Rapid die

A mold and rapid technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult to truly reflect consumer problems, so as to speed up the time to seize the market, save mold costs, and reduce mold opening costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

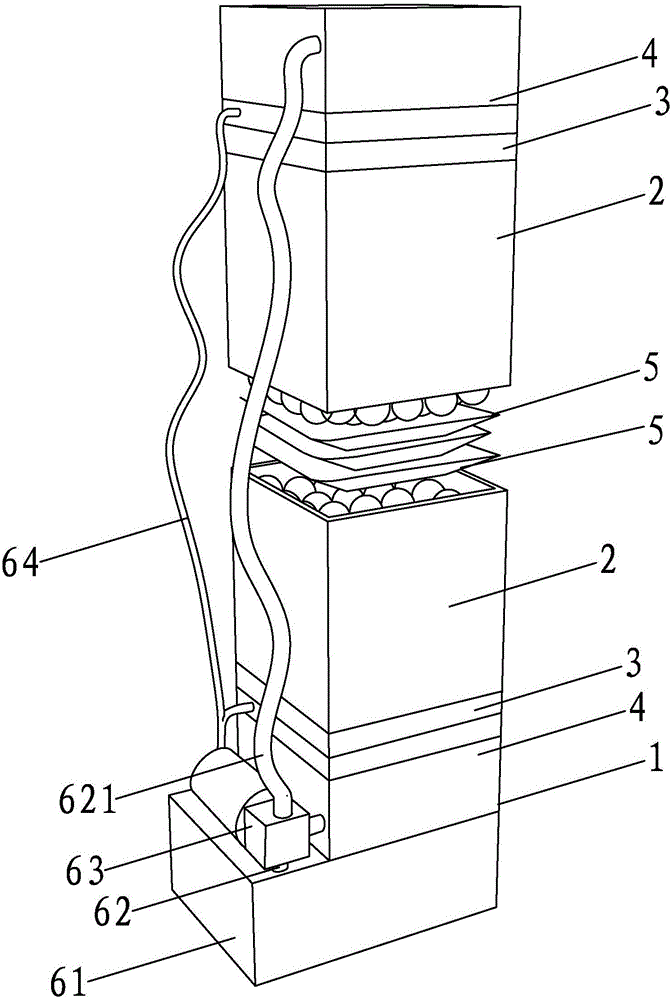

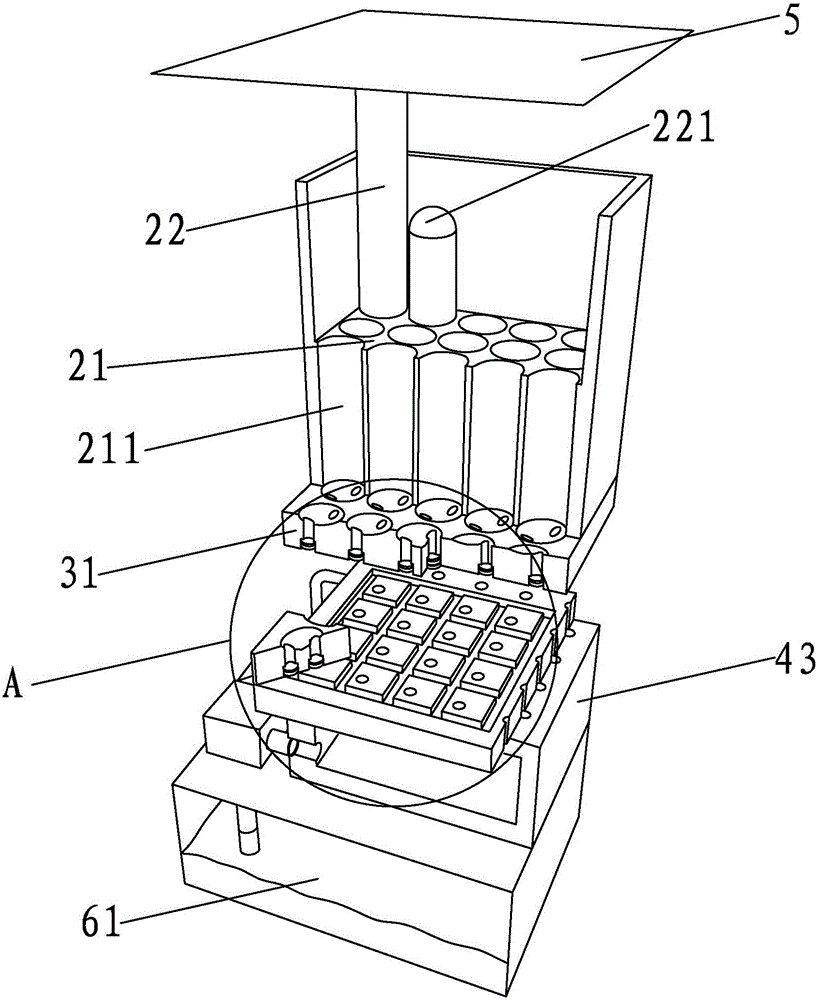

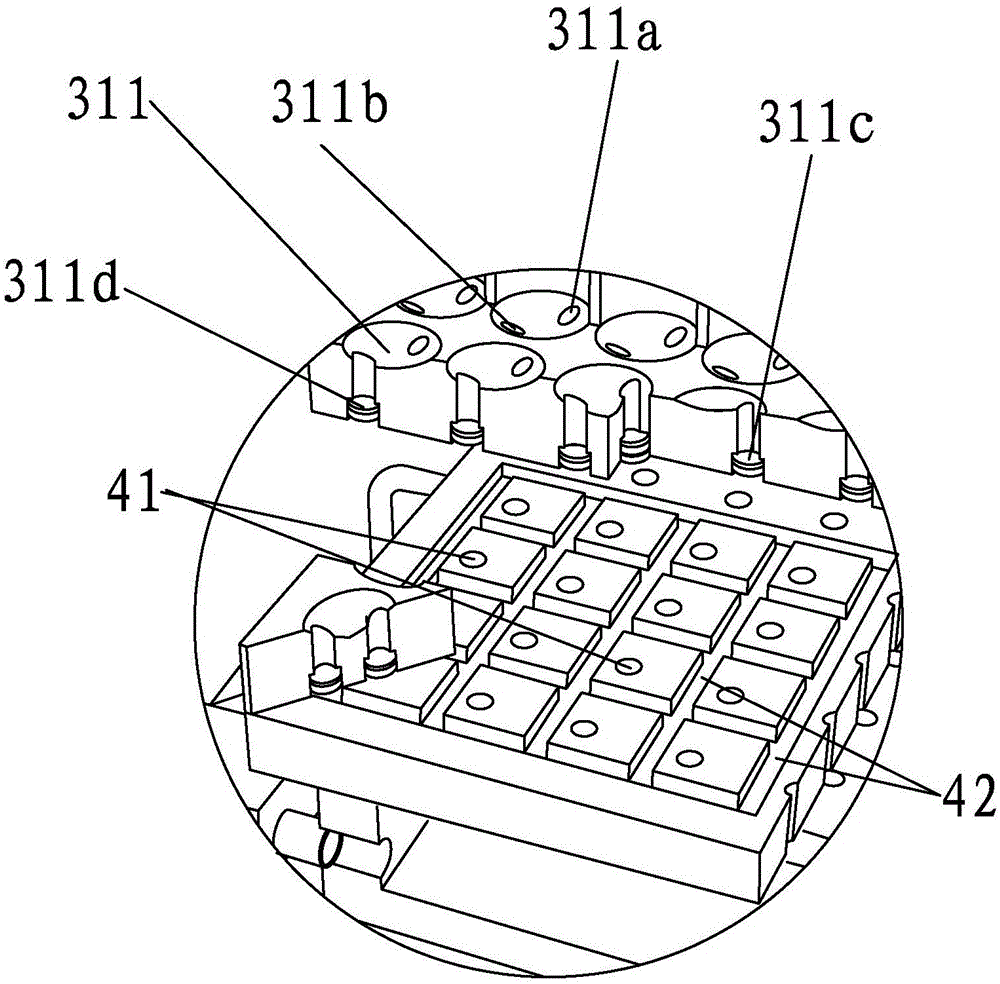

[0046] A rapid tooling such as figure 1 As shown, it includes a closed mold shell 1, two sets of mold units, a mold forming control device and an oil supply device, wherein one set of mold units forms the upper mold of the mold, and the other set of mold units forms the lower mold of the corresponding mold upper mold.

[0047] Such as figure 1 As shown, each set of mold units includes a mold assembly module 2, a movement control module 3, an inlet and outlet oil channel module 4, and a molding module. The oil passage module 4 is arranged vertically in the mold shell 1 from bottom to top in turn, and the molding module, mold combination module 2, movement control module 3 and oil passage module 4 in the mold unit corresponding to the lower mold of the mold are sequentially arranged from top to bottom Vertically arranged in the mold shell 1, the molding module in the mold unit corresponding to the upper mold of the mold and the molding module in the mold unit corresponding to t...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the rapid mold includes six sets of mold units, of which two sets of mold units are arranged symmetrically up and down to form corresponding mold upper molds and mold lower molds, and the other four sets of mold units are respectively arranged on the mold Form mold side mold around mold and mold lower mold, and mold shell comprises the mold upper shell that is arranged on the outside of mold upper mold, the mold lower shell that covers is arranged on the mold lower mold that is connected with each other, and four covers are arranged on respectively. Mold side shells outside the individual mold side molds. The lower end of the upper shell of the mold is provided with a fitting edge inclined outwards, the upper end of the lower shell of the mold is also inclined outwards with an upper fitting edge, and the upper end of each mold side shell is inclined outwards and is provided with a joint with the upper shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com