Bottle blowing device for bottle blowing machine

A technology of bottle blowing machine and bottle blowing mould, which is applied in the field of bottle blowing devices, and can solve the problems of unsteady drive, poor control reliability, slow movement, etc., achieve accurate sequence and continuity, avoid bearing damage, and have no time difference in action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples.

[0035] The front, back, left, and right described in the embodiment of the present invention are figure 1 The position placed in the center is determined, the left side of the observer is left, the right hand side is right, the front is close to the observer, and the back is far away from the observer.

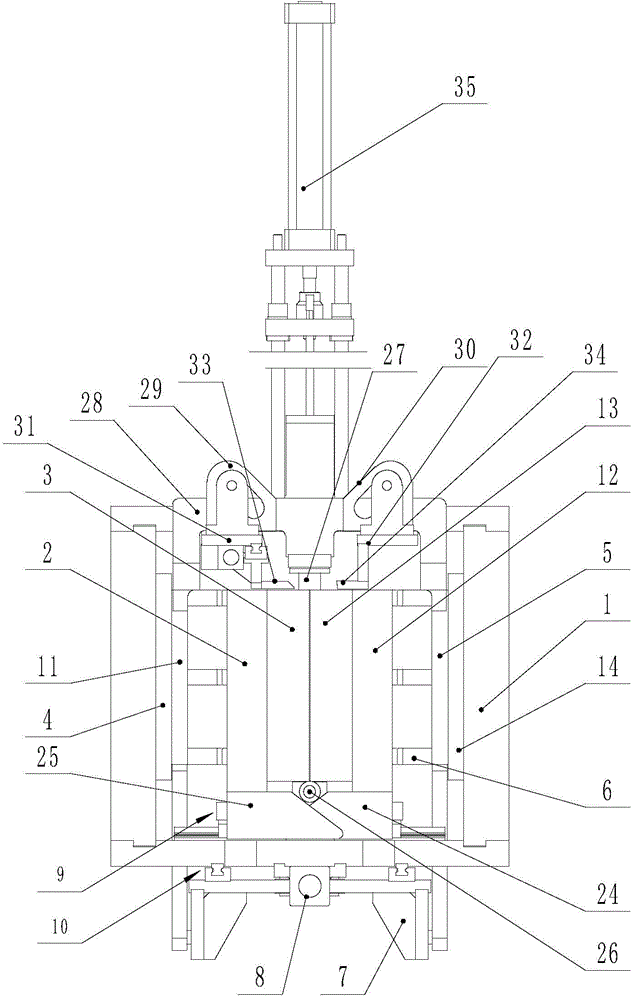

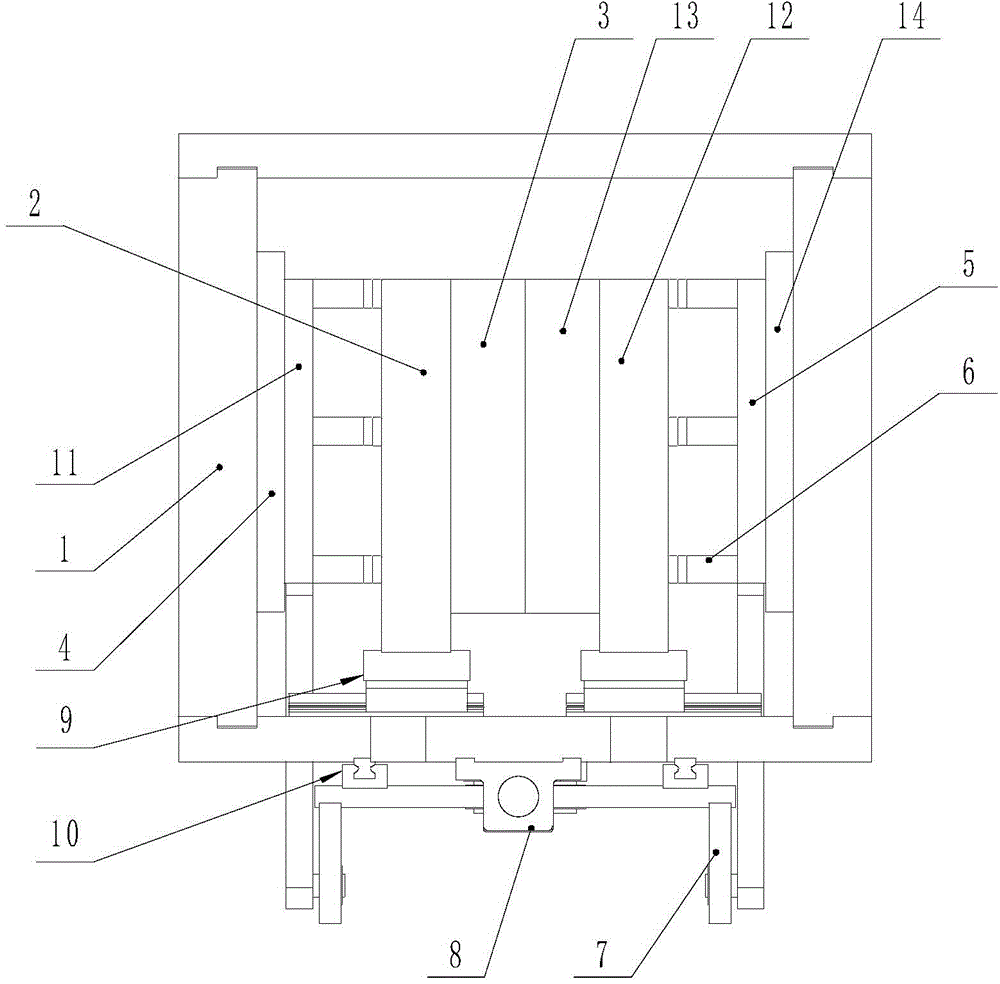

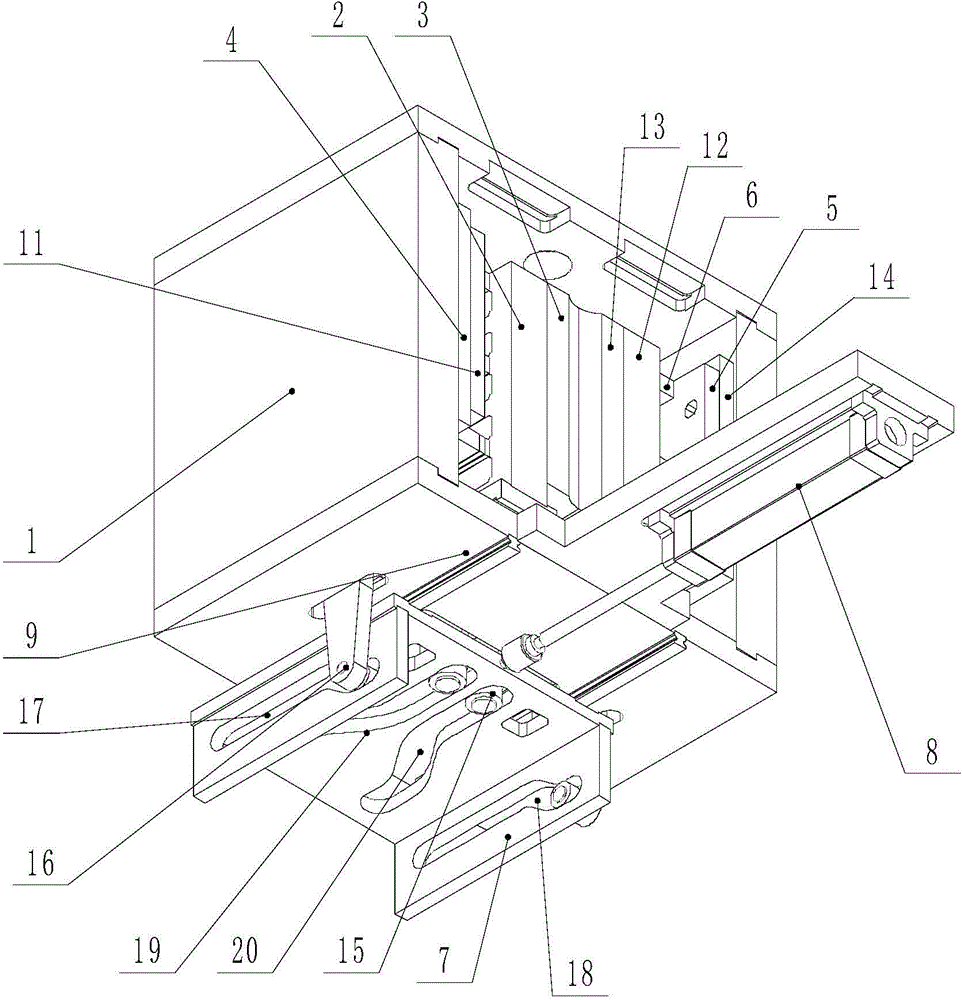

[0036] Such as Figure 1 to Figure 13 As shown, a bottle blowing device of a bottle blowing machine includes a frame, a bottle blowing mold, a preform input device, a bottle output device, a mold opening and closing device, an upper sealing device, a bottom mold lifting device, and an air blowing device.

[0037] Such as Figures 2 to 5 As shown, the bottle blowing mold includes a mold frame 1, left and right mold bases 2, 12, left and right bottle body molds 3, 13, and a bottom mold 36. The mold frame 1 is fixed on the frame, and the mold frame 1 includes a bottom plate, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com