Preparation method and applications of nanometer graphene oxide modified film

A nano-graphite oxide, nano-technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy membrane fouling, increase MBR energy consumption, etc., to improve hydrophilicity and anti-pollution performance. , Improve chemical stability, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Prepare the mold sol, add the film material polyvinylidene fluoride (PVDF) and nano-graphene oxide to the solvent N-methylpyrrolidone (NMP), fully stir and mix to obtain the mold sol, and each group in the gained mold sol The mass percent of the fraction is 50wt.% of film material, 12wt.% of nano-graphene oxide sheet, and the rest are solvents;

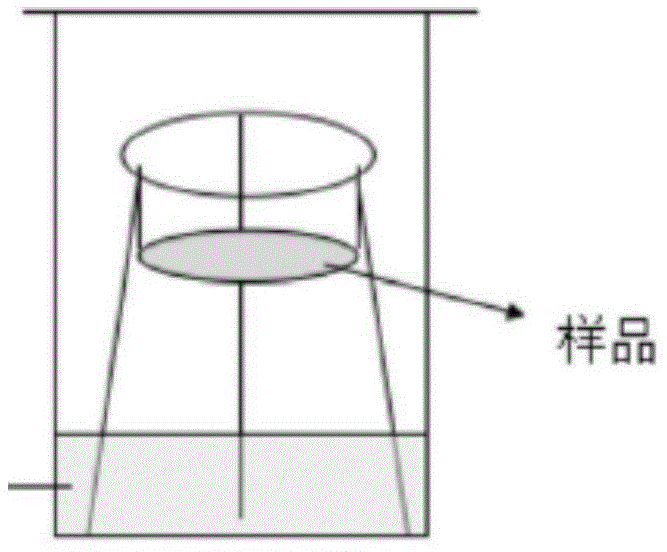

[0020] (2) Scrape the mold sol obtained in step (1) on the non-woven fabric, and the thickness of the scraped film is controlled to be 120 μm. Lay the cloth flat and fix it on the tripod support, the non-woven fabric coated with the mold sol faces up, and then place the support on the bottom of the Teflon sealed tank, which is filled with deionized water , the height of the mold sol coated on the surface of the non-woven fabric from the liquid surface of the deionized water is 1.2 times the depth of the deionized water; heating the deionized water at 120 ° C, the surface of the non-woven fabric located above the deionized w...

Embodiment 2

[0031](1) Prepare the mold sol, add the film material polyvinylidene fluoride (PVDF) and nano-graphene oxide to the solvent N-methylpyrrolidone (NMP), fully stir and mix to obtain the mold sol, and each group in the gained mold sol The mass percent of the fraction is 45wt.% of film material, 10wt.% of nano-graphene oxide sheet, and the rest are solvents;

[0032] (2) Scrape the mold sol obtained in step (1) on the non-woven fabric. The thickness of the scraped film is controlled to be 125 μm. Lay the cloth flat and fix it on the tripod support, the non-woven fabric coated with the mold sol faces up, and then place the support on the bottom of the Teflon sealed tank, which is filled with deionized water , the height of the mold sol coated on the surface of the non-woven fabric from the liquid surface of the deionized water is 1.5 times the depth of the deionized water; heating the deionized water at 130 ° C, the surface of the non-woven fabric located above the deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com