Treatment process and mixing equipment for coal cracking produced sewage

A technology of sewage treatment and mixing equipment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor environmental protection, environmental pollution, and reduced sewage treatment functionality, etc. To achieve the effect of improving functionality and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

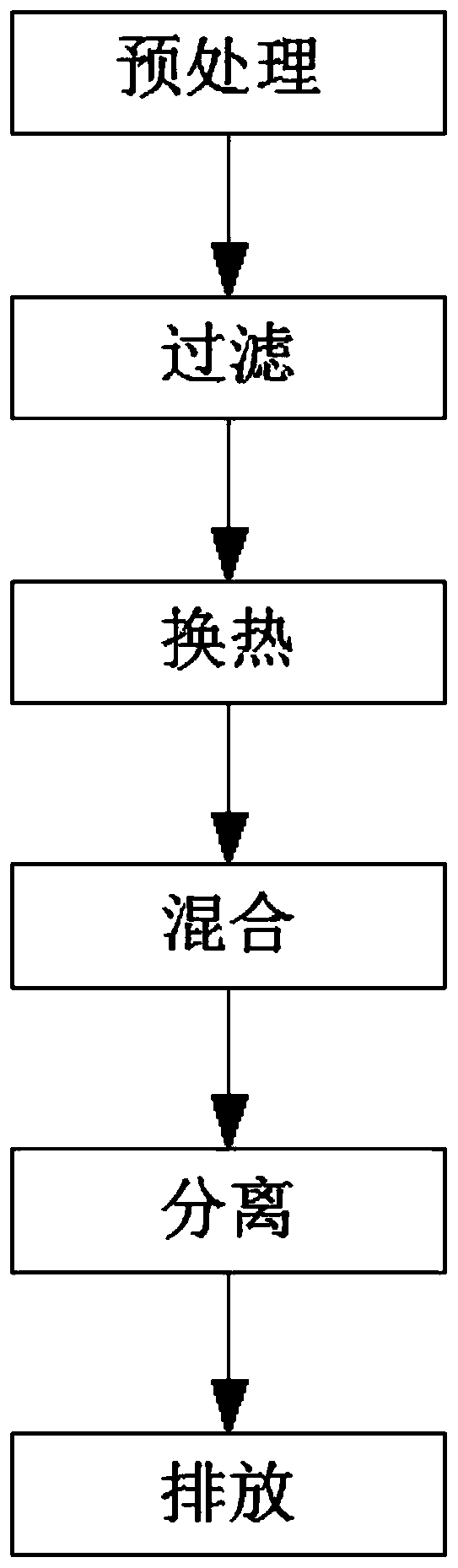

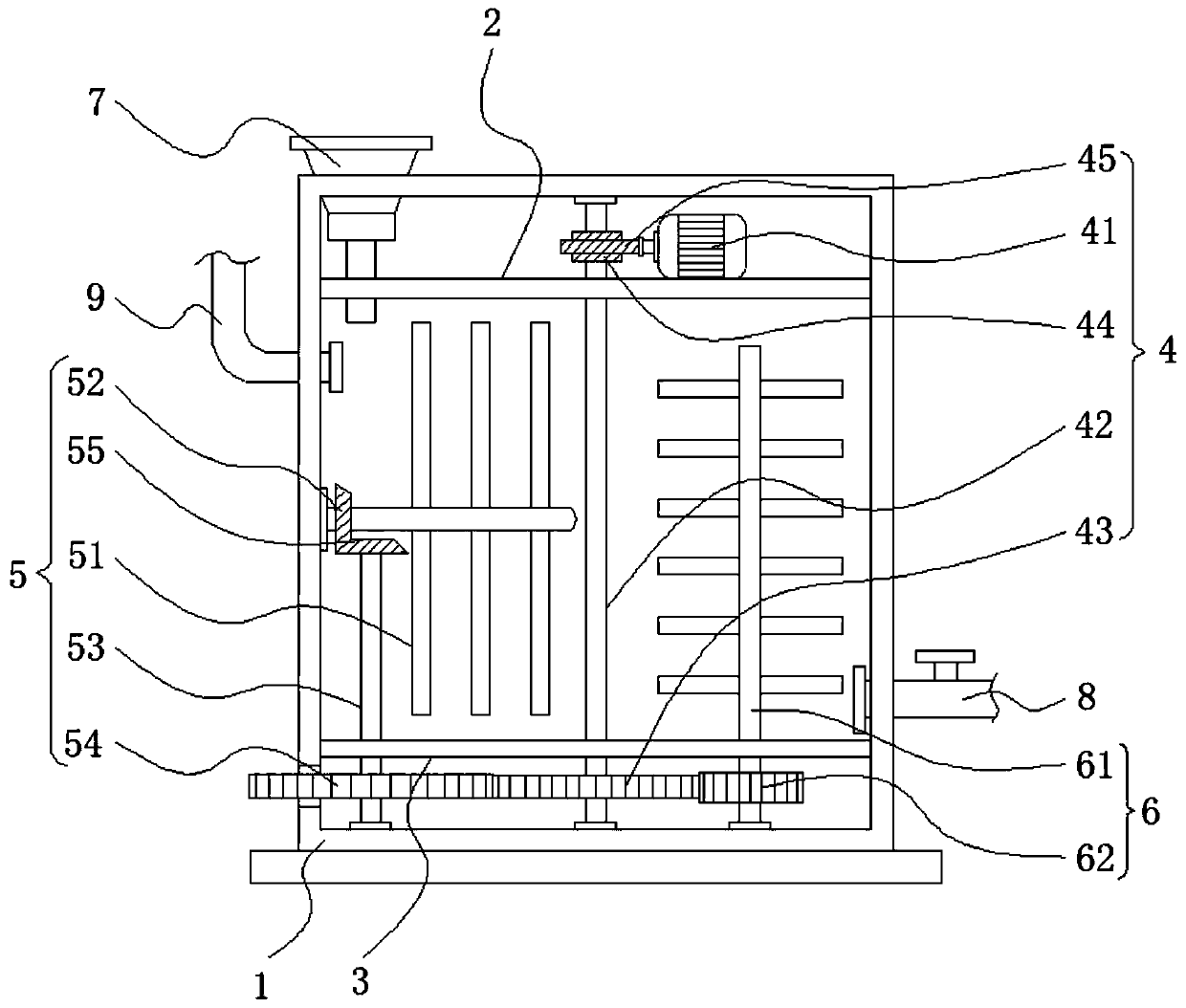

[0030] Please refer to figure 1 with figure 2 ,in, figure 1 The step diagram of the sewage treatment process produced by coal cracking provided by the present invention; figure 2 Schematic diagram of the structure of the mixing equipment provided by the present invention. The sewage treatment process and mixing equipment produced by coal cracking include the following steps:

[0031] S1. Pretreatment: discharge the sewage to be treated into the treatment tank inside the treatment tank through the sewage pipe, and collect the sewage;

[0032] S2. Filtration: The sewage collected in S1 is filtered through the filter plate for tar and other substances in the sewage, and the filtered water is discharged to the bottom of the treatment tank through the water pipe, and then the water on the filter plate is filtered The tar is pushed and discharged to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com