Method for preparing all-solid-state electrochromic device

An electrochromic device and electrochromic layer technology, which can be used in instruments, nonlinear optics, optics, etc., can solve the problems of low coloring efficiency, short cycle discoloration life, etc., and achieve the effect of extremely high electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

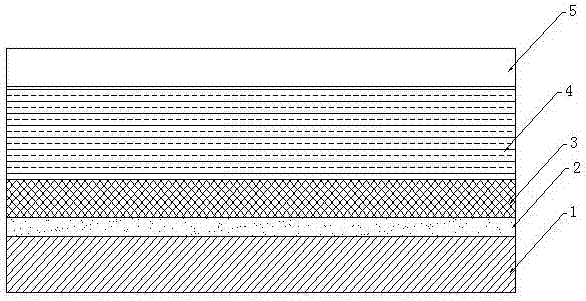

[0018] The preparation method of the all-solid-state electrochromic device of the present invention, such as figure 1 As shown, the device consists of an ITO glass substrate 1, an electrochromic layer 2, an electrolyte layer 3, an ion storage layer 4 and a top layer of ITO 5 in sequence; the preparation method includes the following steps:

[0019] (1) Preparation of electrochromic layer: using clean ITO glass as substrate, metal tungsten as target, argon and oxygen as working gases, electrochromic layer was prepared by reactive magnetron sputtering method; the basic parameters are : The background vacuum is 6*10 -4 Pa, the flow ratio of argon and oxygen is 3:1, the working pressure is 2-3Pa, the sputtering power is DC 220 W, and the substrate temperature is 400°C, deposit once and obtain the first WO 3 Thin-film color-changing layer, when the substrate temperature is 200°C, deposit the second time to obtain the second WO 3 Thin-film color-changing layer, when the substrate...

Embodiment 1

[0027] The preparation method of the all-solid-state electrochromic device in this embodiment, the specific steps of the preparation method are as follows:

[0028] (1) Preparation of electrochromic layer: using clean ITO glass as substrate, metal tungsten as target, argon and oxygen as working gases, electrochromic layer was prepared by reactive magnetron sputtering method; the basic parameters are : The background vacuum is 6*10 -4 Pa, the flow ratio of argon and oxygen is 3:1, the working pressure is 2 3Pa, the sputtering power is DC 220 W, and the substrate temperature is 400°C, deposit once and obtain the first WO 3 Thin-film color-changing layer, when the substrate temperature is 200°C, deposit the second time to obtain the second WO 3 Thin-film color-changing layer, when the substrate temperature is 20°C, deposit the third time to obtain the third WO 3 Thin-film color-changing layer, and then obtain the overall cathodic electrochromic layer 2 with a thickness of 200n...

Embodiment 2

[0033] The preparation method of the all-solid-state electrochromic device in this embodiment, the specific steps of the preparation method are as follows:

[0034] (1) Preparation of electrochromic layer: using clean ITO glass as substrate, metal tungsten as target, argon and oxygen as working gases, electrochromic layer was prepared by reactive magnetron sputtering method; the basic parameters are : The background vacuum is 6*10 -4 Pa, the flow ratio of argon and oxygen is 3:1, the working pressure is 2 Pa, the sputtering power is DC 220 W, and the substrate temperature is 400°C, deposit once and obtain the first WO 3 Thin-film color-changing layer, when the substrate temperature is 200°C, deposit the second time to obtain the second WO 3 Thin-film color-changing layer, when the substrate temperature is 20°C, deposit the third time to obtain the third WO 3 Thin-film color-changing layer, and then obtain the overall cathodic electrochromic layer 2 with a thickness of 600nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com