A Production Technology of Concrete Block with Concrete Concrete Block with Concrete Elevation for Floor Slab

A production process and a truncated cone-shaped technology, which is applied to the production process field of truncated cone-shaped elevation concrete blocks, can solve the problems of low yield and easily broken elevation blocks, and achieve the effects of high symmetry, improved demolding efficiency, and strong versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

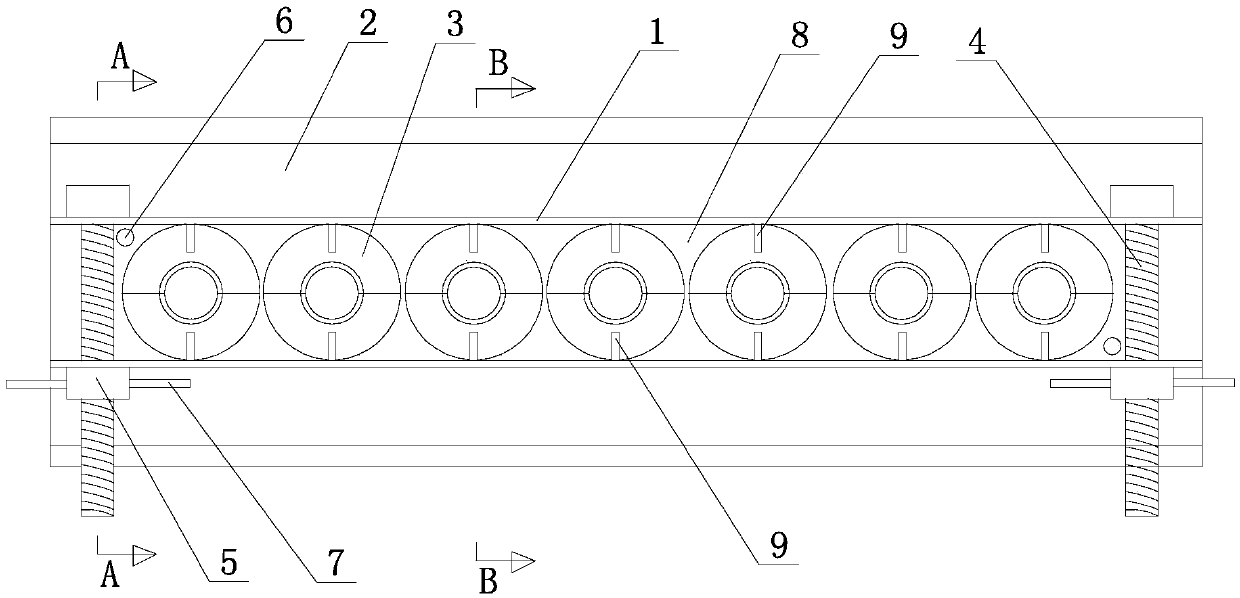

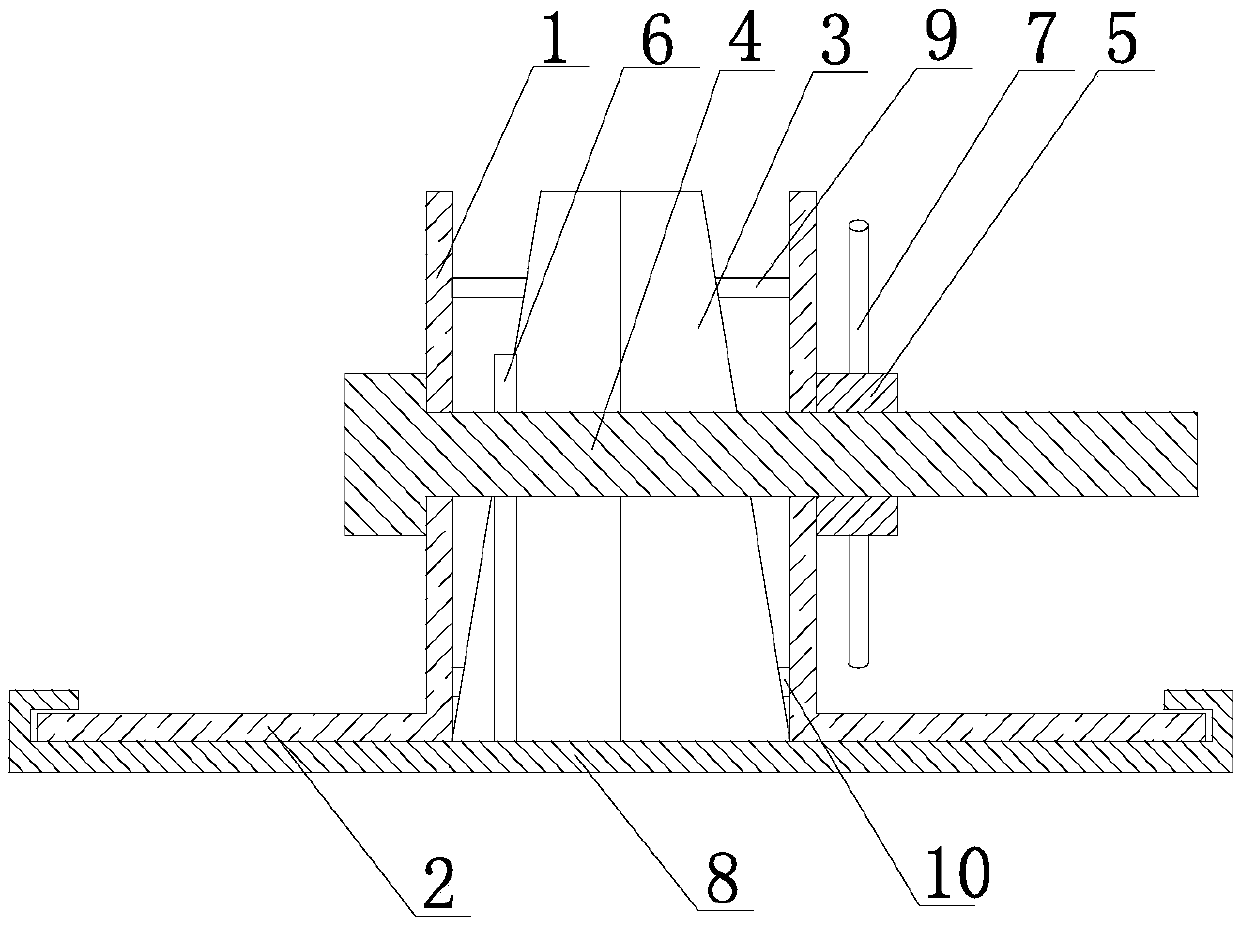

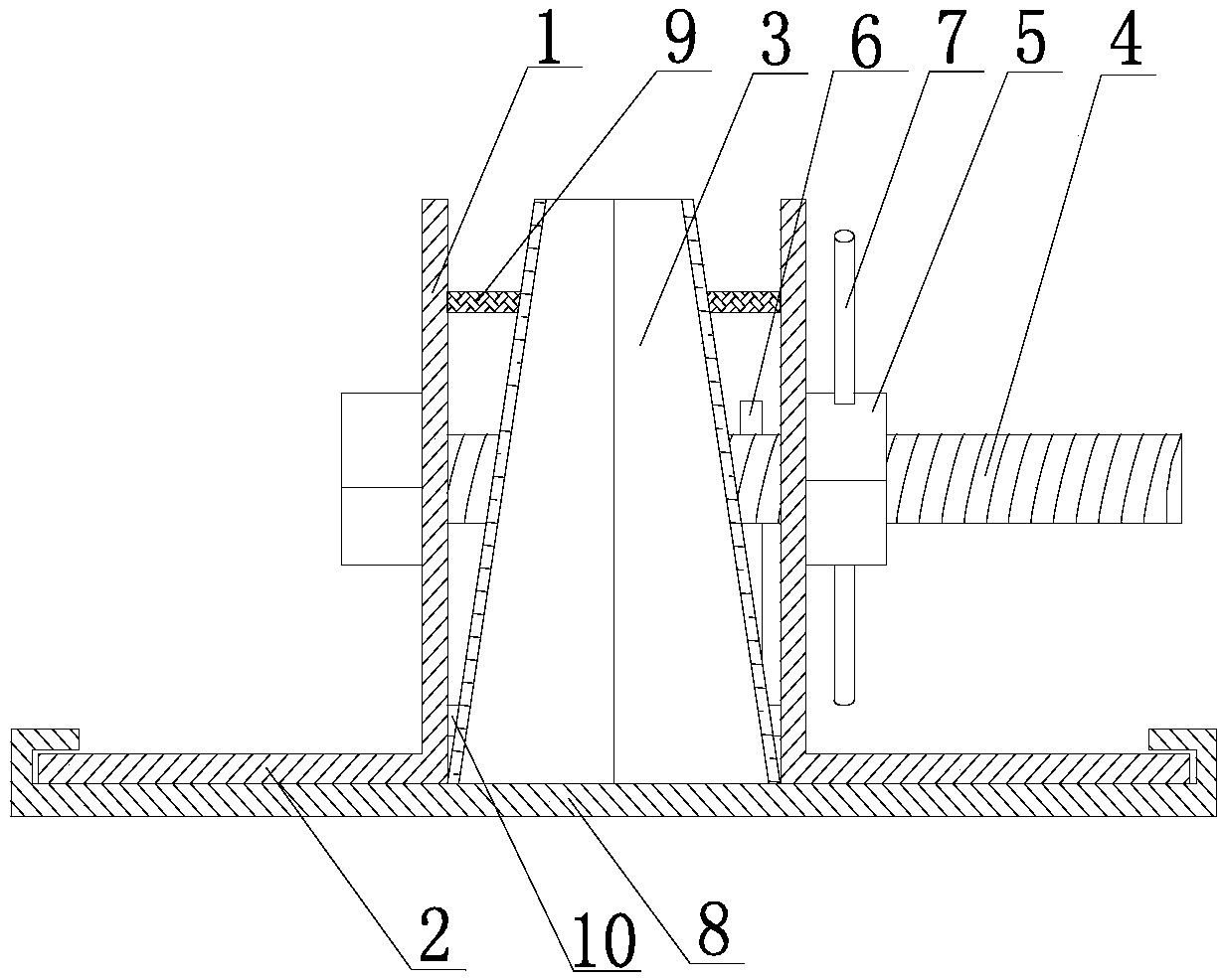

[0041] Such as Figures 1 to 3 As shown, a mold used in the production process of a conical concrete block with a conical elevation for floor slabs in the present invention includes two splints 1 parallel to each other, and a plurality of frustum-shaped ring plates are arranged on the opposite side of the splints 1 3. The ring plate 3 is paired between two splints 1 to form a frustum-shaped mold. The upper side wall of the semi-circular frustum-shaped ring plate 3 is connected to the splint 1 through a connecting column 9, and the lower side wall of the semi-circular frustum-shaped ring plate 3 is connected by a wedge Shaped block 10 is connected with clamping plate 1, and the distance between connecting column 9 and wedge-shaped block 10 is 81%~84% of the length of the slope of ring plate 3, and the bottom of each clamping plate 1 is vertically arranged with ring plate 3 different side plank 2, two splints 1 are connected by at least two groups of paired bolts 4 and nuts 5, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com