Patents

Literature

138results about How to "Easy to open mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

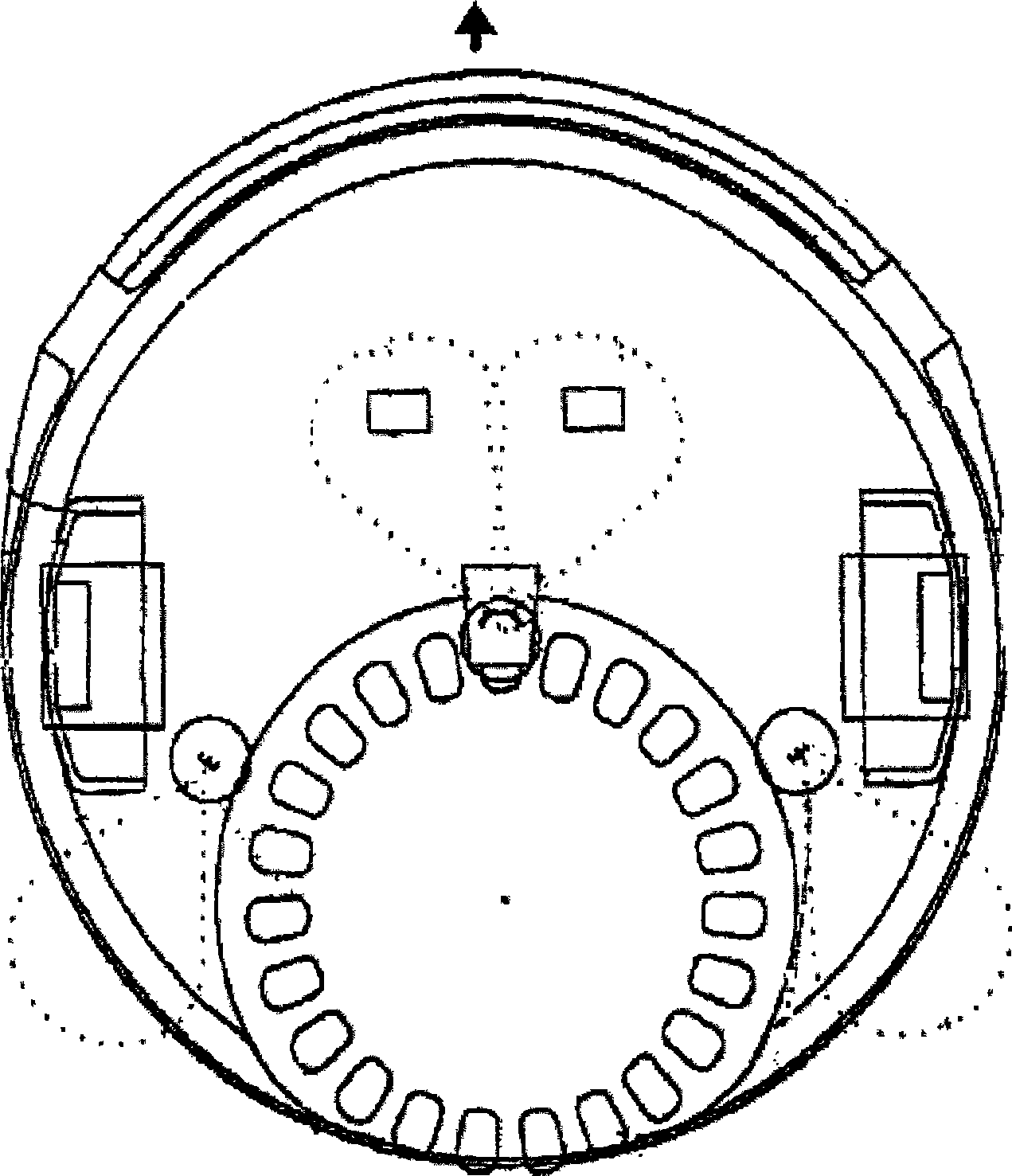

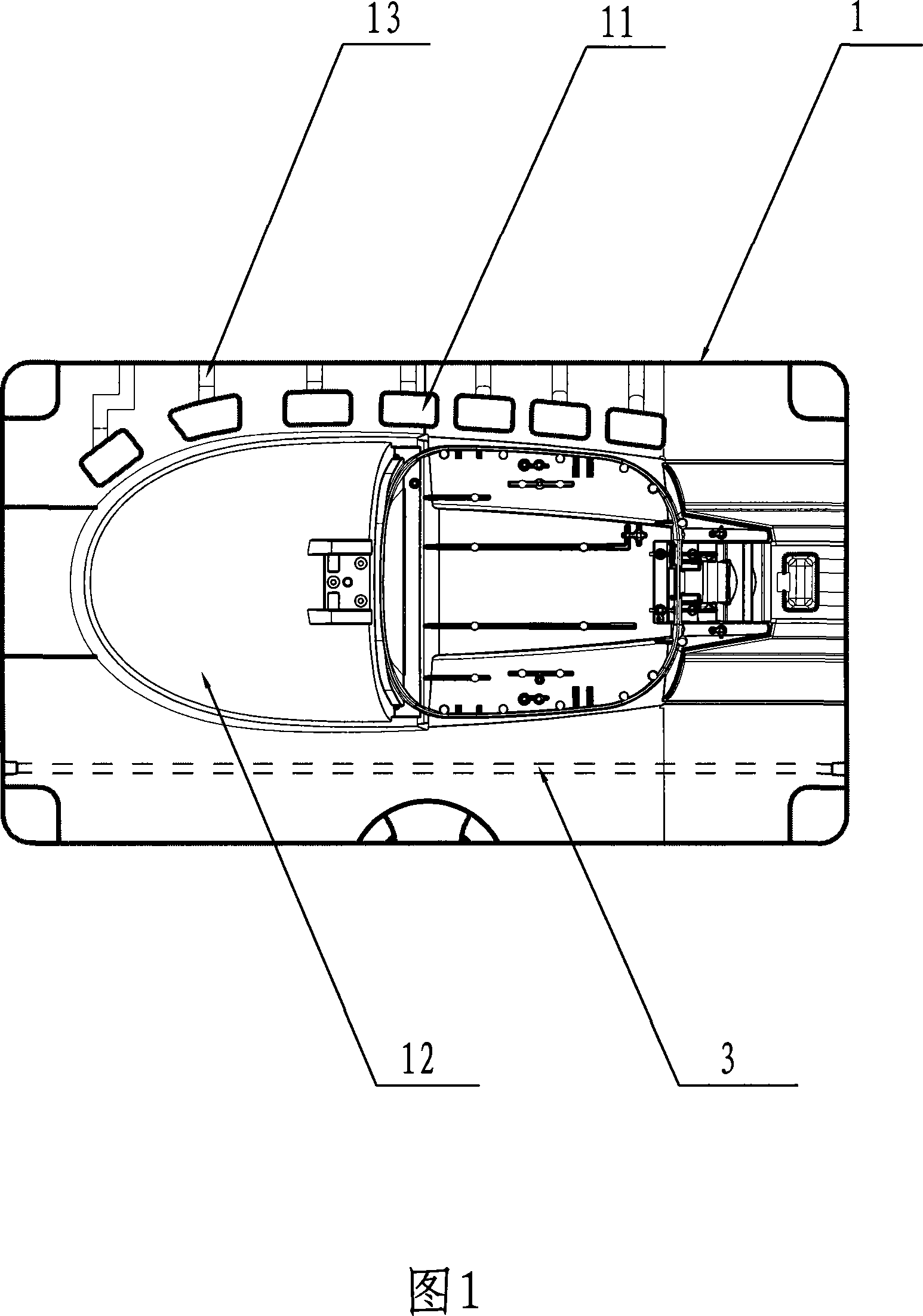

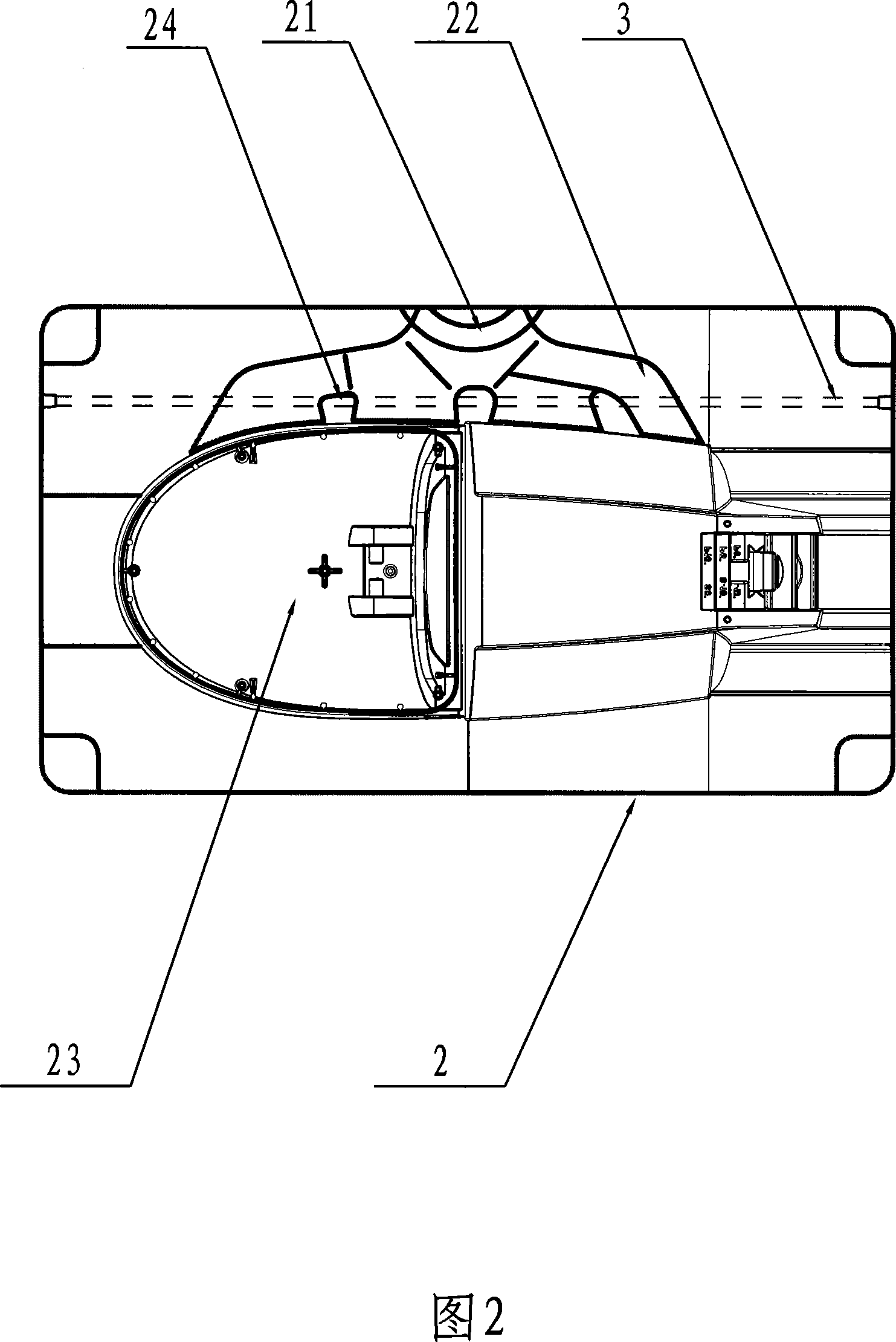

Ground processing system and method for contacting joint of ground processing equipment and charging stand

InactiveCN101375781AEasy to implement docking functionLow costCarpet cleanersFloor cleanersEnergy supplyEngineering

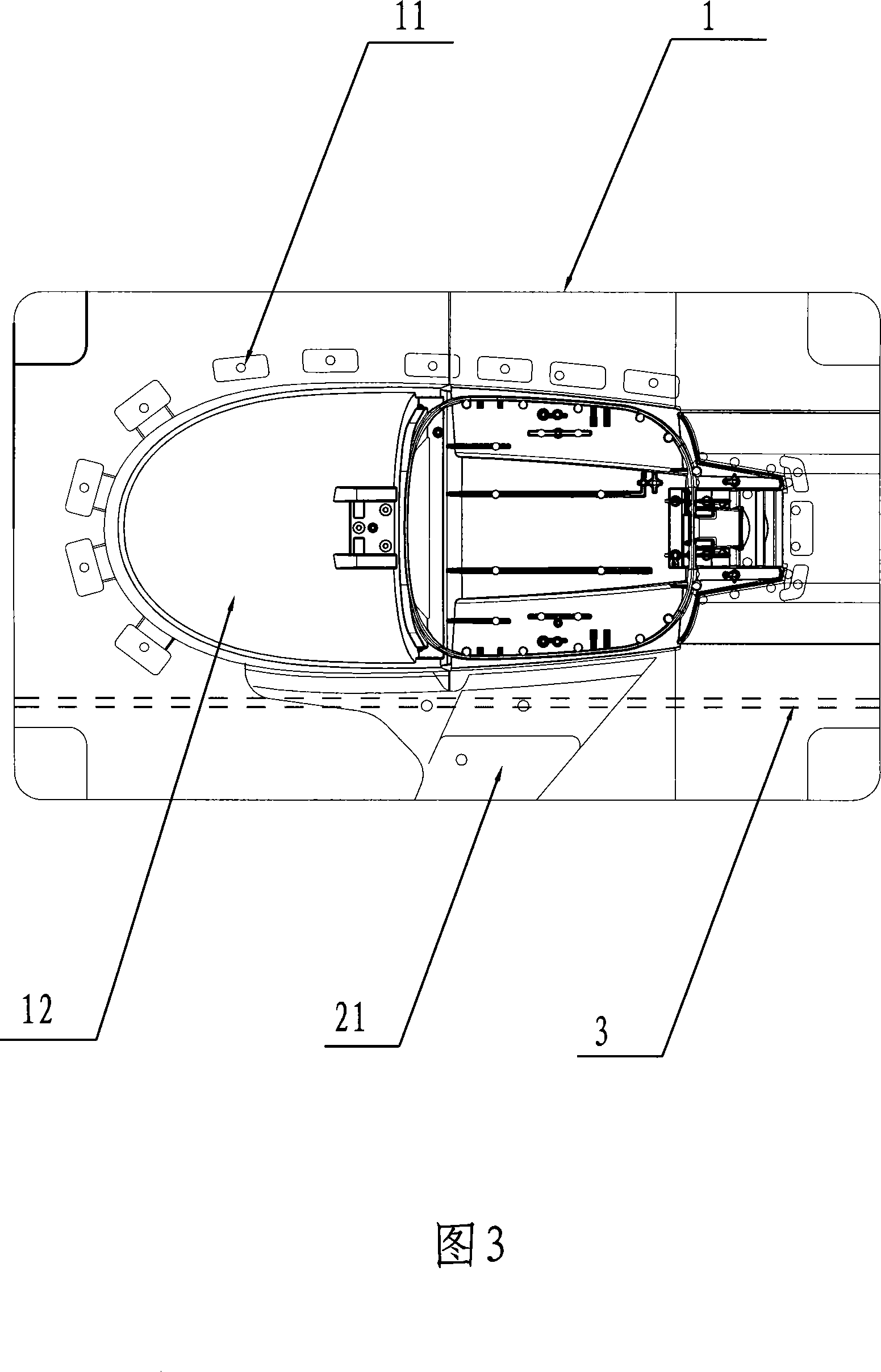

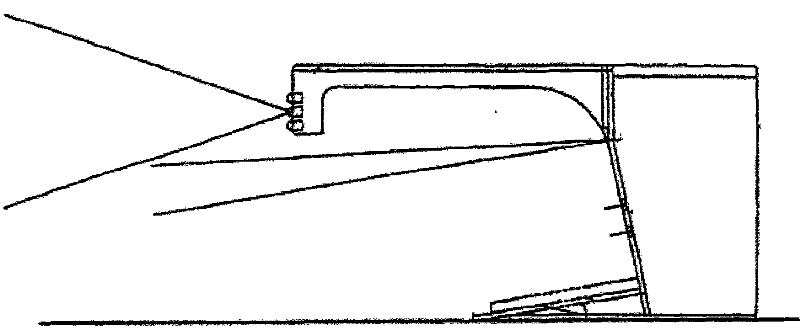

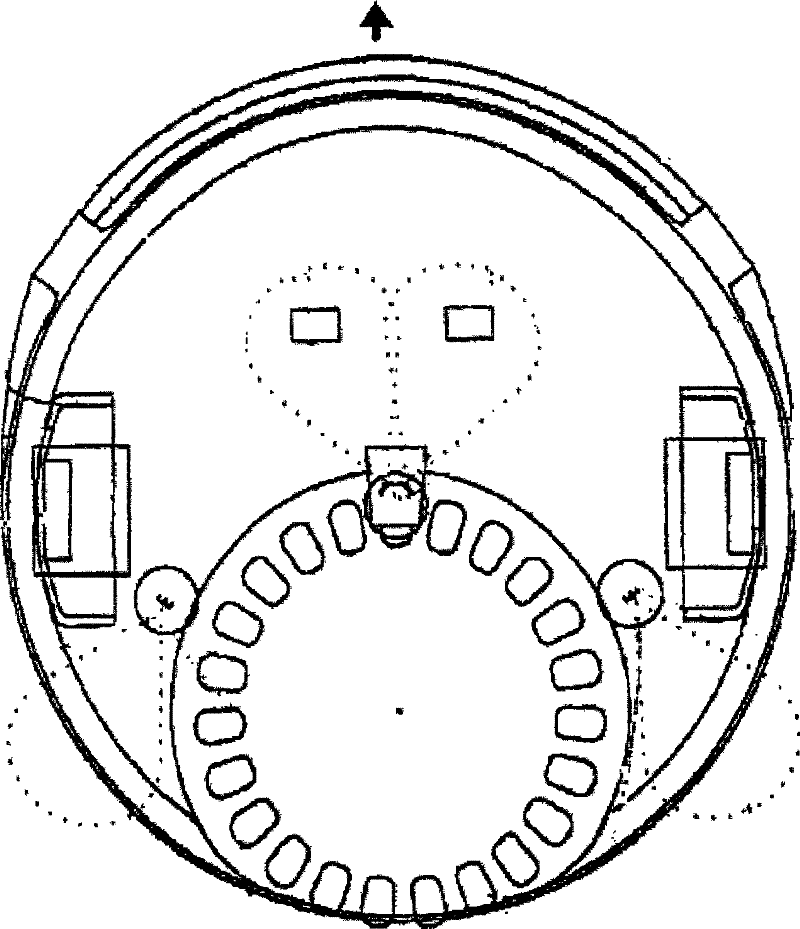

The invention relates to a ground handling system including an automatic moving ground handling device and a charger. The ground handling device is provided with a working mode and a charging mode and includes an energy supply unit and a control unit which can be charged repeatedly. When the electric quantity of the energy supply unit is lower than a preset value, the ground handling device is changed into the charging mode from the working mode through the control unit. The charger is used for charging the energy supply unit and is equipped with a signal emission device. A directional receiver and an omnidirectional receiver for receiving the signals emitted by the signal emission device are arranged at the front end and the top part of the ground handling device, and enable the ground handling device to automatic return to the charger for charging in the charging mode. The invention shortens the time of abutting joint and charging of the ground handling device, thereby prolong the efficient working time thereof and improving the working efficiency.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

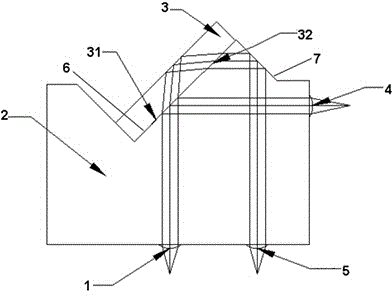

High-speed transmission optical assembly with backlight monitoring function

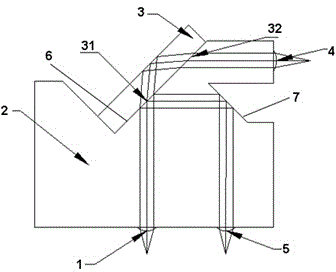

ActiveCN104577708ASimple structureBacklight monitoring implementationLaser detailsLaser output parameters controlVertical-cavity surface-emitting laserPower flow

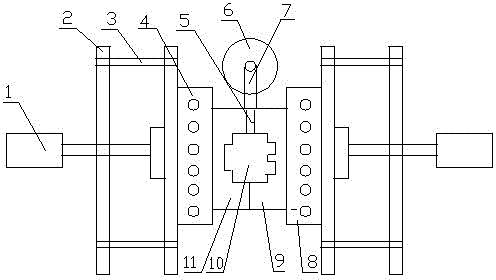

The invention relates to a high-speed transmission optical assembly with the backlight monitoring function. The high-speed transmission optical assembly comprises a VCSEL (Vertical Cavity Surface Emitting Laser), an incidence collimating lens, a lens matrix, a diaphragm, an emergence focusing lens and a backlight monitoring lens, wherein the lens matrix is provided with a first beam turning face and a second beam turning face; the diaphragm is arranged on the first beam turning face; the diaphragm is divided into two half parts; the top half part is an anti-reflection film; the bottom half part is an energy beam splitting film; light emerged from the VCSEL enters the diaphragm through the incidence collimating lens; one part of light is emitted out through the emergence focusing lens after being reflected by the diaphragm; the other part of light enters a diaphragm matrix by refraction of the energy beam splitting film of the diaphragm, enters the second beam turning face after being totally reflected by the other surface of the diaphragm and is emitted out by the backlight monitoring lens after total reflection. The high-speed transmission optical assembly with the backlight monitoring function can effectively solve the problem that a threshold current of the laser cannot be fed back and regulated in real time as power of output light cannot be monitored at any time in the prior art.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

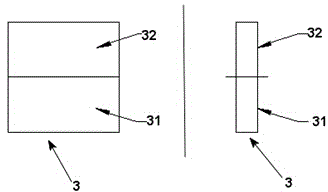

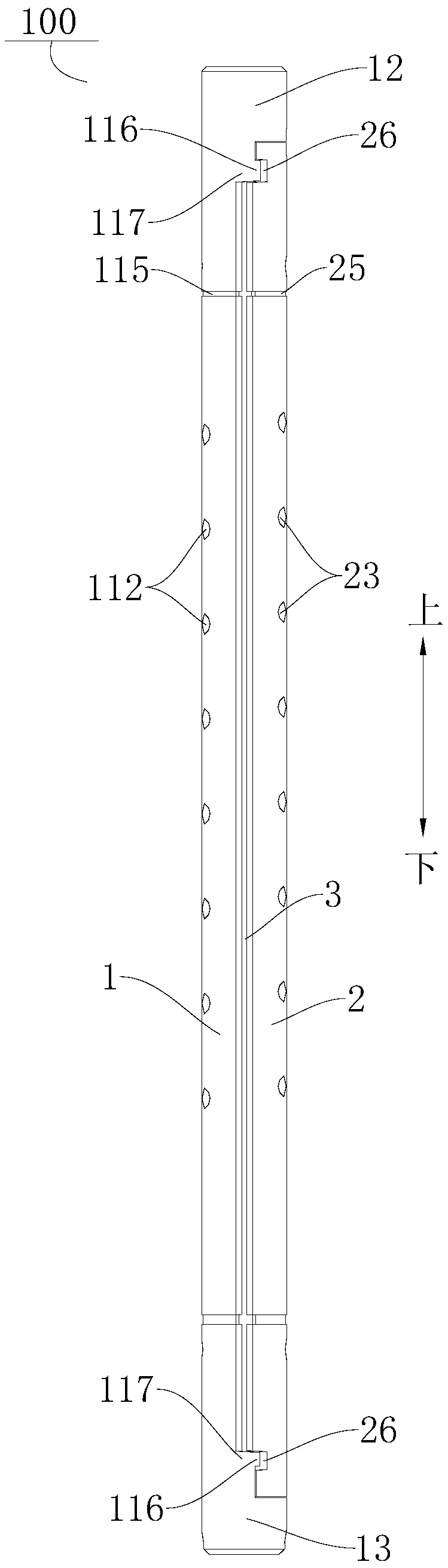

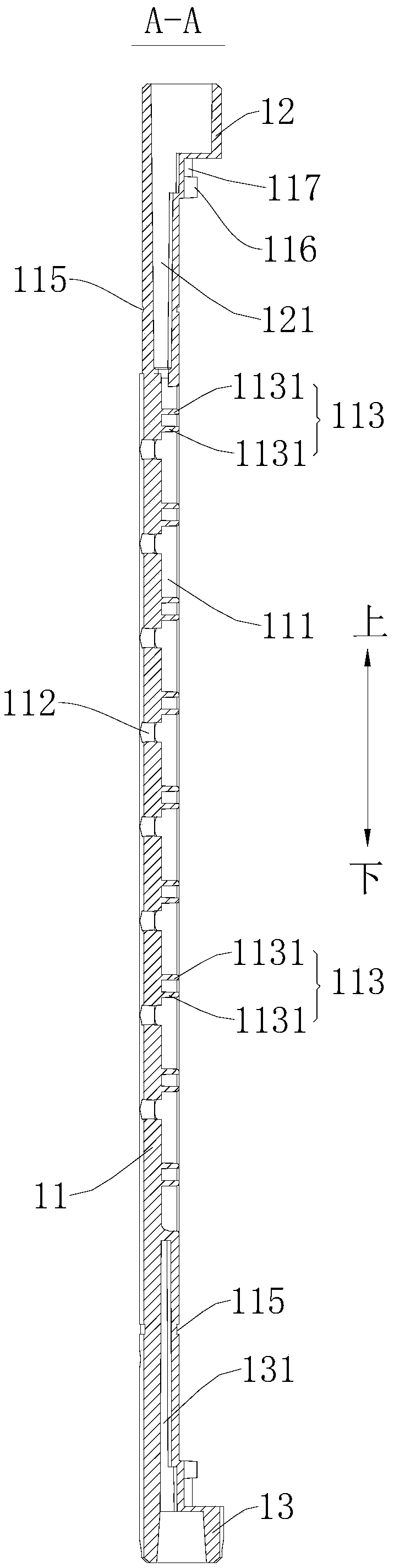

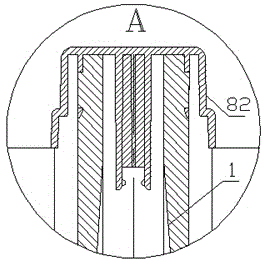

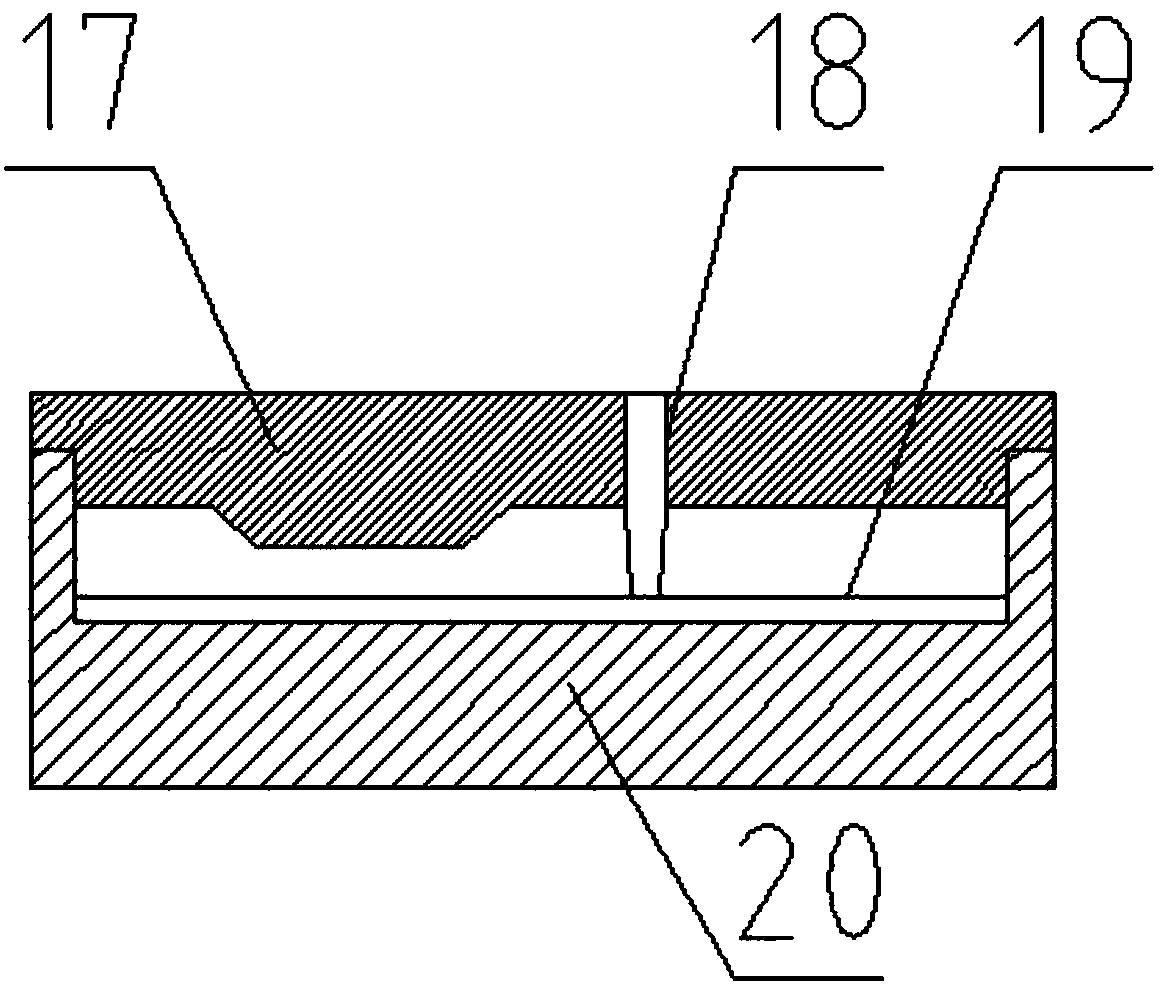

Central tube for filter element and filter device provided with same

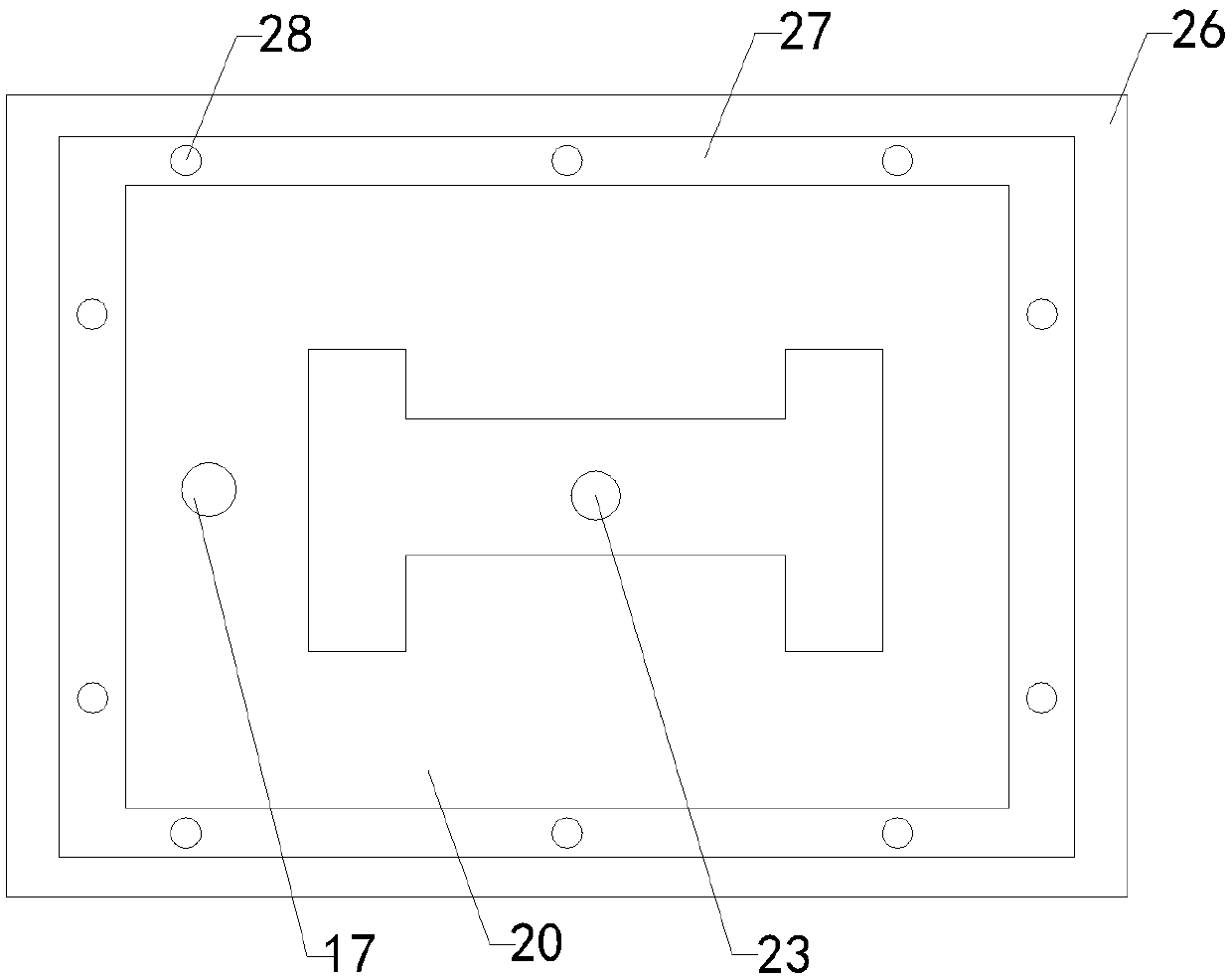

ActiveCN105498544ASimple structureEasy to open moldSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisBatch productionBiomedical engineering

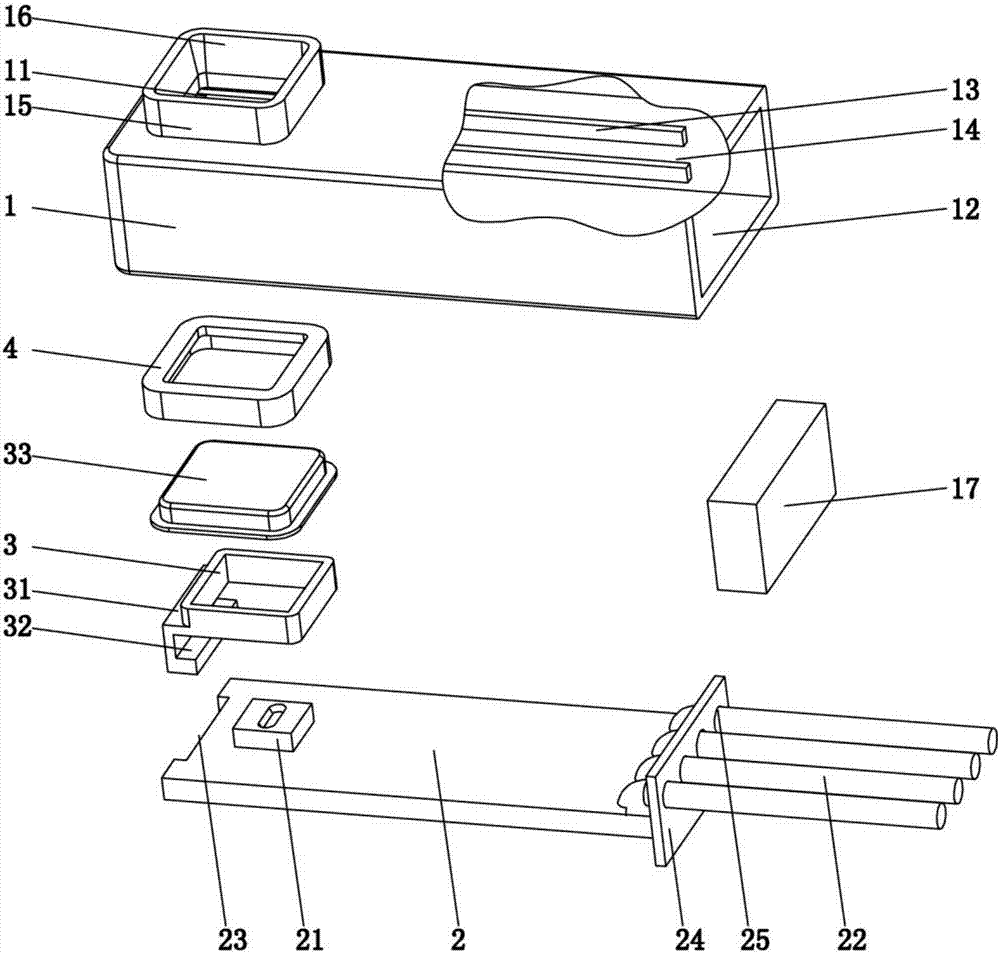

The invention discloses a central tube for a filter element and a filter device provided with the same. The central tube comprises a first half tube, a second half tube and a membrane element, wherein the first half tube has a first matching surface which extends in the axial direction of the first half tube, and a groove is formed in the first matching surface to form a first flow path which extends in the axial direction; the second half tube has a second matching surface which extends in the axial direction of the second half tube, and a groove is formed in the second matching surface to form a second flow path which extends in the axial direction; the first half tube and the second half tube are in butt joint, and the first matching surface and the second matching surface are opposite; the first half tube and the second half tube are matched to form a hollow straight tube; the membrane element is arranged between the first half tube and the second half tube and seals the first flow path and the second flow path. According to the central tube for the filter element, the structure of the central tube can be simplified, mold making of the central tube is convenient, and then batch production of the central tube can be achieved.

Owner:芜湖宇边智能科技有限公司 +1

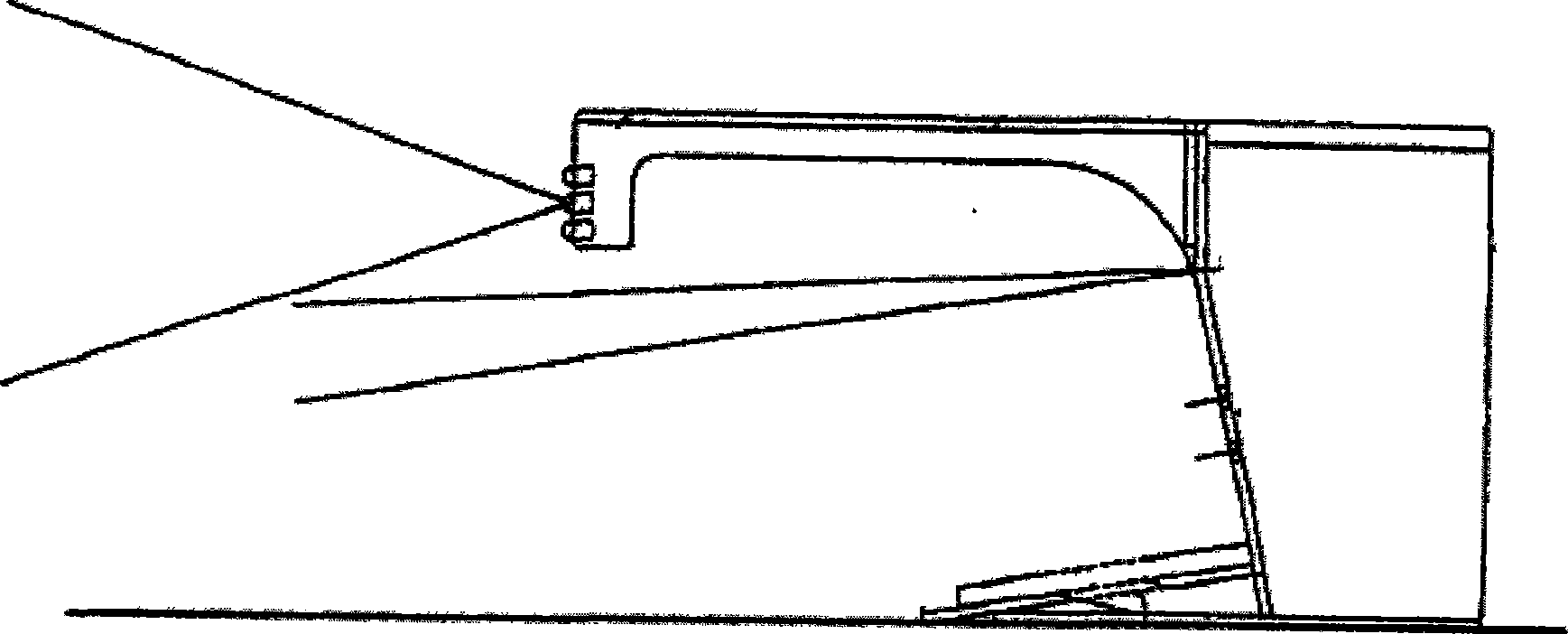

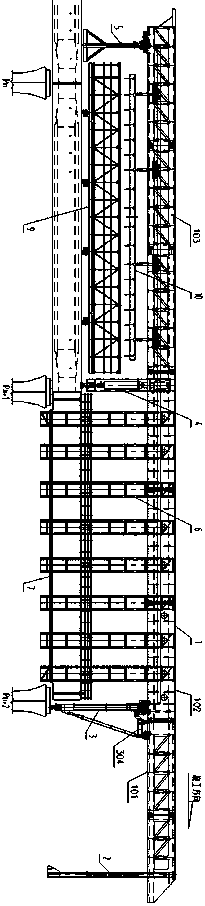

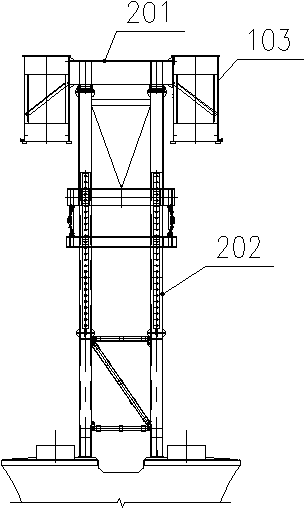

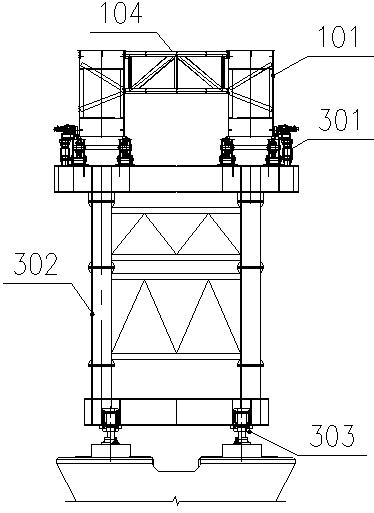

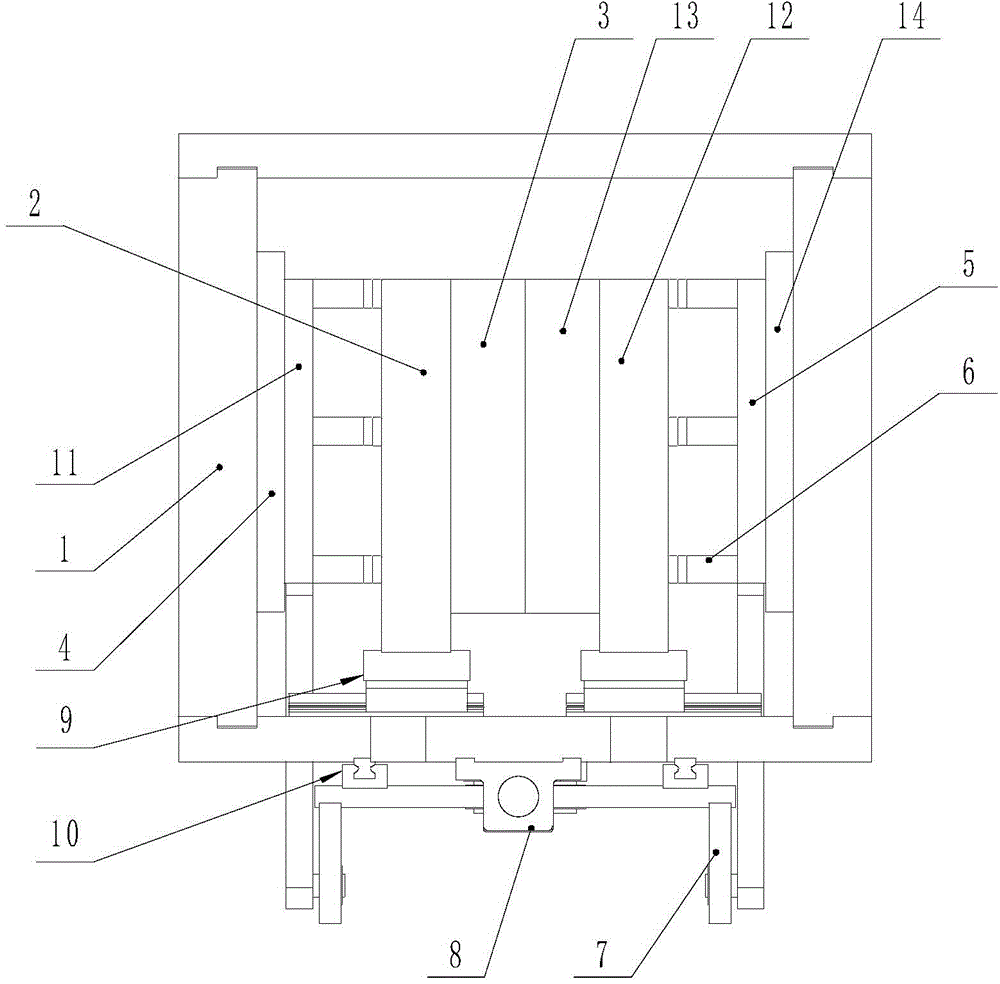

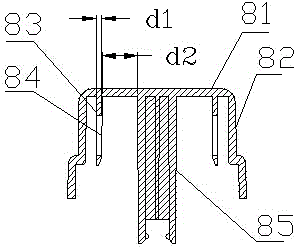

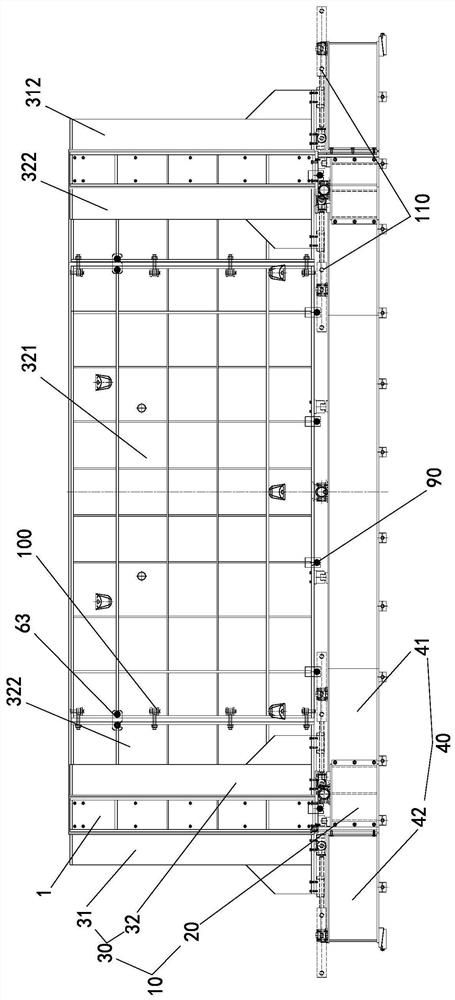

Mobile formwork bridge fabrication machine and construction method for cast-in-situ bridge fabrication

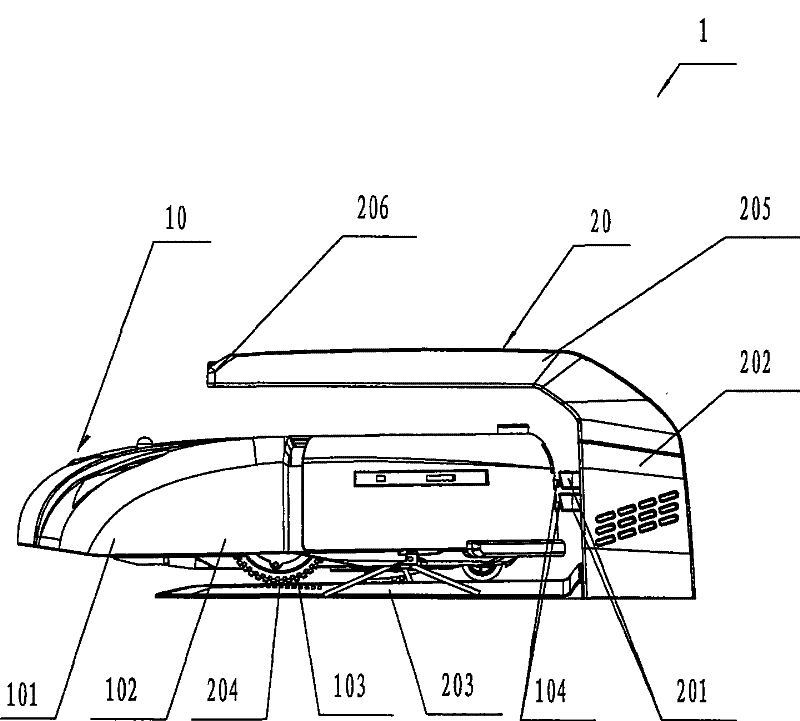

PendingCN108442255AEasy to moveReduce the overall heightBridge erection/assemblyPre stressEngineering

The invention relates to a mobile formwork bridge fabrication machine and a construction method for cast-in-situ bridge fabrication. According to the mobile formwork bridge fabrication machine, a front auxiliary supporting leg is arranged at the front end of a front guide beam, a rear auxiliary supporting leg is arranged on a rear guide beam, and a front main supporting leg and a rear main supporting leg are arranged on a bearing main beam; a rail is arranged below the bearing main beam and the rear guide beam, a reinforcement cage lifting system is arranged on the rail, and multiple sets of hanging outer ribs are arranged at the left and right sides of the bearing main beam and connected with the bearing main beam; the rear auxiliary supporting leg and the rear main supporting leg can upwards rotate and be folded, the heights of the front auxiliary supporting leg and the front main supporting leg can be adjusted, and a reinforcement cage binding mobile jig frame is distributed on thepoured beam surface on the rear portion. According to the construction method for cast-in-situ bridge fabrication, the mobile formwork bridge fabrication machine is adopted; by using the machine and the method, for cast-in-situ bridge fabrication, the processes of reinforcement binding, inner mold splicing and prestressed reinforcement pipe installation and the processes of concrete pouring, maintenance and tension of bridges can be conducted synchronously, and the construction period of cast-in-situ bridge fabrication can be effectively shortened.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH +1

Bottle blowing device for bottle blowing machine

The invention discloses a bottle blowing device for a bottle blowing machine. The device comprises a mold frame, a left bottle body mold, a right bottle body mold, a left mold base, a right mold base, a left mold lock plate, a right mold lock plate, and a driving seat. The left and right mold lock plates are vertically and slidably arranged on the mold frame; mold lock blocks at intervals are arranged on the left and the right mold lock plates; the left and right mold seats are provided with embedding holes; the driving seat is driven by a power device; the driving seat is provided with a left mold opening and closing curve groove, a right mold opening and closing curve groove, a left mold lock curve groove and a right mold lock curve groove; the left and right mold seats are respectively provided with a mold opening and closing cooperation part constrained in the left mold opening and closing curve groove, the right mold opening and closing curve groove; and the left and right mold lock plates are respectively provided with a mold lock cooperation part constrained in the left and right mold lock curve grooves. The bottle blowing device uses the driving seat can be realize mold opening and closing and mold locking of the left and right bottle molds at the same time; and the whole bottle blowing action process reduces the number of cylinders, sensors and electromagnetic valves, saves cost, reduces the failure rate and repair, and is also very convenient.

Owner:JIANGSU FEIGE YOULIAN MACHIMERY

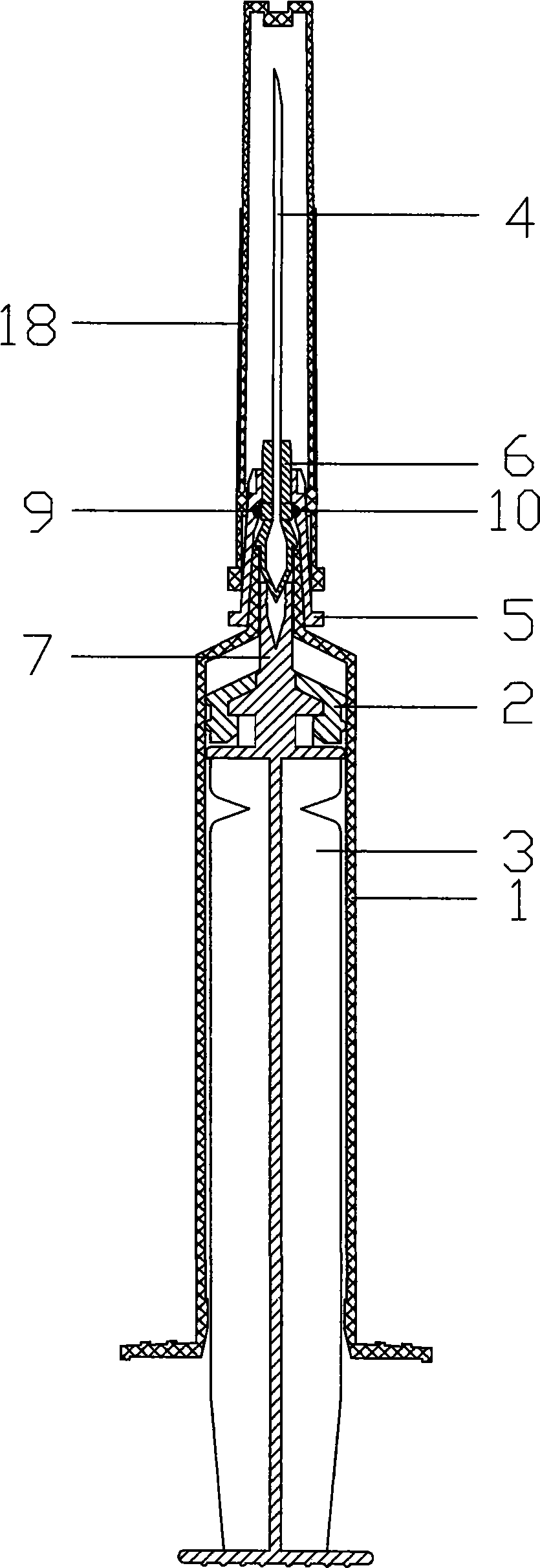

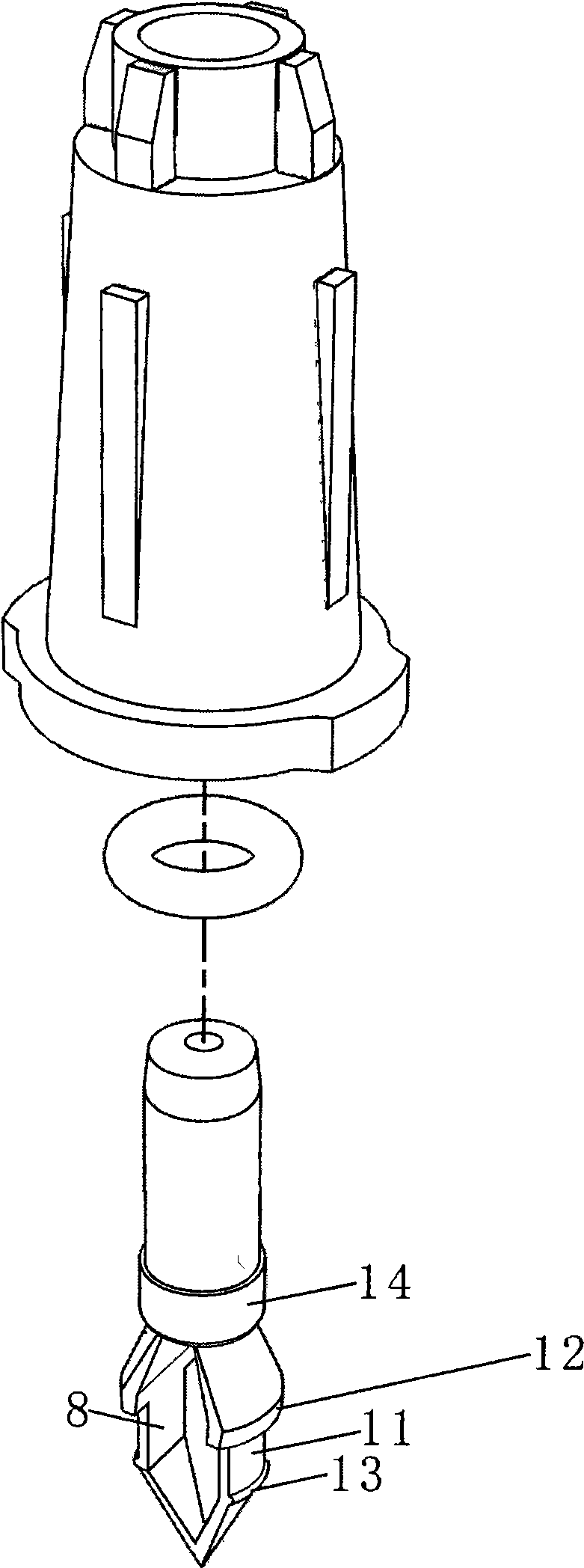

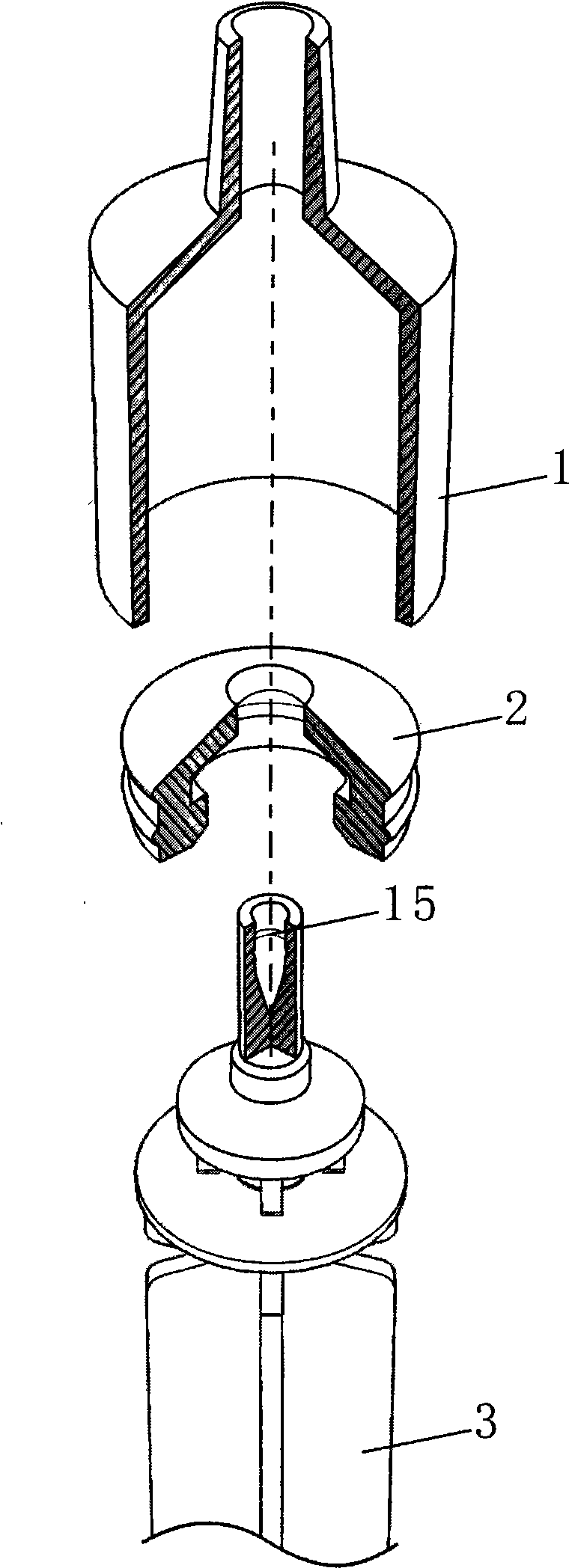

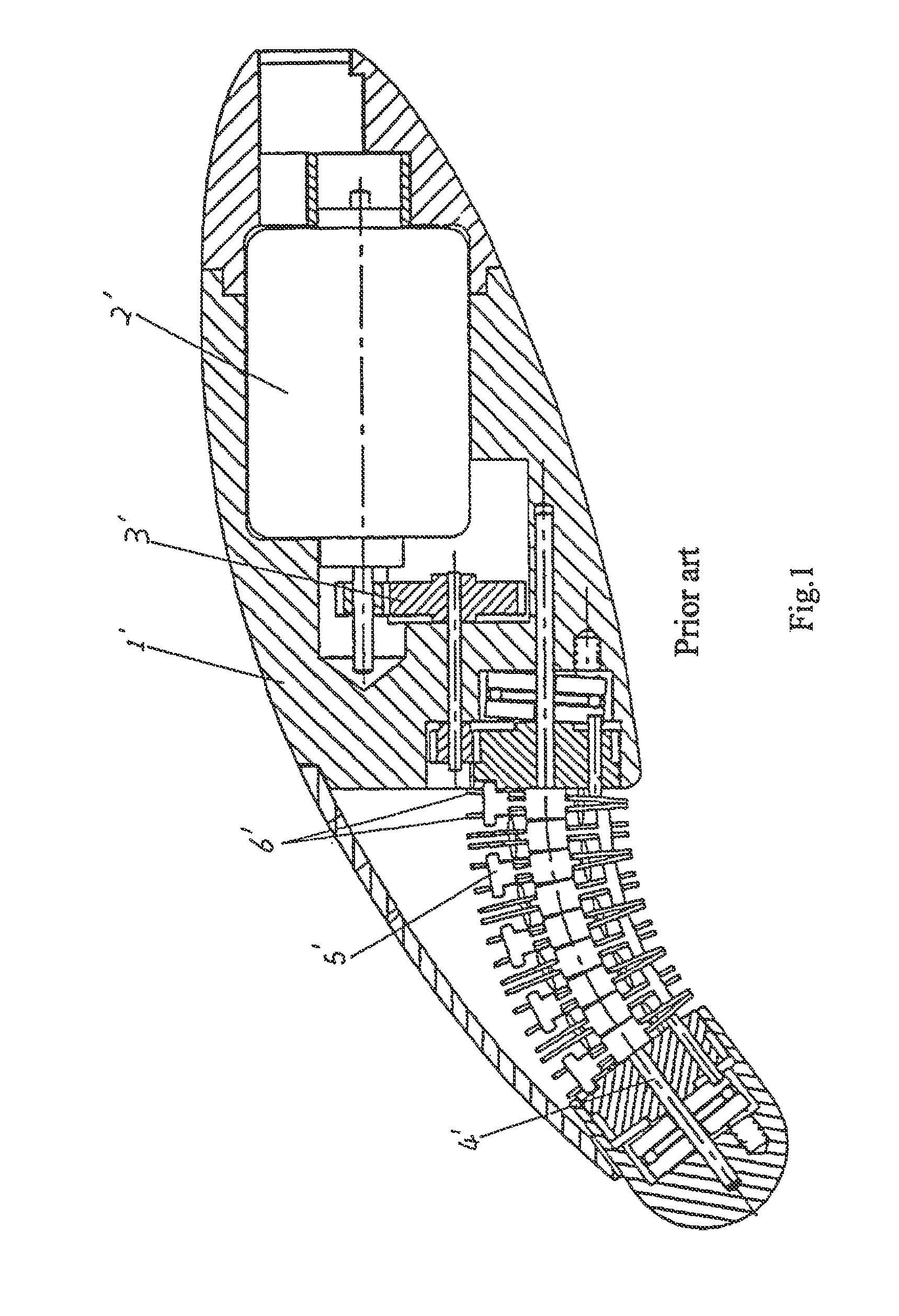

Safety syringe

InactiveCN101530645AOvercome the disadvantage of only being able to withstand a thrust of about 30 NewtonsEasy to open moldInfusion syringesInfusion needlesPull forcePlastic materials

The invention discloses a safety syringe, which is characterized in that: a needle head is formed by sheathing and connecting an outer needle bed and an inner needle bed. The end of a core bar is provided with a return column which protrudes out of the surface of a capsule. The upper part of the inner needle bed is in cylinder shape and the lower part is composed of fins. One end of the fin is fixed at the end of the cylinder shape, while the other end of the fin synthesizes a taper structure which can be in closed state or opening state. The applied drawing force is less than 15N when a product pulls back the core bar and also than the drawing force needed by a traditional safe structure syringe. A sealing ring arranged between the inner and the outer needle bed causes good sealing property at the part of the needle head. The product is applicable to tropical and frigid zones, the rest parts adopt full plastic material except a needle tube and all parts are convenient in die sinking. The syringe can realize full automatic part assembly, is simple and practical in the product structure, high in the stability of a safe locking structure and has good market prospect.

Owner:张宇圣

Mold for producing lamp frame reflecting body of selenium lamp

The invention in particular relates to a die for producing a reflecting body of a lamp frame of a selenium lamp. The invention comprises a terrace die and a cavity die, wherein a die cavity convex surface of the reflecting body of the lamp frame of the selenium lamp is arranged on the terrace die, a die cavity concave surface of the reflecting body of the lamp frame of the selenium lamp is arranged on the cavity die, the terrace die and the cavity die are combined to form a die cavity of the reflecting body of the lamp frame of the selenium lamp, a plurality of slag bags are arranged on a die combining surface of the cavity die, cooling water slots are arranged on the terrace die and the cavity die, a pourer of the die is arranged on the terrace die, the pourer adopts setback type pourer surface, slots are formed on a portion of the pourer which is communicated to the die cavity of the reflecting body of the lamp frame of the selenium lamp, the slag bags are arranged on one side of the concave surface of the die cavity of the reflecting body of the lamp frame of the selenium lamp, the concave surface is corresponded with the pourer, and a plurality of air discharging slots are arranged on the concave die which is on a portion of the slag bags. Due to the structure, the invention has the advantages of good air discharging, reasonable flow diversions of metal fluid, and the metal fluid can be flowed rapidly into the die cavity of the reflecting body of the lamp frame of the selenium lamp, parting surfaces are reasonable, mold openings are convenient, material explosion can be avoided effectively, and mold opening efficiency can be increased.

Owner:宁波久腾车灯电器有限公司

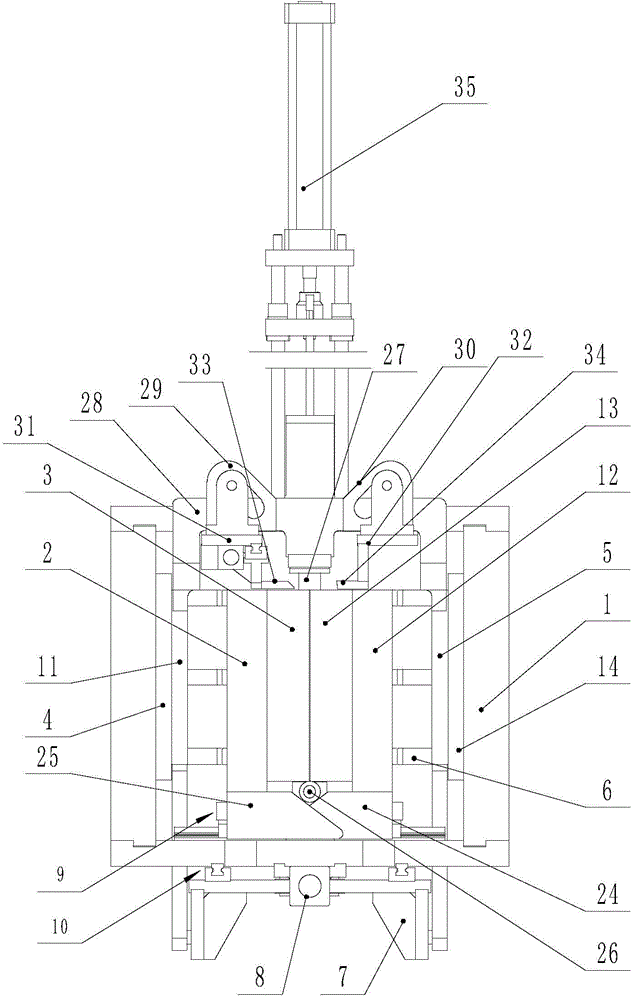

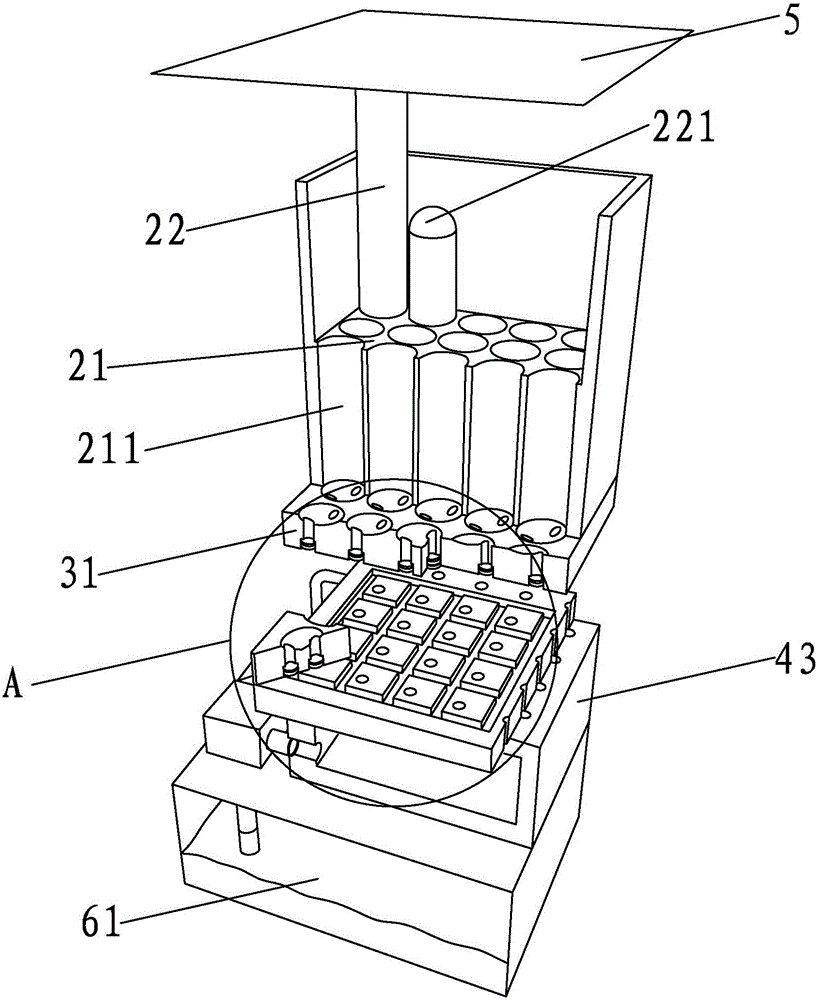

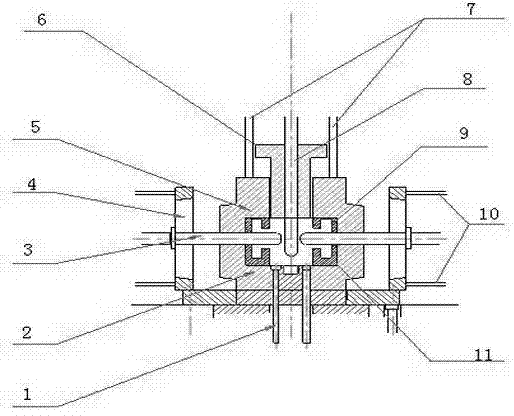

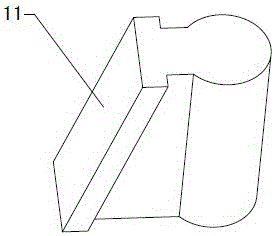

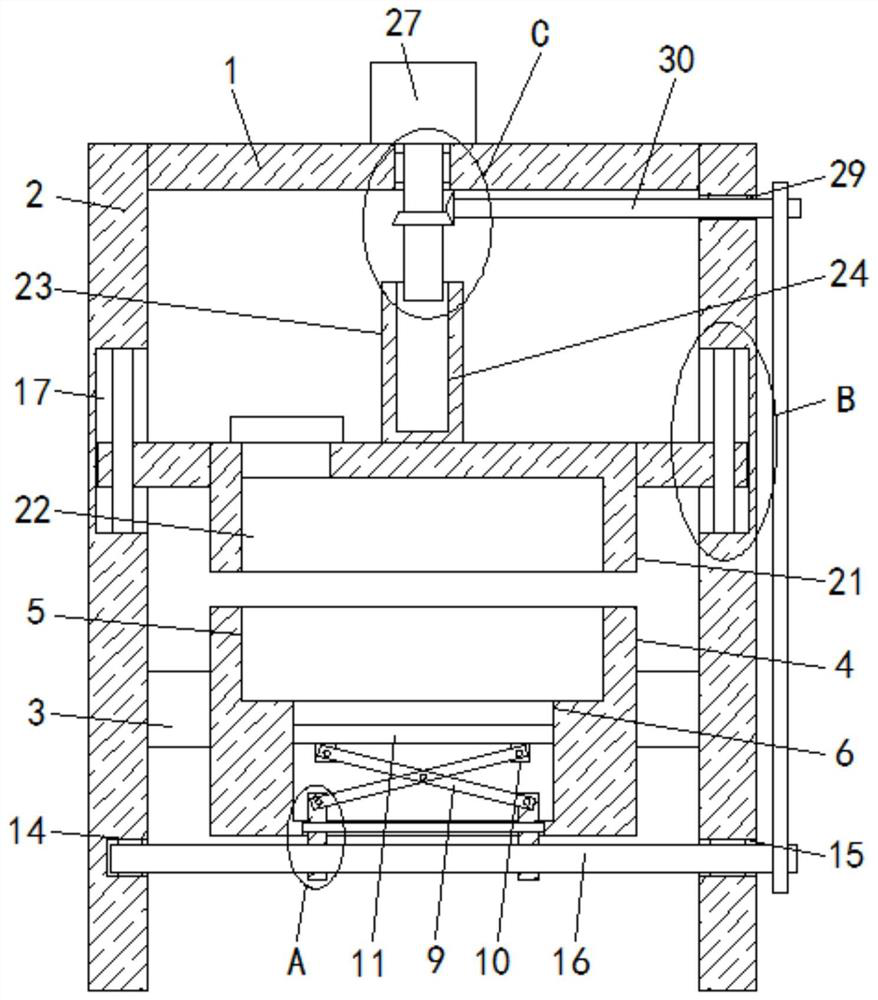

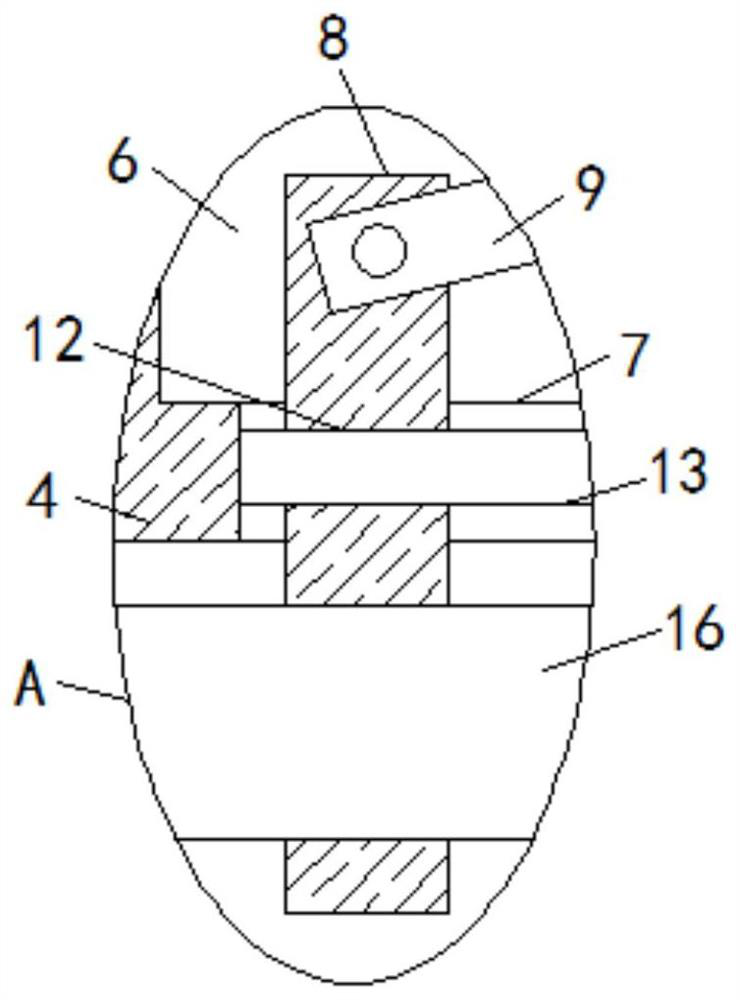

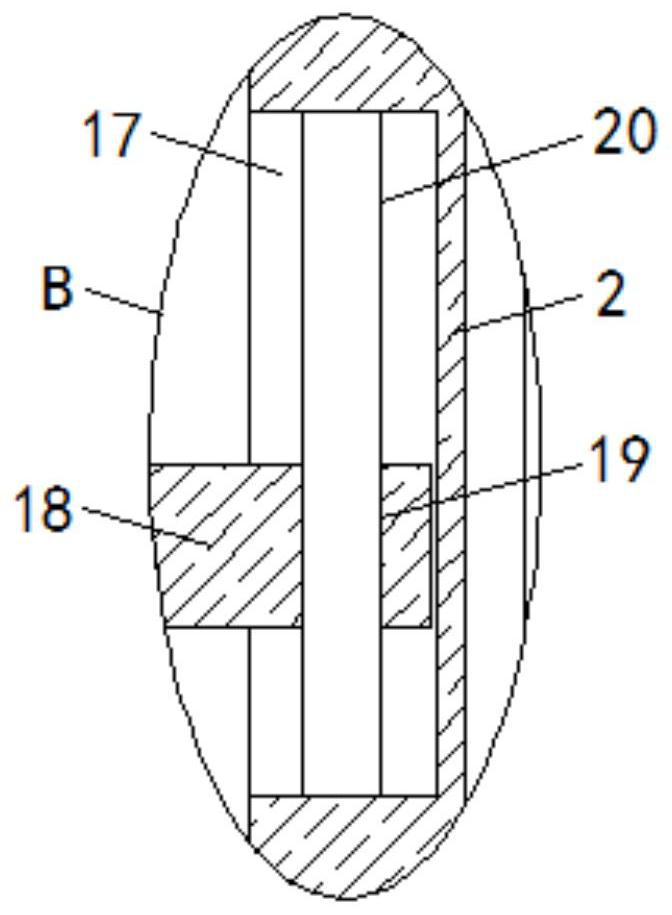

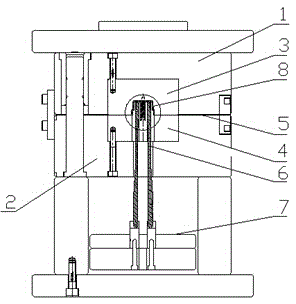

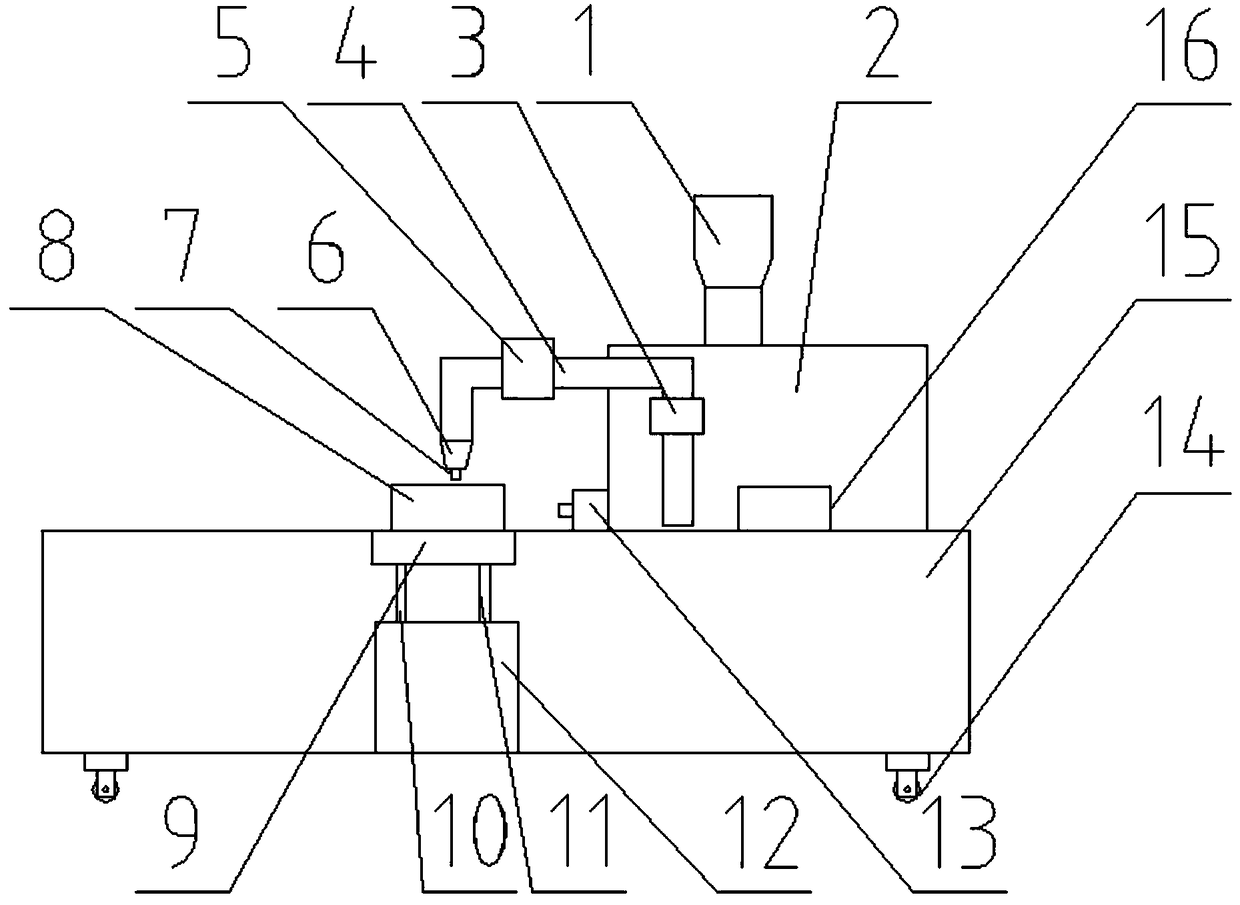

Epoxy resin pressure gel forming machine

InactiveCN103144232AReduce manufacturing costsCompact structureCoils manufactureEpoxyVacuum pressure

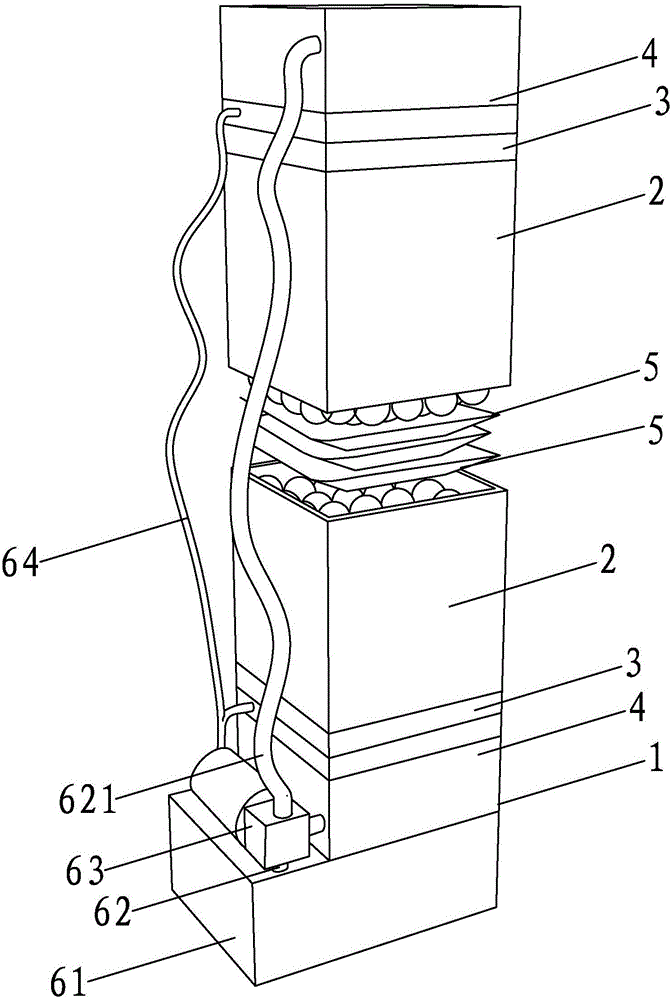

The invention discloses an epoxy resin pressure gel forming machine which comprises a movable rack, a heating plate (4) assembled on the rack and an open-close type mould (8) assembled on the heating plate, wherein an ejecting mechanism capable of withdrawing a voltage transformer blank body (9) in the mould is arranged on the rack, the mould is connected with a vacuum stirring tank (6) through a gel injecting hole (5) and a gel injecting pipe (7), and gel is injected into the mould by the vacuum stirring tank when the vacuum pressure is 8kg / cm<3> (about 0.8MPa). Compared with an existing epoxy resin pressure gel forming device, the epoxy resin pressure gel forming machine disclosed by the invention has the advantages that the machine is compact in structure, small in floor space, and convenient to operate; the machine is quick to heat, short in heating time, and short in curing time, so that the manufacture efficiency can be improved; a set of mould can be recycled, so that the manufacture cost of the mould can be saved, and the cost can be reduced; and the gel is convenient to inject, and the mould is convenient to open, so that the machine is small in labor intensity, and environment-friendly in working environment.

Owner:林小平 +1

Temperature and humidity sensor

InactiveCN106871973AReduce dosageReasonable structureMeasurement apparatus housingsInterference fitEngineering

The invention relates to the technical field of temperature and humidity sensing devices and specifically relates to a temperature and humidity sensor. The temperature and humidity sensor comprises a hollow packaging shell, a PCB board is arranged in the packaging shell, a front part of the PCB board is provided with a humidity sensitive chip, a panel of the packaging shell is provided with a detection window, and the PCB board is provided with a shaping frame and a setting frame that have ring sleeve structures; the shaping frame, the setting frame and the detection window are orderly mounted in a nested manner with interference fits being formed among the same; the shaping frame is arranged at periphery of the humidity sensitive chip in an annular manner and is connected with the PCB board in a matched manner, an upper port of the shaping frame is covered with a filter membrane, and an edge of the filter membrane is clamped between the shaping frame and the setting frame; the temperature and humidity sensor is reasonable in structure, sealant applied on packaging openings can be reduced via use of an inner cavity of a partitioned packaging shell of a threading plate,, the PCB board is fixed via a guiding groove in the packaging shell, the shaping frame and the setting frame cooperate with the filter membrane to fulfill sealing protection around the humidity sensitive chip, packaging efficiency and effects can be improved, and normal state steam outflow is formed on the detection window; protection performance, sensitivity and reliability are further improved.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

Rapid die

The invention discloses a rapid die. The rapid die comprises a closed die outer shell, one or more die units, a die formation control device and an oil supplying device. Each die unit comprises a die combination module, a motion control module, an oil inlet / outlet line module and a formation module. Each die combination module comprises a hydraulic oil cylinder and multiple hydraulic ejection rods which are arranged and combined according to a certain array and densely distributed. Each motion control module comprises an oil mass control oil cylinder which communicates with the corresponding hydraulic oil cylinder and is used for controlling the corresponding hydraulic ejection rods to ascend and descend. Each oil inlet / outlet line module comprises oil inlet pipelines used for oil inlet, oil outlet pipelines used for oil drainage and a high pressure oil tank used for supplying oil. The oil supplying device comprises an oil supplying pool, an oil supplying pipeline and a high pressure oil pump mounted on the oil supplying pipeline. By means of the rapid die, a die with a corresponding cavity can be combined directly and rapidly; by means of the combined die, injection molding parts or stamping parts can be produced rapidly; it is convenient to open the die and release the parts from the die; and the rapid die is applicable to mass production.

Owner:福建省加成信息技术有限公司

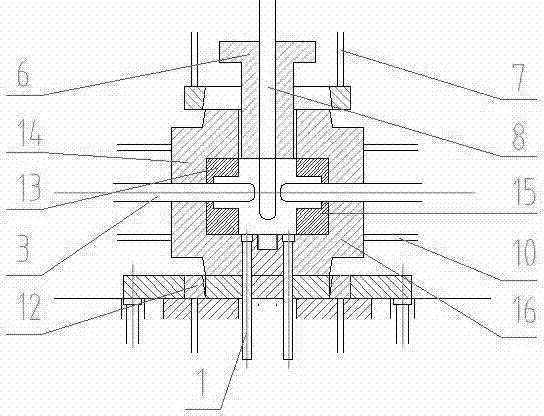

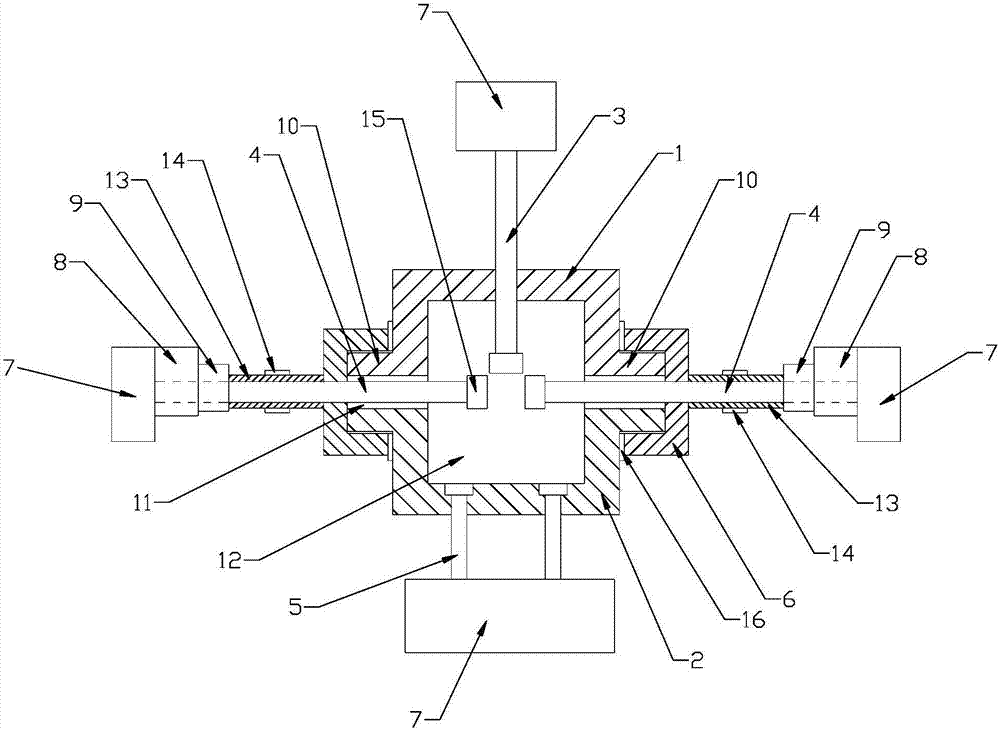

Vertical demoulding method of multidirectional die forging hydraulic press

InactiveCN104841825AReliable closureReduce manufacturing costMetal-working apparatusEngineeringEnergy consumption

The invention relates to a vertical demoulding method of a multidirectional die forging hydraulic press. Protruding portions of a left mould sleeve and a right mould sleeve and the inner side wall of a mould locking ring cooperate with each other and are wedge-shaped. By adopting the vertical demoulding method, a demoulding face can be reliably closed during forging, a mould closing force dose not needed to be taken into account when the hydraulic press works, the energy consumption can be greatly reduced, and a mould can be conveniently opened after forging. A mould locking device is simple in structure, easy to implement and low in manufacturing cost.

Owner:SUZHOU DONGSHENG FORGING

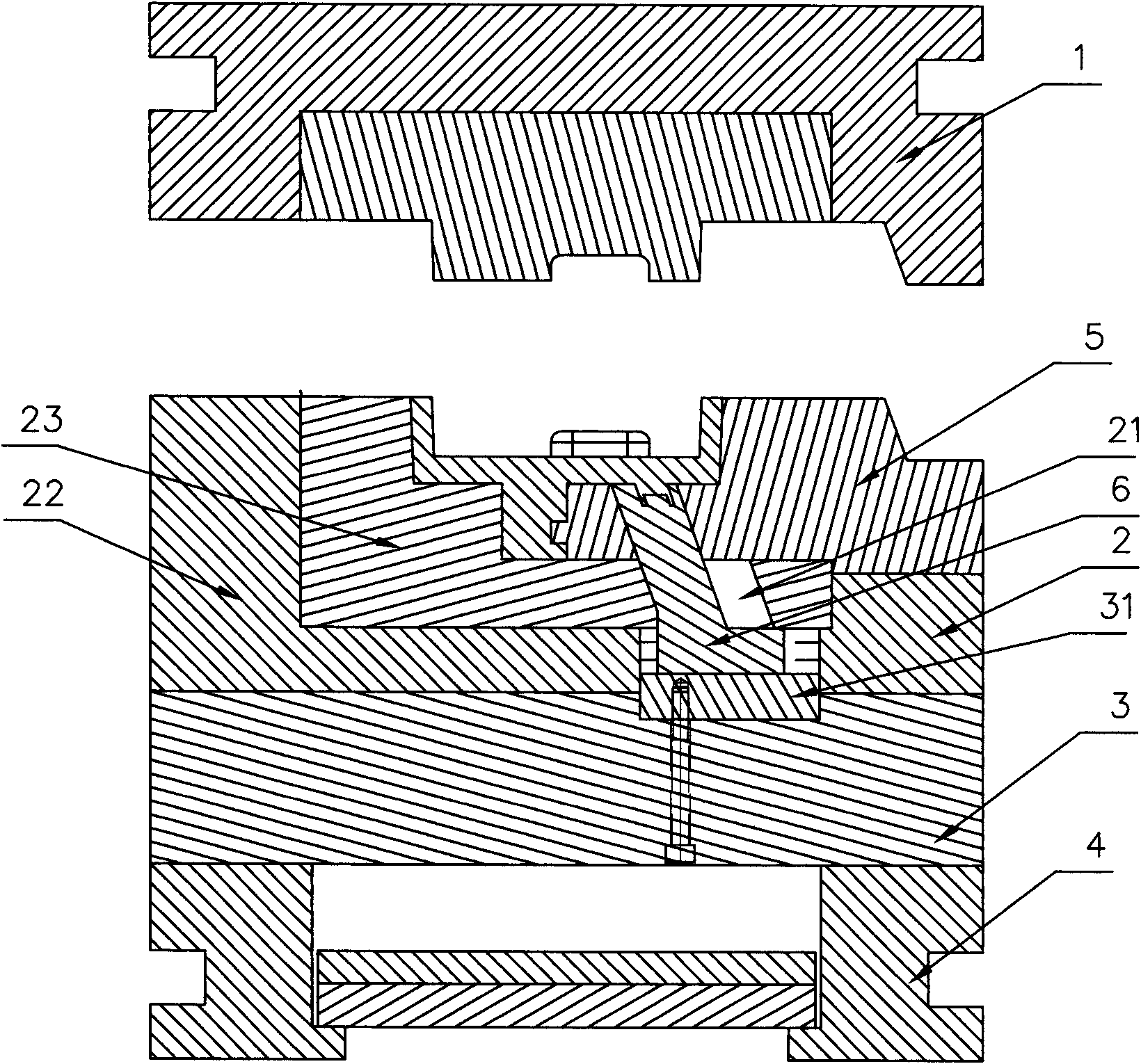

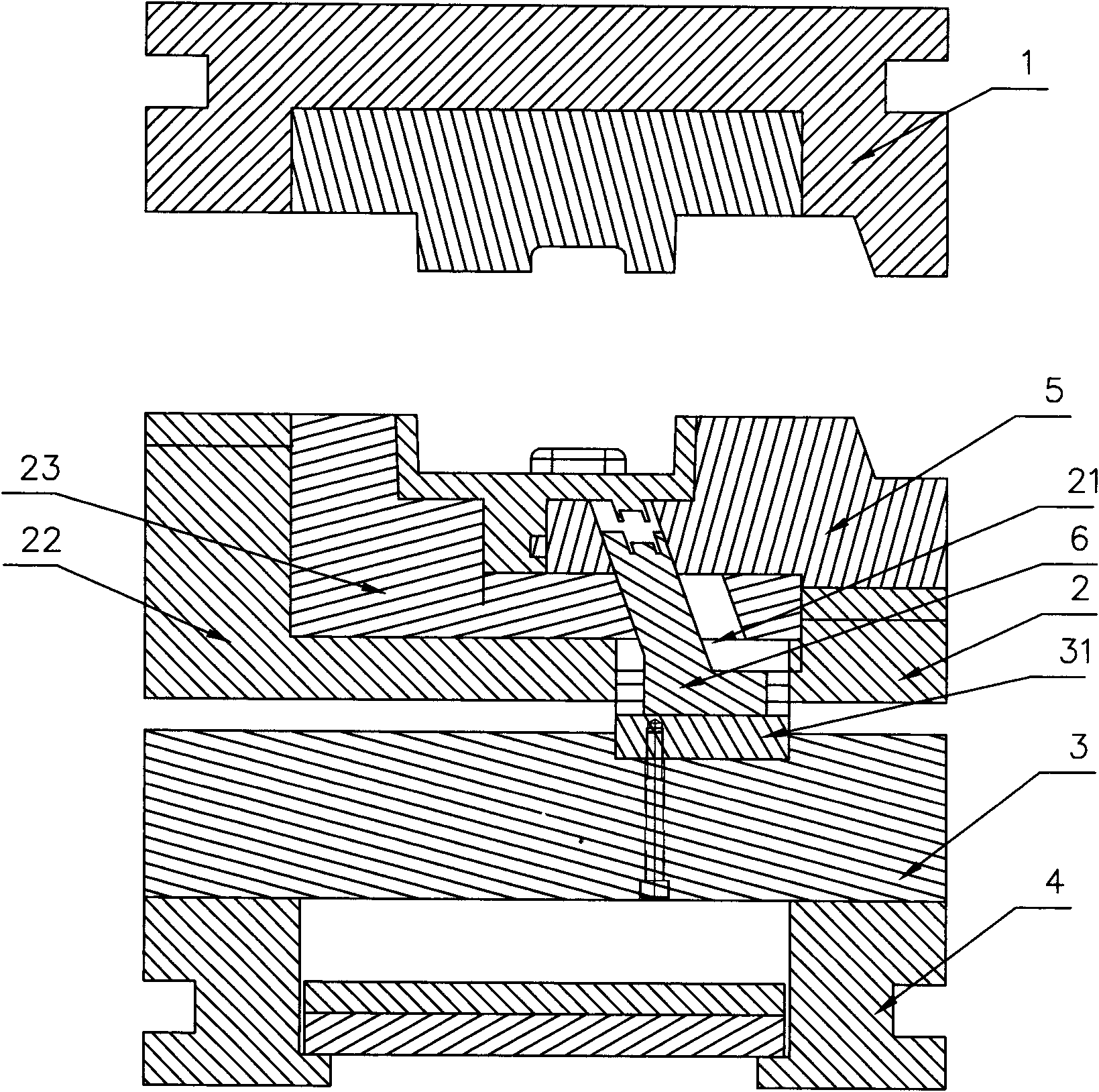

Middle plate type multiple-slider structure die

The invention discloses a middle plate type multiple-slider structure die which comprises an upper die, a middle die, a lower die and die feet, wherein taking the use direction as a reference, the middle die is located right below the upper die in a vertically slidable mode; the lower die is located right above the middle die in a vertically slidable mode and is fixedly arranged above the die feet; a radially slidable side slider is arranged on one side wall of the middle die, and the side slider is provided with a longitudinal through slant hole; a through opening slot is arranged on the lower side wall of the middle die, and the upper end of the opening slot corresponds the position of the slant hole of the side slider; a slider seat is fixedly arranged on the upper side of the lower die, a radially slidable slant slider is arranged on the slider seat, and the upper end of the slant slider passes through the opening slot at the lower end of the middle die and is just accommodated inthe slant hole of the side slider; and the width of the opening slot of the middle die along the tilting direction of the slant slider is greater than a set value of the slant slider. The invention has the advantages of simple structure, convenient die opening, stable die ejection, high machining accuracy and low cost, and is applicable to the molding of complex products with inverse fasteners.

Owner:FUJIA ELECTRONICS KUSN

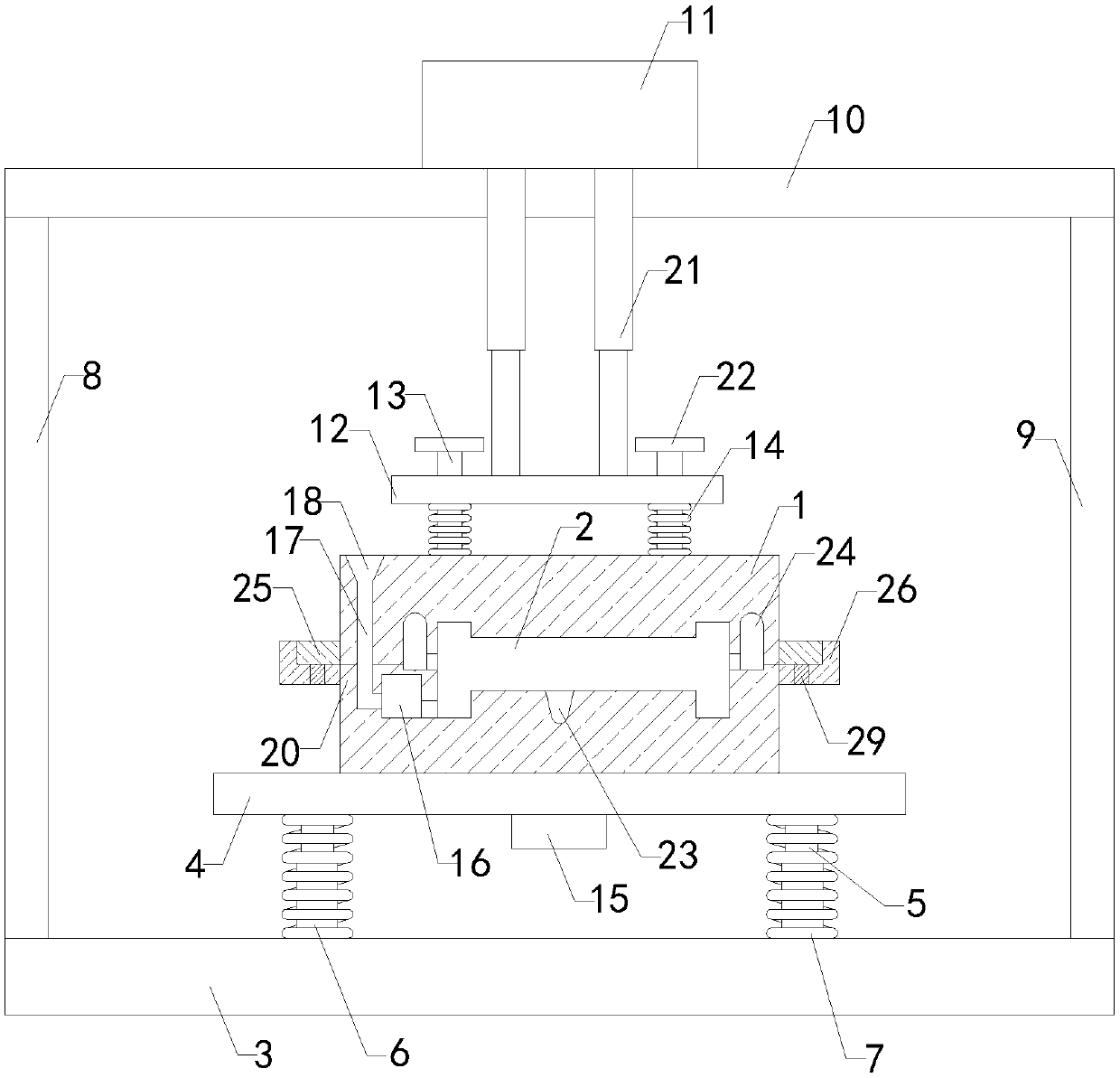

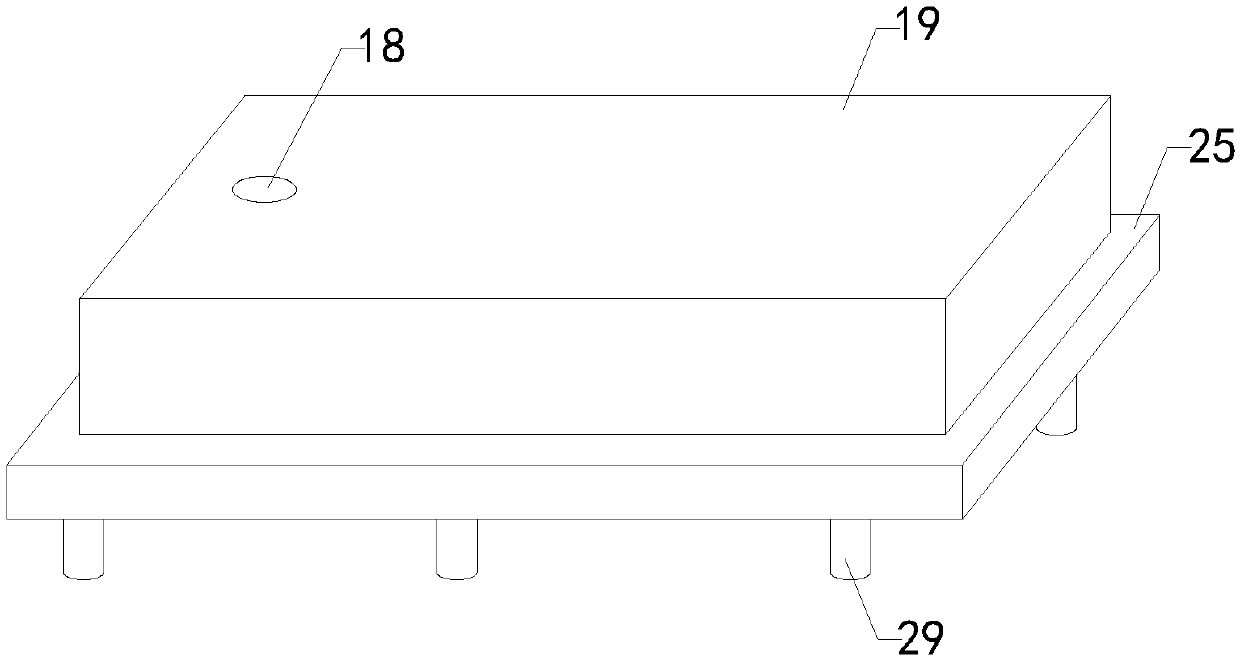

Tool mold for high-speed railway part casting

InactiveCN109622892AAvoid MicrobubblesGuaranteed qualityFoundry mouldsFoundry coresPiston rodMaterials science

The invention relates to the technical field of part casting auxiliary devices, in particular to a tool mold for high-speed railway part casting; and the tool mold can effectively prevent the condition of generation of micro bubbles due to impact force when molten metal is guided into a mold cavity, guarantees the workpiece molding quality, improves the practicability, is convenient to fix and open a mold main body, is convenient to operate, and improves the use reliability. The tool mold comprises the mold main body; the mold cavity is formed in the mold main body; a buffer pack and a pouringgate are arranged in the mold main body; a casting port is formed in the top end of the mold main body; the top end of the pouring gate communicates with the casting port; the bottom end of the pouring gate communicates with the buffer pack; and the buffer pack communicates with the mold cavity. The tool mold further comprises a worktable, a support plate, four sets of guide columns, four sets ofguide sleeves, four sets of support springs, a left support plate, a right support plate, a top plate, a double-shaft cylinder, a connecting plate, four sets of limiting rods, four sets of pressing springs, a vibrator, a piston rod and four sets of limiting plates.

Owner:上海汇警市政工程有限公司

Ground processing system and method for contacting joint of ground processing equipment and charging stand

InactiveCN101375781BEasy to implement docking functionLow costCarpet cleanersFloor cleanersWork periodEnergy supply

The invention relates to a ground handling system including an automatic moving ground handling device and a charger. The ground handling device is provided with a working mode and a charging mode and includes an energy supply unit and a control unit which can be charged repeatedly. When the electric quantity of the energy supply unit is lower than a preset value, the ground handling device is changed into the charging mode from the working mode through the control unit. The charger is used for charging the energy supply unit and is equipped with a signal emission device. A directional receiver and an omnidirectional receiver for receiving the signals emitted by the signal emission device are arranged at the front end and the top part of the ground handling device, and enable the ground handling device to automatic return to the charger for charging in the charging mode. The invention shortens the time of abutting joint and charging of the ground handling device, thereby prolong the efficient working time thereof and improving the working efficiency.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Horizontal demoulding method of multidirectional die forging hydraulic press

InactiveCN104841824AReduce energy consumptionEasy to open moldMetal-working apparatusForgingEnergy consumption

The invention relates to a horizontal demoulding method of a multidirectional die forging hydraulic press. Protruding portions of an upper mould sleeve and a lower mould sleeve and the inner side wall of a mould locking ring cooperate with each other and are wedge-shaped. By adopting the horizontal demoulding method, a demoulding face can be reliably closed during forging, a mould closing force dose not needed to be taken into account when the hydraulic press works, the energy consumption can be greatly reduced, and a mould can be conveniently opened after forging. A mould locking device is simple in structure, easy to implement and low in manufacturing cost.

Owner:SUZHOU DONGSHENG FORGING

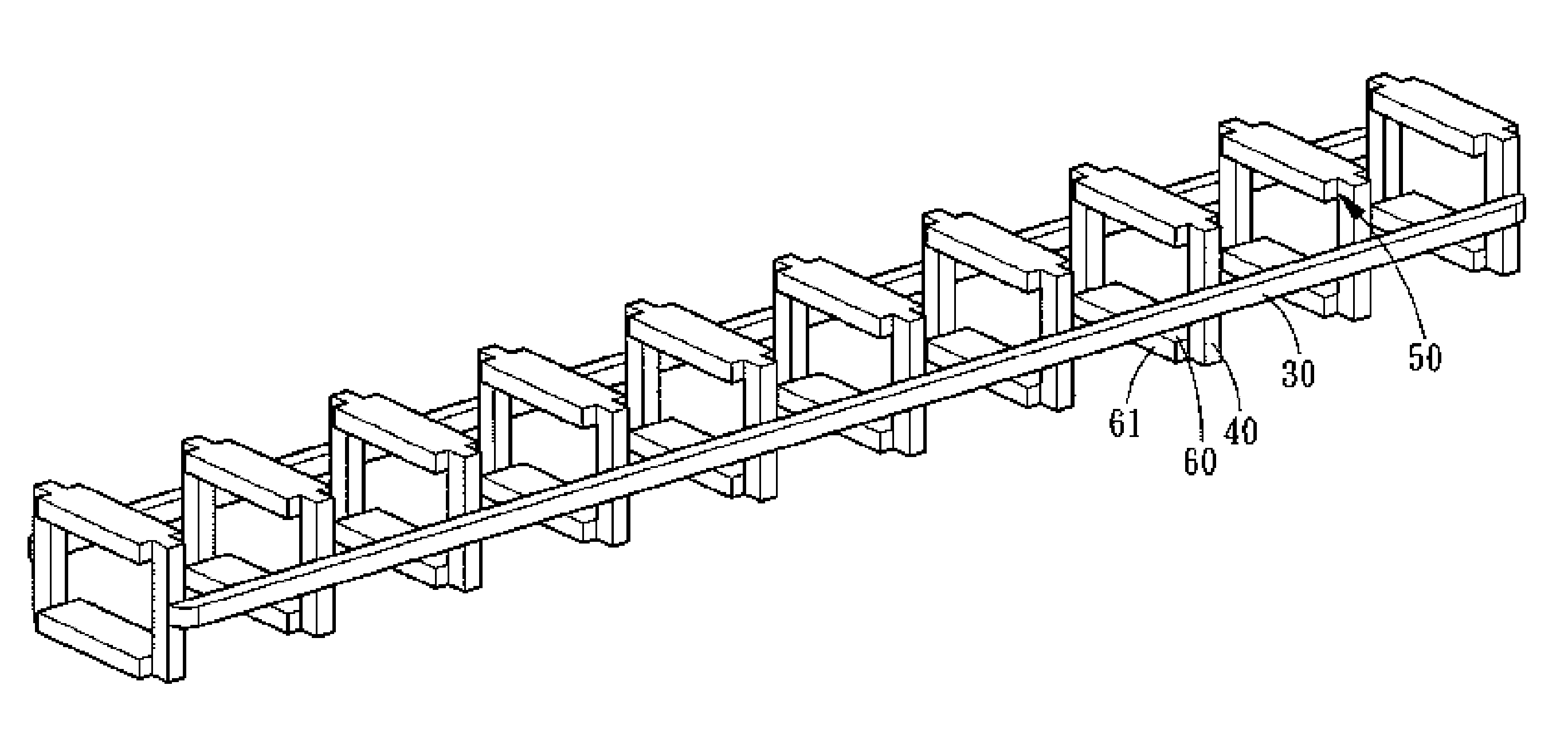

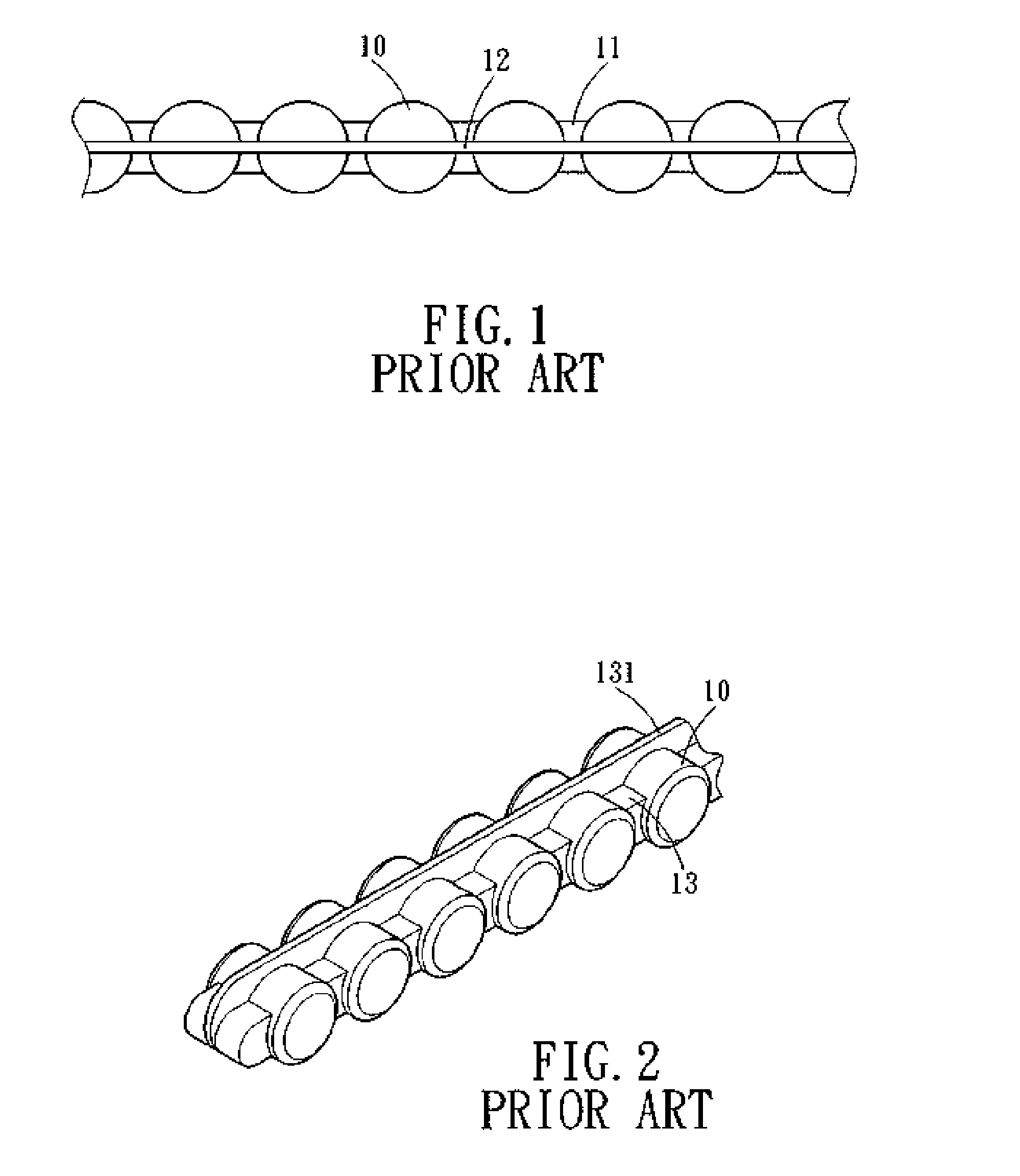

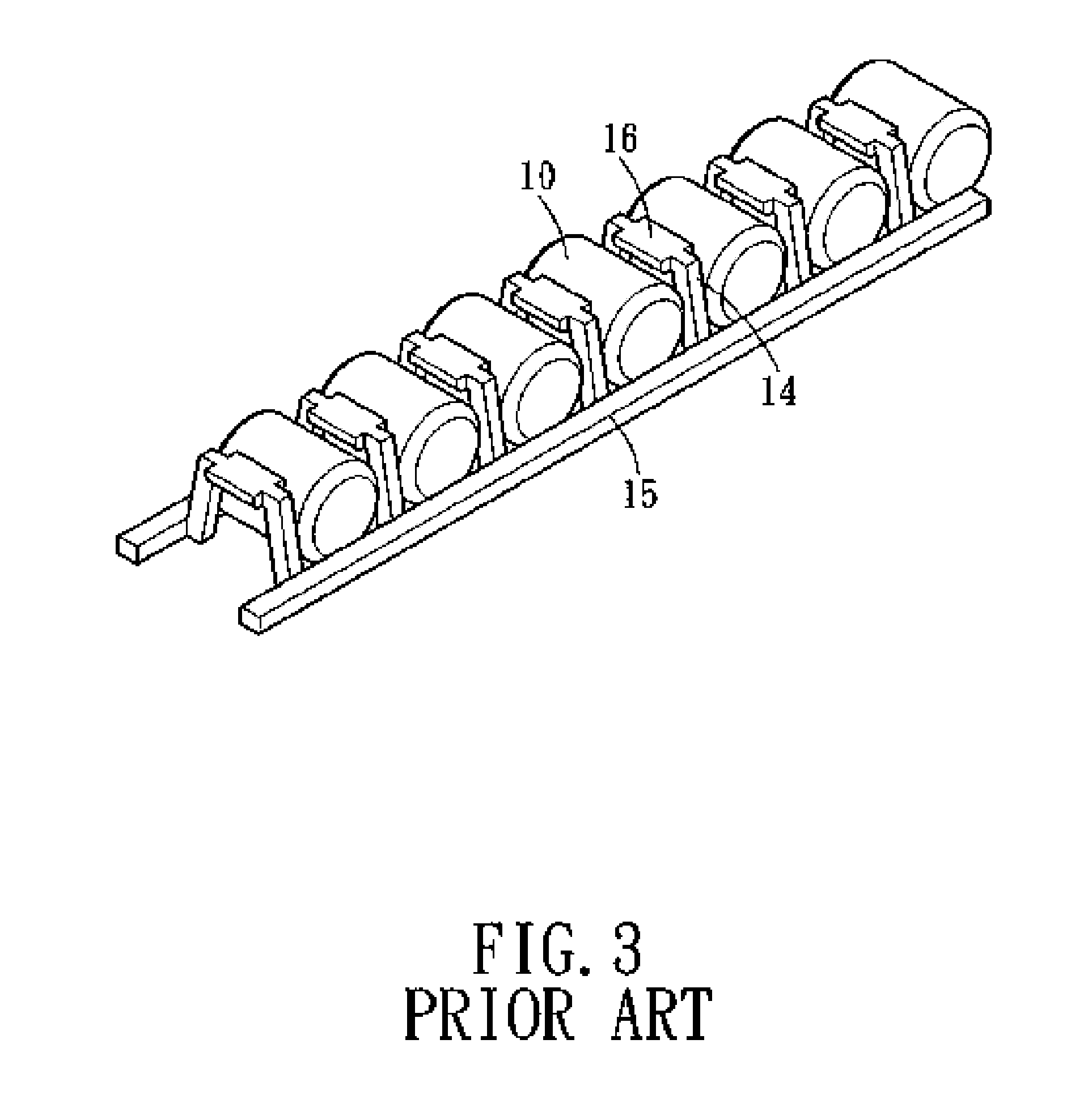

Roller Connecting and Retaining Device

ActiveUS20070201777A1Rapid mass productionEasy injection moldingLinear bearingsRolling contact bearingsEngineeringInjection molding process

A roller connecting and retaining device comprises two connecting portions, a plurality of retaining portions and spacer portions. The retaining portions are oppositely arranged in pairs and connected vertically to the connecting portions. The spacer portions are connected between the upper end and the lower end of the paired opposite retaining portions. Two contacting edges are formed at both sides of the respective spacer portions and have a linear contact with the rolling surface of the rollers, and the contacting edges of the opposite spacer portions are located correspondingly to the axial center of the rollers and are arranged at both sides of the inactive contact surface of the rollers. A mold-releasing concave is formed in each conjunction between the spacer portion and the retaining portion. Such design facilitates injection molding process, mold opening, and mass production. The contacting edge of the opposite spacer portions can prevent the problems of the rollers during rolling motion, such as slant position, friction, impact and skip.

Owner:HIWIN TECH

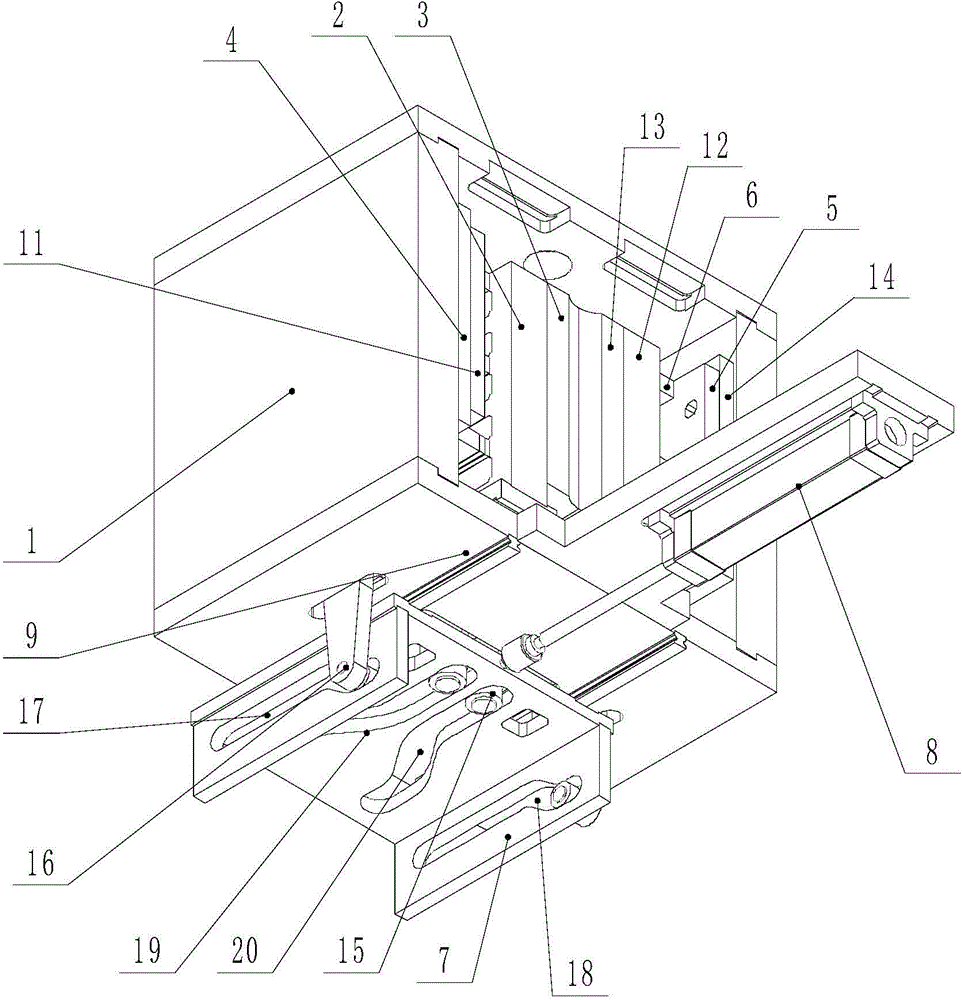

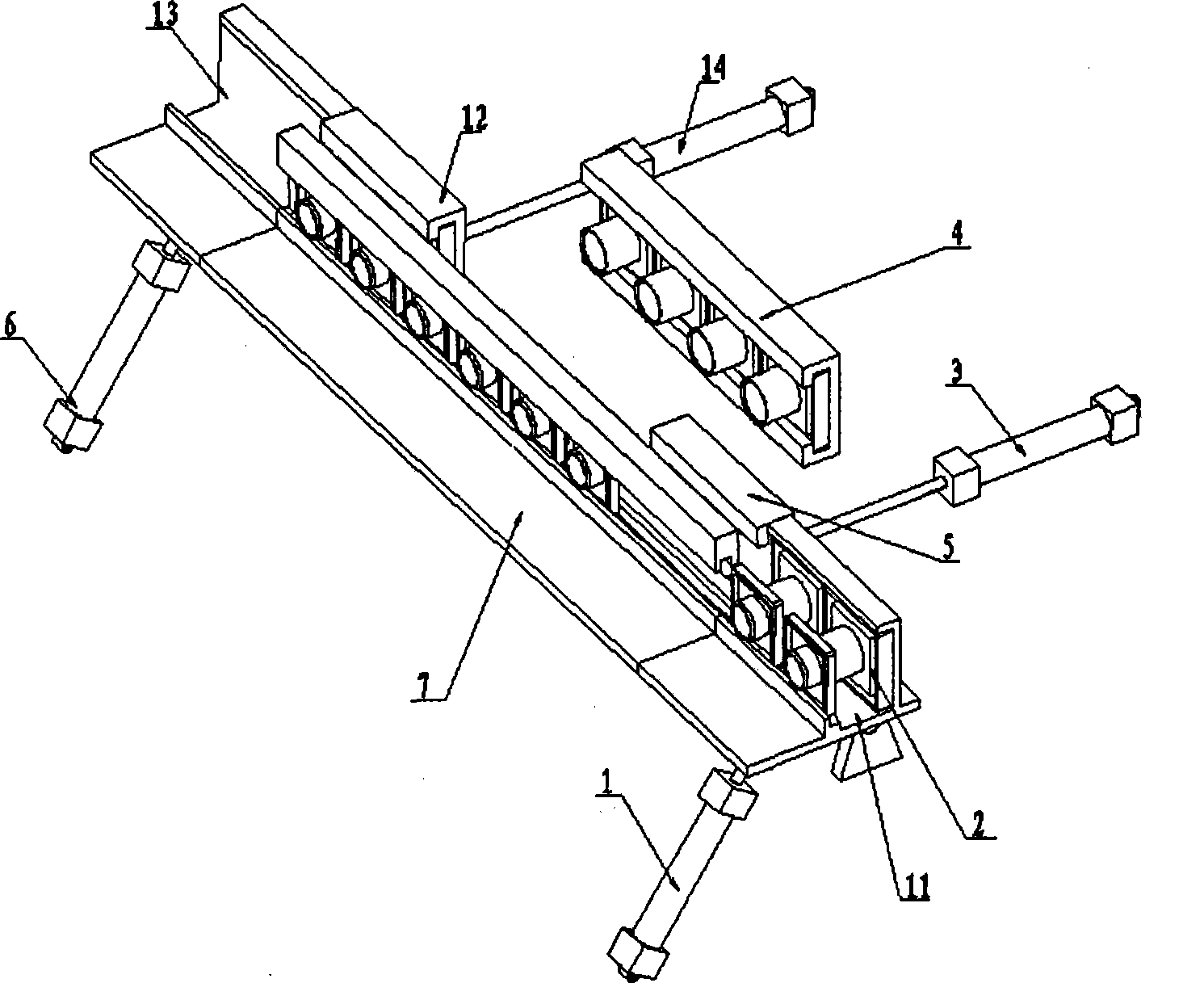

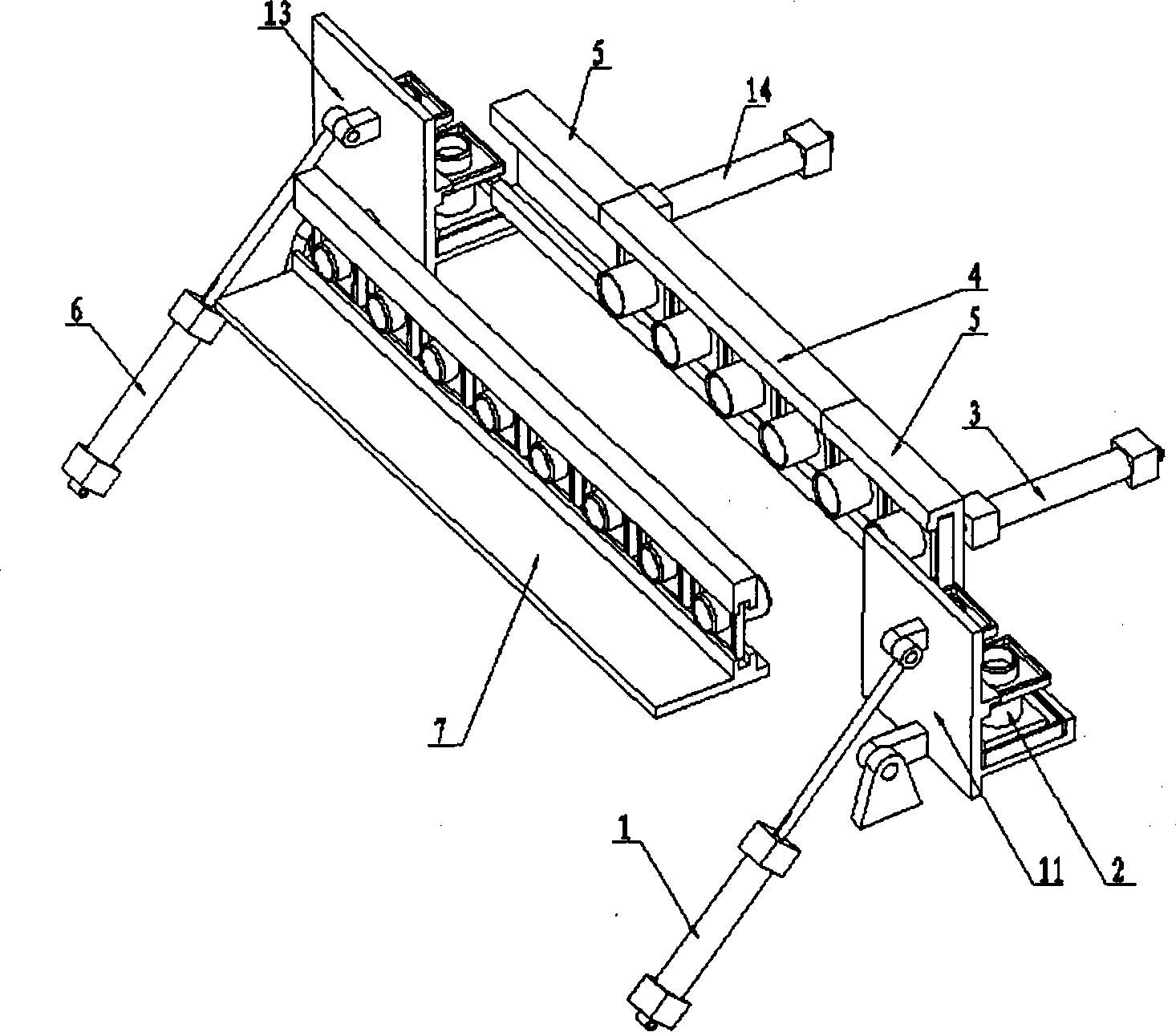

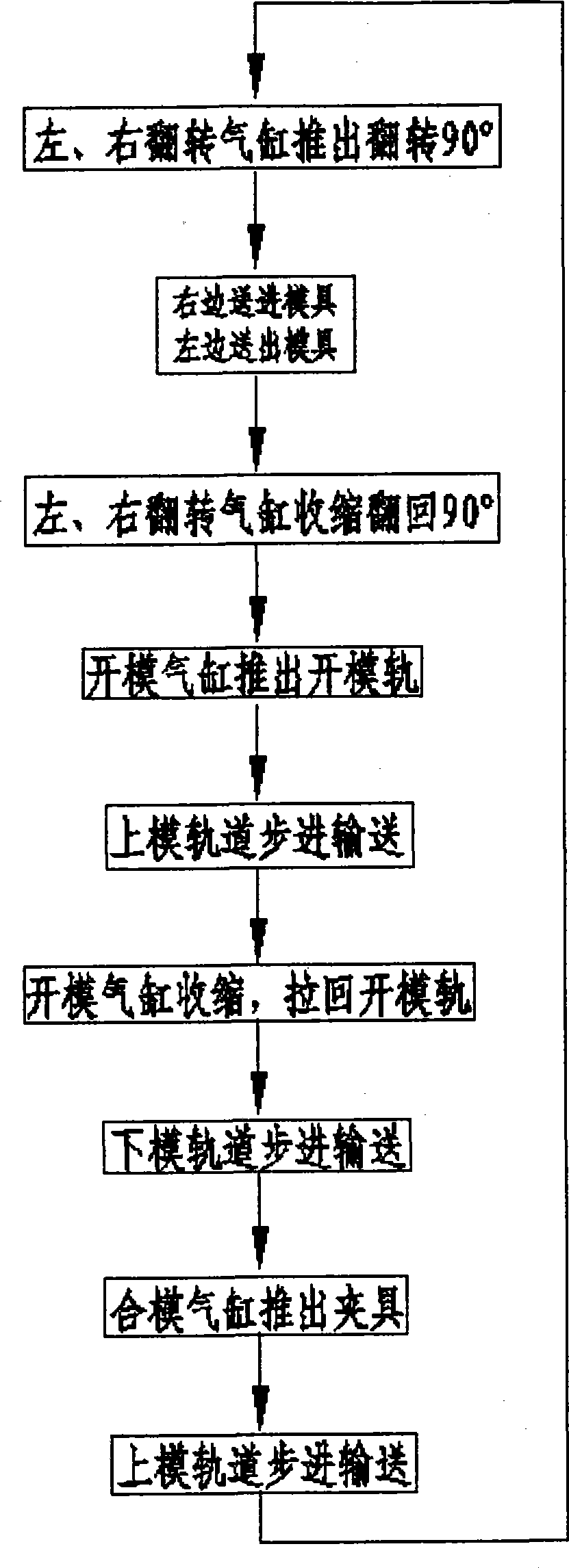

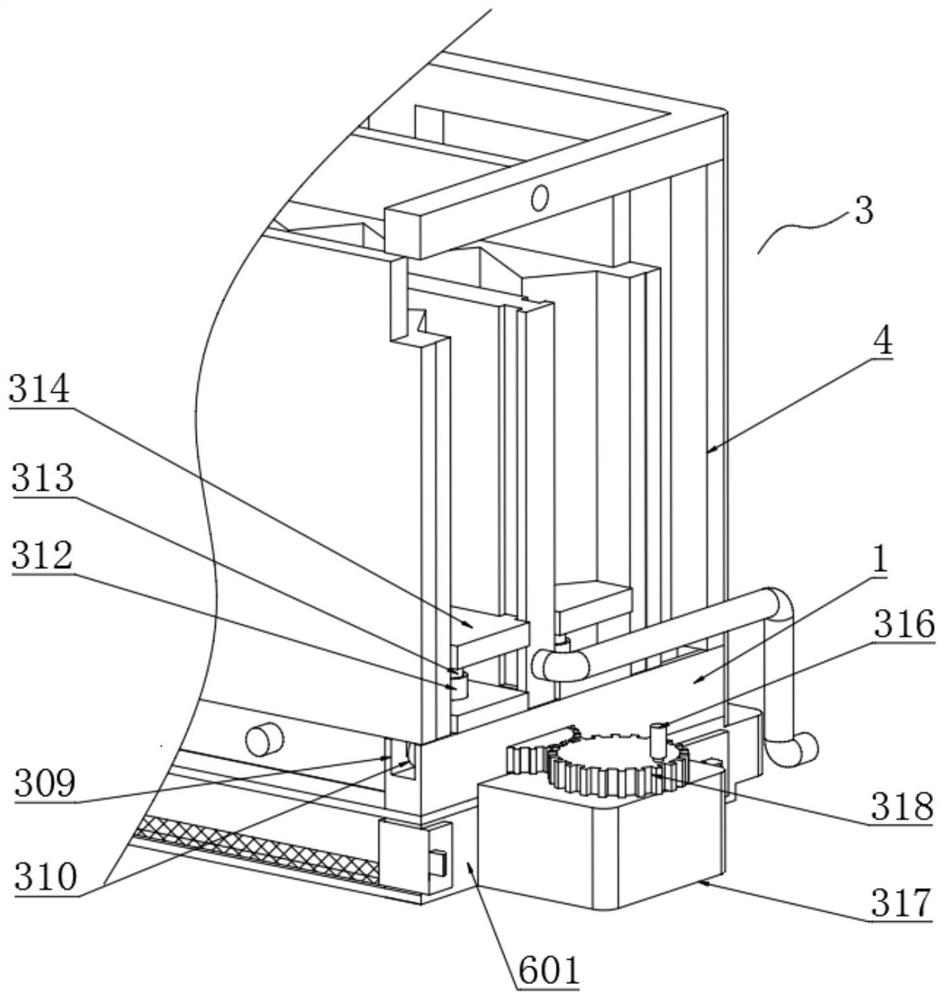

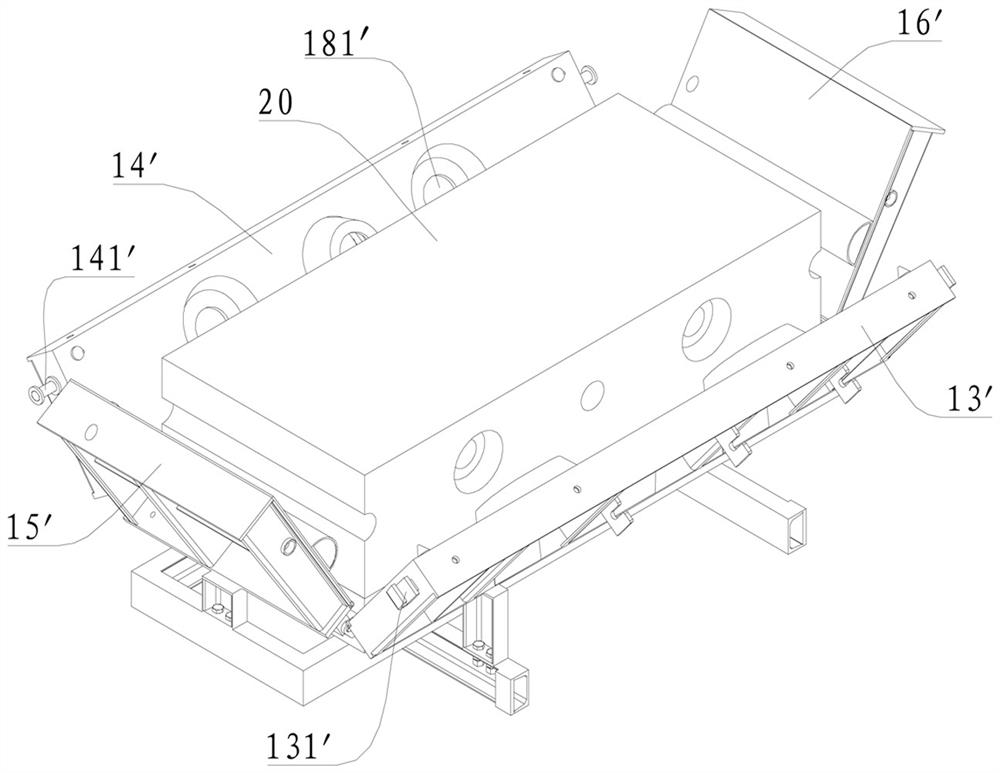

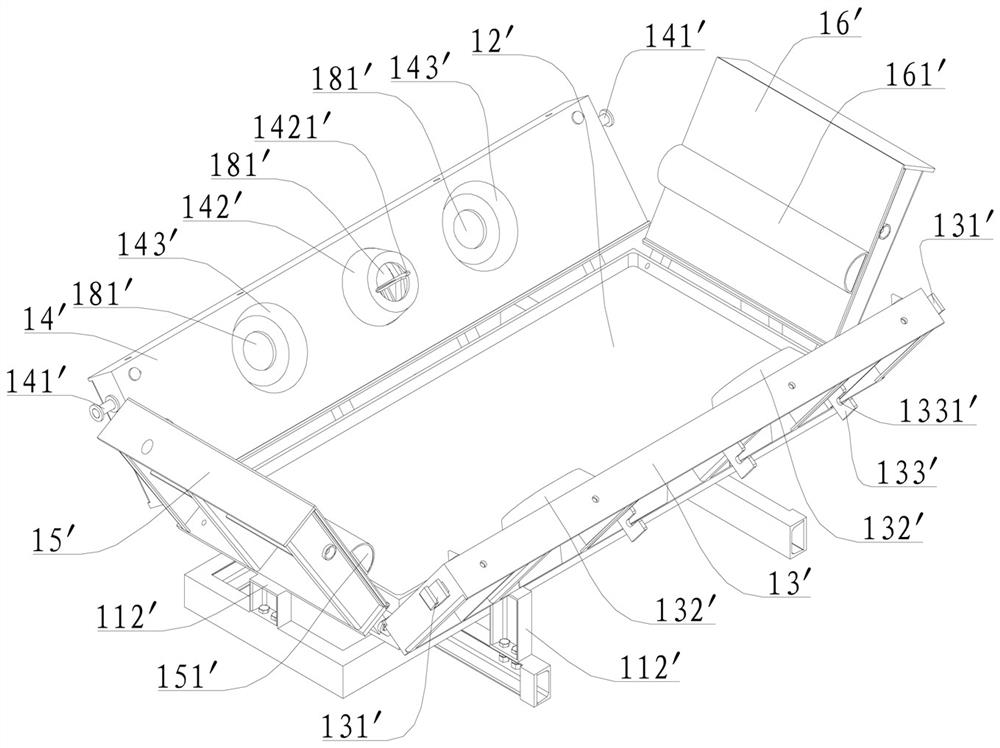

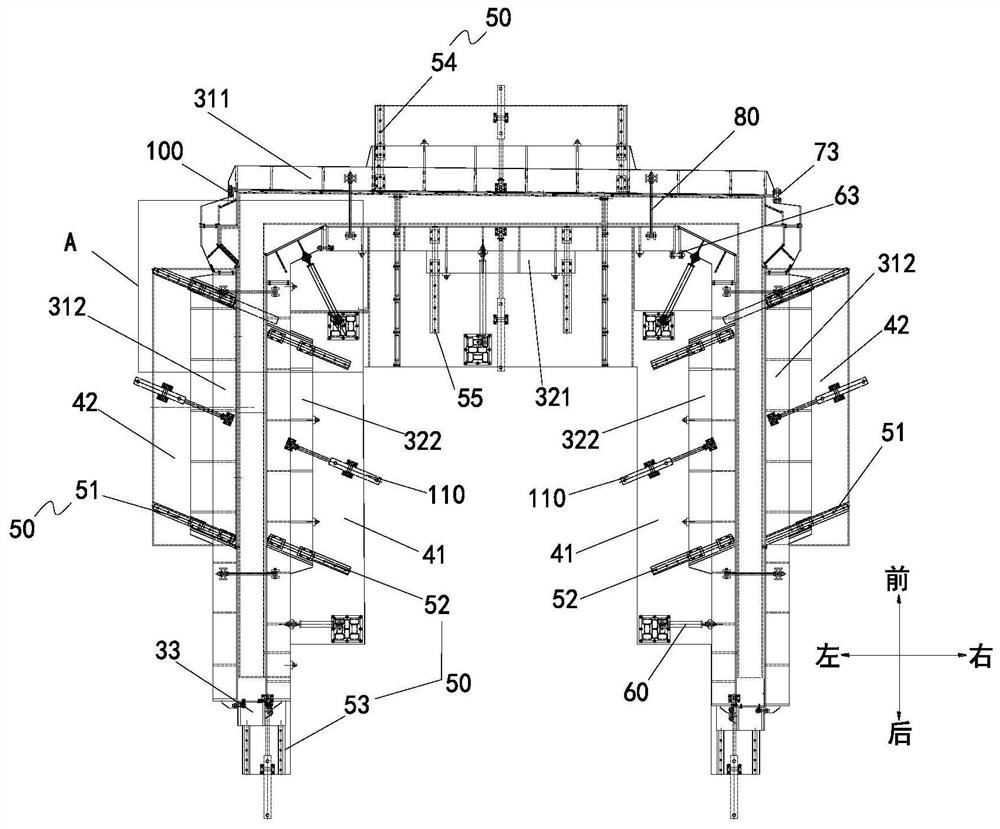

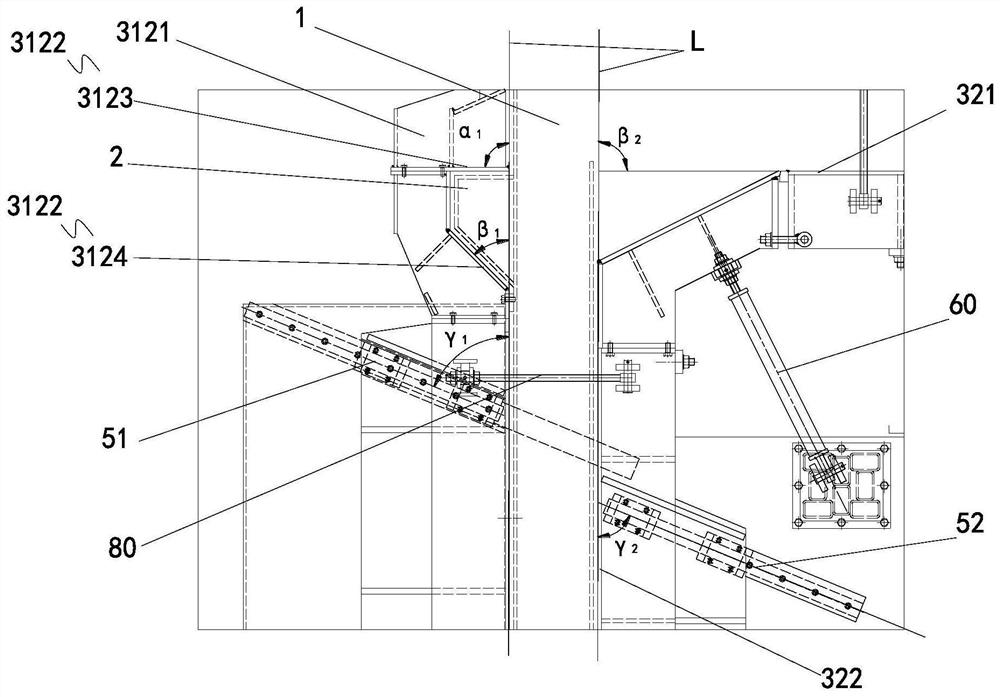

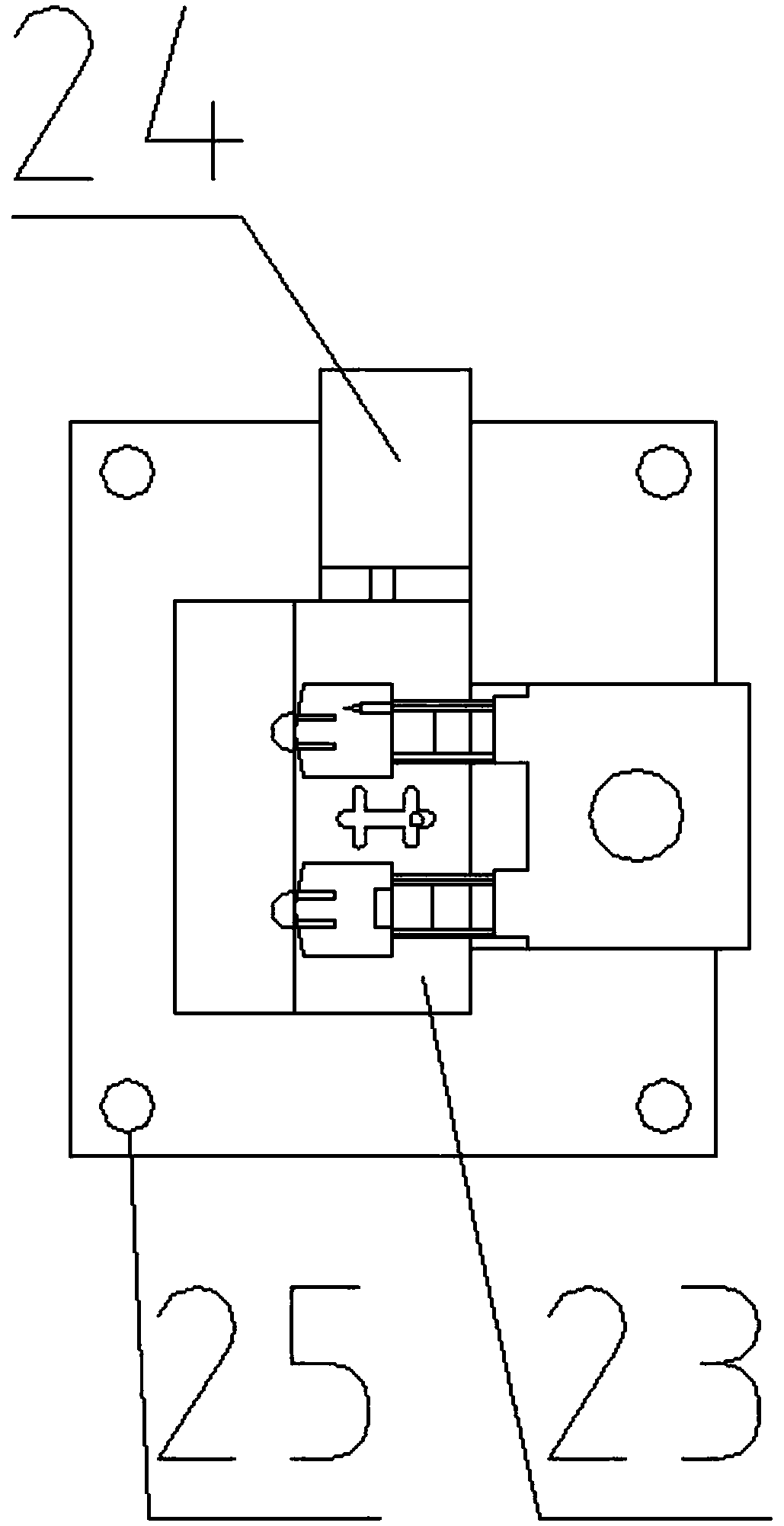

90-degree overturning, mould-opening and closing method of follower fixture and equipment thereof

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

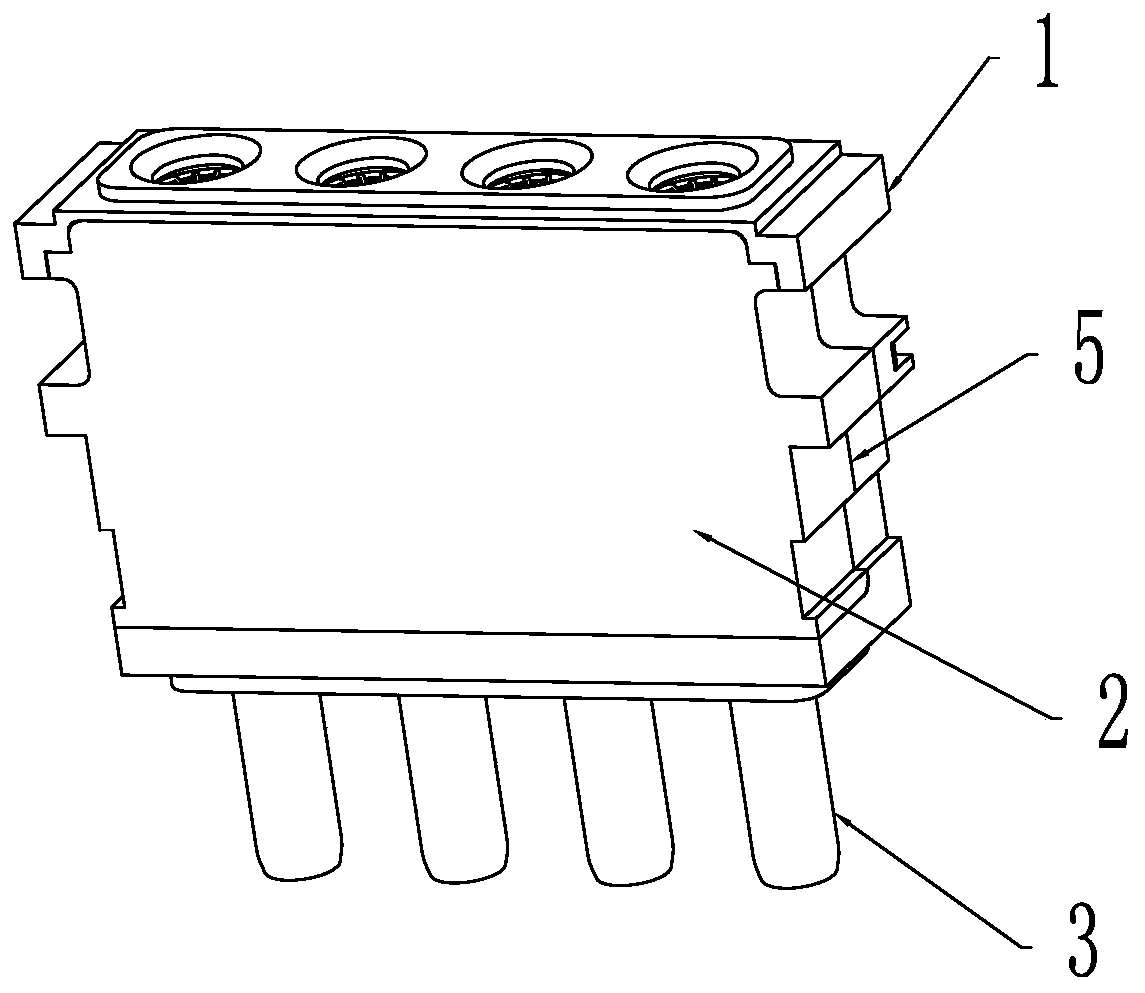

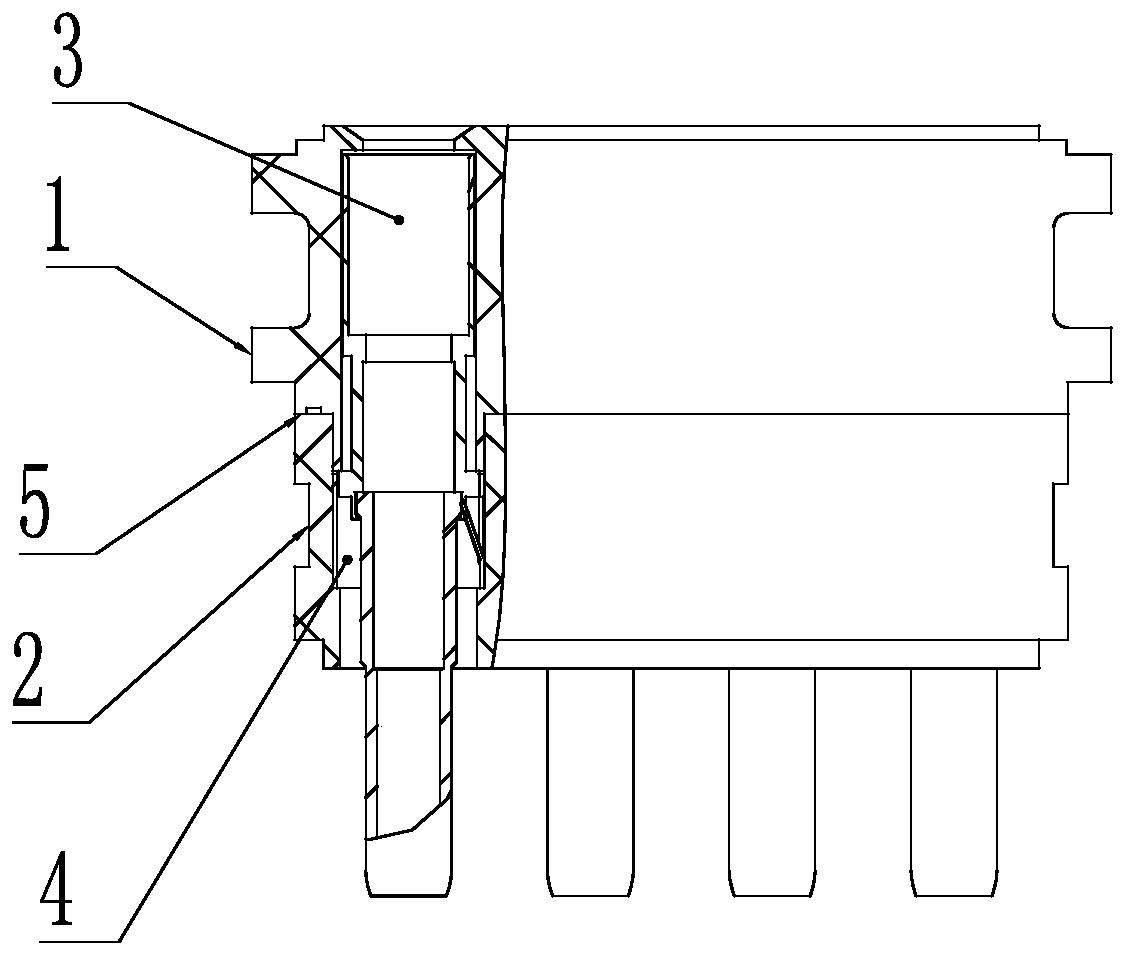

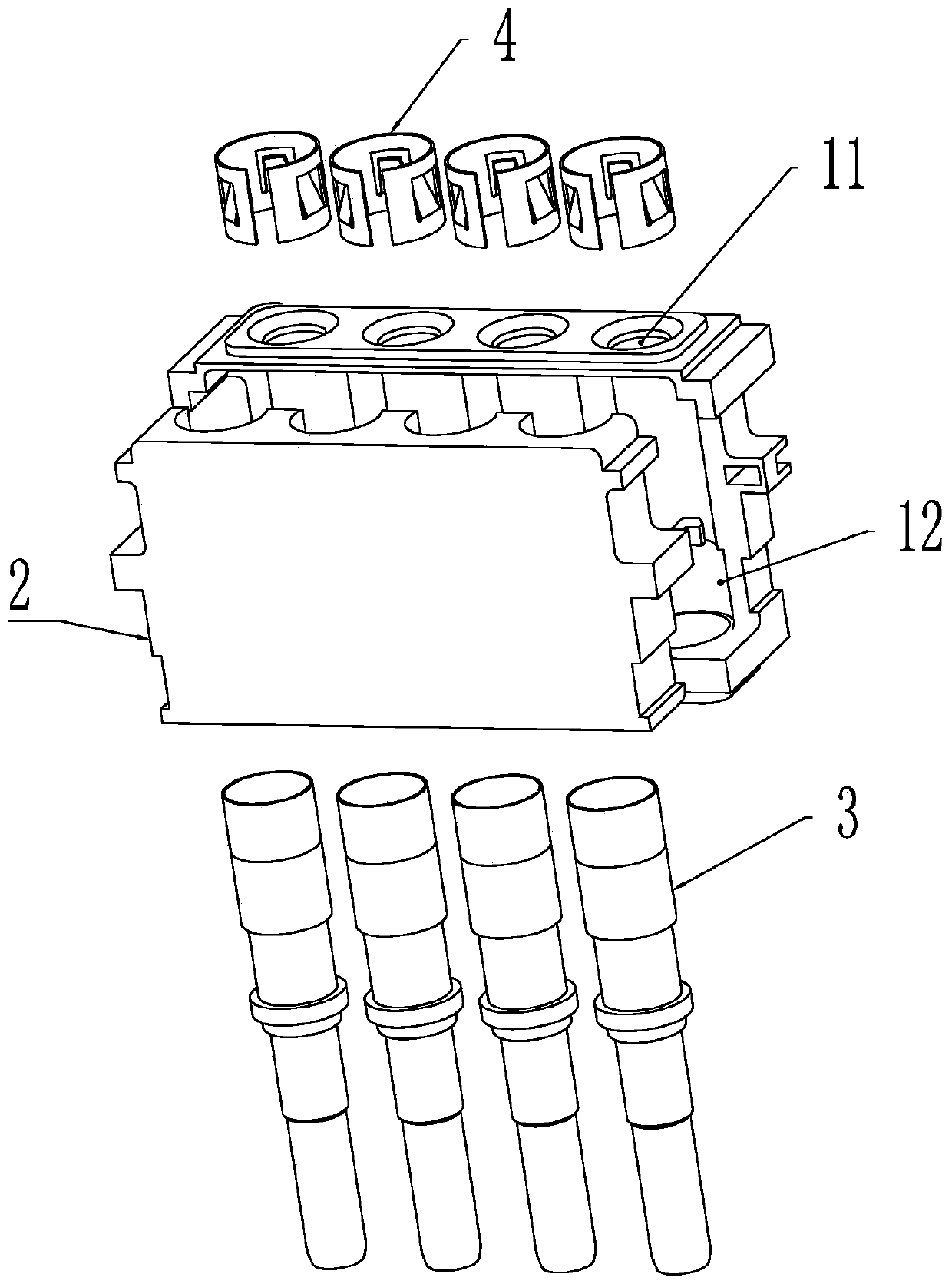

Side buckled modular connector

ActiveCN110247240AImprove Assembly ConsistencyIncrease productivityCoupling device detailsEngineeringModular connector

The invention relates to a side buckled modular connector. The side buckled modular connector includes an insulator (1), an insulation pressing plate (2) and a contact member (3) assembled in the insulator, wherein the insulation pressing plate (2) is buckled with a side surface of the insulator (1) to form a combination surface (5), and the combination surface (5) and an insertion direction of the contact member (3) are in non-perpendicular setting. The connector is advantaged in that the insulator and the insulation pressing plate are in side surface buckling matching mode, the combination surface (5) and the insertion direction of the contact member (3) are in a non-perpendicular setting mode, during operation, the combination surface bears no force, a force bearing point is on the insulator, product quality consistency and reliability of the modular connector are guaranteed, and problems of difficulty in detecting connector quality and lower production efficiency are solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

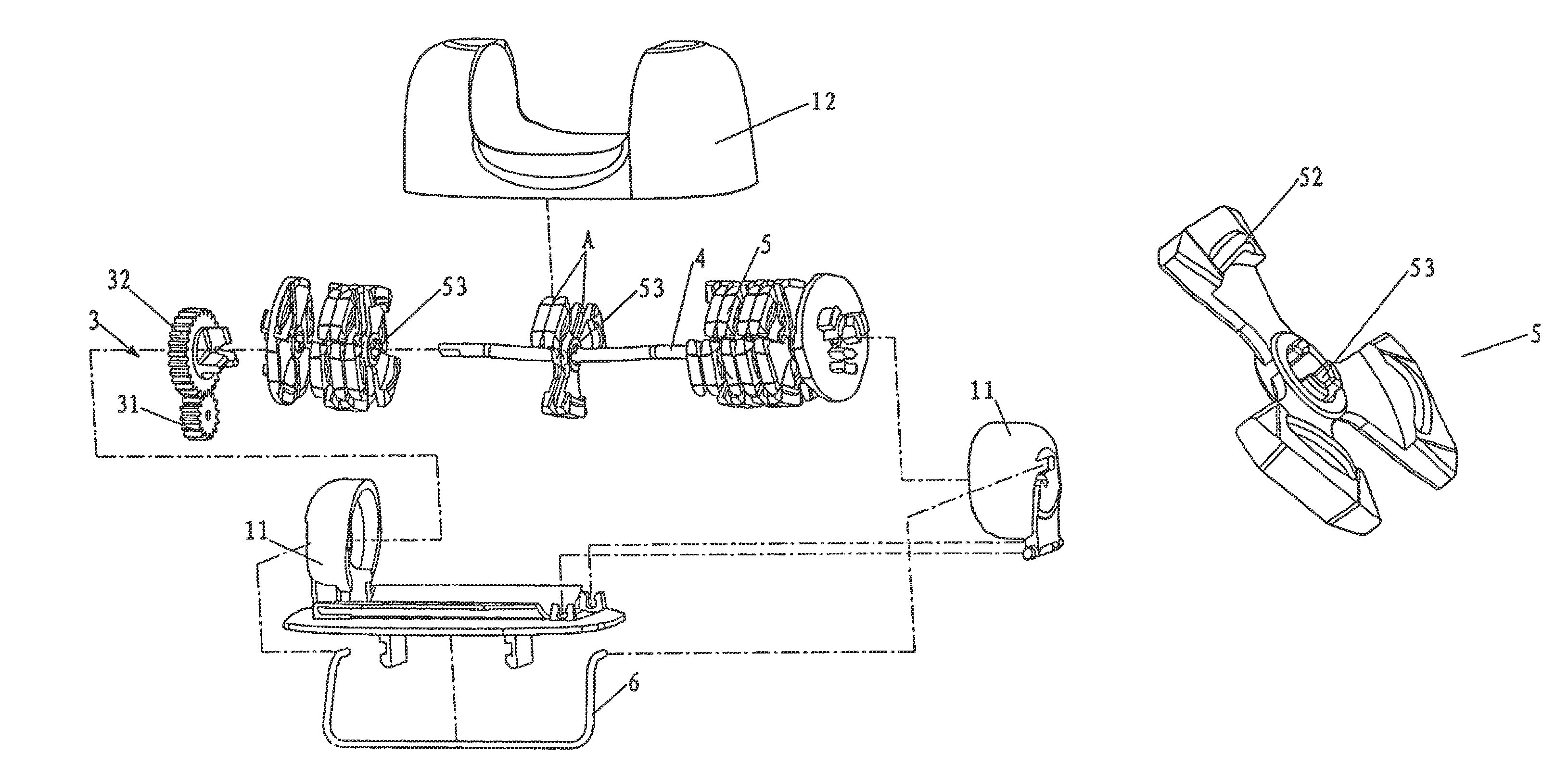

Electrical depilator

Owner:LIU LAISHENG

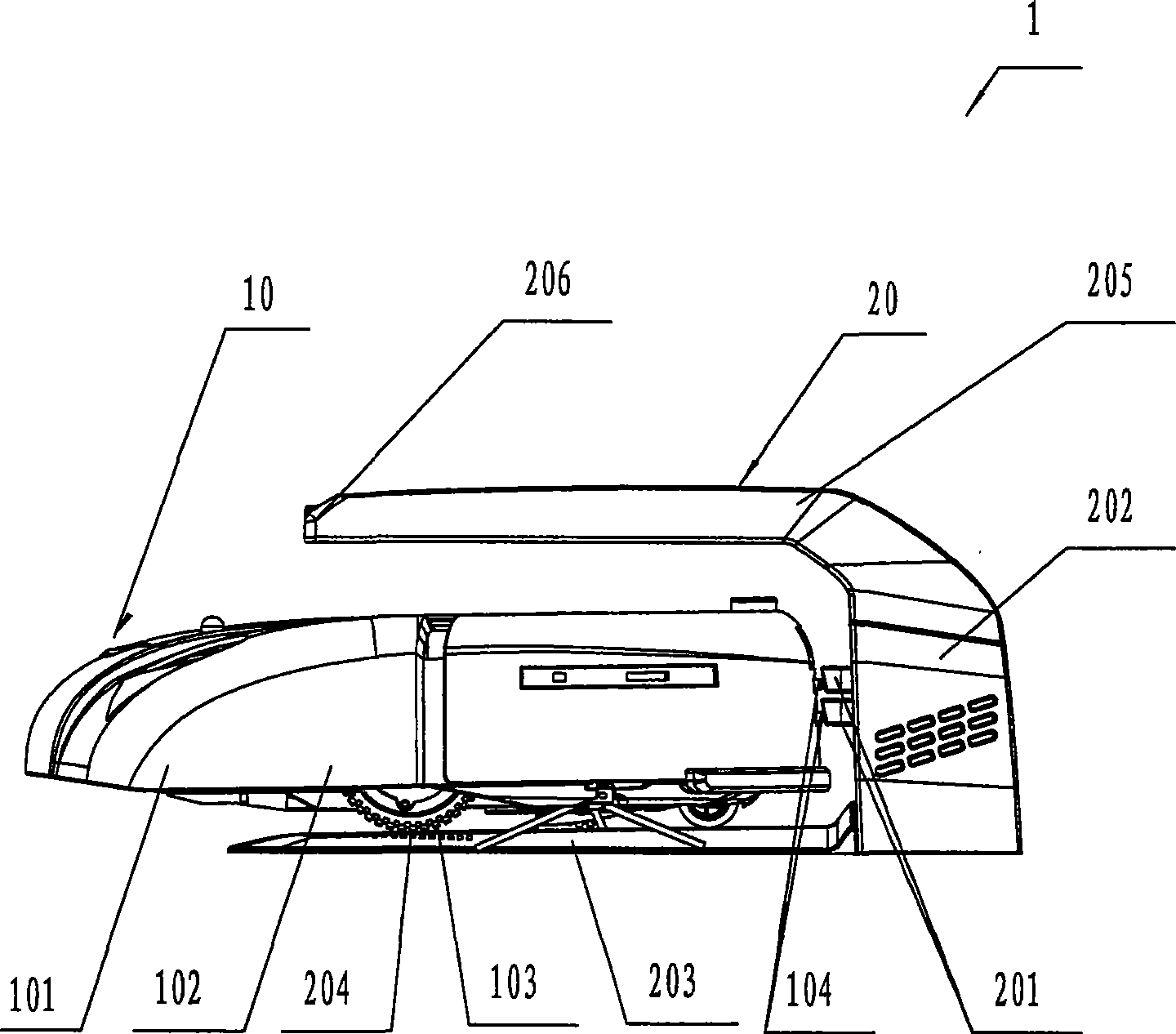

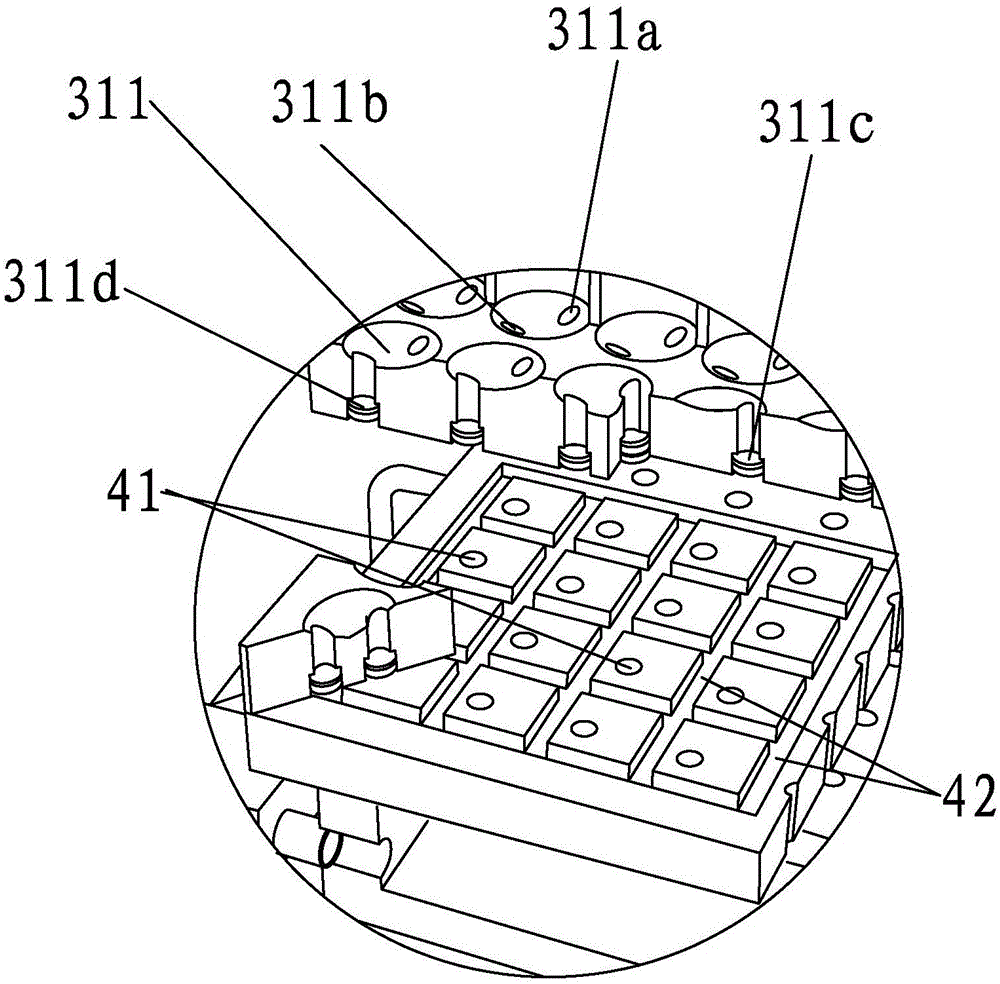

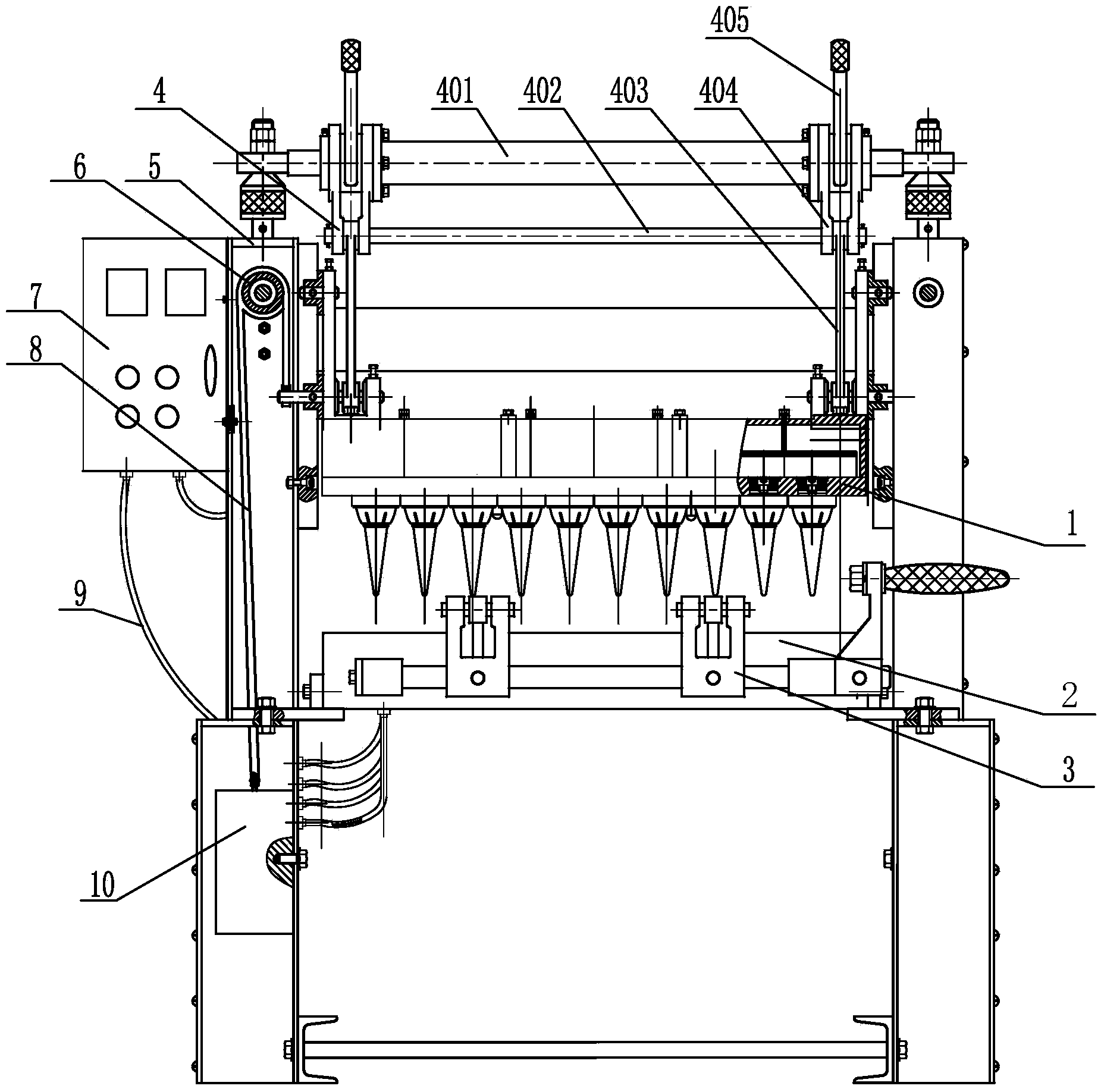

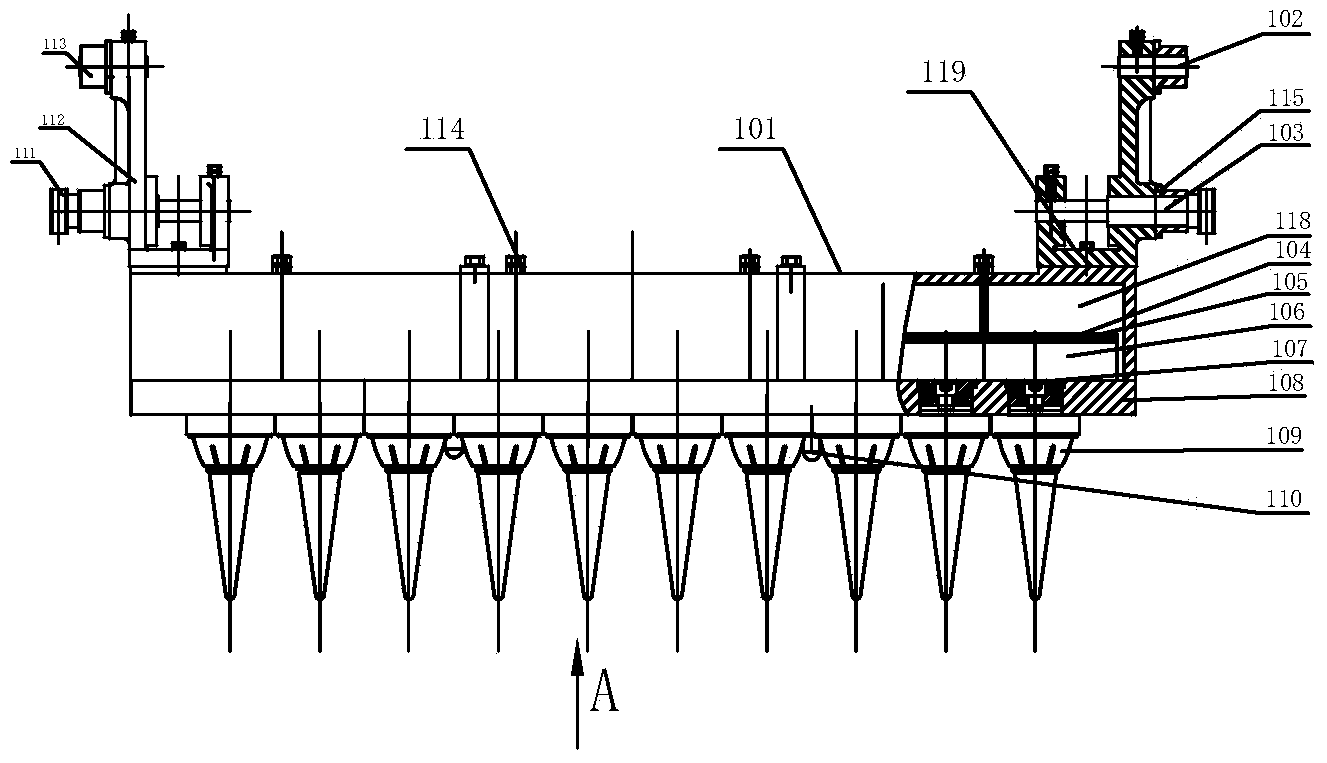

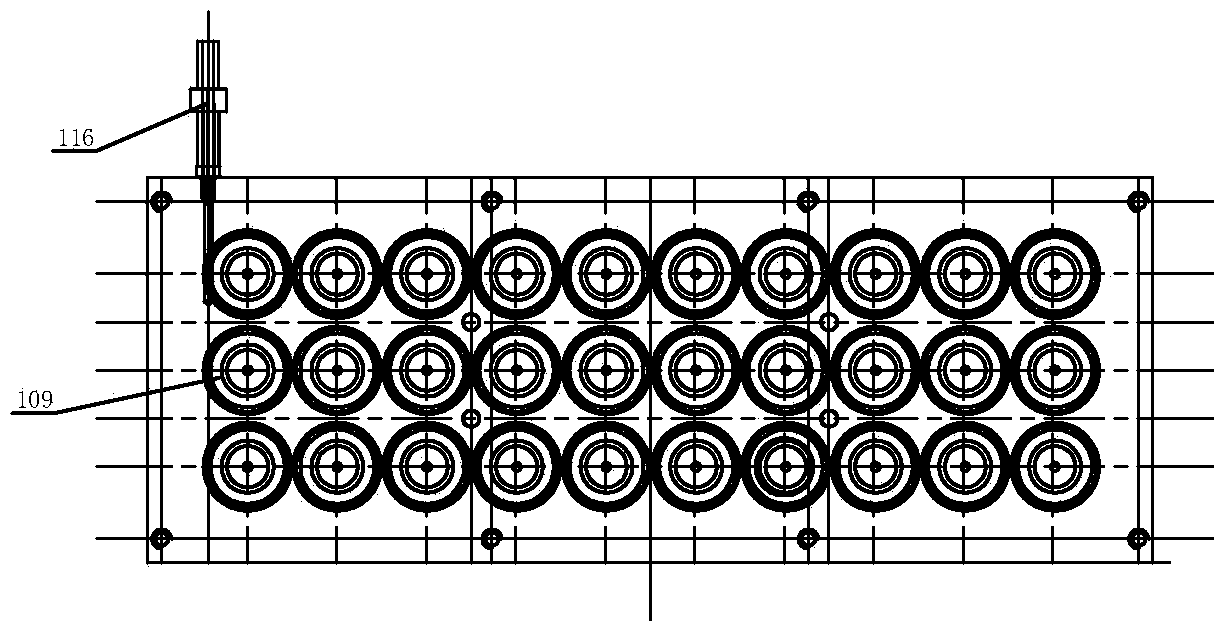

Ice cream egg carton machine

ActiveCN103518789AQuality improvementDisplay temperature in real timeHollow article bakingBaking-tinsCartonRoller chain

The invention provides an ice cream egg carton machine, and belongs to the technical field of ice cream egg carton forming equipment. The ice cream egg carton machine comprises a machine frame, an upper die, a lower die, an upper die drive and a lower die drive, and further comprises a control box, two bush roller chains and weights of the bush roller chains, wherein chain wheels of the two bush roller chains are symmetrically installed on the upper portion of the machine frame, one end of each bush roller chain is connected to one end of a long shaft of the upper die, the other end of each bush roller chain winds around the corresponding chain wheel and is connected to each weight on the lower portion of the machine frame, and the control box is connected with the upper die and the lower die respectively and controls displaying of the temperature of the upper die and the temperature of the lower die. According to the ice cream egg carton machine, an electric hot plate or a fuel pipeline is adopted to heat the upper die and the lower die, heat preservation devices are arranged, not only can the temperatures be displayed in real time, the temperatures can also be controlled, good quality of an egg carton is guaranteed, and the egg carton is not likely to be burnt. A fuel circulating system is adopted to heat the upper die and the lower die, so the upper die and the lower die are uniformly heated, heat efficiency is high, and the egg carton can be easily formed. A filter of the circulating system is used for filtering out impurities in the system and oil colloidal materials, and a filter screen is cleaned and replaced at regular time.

Owner:YINGKOU ELECTRICAL & ENVIRONMENTAL PROTECTION EQUIP MFG

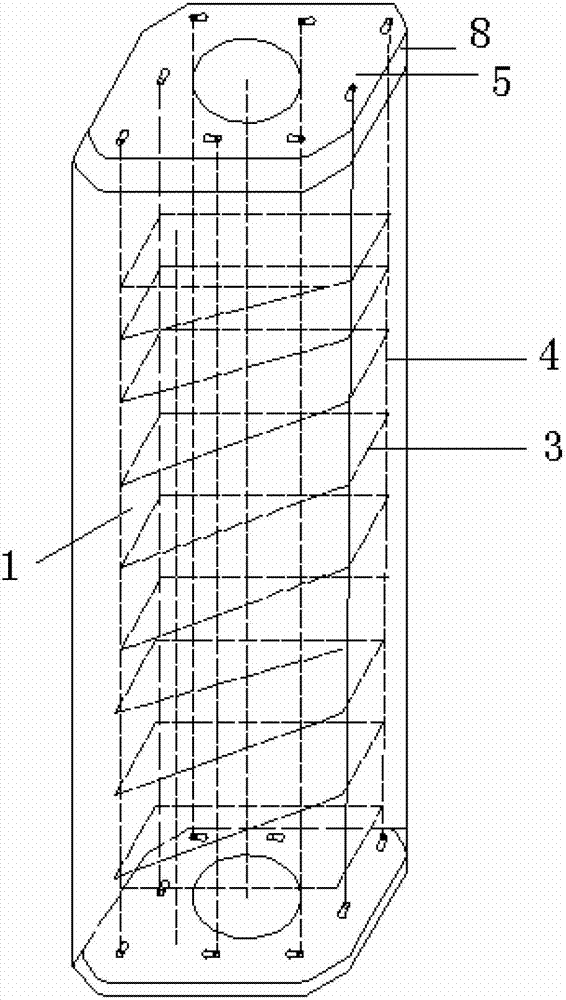

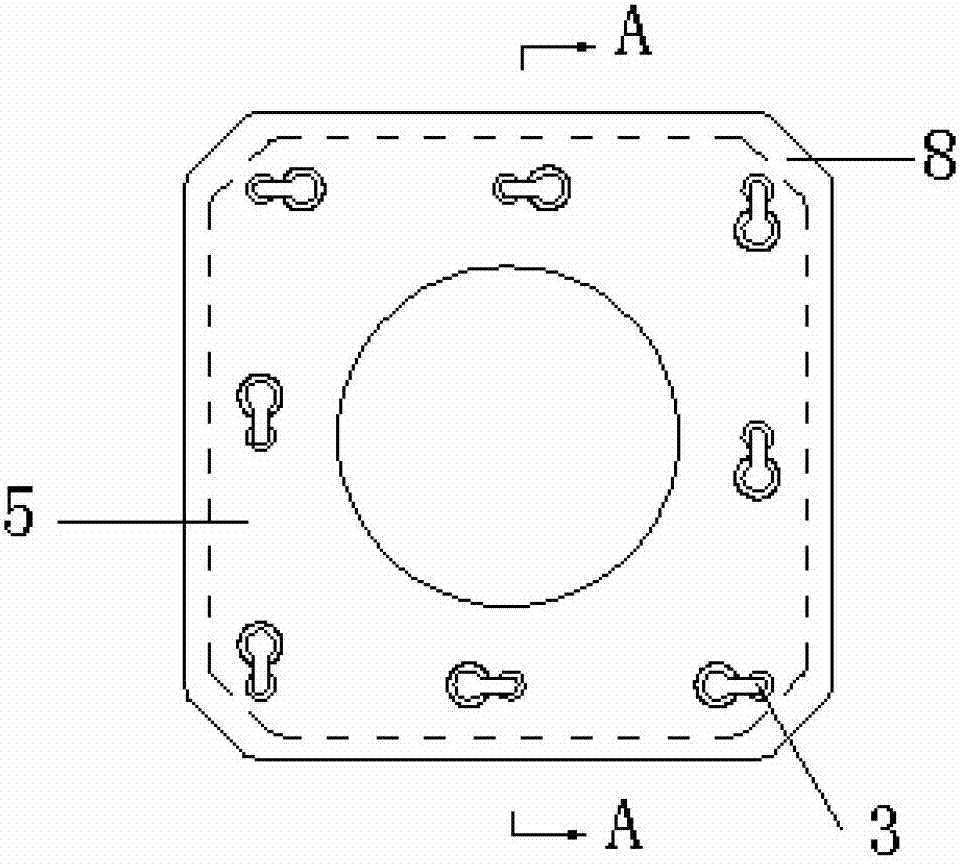

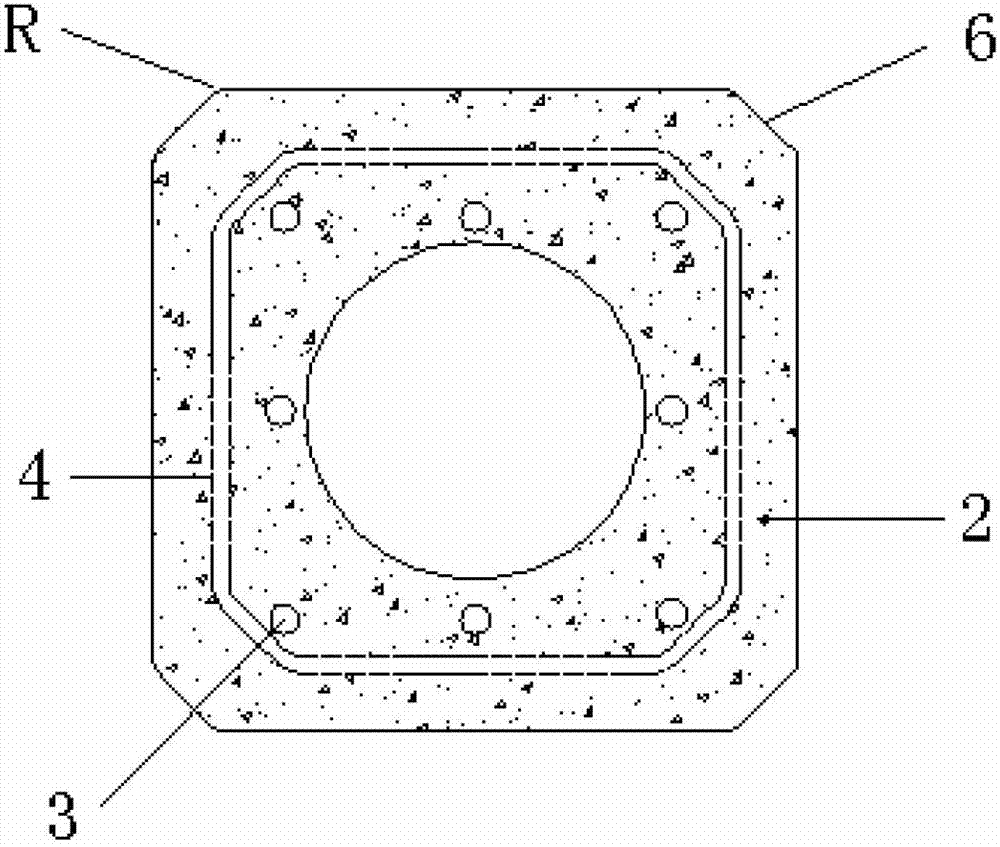

Octagonal concrete centrifugal pile and forming mould thereof

InactiveCN102808404AImprove molding qualityGuarantee molding qualityMouldsBulkheads/pilesStress reliefEnergy analysis

The invention provides an octagonal concrete centrifugal pile and a forming mould thereof. A pile body adopts a hollow structure, and the outer profile of the cross section of the pile body is in an octagonal shape. The edges of the octagonal shape have different length, the short edges are respectively 40 mm, 45 mm, 50 mm and 55 mm in length according to different pile shapes, and all the corners of the edges are in a stress relief arc shape; and the arc radii are the same and are respectively 18 mm, 22 mm, 24 mm and 26 mm according to the different pile shapes. The octagonal concrete centrifugal pile has the benefits as follows: the material is saved, the self weight is light, the pile is not easy to damage, the pile body is good in ductility, the pile forming quality is improved by 20%, the bending and shearing resistance is improved by 30%, the production process is easier to control and the mould is easier to make. Poor durability of pile body concrete due to pile material damage in the transportation and construction processes can be avoided. The bearing capacity provided by a single pile is 30% higher than that provided by the general process, the economic property is good, and the cost is saved by about 25%. The pile body of the forming mould is easy to de-mould, and the effects of energy saving and emission reduction can be achieved.

Owner:TIANJIN JIANCHENGJIYE GRP

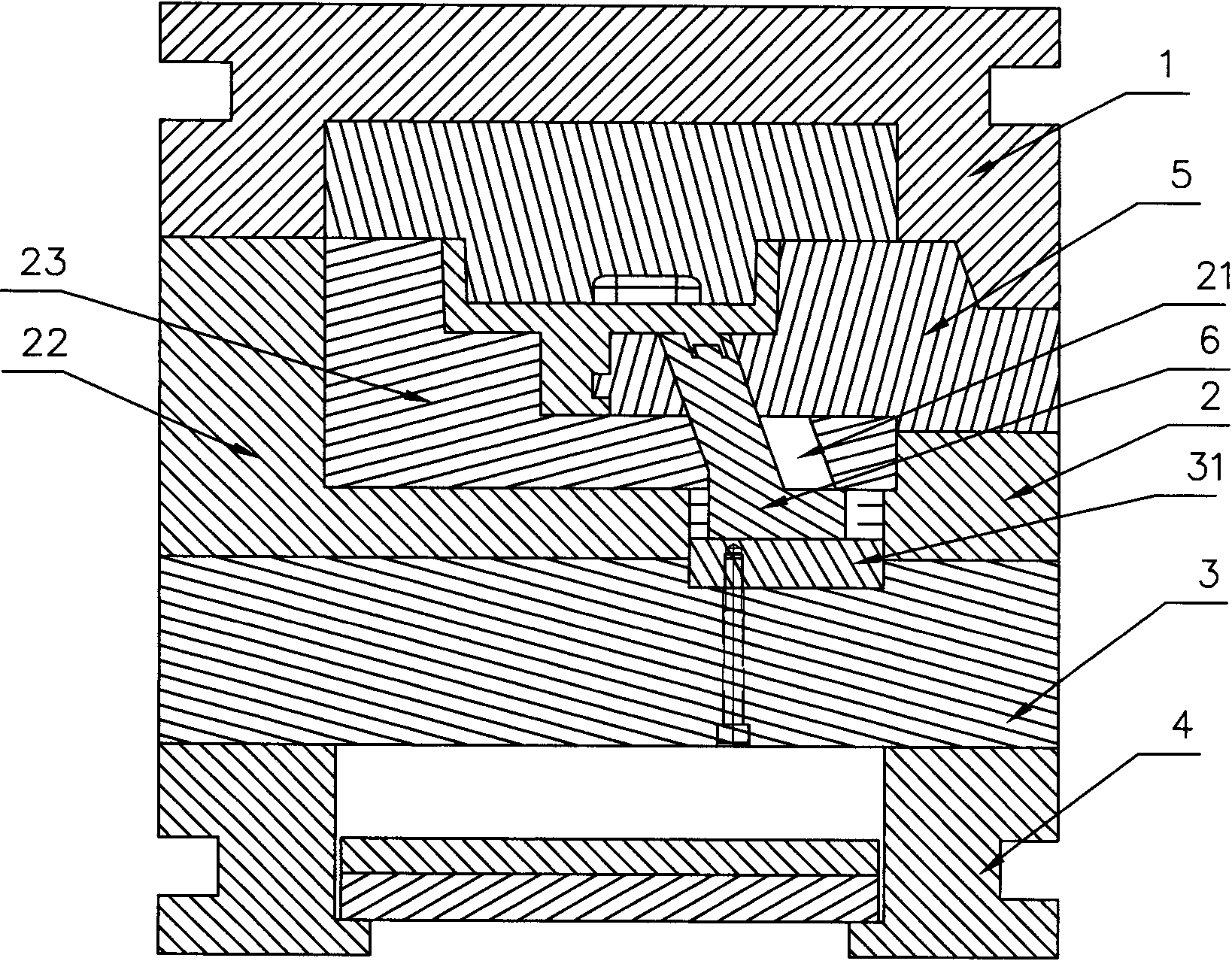

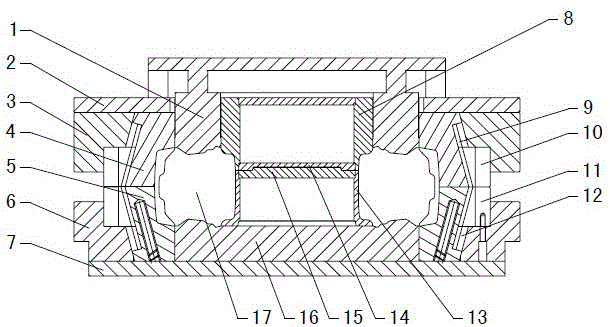

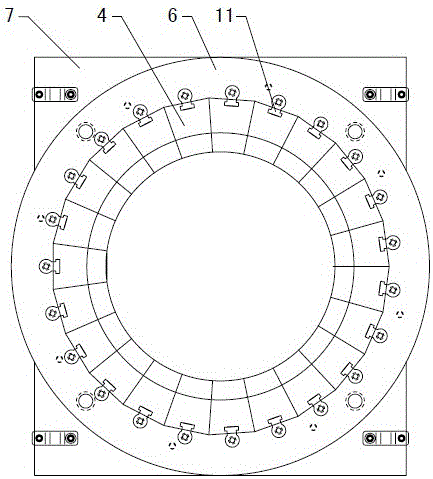

Polyurethane solid tire mold and its processing method

A polyurethane solid tire mold and a processing method thereof belong to the technical field of solid tire processing. The lower pattern module is composed of a plurality of lower pattern blocks (5) spliced along the circumferential direction, and the lower pattern blocks (5) are slidably arranged in the lower fixing seat (6) through the lower pattern block guide mechanism, and the lower pattern block guide mechanism makes the lower pattern block (5) Displacement radially outward occurs while sliding upward. When the mold is opened, the lower pattern block slides upwards and produces a radially outward displacement, so that the lower pattern blocks are separated from each other and separated from the tire, which is convenient for taking the tire out of the tire mold cavity. The processing method of polyurethane solid tire can be The air bubbles in the raw materials are extruded and vulcanized twice to produce polyurethane low-speed solid tires with wear resistance 5 to 10 times that of ordinary rubber. The load capacity is large, which solves the common problems of falling blocks and cracks in rubber solid tires, and can achieve no traces of running brakes, which is environmentally friendly and clean.

Owner:ZIBO SAITONG POLYURETHANE

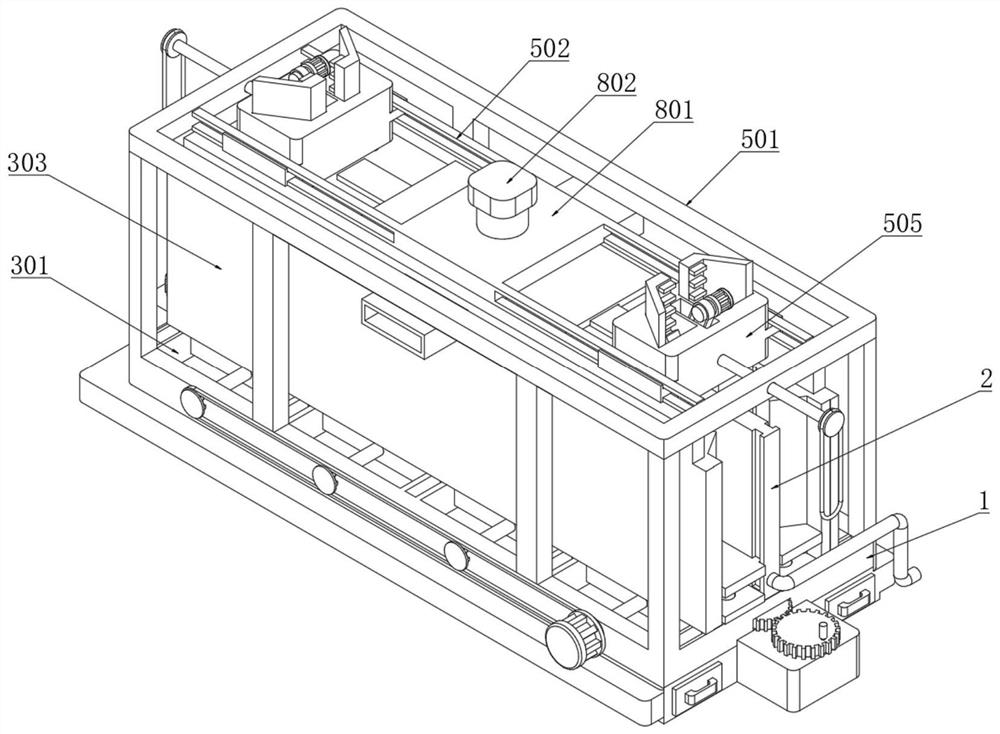

Environment-friendly construction method for building decoration

ActiveCN111890517AReduce resistanceImprove applicabilityDischarging arrangementMouldsElectric machineConstruction engineering

The invention discloses an environment-friendly construction method for building decoration. A stair die comprises a machine base, wherein a partition plate is fixedly connected to the middle of the top end of the machine base; each corner at the top end of the machine base is fixedly connected with a supporting plate; the top ends of the supporting plates are fixedly connected with length adjusting mechanisms; the bottom at the outer end of the machine base is fixedly connected with an energy utilization and heat-proof and cold-proof mechanism; and two ends of the partition plate are symmetrically and movably connected with die opening and width adjusting mechanisms. According to the environment-friendly construction method, the structure is scientific and reasonable, and use is safe andconvenient; the die opening and closing and width adjusting mechanisms are arranged, a rotating motor drives a chain wheel to rotate, and the chain wheel drives a lead screw to rotate together throughthe transmission of a chain, so that a movable plate and frameworks are pushed to move, and the distance between the two frameworks and the partition plate is adjusted so as to open and close the die; and meanwhile, through the cooperation of a rolling groove and a roller, the resistance of the two frameworks during moving is reduced, the consumption of kinetic energy is reduced, and the efficiency of the movement is improved.

Owner:广东田业建设有限公司

Hydraulic automatic mould-locking forging device

InactiveCN107537962AReliable closureQuality assuranceForging/hammering/pressing machinesQuality assuranceEngineering

The invention relates to the field of metal material machining, in particular to a hydraulic automatic mould-locking forging device. The hydraulic automatic mould-locking forging device comprises an upper mould, a lower mould, an upper pressure head, two oppositely arranged side pressure heads, a material jacking rod, a threaded sleeve, a hydraulic cylinder, a motor and a reducer. Flanges are arranged at the two ends of each of the upper mould and the lower mould correspondingly, the flanges corresponding to each other up and down are tightly attached and then form a cylindrical boss, a through hole A consistent with the axis of the cylindrical boss is formed in the middle of the cylindrical boss, and a cavity which is formed after the through hole A and the upper mould and the lower mouldare combined is through. The hydraulic automatic mould-locking forging device adopting the technical scheme has the characteristics that the energy consumption is reduced, the forge piece quality isensured, and the working efficiency is improved.

Owner:成都瑞联汇诚机电设备有限公司

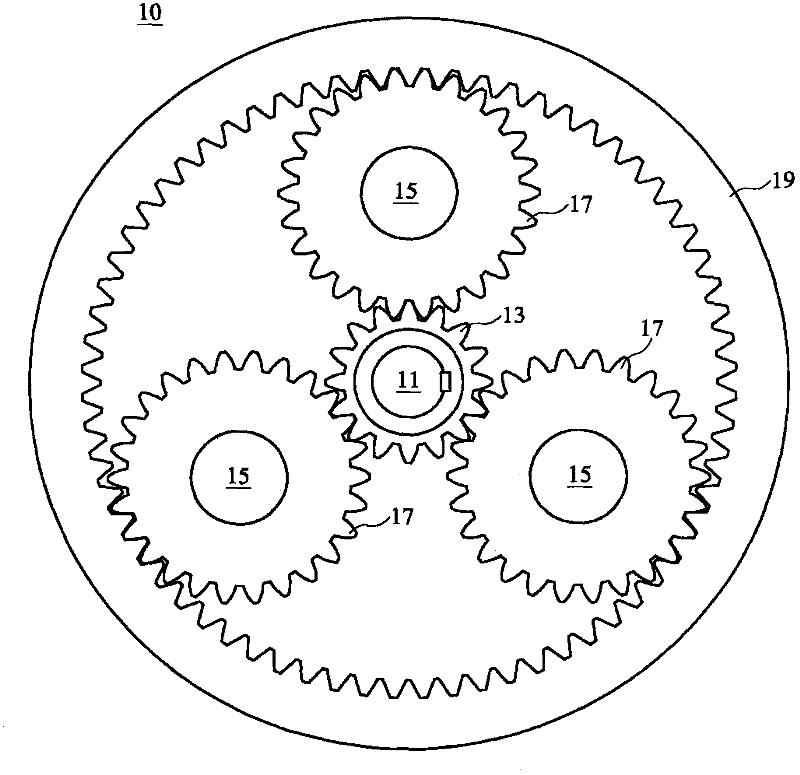

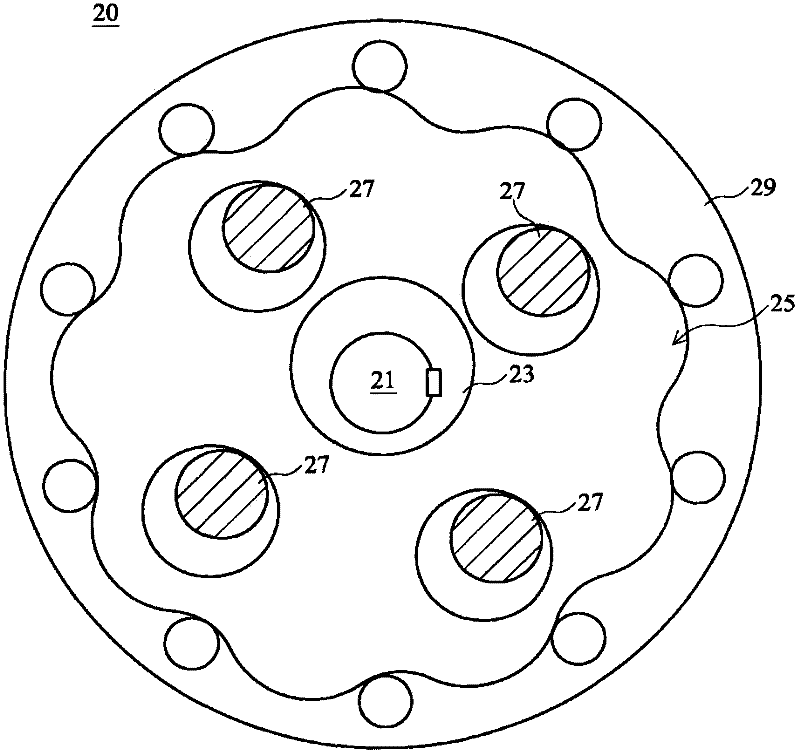

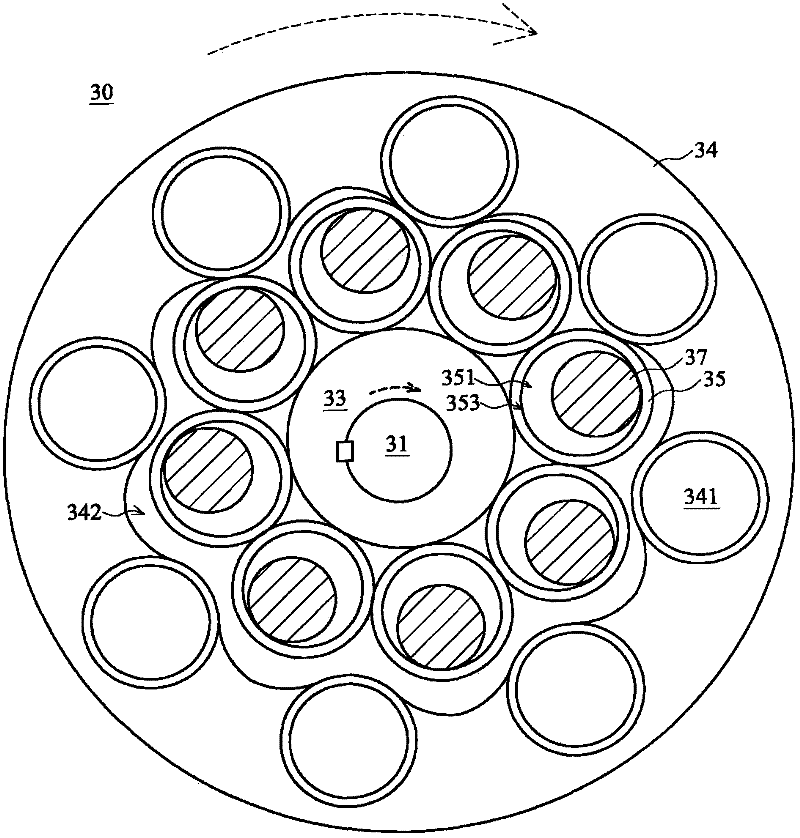

Roller servo storage system

InactiveCN102653121AReduce wearExtended service lifeToothed gearingsInjection molding machineServomotor

The invention discloses a roller servo storage system. The system mainly comprises an input shaft, an eccentric wheel, a bearing, a plurality of hollow column bodies, a plurality of bolts, an output disc, a servo motor and an injection molding device, wherein the servo motor is used for driving the input shaft to rotate; the input shaft is about to drive the eccentric wheel to swing when rotating, so that the eccentric wheel pushes the hollow column bodies via the bearing and the driven hollow column bodies drive the output disc to rotate via the bolts and drive the injection molding device; and the bearing is arranged on the eccentric wheel, so that the eccentric wheel is about to rotate relative to the bearing in the process of pushing the hollow column bodies, thus wear generated by the eccentric wheel and the hollow column bodies in the operation processes can be reduced and the service life and efficiency of the roller servo storage system can be improved.

Owner:MODAOWN & SOMAX INDUSRY INC

Automatic jacking device of injection mold

The invention relates to the technical field of injection molds, and discloses an automatic jacking device of an injection mold. The automatic jacking device of the injection mold comprises a top board, wherein supporting columns are fixedly installed at both sides of the top board, fixing boards are fixedly installed at both sides, close to each other, of the two supporting columns, a same lowerhalf is fixedly installed at the sides, close to each other, of the two fixing boards, a lower half cavity is formed in the top of the lower half, a sliding groove is formed in an inner wall of the bottom of the lower half cavity, a sealing groove is formed in the bottom of the lower half, the sealing groove communicates with the sliding groove, two sliding boards are slidingly installed in the sealing groove, and rotating boards which are obliquely arranged are rotatably installed on both the sliding boards. The automatic jacking device of the injection mold is simple in structure and convenient to operate, by moving an upper half upwards and downwards, the lower half cavity and an upper half cavity are closed and opened conveniently, through movement of jacking boards, injection moldingparts are jacked, a yield of the injection molding parts is increased, use is convenient and ingenious, the automatic jacking device of the injection mold is suitable for wide popularization, and useeffects are met.

Owner:ANHUI ANLAN MOLD

Mold for producing automobile glass switch button and mold opening method of mold

Owner:SUZHOU WEIKAI PRECISION MOLD

Slope protection block prefabricated part mold and slope protection block prefabricated part

ActiveCN114227873AEasy to open and close the moldMold clamping stabilityMoulding surfacesMould panelsLocknutStructural engineering

Owner:FUJIAN QUNFENG MACHINERY

Box culvert mold of shield tunnel

ActiveCN111745794AEasy to open moldEasy to moldCeramic shaping mandrelsCeramic shaping coresShield tunnelingMechanical engineering

The invention provides a box culvert mold of a shield tunnel. The box culvert mold of the shield tunnel comprises a mold body, bases, a guide rail structure and a driving mechanism; the mold body comprises a bottom mold and side molds, the side molds are located on the inner and outer sides of the bottom mold, the side molds comprise mold closing positions and mold opening positions, under the condition that the side molds are located at the mold closing positions, a pouring cavity is defined by the bottom mold and the side molds, under the condition that the side molds are located at the moldopening positions, the side molds are away from the bottom mold; the bases are arranged on the inner side and the outer side of the bottom mold; the guide rail structure is arranged on the bases and / or the bottom mold, the side molds can slide on the guide rail structure; and the driving mechanism drives the side molds to move between the mold closing positions and the mold opening positions. Byapplying the technical scheme of the box culvert mold of the shield tunnel, the problem that in the prior art, the box culvert mold is difficult to assemble and disassemble can be effectively solved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

Acid treatment big hook injection molding device and injection molding method thereof

The invention discloses an acid treatment big hook injection molding device and an injection molding method thereof. The acid treatment big hook injection molding device comprises a hopper, a hot melting box and a suction pump; the hot melting box is arranged below the hopper; a heater is arranged in the hot melting box; a transmission pipe is arranged on one side of the heater; the suction pump is arranged on the outer side of the transmission pipe; a control valve is arranged on one side of the suction pump; an injection molding head is arranged below the control valve; an injector is arranged below the injection molding head; an injection mold is arranged below the injector; a cooling fan is arranged on one side of the injection mold; a machine tool is arranged below the injection mold;a bearing block is arranged in the machine tool; and a water inlet pipe is arranged below the bearing block. The acid treatment big hook injection molding device has the following beneficial effects:the mold is cooled by a water cooling and air cooling cooperative mode, the cooling effect is good and the production efficiency of products is improved; meanwhile, mold opening is facilitated, positioning accuracy is achieved, sealing property is high, and the quality of big hook injection molding is guaranteed.

Owner:天津赫鑫机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com