Polyurethane solid tire mold and its processing method

A technology of solid tires and processing methods, applied to tires, household utensils, and other household utensils, etc., can solve the problems of inconvenient cleaning, oil resistance, and difficulty in taking tires, and achieve the effect of easy cleaning and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

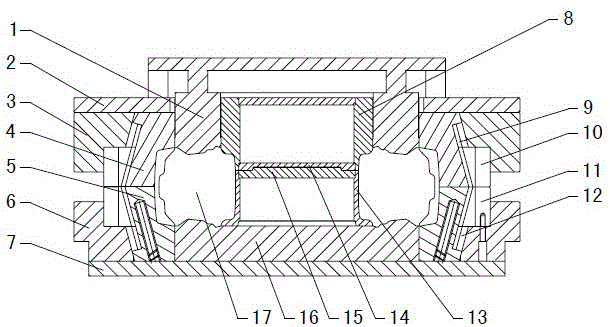

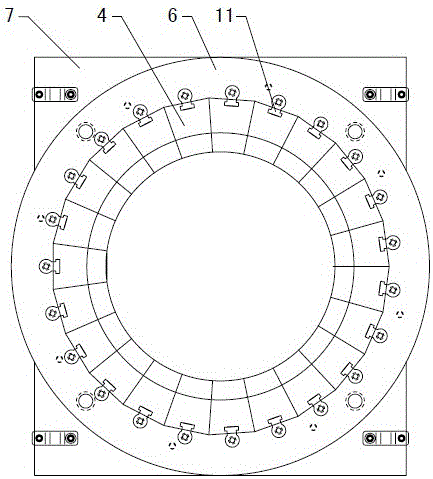

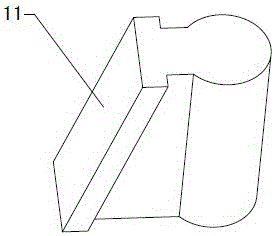

[0031] Figure 1~3 It is the best embodiment of the mold of this polyurethane solid tire and its processing method, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0032] refer to Figure 1~2 , the mold of the polyurethane solid tire includes a hub module, a pattern module, a lower mold 16 and an upper mold 1, the hub module is arranged vertically, the pattern module is coaxially sleeved on the outside of the hub module, and is formed between the hub module and the pattern module An annular tire mold cavity 17, the lower mold 16 is sealed and fixed on the lower side of the tire mold cavity 17, and the upper mold 1 is pressed downward on the upper side of the tire mold cavity 17;

[0033] The pattern module includes an upper pattern module and a lower pattern module that are docked up and down. The upper pattern module is arranged on the inner side of the circumference of an annular upper holder 3, and the lower pattern module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com