90-degree overturning, mould-opening and closing method of follower fixture and equipment thereof

A technology of traveling clamps and turning cylinders, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, unable to keep up with the rhythm, etc., and achieve the effect of eliminating manpower, saving time, and convenient mold opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

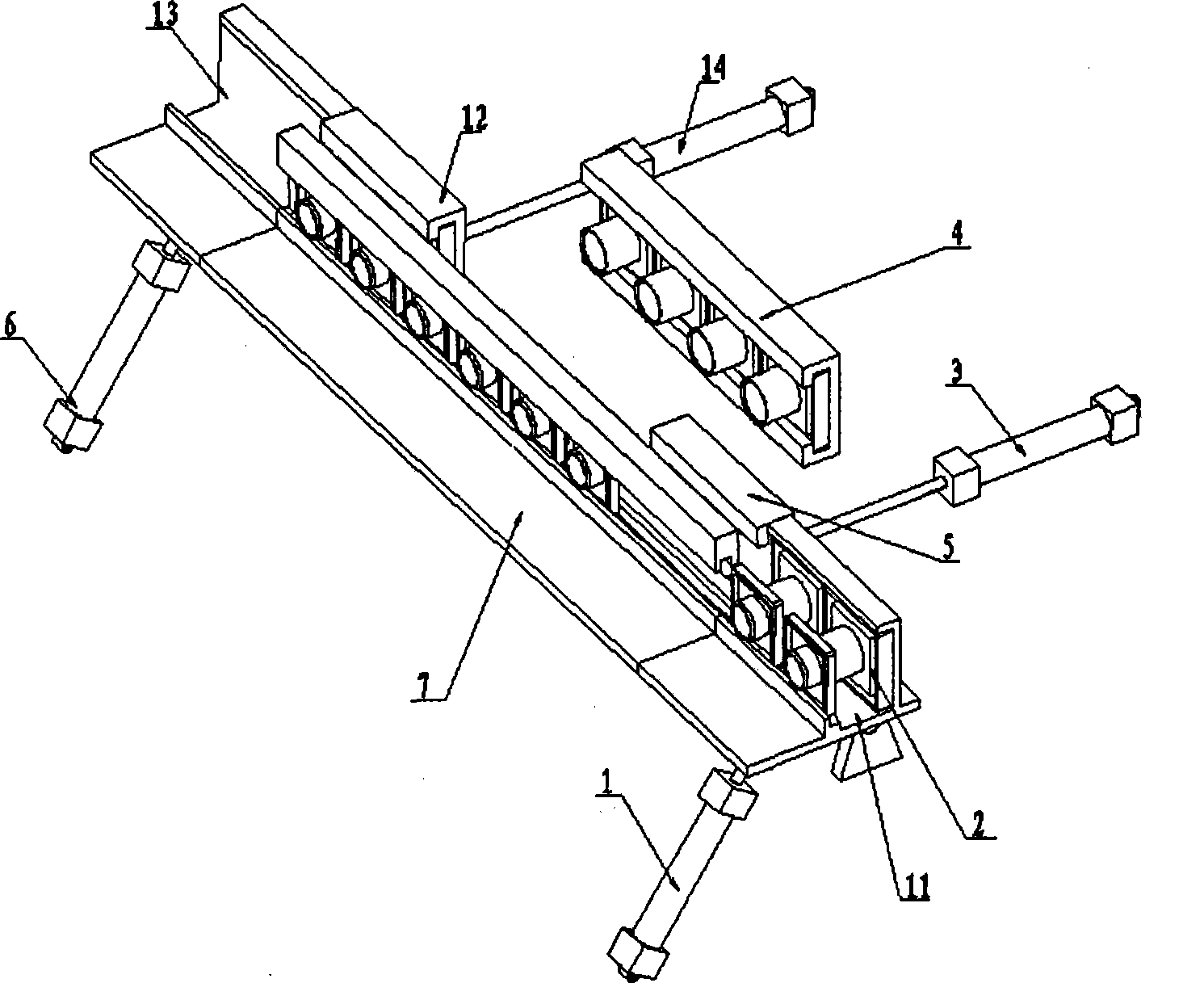

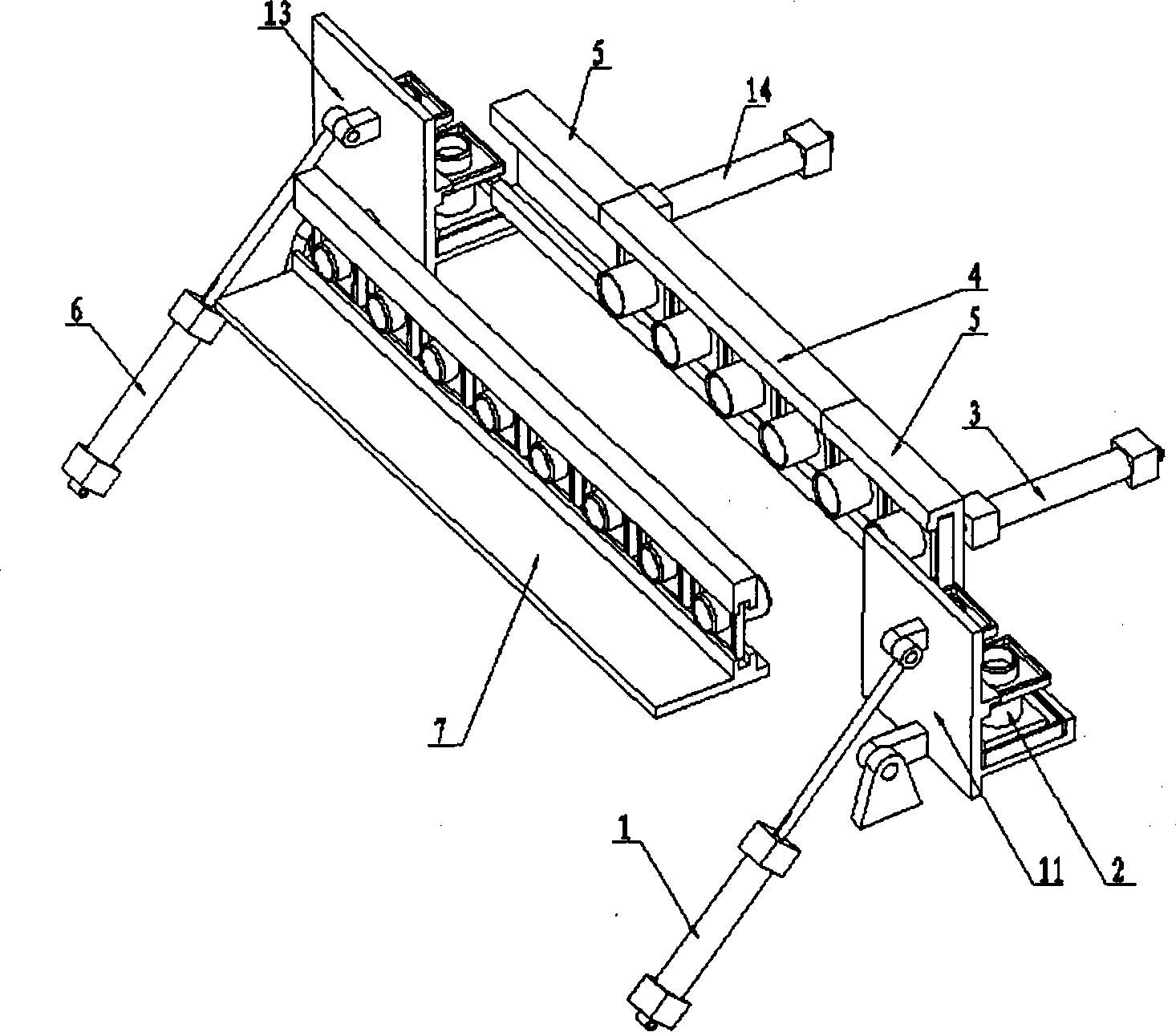

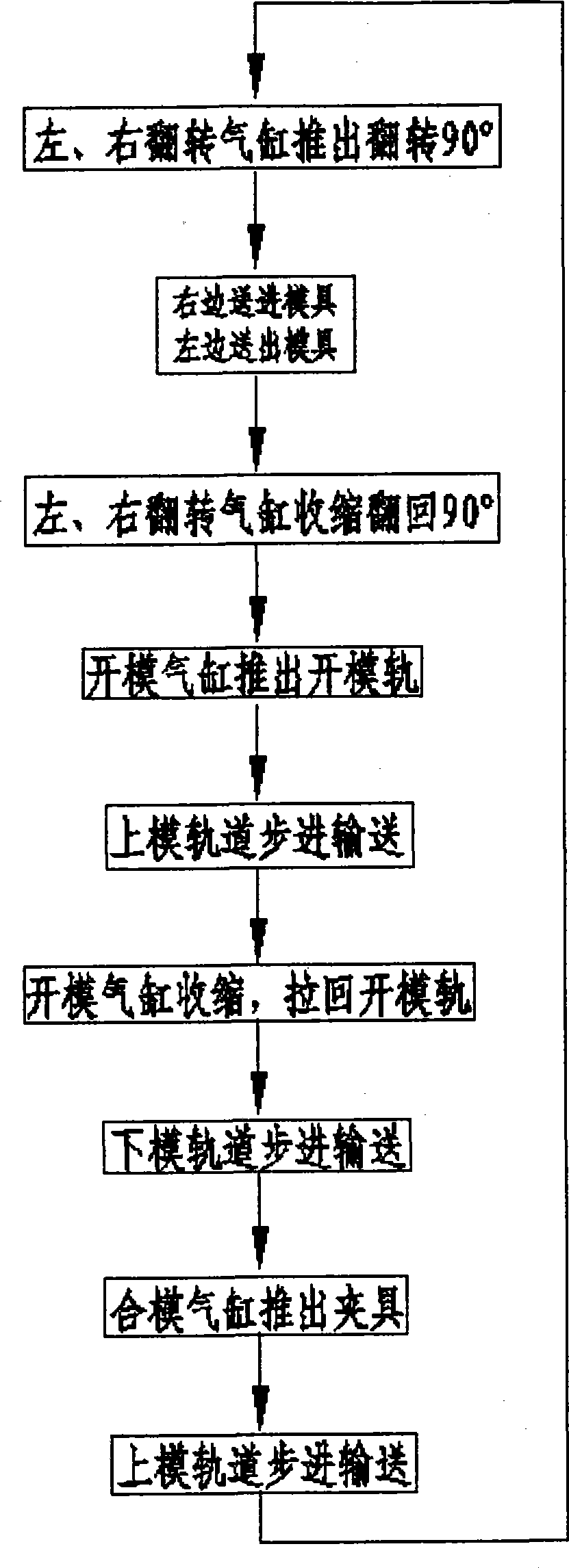

[0017] Right mold opening process:

[0018] ①When the accompanying fixture 2 is about to be transported to the right turning track, the left turning cylinder and the right turning cylinder in the left turning track 6 push out the track;

[0019] ② After the accompanying fixture 2 is transported to the right turning track, the right turning cylinder pulls back the track, and the traveling fixture realizes 90° turning;

[0020] ③The right mold opening cylinder 3 pushes out the right mold opening rail 5, and after the accompanying fixture is transported to the upper mold conveying track step by step, the right mold opening cylinder 3 retracts, and the accompanying fixture realizes mold opening; the left mold closing method is the same as the process in reverse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com