Method for processing thermoplastic elastomer materials by using waste rubber

A thermoplastic elastomer, waste rubber technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problem that thermoplastic materials are not resistant to high temperature, achieve the effect of not easy to polymerize, protect the ecological environment, and increase wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

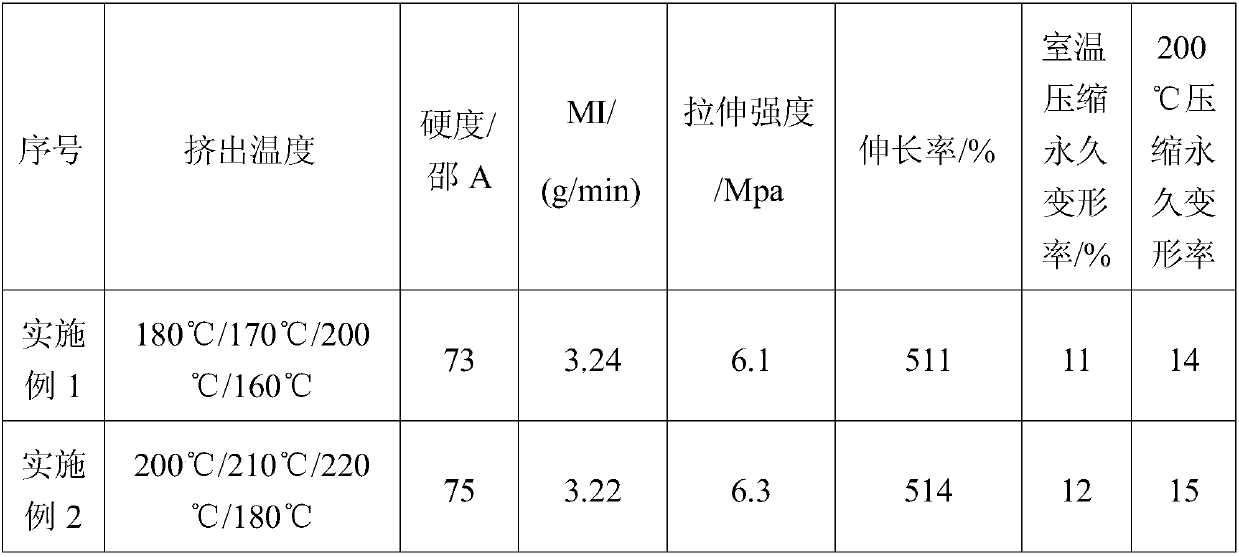

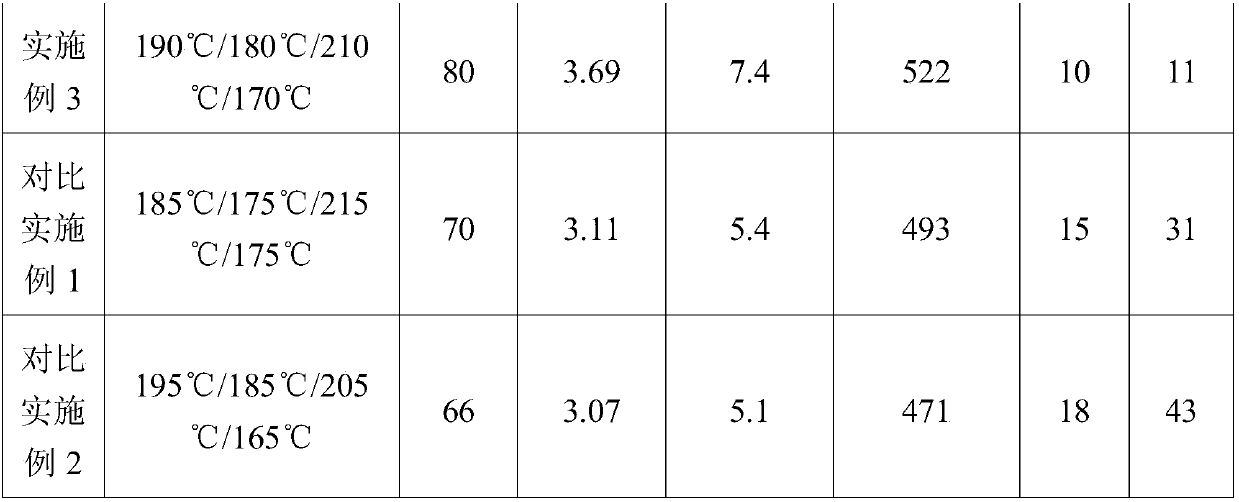

Embodiment 1

[0019] The method for utilizing waste rubber to process thermoplastic elastomer materials comprises the following steps:

[0020] ①Preparation of modified rubber powder: cut waste rubber into small pieces with a weight range of 400g, and ultrasonically clean them for 3 minutes; then pulverize them through a pulverizer, and pass through a 200-mesh sieve to obtain rubber powder; mix sulfur powder, silane coupling agent Si69, Polyethylene glycol and stearyl alcohol are mixed in a weight ratio of 5:2:50:10 and added to the waste rubber powder in the form of a spray. The amount added is 20% of the weight of the waste rubber powder. First, put it under an infrared lamp for 20 minutes. Then put the waste rubber powder into the ball mill and then add white carbon black for blending, then ball mill for 5 minutes at a speed of 1000r / min, then put the ball-milled waste rubber powder into the cold cathode fluorescent lamp irradiation box for 30 minutes, and pass nitrogen and gas into the b...

Embodiment 2

[0023] The method for utilizing waste rubber to process thermoplastic elastomer materials comprises the following steps:

[0024]①Preparation of modified rubber powder: cut waste rubber into small pieces with a weight range of 450g, and ultrasonically clean them for 5 minutes; then pulverize them through a pulverizer, and pass through a 200-mesh sieve to obtain rubber powder; mix sulfur powder, silane coupling agent Si69, Polyethylene glycol and stearyl alcohol are mixed in a weight ratio of 5:2:50:10 and added to the waste rubber powder in the form of a spray. The amount added is 25% of the weight of the waste rubber powder. Then put the waste rubber powder into the ball mill and then add white carbon black for blending and then ball mill for 10 minutes at a speed of 1000r / min, then put the ball-milled waste rubber powder into the cold cathode fluorescent lamp irradiation box for 50 minutes, and at the same time, nitrogen gas and Oxygen, so that the volume ratio of nitrogen a...

Embodiment 3

[0027] The method for utilizing waste rubber to process thermoplastic elastomer materials comprises the following steps:

[0028] ①Preparation of modified rubber powder: cut waste rubber into small pieces with a weight range of 425g, and ultrasonically clean them for 4 minutes; then pulverize them through a pulverizer, and pass through a 200-mesh sieve to obtain rubber powder; mix sulfur powder, silane coupling agent Si69, Polyethylene glycol and stearyl alcohol are mixed in a weight ratio of 5:2:50:10 and added to the waste rubber powder in the form of a spray. The amount added is 23% of the weight of the waste rubber powder. First, put it under an infrared lamp for 25 minutes. Then put the waste rubber powder into the ball mill and then add white carbon black for blending, then ball mill for 8 minutes at a speed of 1000r / min, then put the ball-milled waste rubber powder into the cold cathode fluorescent lamp irradiation box for 40 minutes, and pass nitrogen and gas into the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com