Roller servo storage system

A roller and material storage technology, applied in the field of roller servo material storage system, can solve the problem of high cost of planetary gear transmission device and cycloidal gear transmission device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The connection mentioned in the present invention refers to a direct connection or an indirect connection between one or more objects or components, for example, there may be one or more intermediate connections between one or more objects or components.

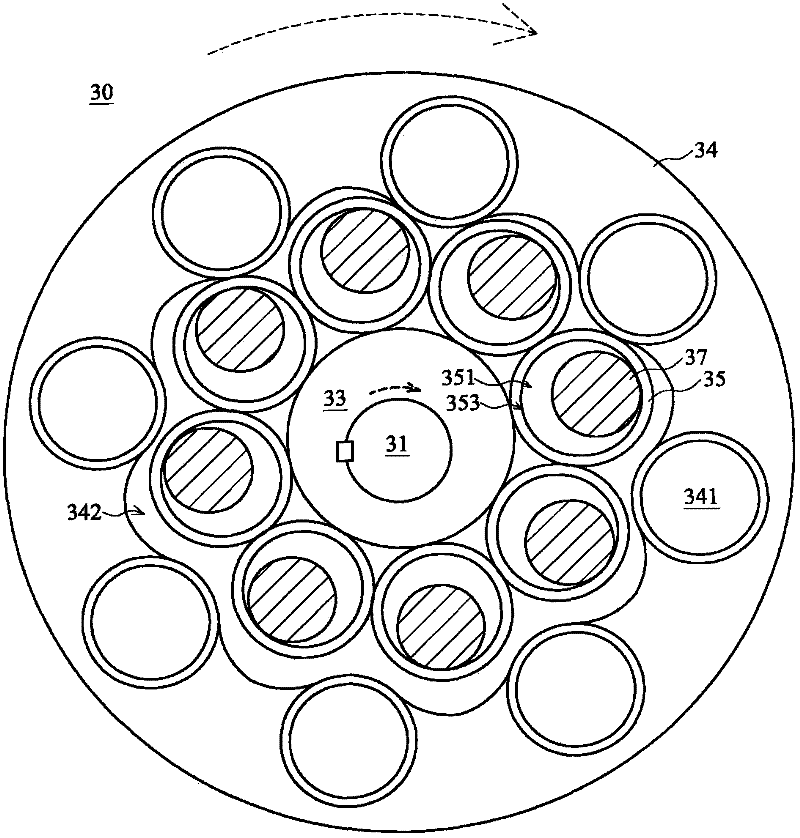

[0057] see image 3 and Figure 4 Shown are the front side schematic diagram and the rear side schematic diagram of an embodiment of the transmission device of the roller servo storage system of the present invention, respectively. As shown in the figure, the speed change device 30 of the present invention includes an input shaft 31, an eccentric wheel 33, a plurality of hollow cylinders 35, a plurality of pins 37 and an output disk 39, wherein a plurality of hollow cylinders 35 are arranged around Around the eccentric wheel 33, a rolling gear structure is formed.

[0058] In the embodiment of the present invention, one end of the input shaft 31 can be connected with an external motor, and transmit the power generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com