Middle plate type multiple-slider structure die

A slider and multiple technology, which is applied in the field of medium-plate multi-slider structure molds, can solve the problems of demoulding, the inability to use the mold to pull out the slider, and the reduction of the scope of use of the mold. It achieves low cost, simple structure, and convenient mold opening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

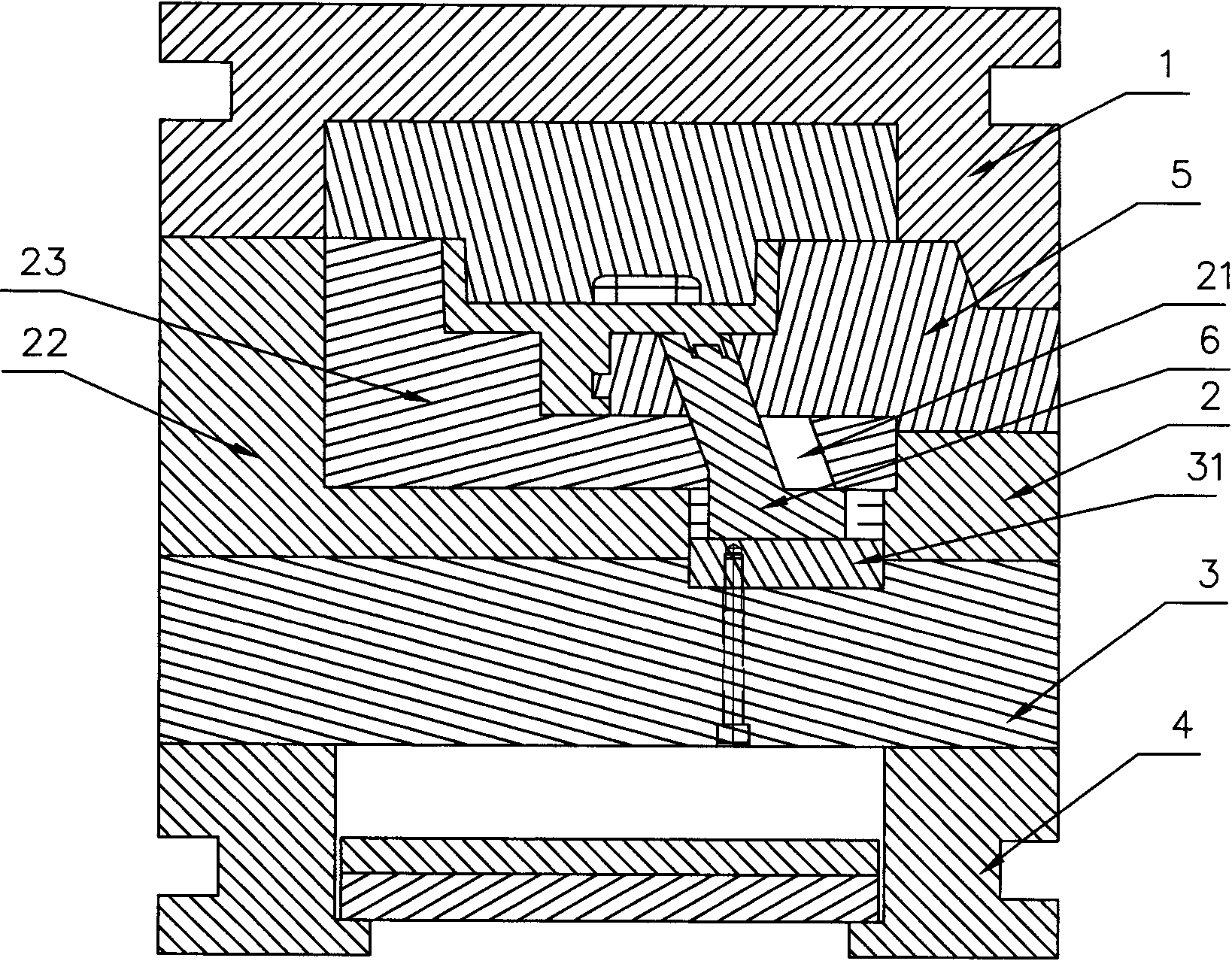

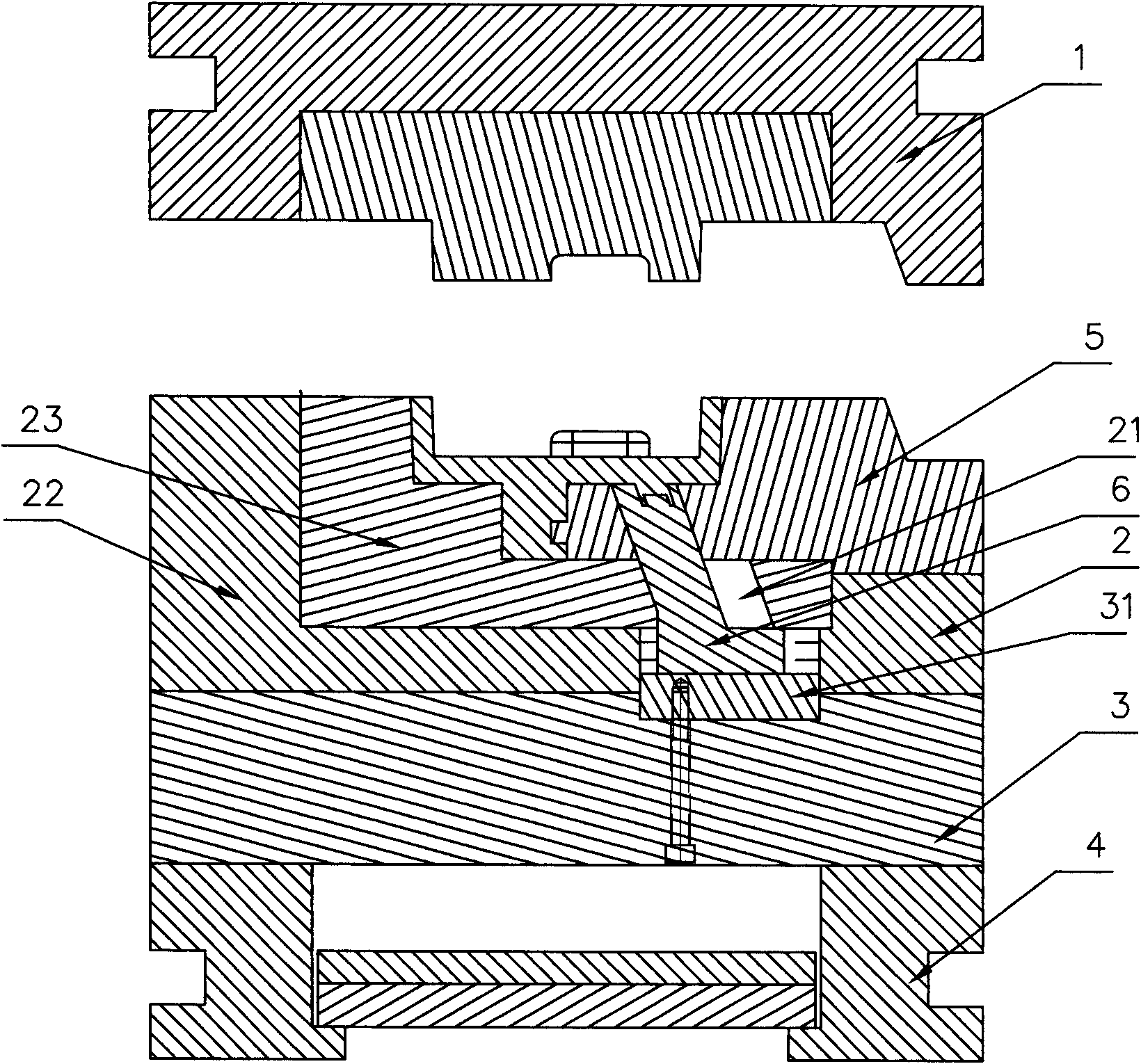

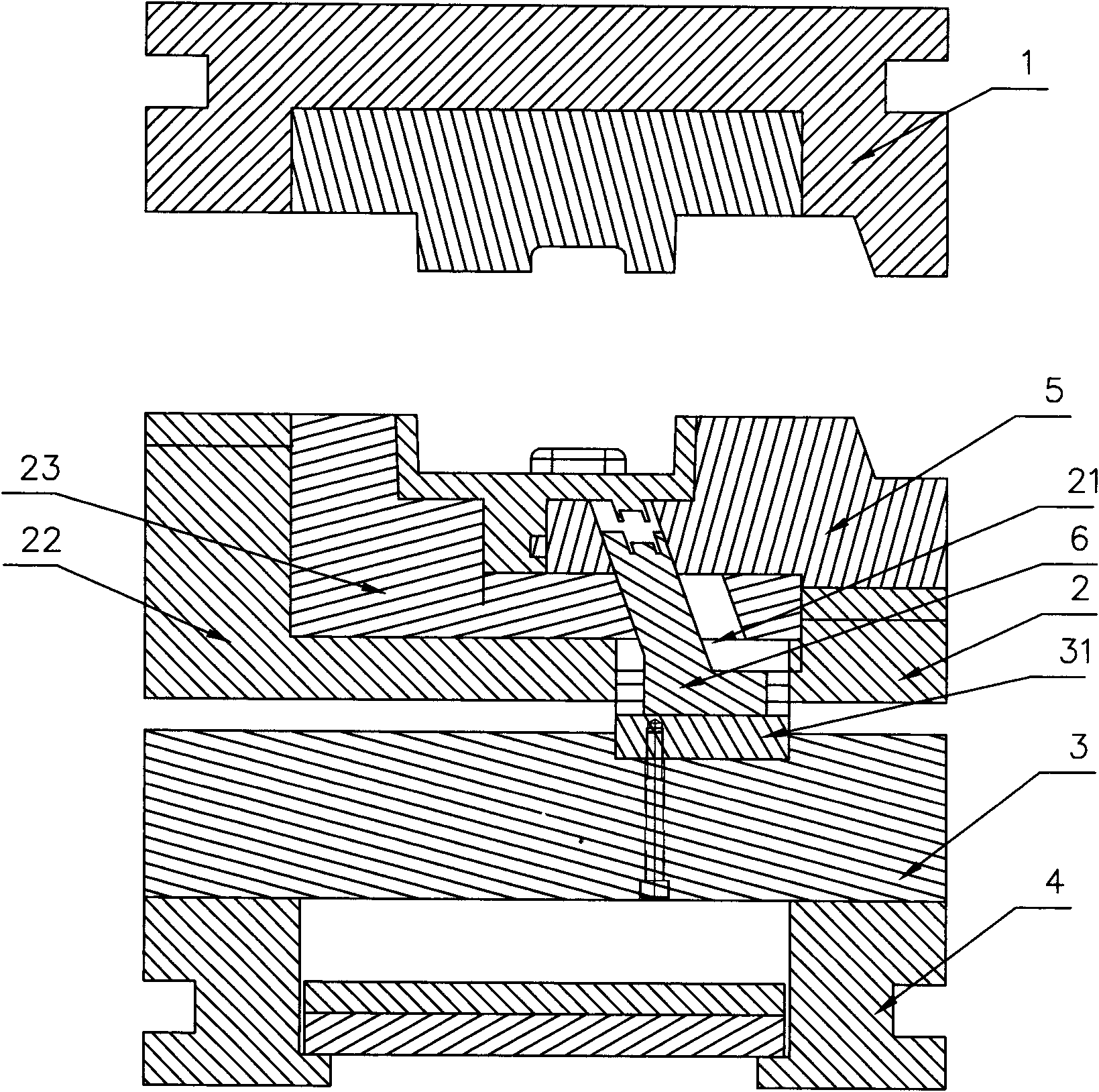

[0012] Embodiment: A middle plate type multiple slider structure mold, including upper mold 1, middle mold 2, lower mold 3 and die foot 4, based on the use direction, the middle mold 2 can slide vertically and is located directly under the upper mold 1 , the lower mold 3 is slidable in the vertical direction and is located directly below the middle mold 2, the lower mold 3 is fixed above the mold foot 4, and the side wall of the middle mold 2 is radially slidable and provided with a side slider 5, the side sliding Block 5 is provided with a slanted hole 51 longitudinally through (the slanted hole 51 is consistent with the inclination angle of the undercut of the product to be produced), and the lower side wall of the middle mold 2 is provided with a through opening groove 21, and the upper end of the opening groove 21 is connected to the side. Slider 5 oblique hole 51 positions are corresponding, and described lower die 3 upper side is fixedly provided with a slider seat 31, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com