Toggle lever metal extruder

A metal extrusion and toggle lever technology, applied in the field of metal extrusion presses, can solve the problems of oil drill pipe flash, bolts are easy to break, and work efficiency is low, and achieves good frame force effect, not easy to break, and pressing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

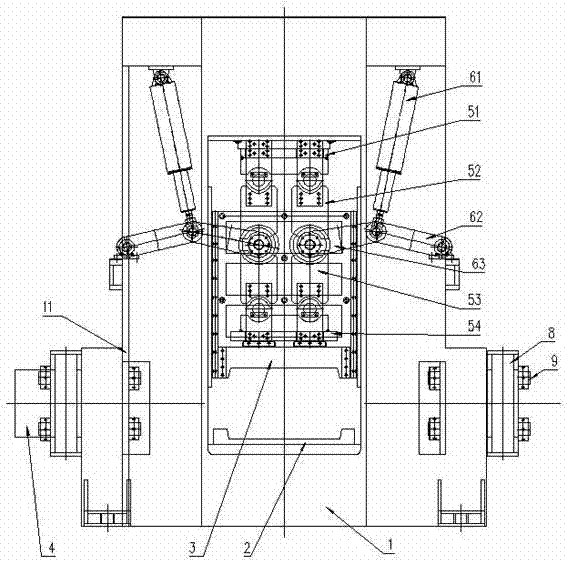

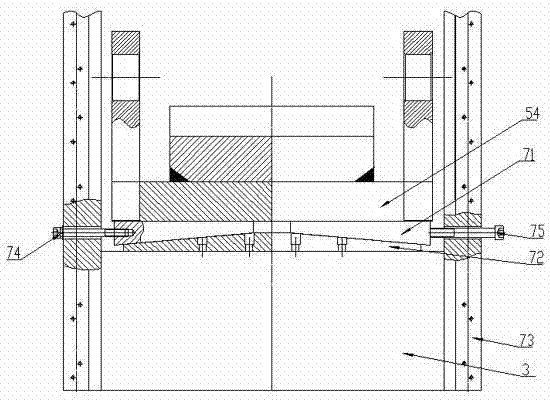

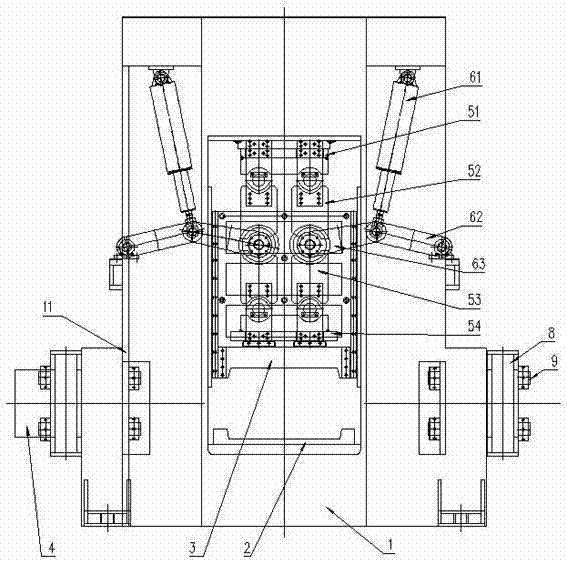

[0014] Such as figure 1 Shown, frame 1, workbench 2, slider 3, side pressing cylinder 4, upper support 51, upper toggle 52, lower toggle 53, lower support 54, hydraulic cylinder 61, first connecting rod 62 and The second connecting rod 63 .

[0015] The above-mentioned frame 1 is a frame type, the lower part of the frame 1 is a workbench 2, and a slider 3 is arranged on the top of the workbench 2. The vertical guide rail of the frame 1 reciprocates along the vertical direction, and the two sides of the workbench 2 are provided with side pressing cylinders 4 .

[0016] A pair of toggle mechanisms arranged symmetrically on the left and right are arranged on the upper part of the frame 1. The toggle mechanism mainly includes an upper support 51, an upper toggle 52, a lower toggle 53, and a lower support 54 arranged in sequence from top to bottom. , The upper support 51 is connected with the upper toggle 52 by the upper pin, the upper toggle 52 is connected with the lower toggle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com