Acid treatment big hook injection molding device and injection molding method thereof

An injection molding and acid treatment technology, which is applied in the field of acid treatment large hook injection molding device, can solve the problems of inaccurate control of injection molding device, poor mold cooling effect, and affecting production effect, etc., and achieve good cooling effect, good sealing, The effect of convenient mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

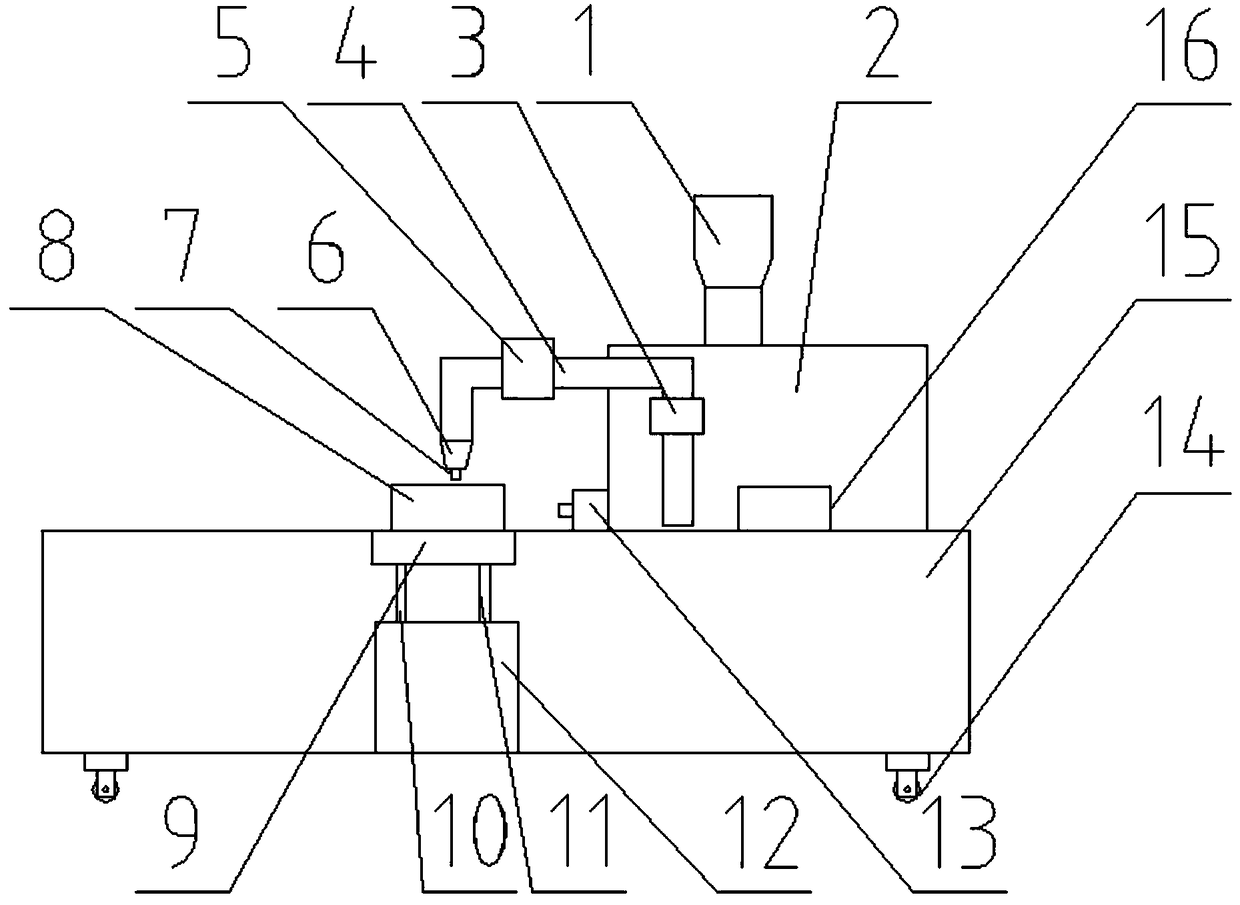

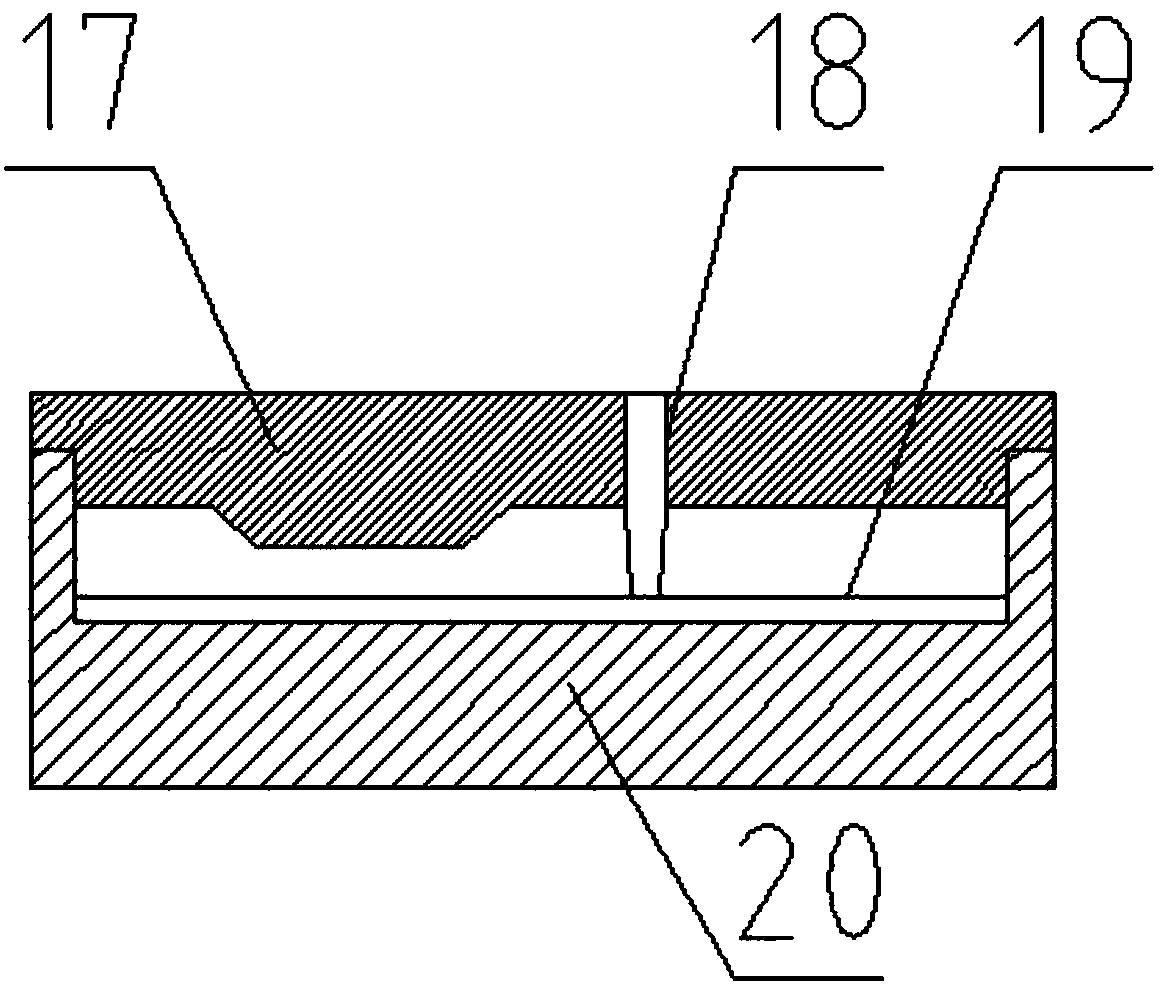

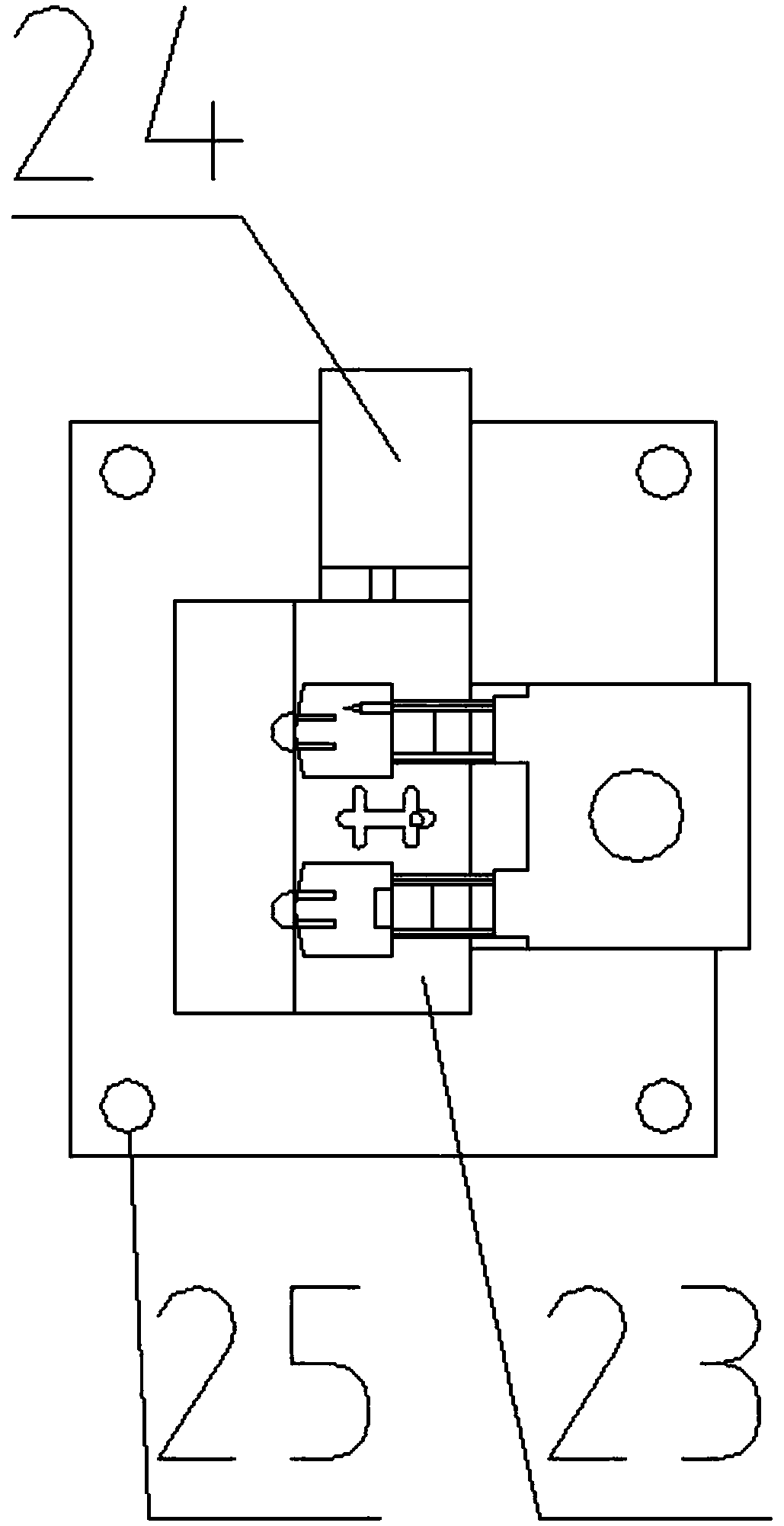

[0024] Such as Figure 1-Figure 4 As shown, an acid-treated large hook injection molding device includes a hopper 1, a hot melt tank 2, and a suction pump 3. The hot melt tank 2 is arranged below the hopper 1, and the hot melt tank 2 is provided with A heater 16, a transfer pipe 4 is arranged on one side of the heater 16, the suction pump 3 is arranged on the outside of the transfer pipe 4, and a control valve 5 is arranged on one side of the suction pump 3, and the control valve 5, an injection head 6 is arranged below the injection head 6, an injector 7 is arranged under the injection head 6, an injection mold 8 is arranged under the injector 7, a cooling fan 13 is arranged on one side of the injection mold 8, and a cooling fan 13 is arranged under the injection mold 8. There is a machine tool 15, a bearing block 9 is arranged inside the machine tool 15, a water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com