Tool mold for high-speed railway part casting

A technology for high-speed railways and parts, applied in the direction of manufacturing tools, casting equipment, casting molding equipment, etc., can solve the problems of low reliability, easy generation of micro-bubbles, and low practicability, so as to improve the reliability of use, facilitate fixing and Mold opening, effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

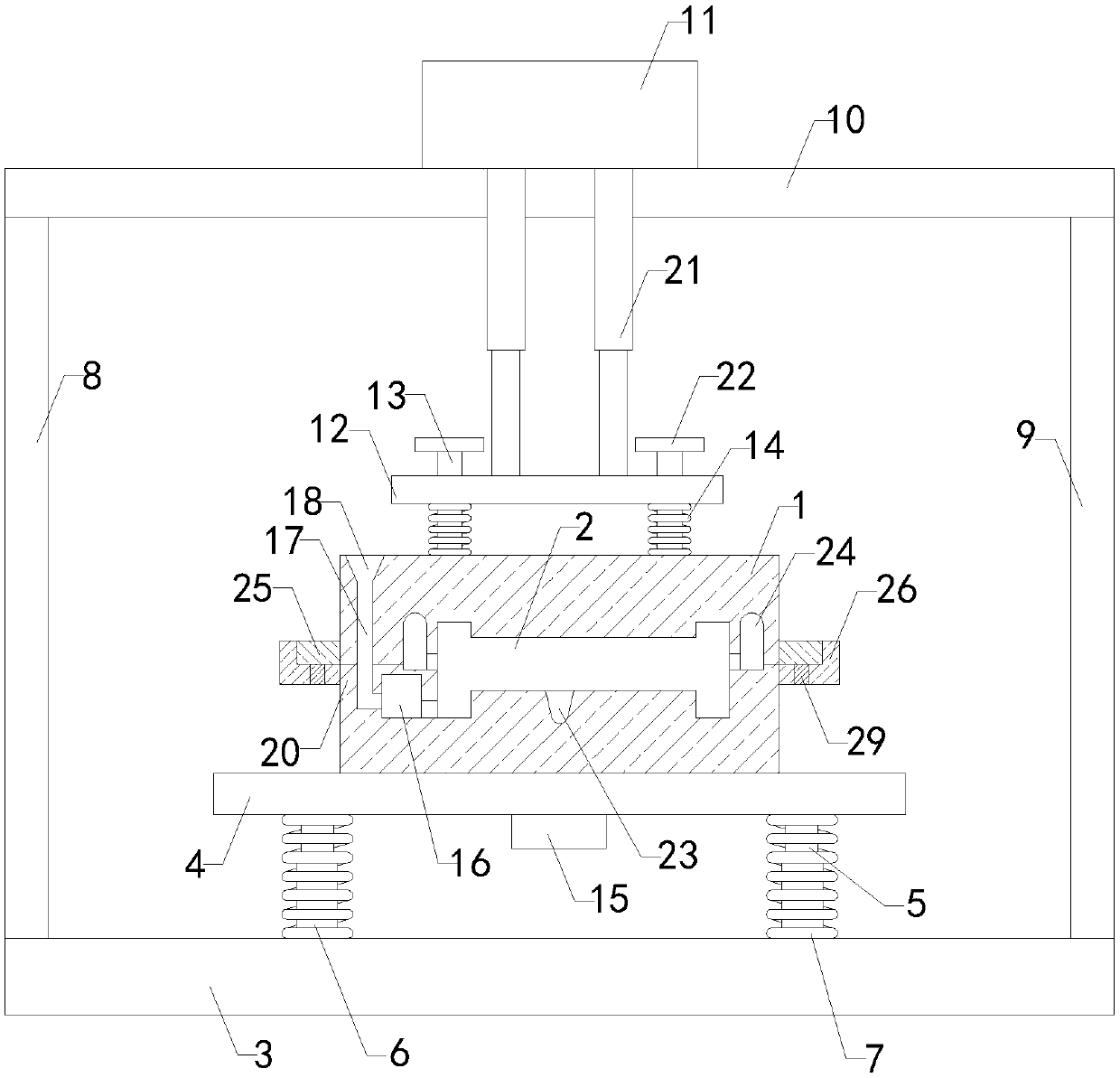

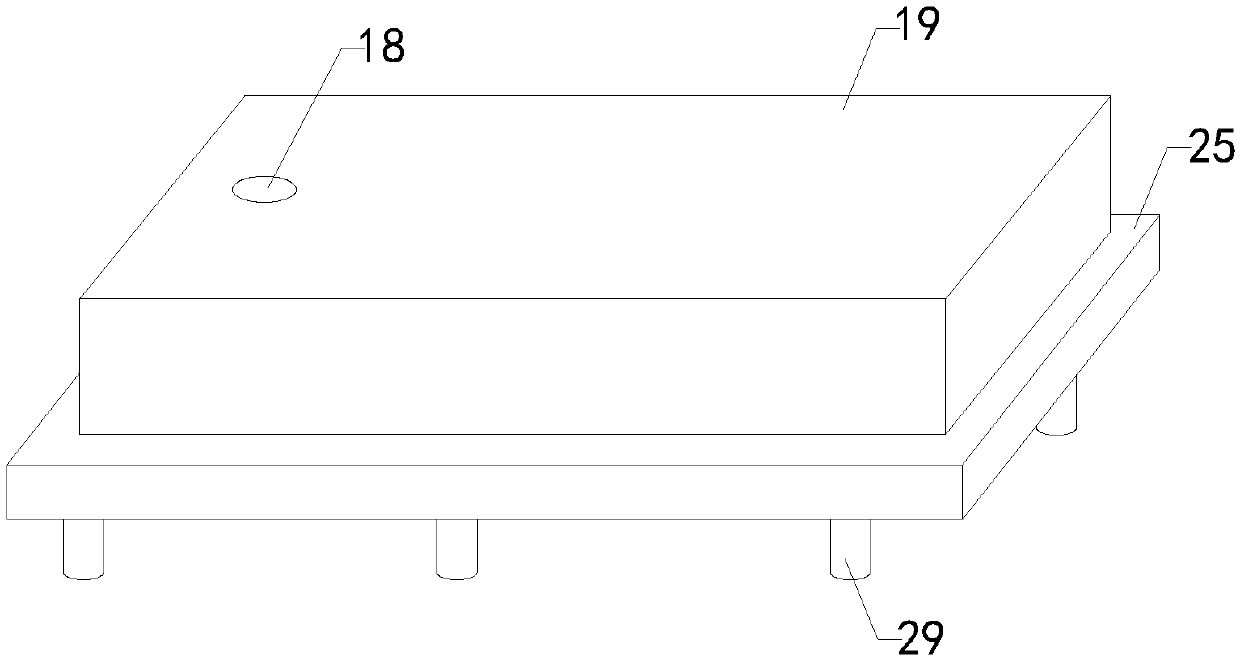

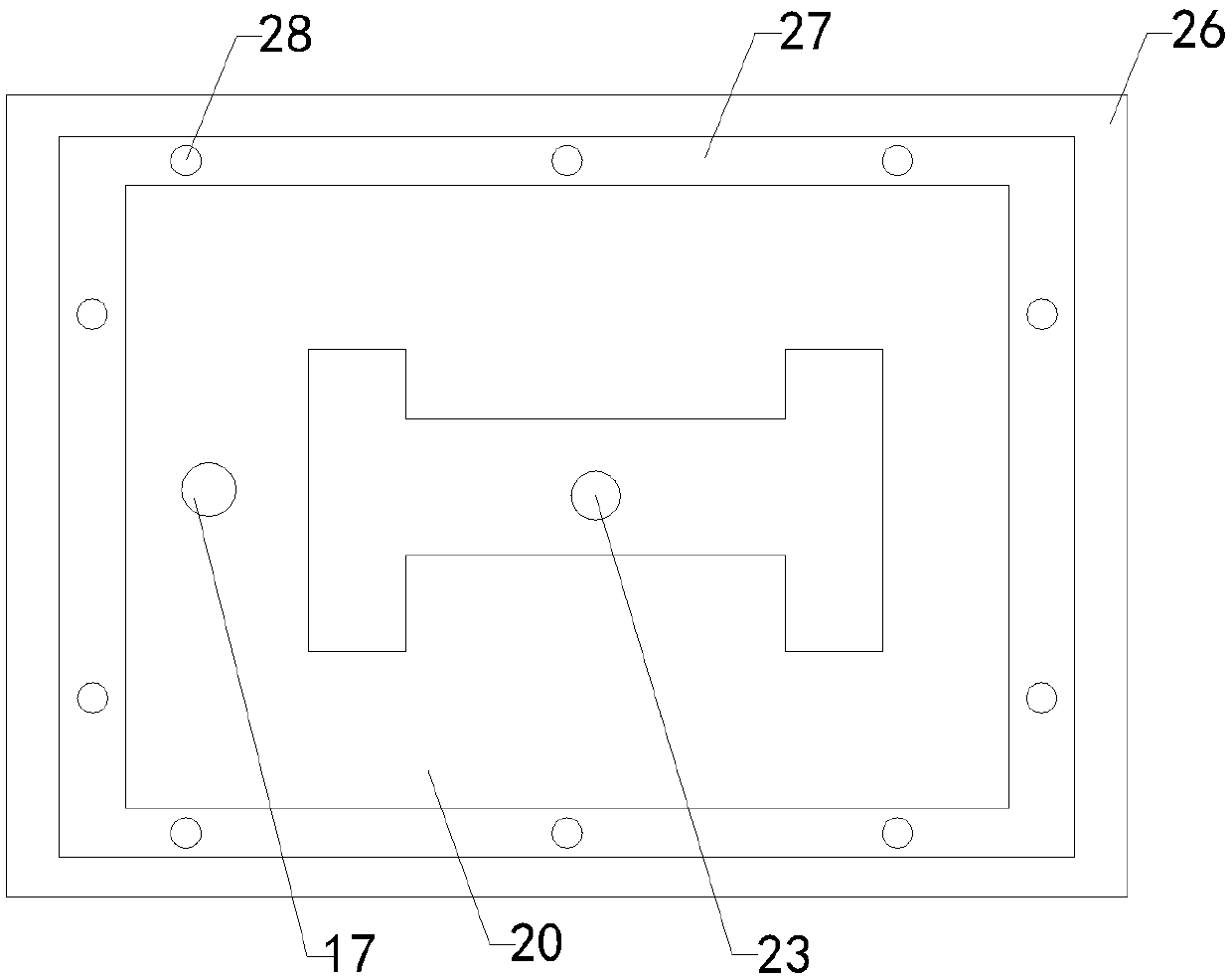

[0018] like Figure 1 to Figure 3 As shown, a kind of casting tooling mold for high-speed railway parts of the present invention includes a mold body 1, and the inside of the mold body 1 is provided with a mold cavity 2; it also includes a workbench 3, a support plate 4, four groups of guide pillars 5, Four sets of guide sleeves 6, four sets of support springs 7, left support plate 8, right support plate 9, top plate 10, biaxial cylinder 11, connecting plate 12, four sets of limit rods 13 and four sets of compression springs 14, four sets The bottom ends of the guide sleeves 6 are respectively connected to the left front side, right front side, left rear side and right re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com