Slope protection block prefabricated part mold and slope protection block prefabricated part

A technology of prefabricated components and slope blocks, which is applied in the direction of mold auxiliary parts, mold trays, mold panels, etc., can solve the problems of inconvenient mold clamping and demoulding operations, reduced mold service life, and complicated connection relations, etc., to achieve mold clamping or The mold opening operation is convenient, the production efficiency is improved, and the mold closing is firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

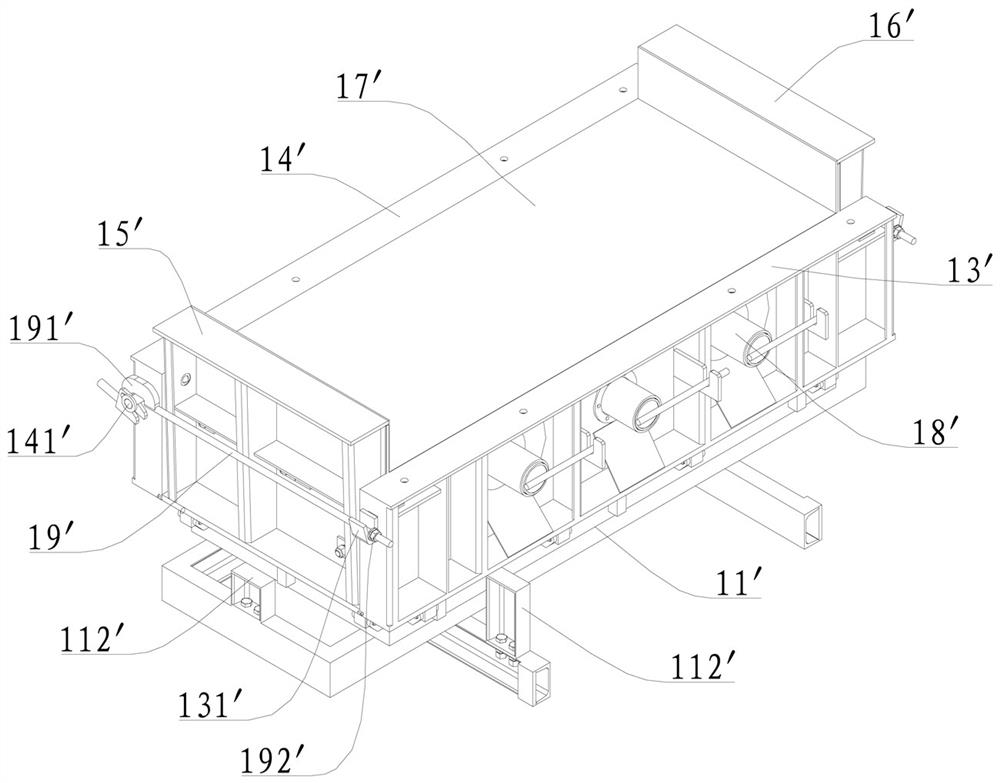

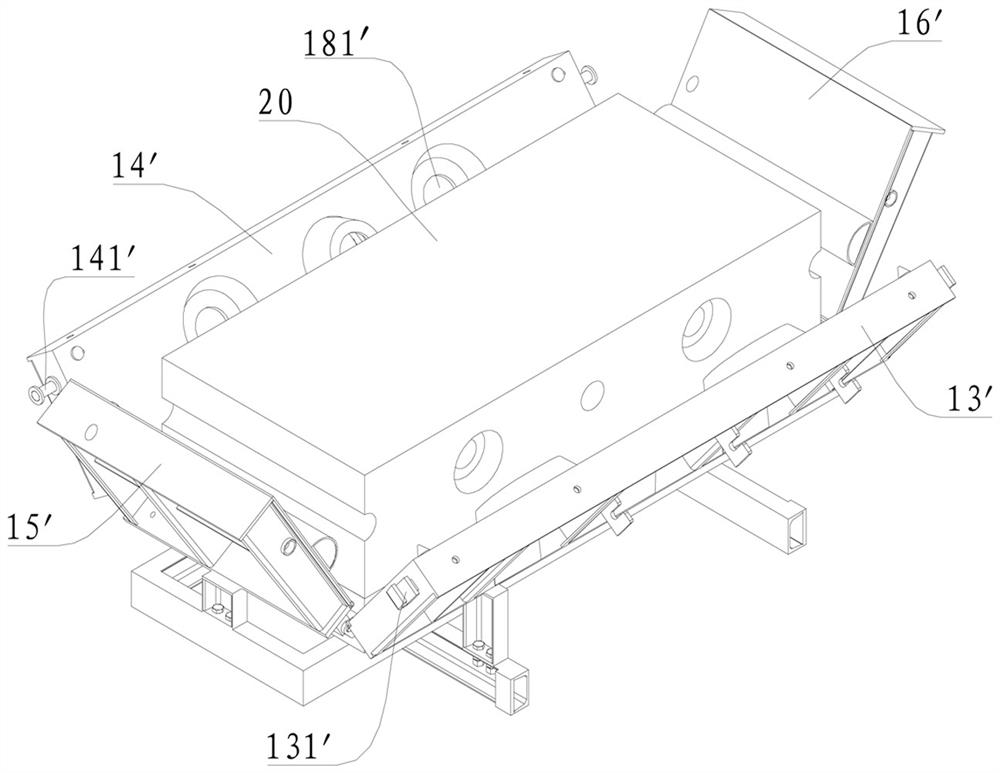

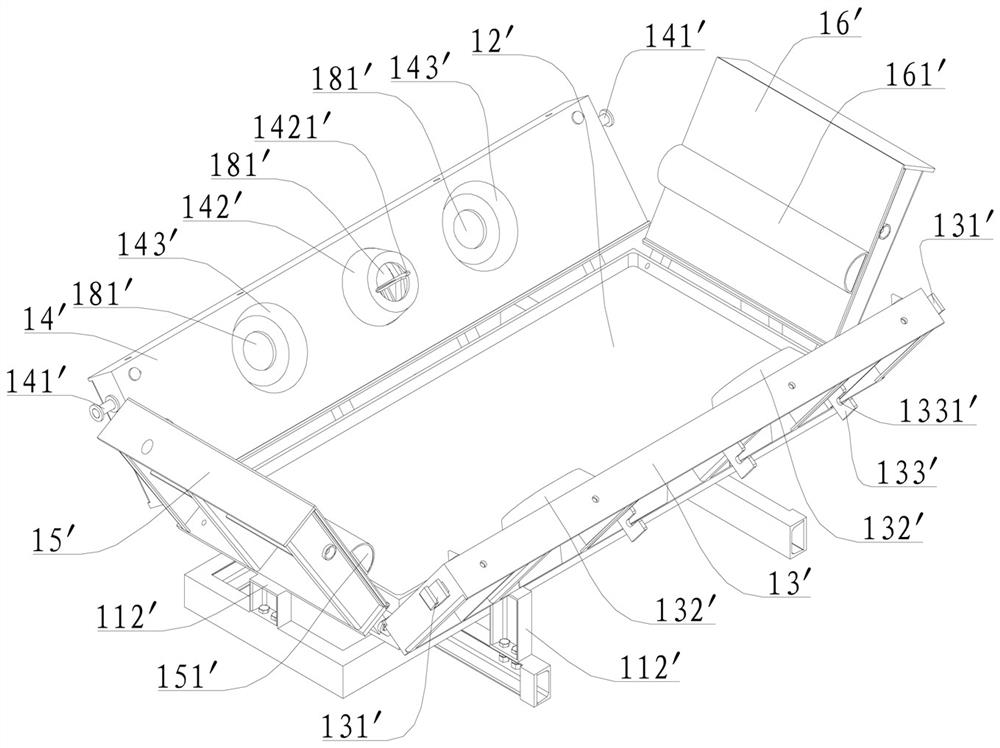

[0037] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0038] see Figure 1 to Figure 17 , the present invention discloses a slope protection block prefabricated component mold for producing a slope protection block prefabricated component 20, which has a bottom frame 11', a bottom mold 12', a front side mold 13', a rear side mold 14', and a left side mold 15', right side mold 16', top mold 17', core rod 18' and two locking rods 19'; the bottom mold 12' is set on the top surface of the bottom frame 11', and the front side The side mold 13', the rear side mold 14', the left side mold 15', and the right side mold 16' are pivotally connected to the four sides of the bottom frame 11' respectively. The front side mold 13', The rear side mold 14' is provided with a plurality of through holes 181' for the core rod 18' to pass through; the bottom mold 12', the front side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com