Mobile formwork bridge fabrication machine and construction method for cast-in-situ bridge fabrication

A technology of moving formwork and bridge building machine, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of slow speed, high construction cost, large construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings of the present invention: the present invention will be further described below in conjunction with the accompanying drawings of the present invention:

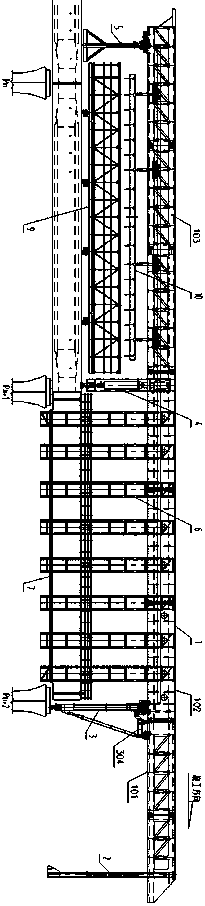

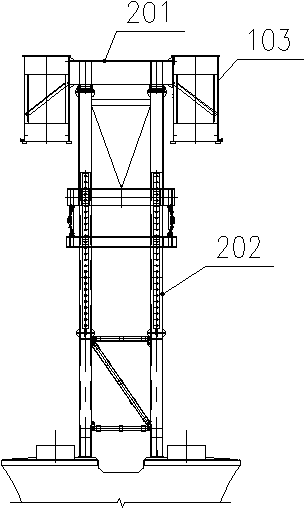

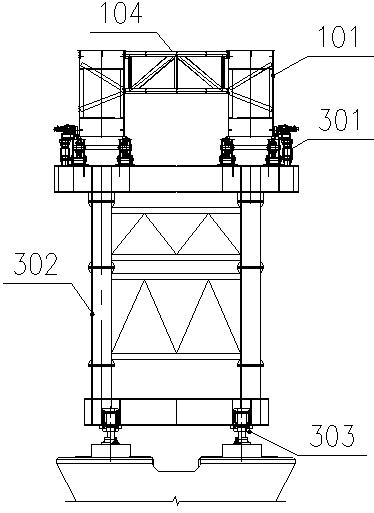

[0076] Such as Figure 1 to Figure 44 As shown, the mobile formwork bridge-building machine disclosed in the present invention belongs to the top-supporting type, and is a bridge-building machine whose main structure is supported above a concrete bridge. "Pn" "Pn+1" "Pn+2" in the diagram... indicates the number of the bridge pier, indicating the formwork construction pier span. The term "front" used in the present invention refers to the same direction as the construction direction, and the term "rear" refers to the direction opposite to the construction direction; the term "longitudinal" refers to the length direction of the bridge, and the term "transverse" refers to The width direction of the bridge; the term "vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com