Integrated circulation glass washing device

A technology for cleaning equipment and glass, applied in the direction of cleaning methods using liquids, cleaning flexible objects, chemical instruments and methods, etc., can solve problems such as increasing costs, environmental pollution, wasting cleaning fluid, etc., to increase stability and improve cleaning effects , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to prevent glass breakage and the harm of broken glass to the human body, protect the safety of staff, company property and employee property, and ensure the normal work of the site, the cleaning process must implement the policy of "safety first, prevention first" to reduce glass and The damage of glass cleaning equipment during the cleaning process protects the personal and property safety of production and on-site workers.

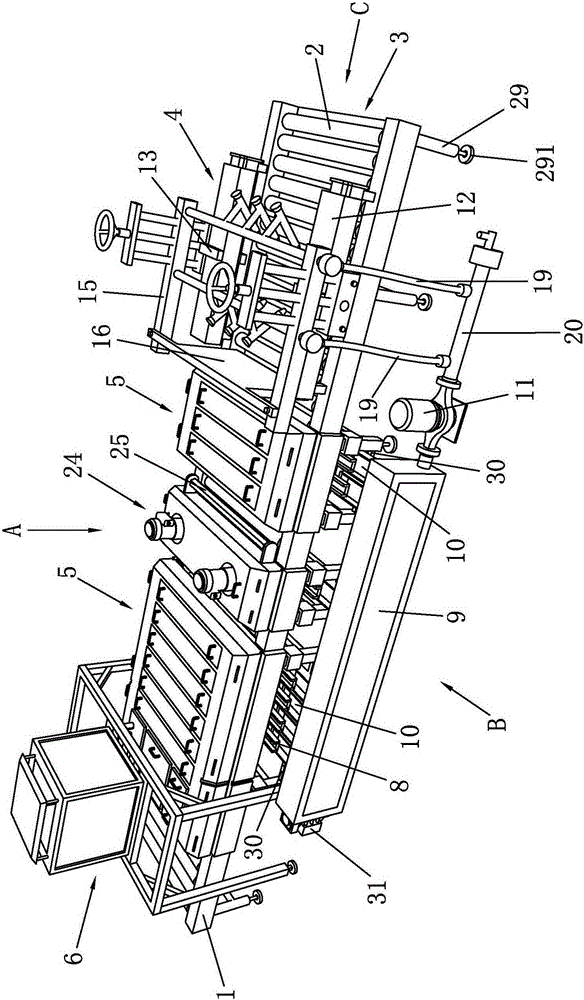

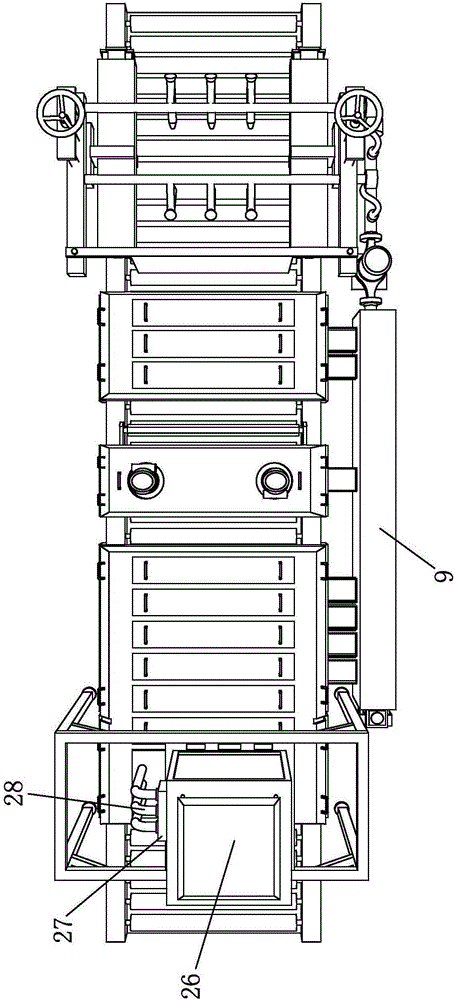

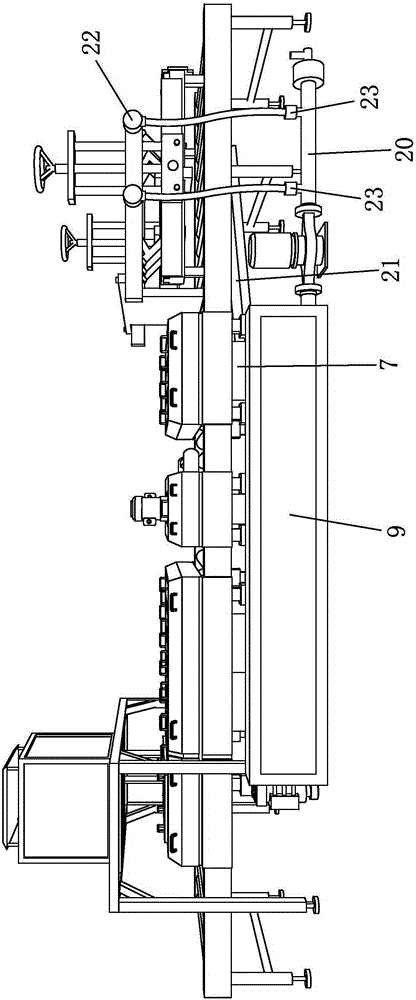

[0027] like Figure 1 to Figure 7 As shown, it is an integrated glass cycle cleaning device of the present invention, including a base 1. In order to reduce the weight, the material of the base 1 should be made of light and high-strength materials as much as possible. Generally, an aluminum alloy frame is used. Since the aluminum frame is in contact with the ground, The base 1 will be slightly worn, and the base 1 will slip to a certain extent on the ground. In order to prevent this kind of phenomenon from happening and to prolong the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com