Temperature and humidity sensor

A temperature and humidity sensor and humidity-sensitive technology, applied in the direction of instruments, measuring device shells, measuring devices, etc., can solve problems such as low production efficiency and yield rate, complex packaging structure, and complicated packaging procedures, so as to improve packaging efficiency and effect, Sensitivity and reliability improvement, effects of sensitivity and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

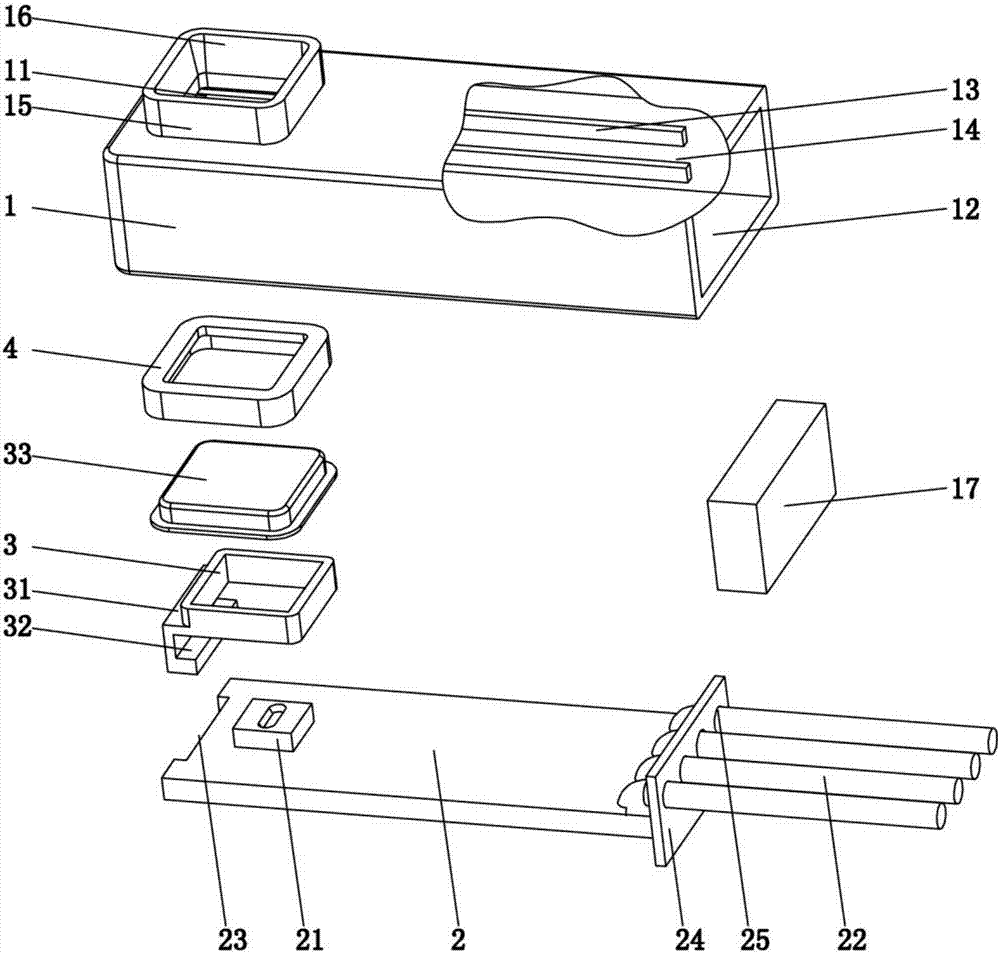

[0017] Such as figure 1 As shown, a kind of temperature and humidity sensor described in the present invention comprises a hollow package shell 1, and the package shell 1 is provided with a PCB board 2, and the front portion of the PCB board 2 is provided with a humidity-sensitive chip 21; The detection window 11 corresponding to the upper and lower sides of the moisture sensitive chip 21 is provided on the panel, and the shaping frame 3 and the shaping frame 4 of the ring structure are arranged on the PCB board 2, and the shaping frame 3, the shaping frame 4 and the detection window 11 are nested in sequence and mutually There is an interference fit between them, and the shaping frame 3 is arranged around the humidity sensitive chip 21 and connected with the PCB board 2; the upper port of the shaping frame 3 is covered with a filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com