Microcrystal vitrification process for ultrafine grinding and microwave sintering of garbage fly ash

A technology of glass-ceramic and microwave sintering, which is applied in the field of micro-ceramic vitrification of garbage fly ash ultra-fine grinding and microwave sintering, can solve problems such as affecting the performance of glass-ceramic, and achieves increased performance, increased mixing degree, and increased overall the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

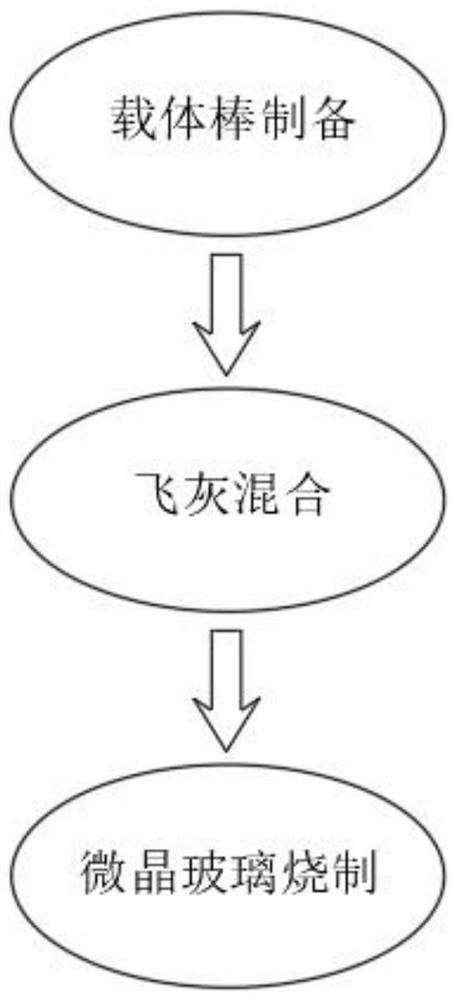

[0044] see Figure 1-10 , a micro-ceramic vitrification process of ultra-fine grinding and microwave sintering of garbage fly ash, the main steps of which include:

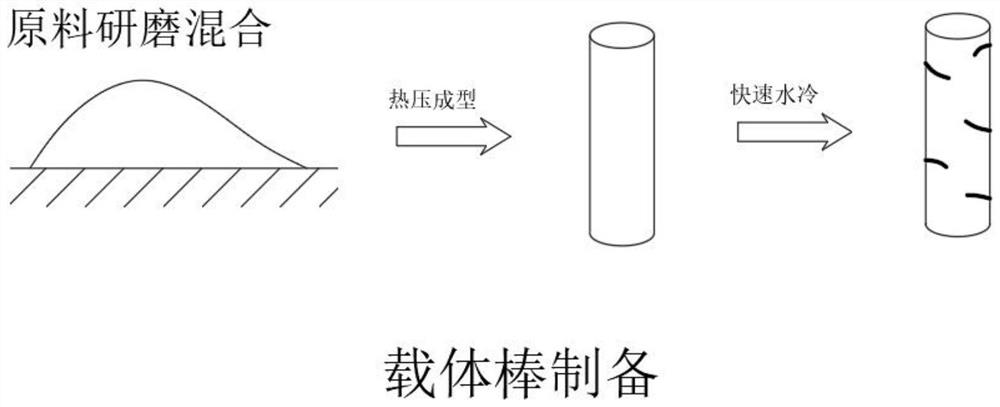

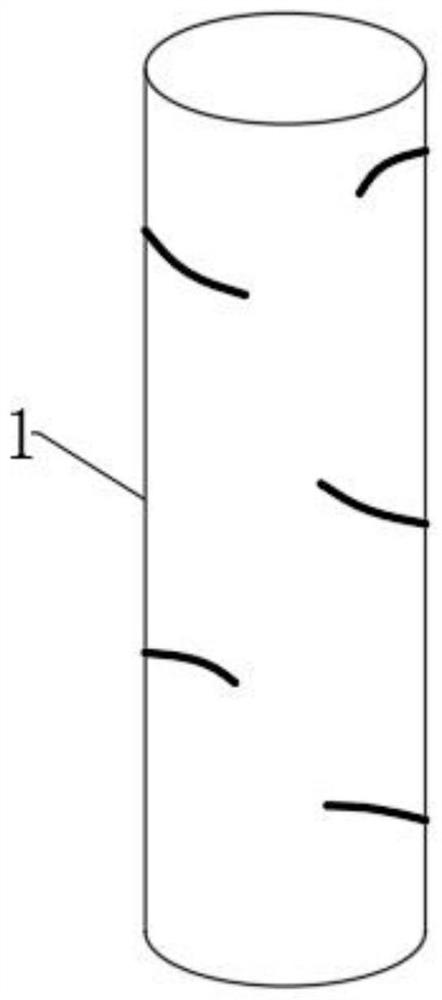

[0045]S1. Preparation of the carrier rod, grinding and mixing the raw materials for the production of glass-ceramic for removing fly ash according to the proportion, and the above-mentioned raw materials mainly include SiO 2 and Al 2 O 3 , and its mass ratio is 1.5:1. After heating the raw material to 150 degrees Celsius, it is hot-pressed to obtain a carrier rod 1. After that, the carrier rod 1 is put into cold water for rapid water cooling, so that the surface and the interior of the carrier rod 1 form more A temperature change crack 102 is obtained to obtain a carrier rod;

[0046] The raw materials are mixed with a plurality of attachment fibers 103 and mixed uniformly to increase the strength of the formed carrier body 101, so that the carrier body 101 is not easily broken along the plurality of temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com