Horizontal demoulding method of multidirectional die forging hydraulic press

A technology of multi-directional die forging and horizontal parting, applied in the field of multi-directional forging, can solve the problems of increasing the tonnage of equipment, reducing the quality of forgings, affecting the forming of forgings, etc., and achieves the effects of convenient mold opening, low manufacturing cost, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

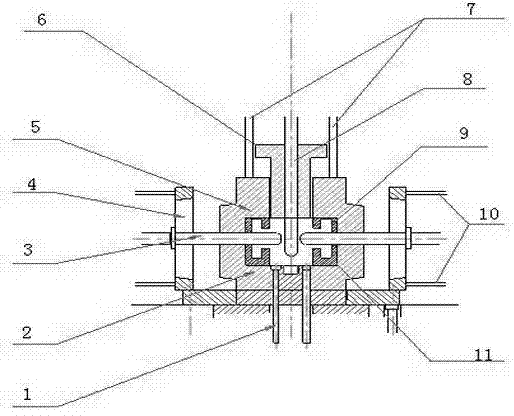

[0018] Embodiment 1: A method for horizontal parting of a multi-directional die forging hydraulic press, which includes the following steps:

[0019] (1) The vertical push rod 7 pushes the upper die 9 down to realize the clamping of the upper die 9 and the lower die 11, and puts the billet after heating, descaling and blank making into the mold cavity of the multi-directional die forging press;

[0020] (2) The hydraulic cylinders on the left and right sides act on the horizontal push rod 10 to push the mold clamping ring 4 to the protrusions on the upper mold casing 5 and the lower mold casing 2 respectively, and the upper mold casing 5 and the lower mold casing 2 are engaged. Press and fix;

[0021] (3) The vertical piercing rod 8 goes down to the predetermined position, and then stops, and the main cylinder pressure head 6 of the multi-directional die forging press goes down to the set stroke, and is in a pressure-holding state after completion;

[0022] (4) The horizontal...

Embodiment 2

[0025] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the protruding part and the inner wall of the clamping ring are wedge-shaped to cooperate with each other.

Embodiment 3

[0026] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, except that a hydraulic cylinder is used to act on the horizontal push rod to push the clamping ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com