Hydraulic automatic mould-locking forging device

An automatic die-clamping and hydraulic technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve problems such as increasing equipment tonnage, affecting the forming of forgings, and reducing the quality of forgings. Convenience, convenient mold opening, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

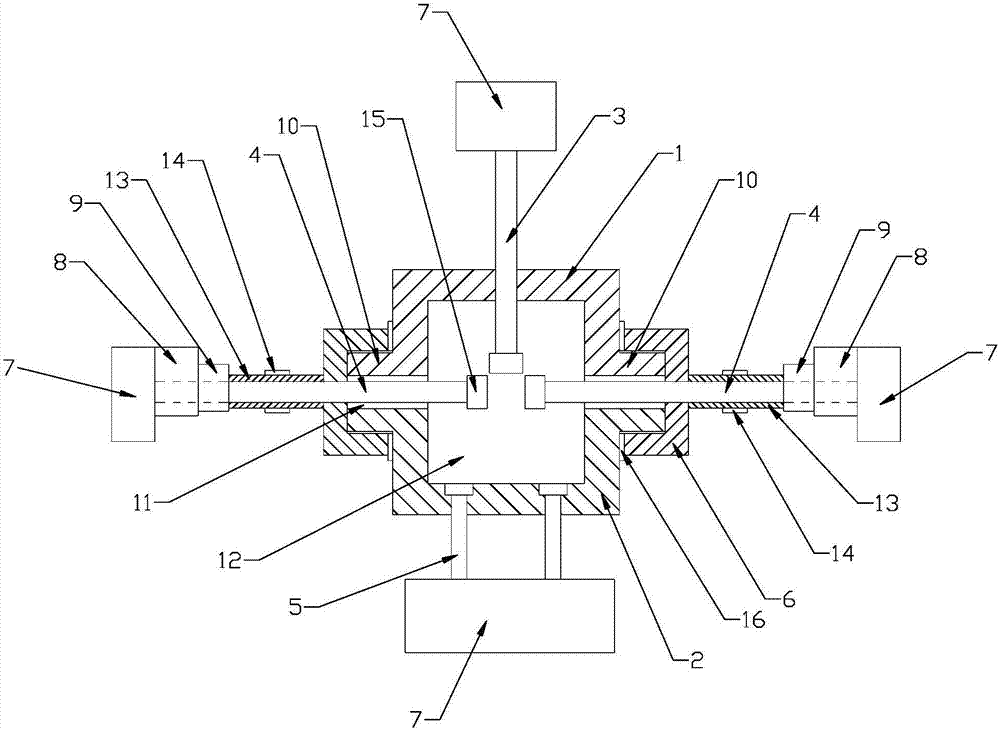

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention provides a hydraulic automatic clamping forging device, which includes an upper die 1, a lower die 2, an upper ram 3, two opposite side rams 4, an ejector rod 5, a threaded sleeve 6, a hydraulic cylinder 7. The motor 8 and the reducer 9, wherein both ends of the upper mold 1 and the lower mold 2 have flanges, and the upper and lower corresponding flanges are closely fitted to form a cylindrical boss 10, and the middle of the cylindrical boss 10 is provided with a The through hole A11 with the same axis, the through hole A11 is connected with the cavity 12 formed after the upper mold 1 and the lower mold 2 are combined, the threaded sleeve 6 is set on the cylindrical boss 10 and the two are threaded, the threaded sleeve 6 Gaskets 16 are arranged between the end parts and the upper mold 1 and the lower mold 2 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com