plants along an insect inlet channel, insects in the landscape plants are attracted to crawl to the position where an insect catching bottle is located through pheromone, at the moment, under the action of the self gravity of the insects and a counter weight part, rubber fan blades easily deform downwards as shown in a figure 8, part of the insects easily fall off from gaps among the multiple rubber fan blades and fall on the pheromone, and kinetic energy generated by falling directly penetrates through the pheromone and a bearing net and falls into distilled water, so that the insects are captured; part of insects open wings to fly in the falling process, do not directly fall to the upper side of the pheromone but slowly fall, but when the insects want to leave the insect catching bottle, the insects are difficult to jack up the rubber fan blades by means of own force, and the insects are difficult to escape from the insect catching bottle.

Owner:宁波核力建筑设计有限公司

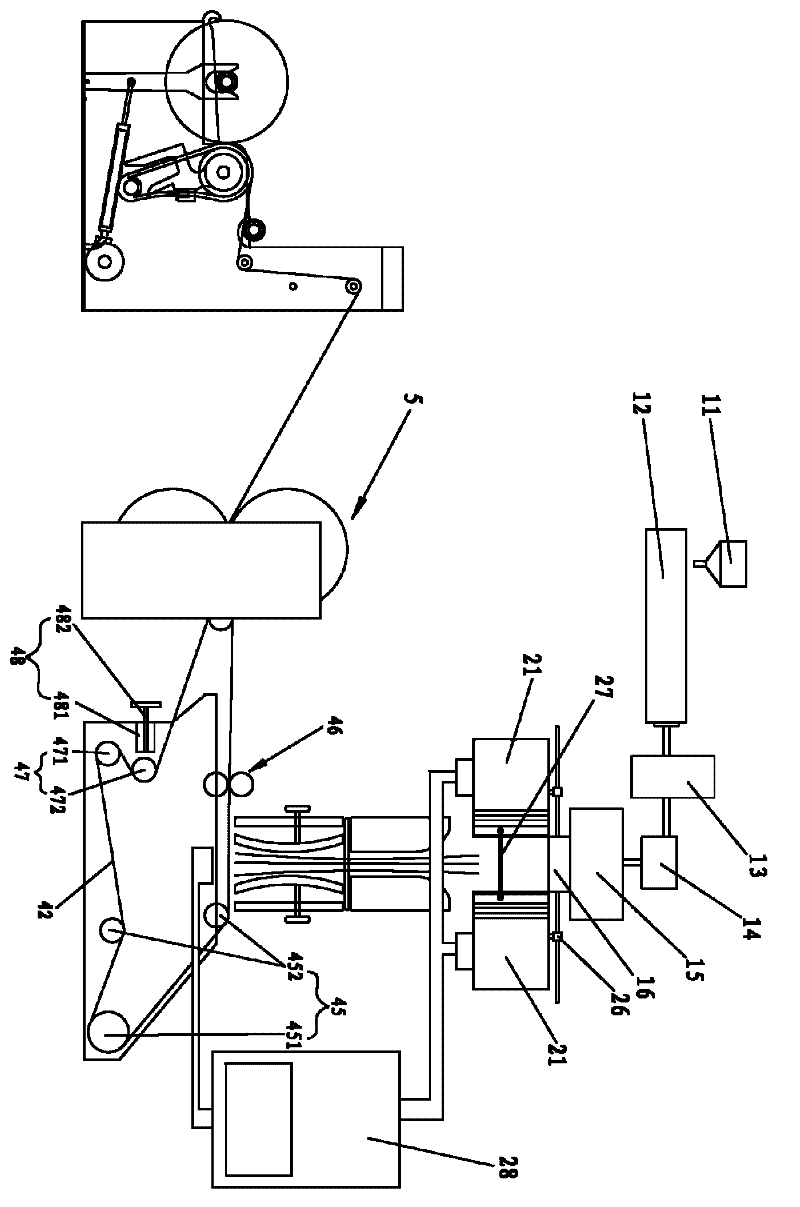

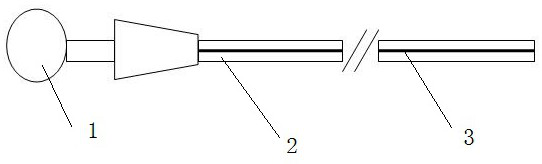

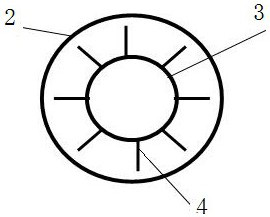

Non-woven fabric forming equipment

ActiveCN101831763BChange tractionTraction Modulation and ControlFilament/thread formingNon-woven fabricsSpinningPolymer

The invention discloses non-woven fabric forming equipment comprising an extruding device, a spinning beam, a packaged air conditioner device, a drawing and stretching device, a net-forming device, a hot rolling device and a wrap-up device, wherein an airflow speedbrake is arranged on the packaged air conditioner device; a closed inner cavity is formed on the drawing and stretching device; an adjusting plate is arranged on the cavity wall and is connected with an adjusting device; a prepressing roller pair is arranged on the net-forming device and also arranged between the position below the drawing and stretching device and the position of the hot rolling device; the airflow speedbrake has the functions of reducing the speed and stabilizing flow, thereby ensuring that the non-woven fabric forming equipment can uniformly spin; the adjusting device enables the bending degree of the adjusting plate to be changed, thereby adjusting the section shape and the caliber of the inner cavity, changing the drawing force of the airflow on a polymer and adjusting and controlling the forming diameter of spinning; and by using the prepressing of the prepressing roller on the fabric width, the invention is beneficial to improving the compactness and the strength of fabrics and ensures that the fabric width thickness is uniform.

Owner:东莞市威骏不织布有限公司

A Batch Forming Process for Building Elevation Concrete Blocks

ActiveCN106891425BGood symmetryImprove integrityBuilding reinforcementsMould fastening meansLacquerPreparation stage

The invention discloses a batch molding technique for building elevation concrete blocks. The batch molding technique comprises the steps of the preparation stage, the pouring stage, vibration molding, arrangement of connecting pieces, formwork removal for molding, and the like. According to the batch molding technique for the building elevation concrete blocks, compared with the way that in the prior art, machine oil is brushed onto the inner surface and the outer surface of a mold, by adoption of the way that the concrete contact surface and the non-contact surface of a mold are treated separately, namely the way that clear lacquer is brushed onto the concrete contact surface of the mold and machine oil is bushed onto the non-contact surface of the mold, oil stains in products can be avoided; and in the prior art, due to the fact that a small amount of machine oil brushed onto the contact surface can drop into the products in the vibrating process, the portions, with the oil stains, of the products are in the broken state; and by adoption of the way that the clear lacquer is brushed onto the contact surface of the mold, the problem of oil stains can be solved, demolding of the products can be achieved more conveniently, and the batch molding technique has the advantage that the surface completeness and the overall quality of the products are good.

Owner:CHINA MCC5 GROUP CORP

Electrode slurry automatic preparation equipment with fast drying function for battery production

InactiveCN109529673AExcellent preparation workHomogenizedTransportation and packagingRotary stirring mixersElectricityBiochemical engineering

The invention relates to electrode slurry automatic preparation equipment with a fast drying function for battery production. The equipment comprises a main body, an electric heating wire and a sievescreen, wherein a water inlet penetrates through the top end of the main body; a rotating shaft penetrates through the middle part of the top end of the main body; the top of the rotating shaft is movably provided with an electric motor; the outer wall of the rotating shaft is connected with a stirring rod. The equipment provided by the invention has the beneficial effects that through the arrangement of the sieve screen, a spring, a feeding opening, the main body, a material storage barrel and a separation plate, the sieve screen and the feeding opening form an elastic structure through the spring; when the equipment performs preparation operation on the electrode slurry, the material charging work on the inner side is needed; through the distribution action of the feeding opening and themain body, the materials vertically enter the equipment, the goal is achieved by one step, and the time is saved; when the materials slide to the sieve screen, through the self gravity of the materials and the opposite action of the spring arranged at the bottom of the sieve screen, the sieve screen better performs material homogenizing treatment, so that the preparation work of the electrode slurry of the device is more excellent.

Owner:俞杰

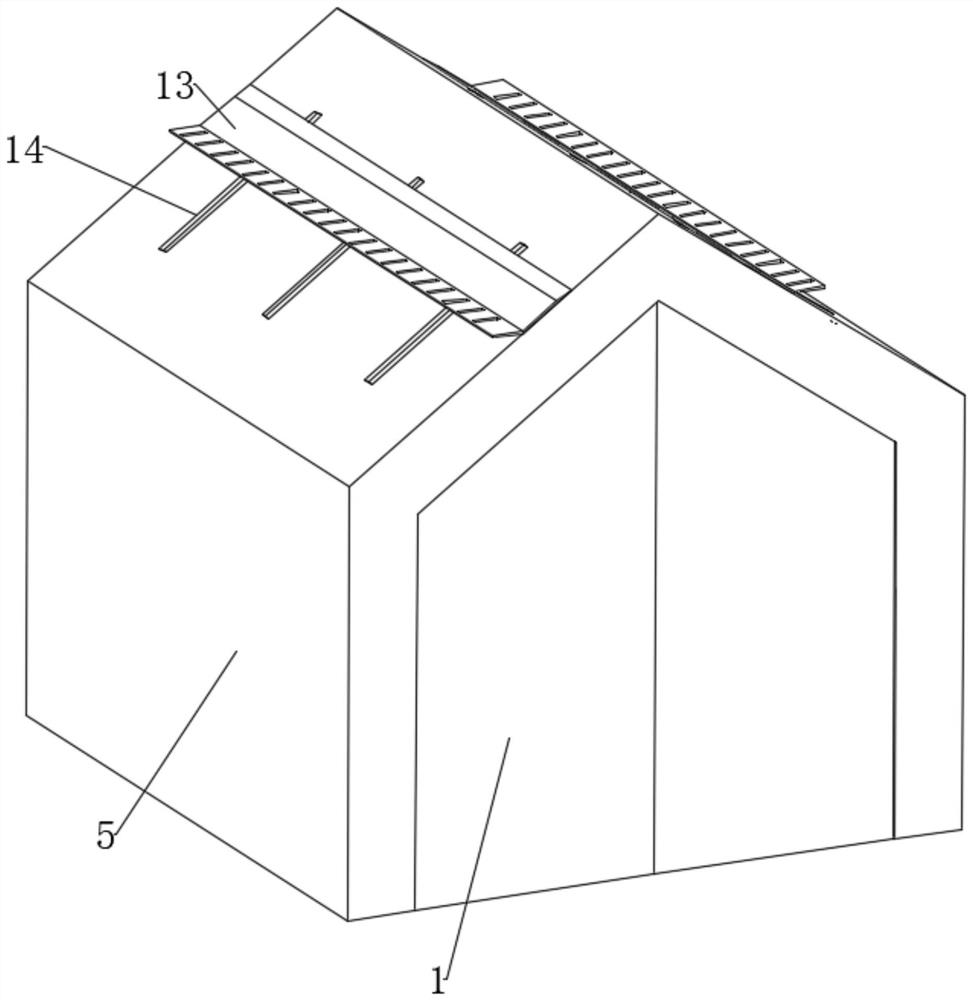

A high-strength tent for polar exploration

ActiveCN111852171BReduce frictionNot easy to cause breakageTents/canopiesSnow trapsSnowpackLiquid layer

Owner:威斯伯特建筑科技(江苏)有限公司

A Forming Device for Concrete Concrete Blocks with Cone-shaped Elevation Concrete Blocks Used for Floor Slabs

ActiveCN106863580BImprove protectionIncrease widthMouldsBuilding material handlingFloor slabRound table

The invention discloses a forming device for a circular-truncated-cone-shaped elevation concrete block for a floor slab. The forming device comprises two parallel clamping plates. A plurality of half circular truncated cone ring plates are arranged on the opposite sides of the clamping plates. The ring plates are paired between the two clamping plates to form a circular-truncated-cone-shaped die. A bed board on the side opposite to the corresponding ring plate is vertically arranged at the bottom of each clamping plate, and the two clamping plates are connected through at least two sets of paired bolts and nuts. According to the forming device, cavities can be formed between the clamping plates and the ring plates through a two-point connecting structure, when the clamping plates are knocked, vibration waves can be formed between the ring plates and the clamping plates through the knocking action, the ring plates are vibrated through the vibration waves, demoulding is facilitated, and in other words, an operator can finish demoulding with small knocking force; and the labor force input is reduced, the demoulding efficiency is greatly improved, knocking on the die is reduced, and accordingly the service life of the die is prolonged.

Owner:CHINA MCC5 GROUP CORP

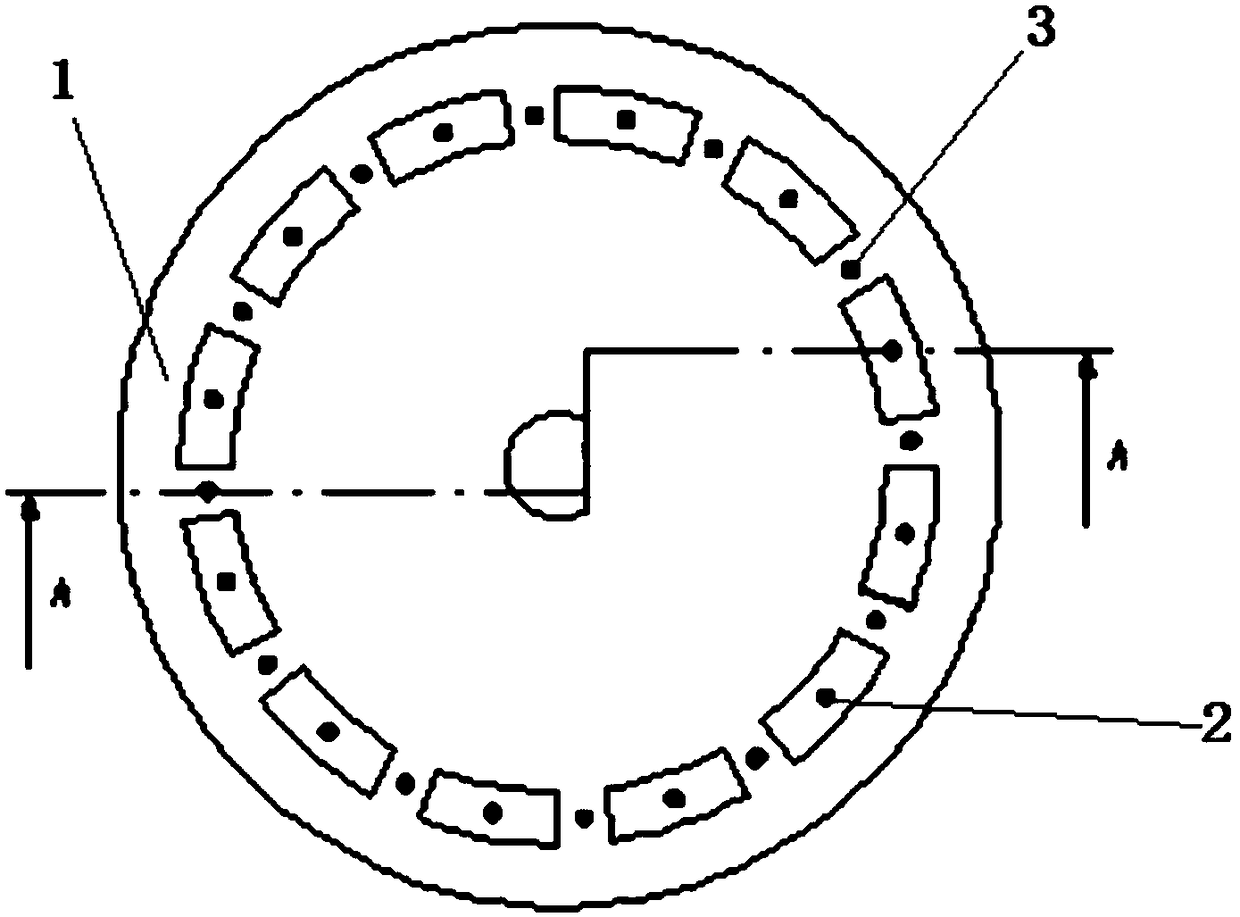

Groove-tooth combined type seed metering disc for high-speed seed metering of spherical small-sized seeds

ActiveCN108811625AReduce frictionSmall scratchSeed depositing seeder partsRegular seed deposition machinesEngineeringFriction force

The invention discloses a groove-tooth combined type seed metering disc for high-speed seed metering of spherical small-sized seeds. According to the seed metering disc, the center of a seed meteringdisc body is provided with a positioning hole, the seed metering disc body is provided with a plurality of limiting grooves which are distributed at intervals and are concentrically arranged with thepositioning hole, a seed stirring tooth is formed between any two adjacent limiting grooves, first adsorption channels are formed in the limiting grooves, and second adsorption channels are formed inthe seed stirring teeth. The seed metering disc has the advantages that a groove-tooth combined structure is adopted, directional stirring is carried out on a seed group, the stable accumulation stateof the seed group is broken, so that a small-sized amount of seeds can be quickly separated from the seed group and enter a fixed annular groove channel to be freely captured and accurately adsorbedby the adsorption channels, so that the seed metering efficiency is improved, high-speed seed metering is realized, meanwhile, the friction force between the groove-tooth combined type seed metering disc and the seed group is small, the stirring quantity is large, the scraping force of a baffle in a seed metering device is small, and the damage of seed coat cannot be easily caused.

Owner:ANHUI AGRICULTURAL UNIVERSITY

U-shaped steel reinforced composite anchor mesh support structure and construction method of deep well high stress soft rock roadway

ActiveCN106401605BImprove stabilityEffective use of anchor rods and anchor cables to develop autonomous bearing capacityUnderground chambersTunnel liningPolyesterFiber

Owner:ANHUI UNIV OF SCI & TECH

A semi-automatic polarizer peeling device for liquid crystal display panels

ActiveCN104808382BEffective peelingAchieve strippingLamination ancillary operationsLaminationLiquid-crystal displaySemi automatic

The invention discloses a semi-automatic polarizer stripping device for a liquid crystal display panel. The semi-automatic polarizer stripping device comprises a base, a first conveyor, a stripping platform, a second conveyor, a support plate, a heating plate and a clamping device. According to the semi-automatic polarizer stripping device, as the first conveyor and the second conveyor are arranged, the liquid crystal display panel can be automatically conveyed onto the stripping platform for stripping a polarizer, and the liquid crystal display panel stripped is conveyed out from the stripping platform, so that the processing efficiency is improved, and the labor cost is reduced; as the heating plate is arranged, the polarizer can be heated, and the stripping strength of the polarizer is reduced; a first roll shaft and a second roll shaft are driven by a first motor and a second motor to rotate for realizing the stripping of the polarizer on the liquid crystal display panel, so that the stress on the polarizer is relatively uniform, and the polarizer is unlikely to be fractured. The device can effectively strip the polarizer, and is good in stripping effect, high in work efficiency, low in processing cost and convenient and quick in operation.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

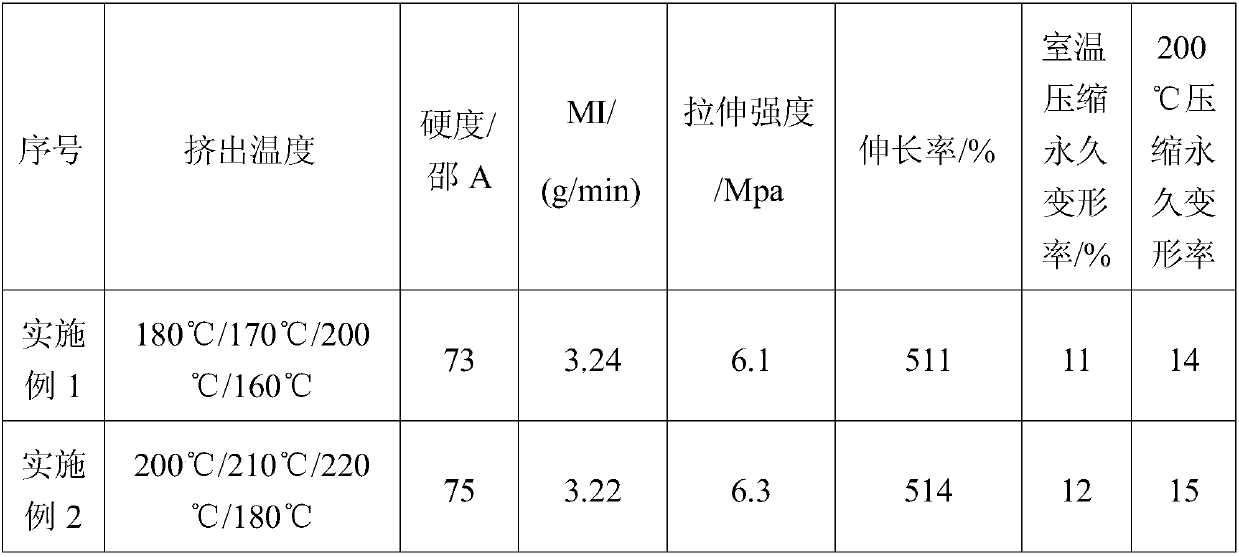

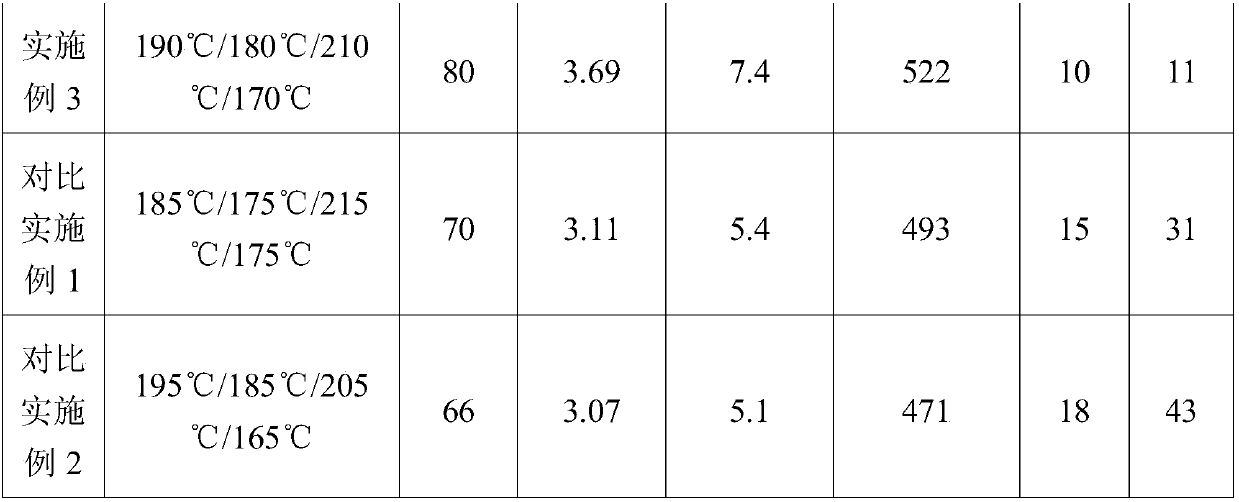

Method for processing thermoplastic elastomer materials by using waste rubber

The invention provides a method for processing thermoplastic elastomer by utilizing waste rubber and relates to the technical field of thermoplastic elastomers. By adopting the method for processing the thermoplastic elastomer by utilizing the waste rubber, on one hand, the waste rubber is recovered and then is processed into modified rubber powder, so that waste resources are very well optimized and configured, and the ecological environment is protected; on the other hand, the processed waste rubber powder is used as a main material, and natural plant fibers such as bagasse fiber and jute fiber and other rubber performance reinforcing agents are used as auxiliary materials, the prepared thermoplastic elastomer has the good properties of large hardness, large tensile strength, high elongation and high heat resistance, the safety of the thermoplastic elastomer material applied to electric wires and cables is ensured, and the service life of the electric wires and cables is prolonged.

Owner:奥世达弹性体(深圳)有限公司

A slotted tooth combined seeding disc for high-speed seeding of small spherical seeds

ActiveCN108811625BReduce frictionSmall scratchSeed depositing seeder partsRegular seed deposition machinesMechanical engineeringBotany

The invention discloses a slotted tooth combined seeding disk for high-speed seeding of small spherical seeds. The center of the seeding disk is provided with a positioning hole, and the seeding disk is provided with a plurality of spaced constraints arranged concentrically with the positioning hole. Slots, seed disturbing teeth are formed between any two adjacent restraining grooves; the restraining grooves are provided with a first adsorption channel, and the seed disturbing teeth are provided with a second adsorption channel. The present invention adopts the combined structure of slotted teeth to perform directional disturbance on the population, breaking the stable accumulation state of the population, so that a small amount of seeds can be quickly separated from the population into a fixed ring groove channel to be freely captured and accurately adsorbed by the adsorption channel, so as to improve seed discharge. High efficiency, realize high-speed seeding, at the same time, the slotted tooth combined seeding plate has low population friction, large disturbance, and small scratching force with the baffle in the seed metering device, which is not easy to cause damage to the seed coat.

Owner:ANHUI AGRICULTURAL UNIVERSITY

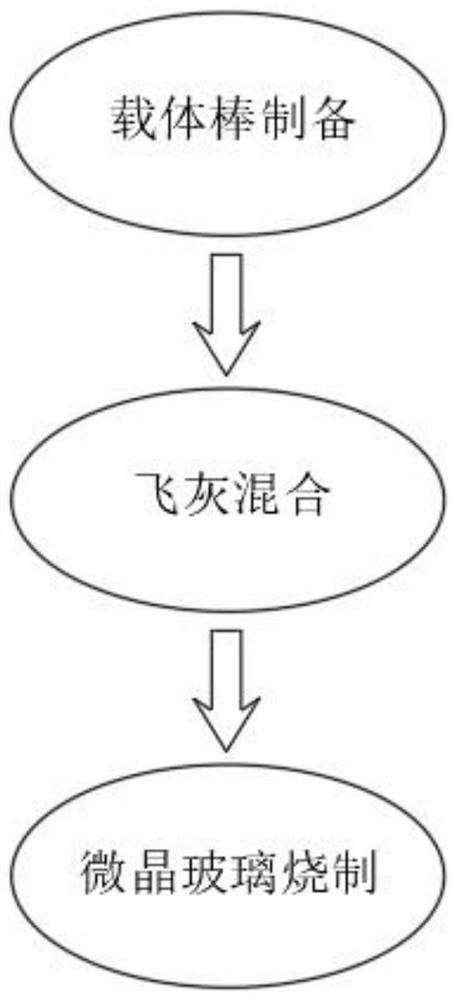

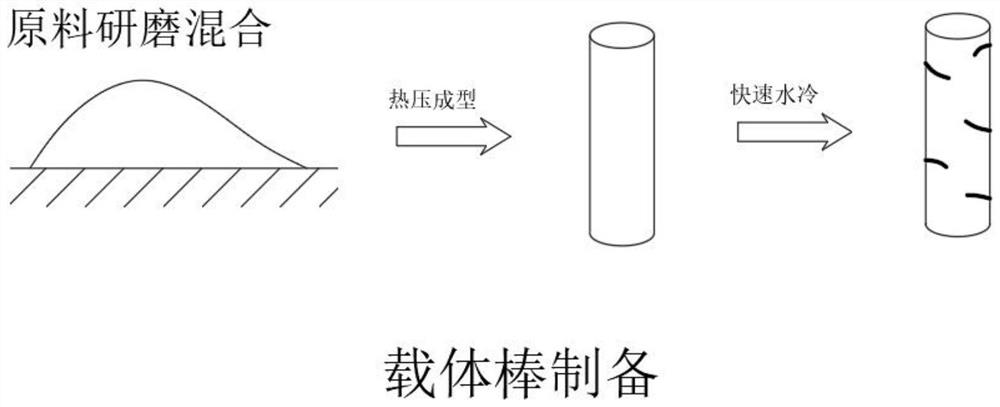

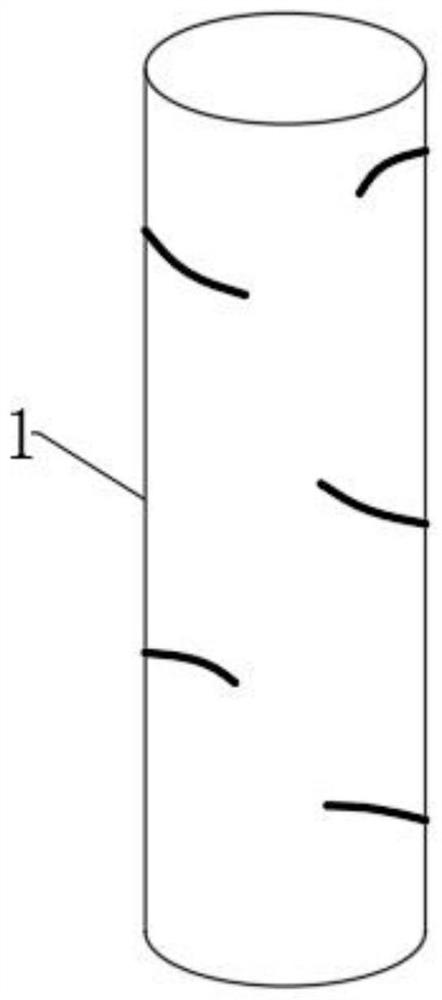

Microcrystal vitrification process for ultrafine grinding and microwave sintering of garbage fly ash

The invention discloses a glass-ceramic vitrification process for ultrafine grinding and microwave sintering of waste fly ash, and belongs to the field of glass-ceramic manufacturing processes, and the glass-ceramic vitrification process for ultrafine grinding and microwave sintering of waste fly ash comprises the following steps: manufacturing a carrier rod from fly ash-removed raw materials of glass-ceramic, and carrying out shock cooling treatment to obtain the glass-ceramic. A large number of temperature change cracks appear on the surface of the carrier rod, fly ash is stored through the temperature change cracks, in the fly ash mixing process, the fly ash is immersed into the temperature change cracks through ultrasonic waves, meanwhile, the fly ash is locked through the attachment fibers, and the fly ash is captured and reserved in the temperature change cracks through a three-dimensional space structure composed of the attachment fibers. In the subsequent drying process, crystal particles of fly ash are easily formed on the inner wall of the temperature change crack, and in the subsequent grinding process, the raw materials are easily and uniformly mixed, so that the mixing degree of the glass ceramic production raw materials can be greatly increased, and the performance of the glass ceramic formed by microwave sintering is improved.

Owner:谢飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com