Ice cream egg carton machine

An ice cream egg tray machine and rack technology, which is applied to baking tins, baked hollow foods, etc., can solve the problems of high price, fire, large volume, etc., and achieve the effect of good egg tray quality, simple structure and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

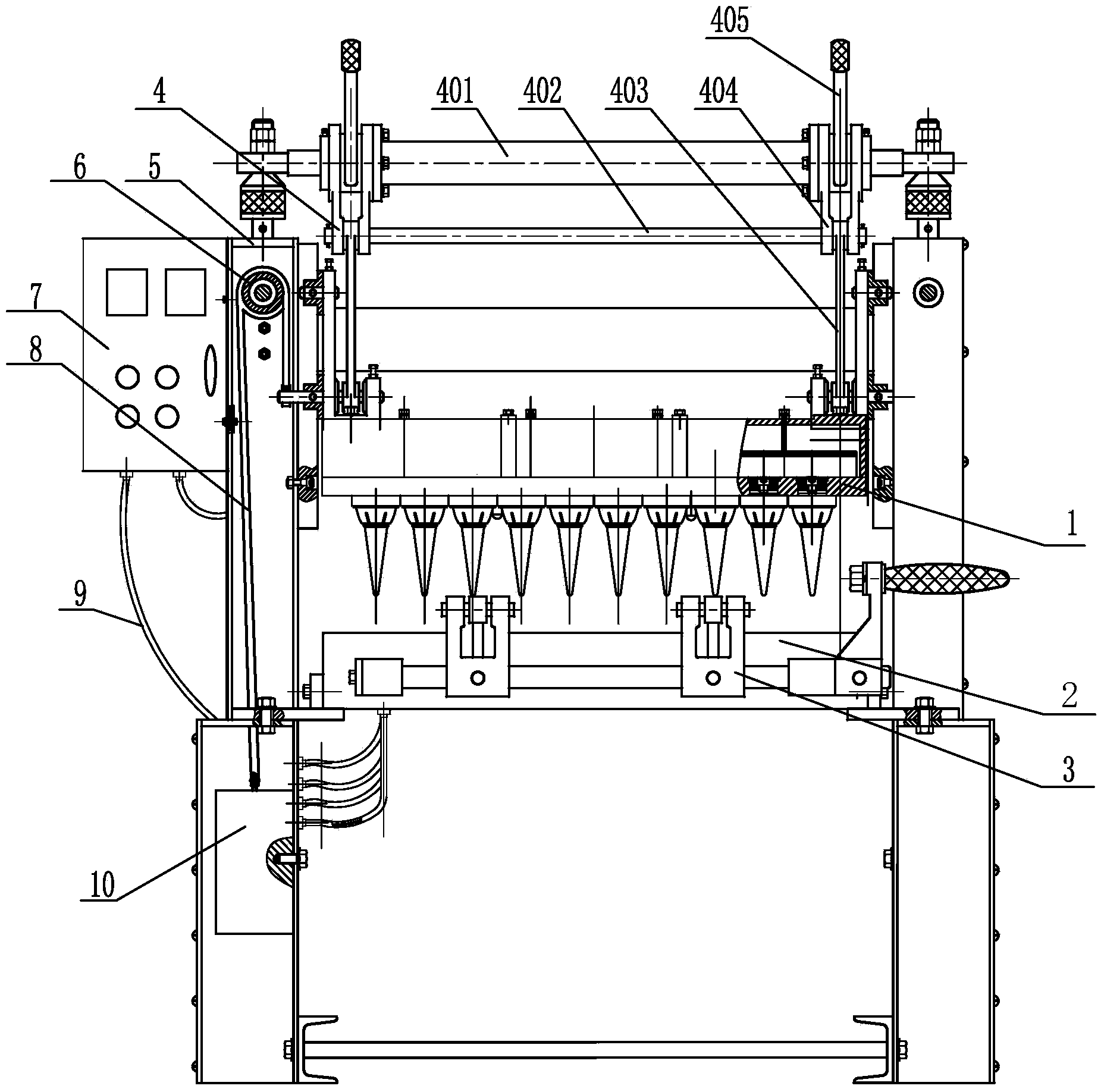

[0041] Embodiment 1: as figure 1 Shown, the present invention comprises frame 5, upper die 1, lower die 2, upper die drive 4 and lower die drive 3, also comprises control box 7, two sleeve roller chains 8 and counterweight 10 thereof, described two The sprocket 6 of the sleeve roller chain 8 is symmetrically installed above the frame 5, one end of the two sleeve roller chains 8 is respectively connected to the two ends of the major axis 103 of the upper mold, and the other ends of the two sleeve roller chains 8 bypass the chain The wheel 6 is connected to the counterweight 10 below the frame 5, and the control box 7 is connected to the upper mold 1 and the lower mold 2 respectively. The control box 7 in this example is an existing temperature control box for controlling and displaying the upper and lower molds. 1, 2 temperature.

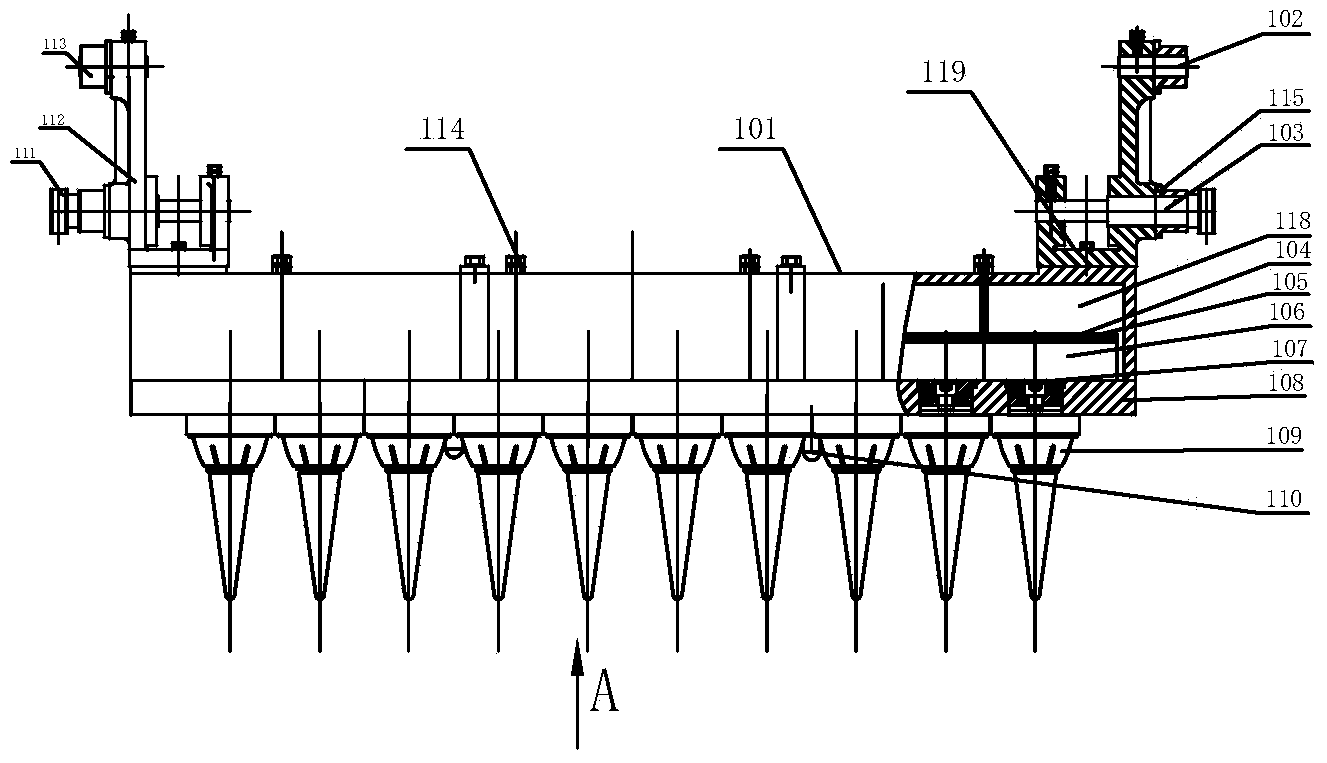

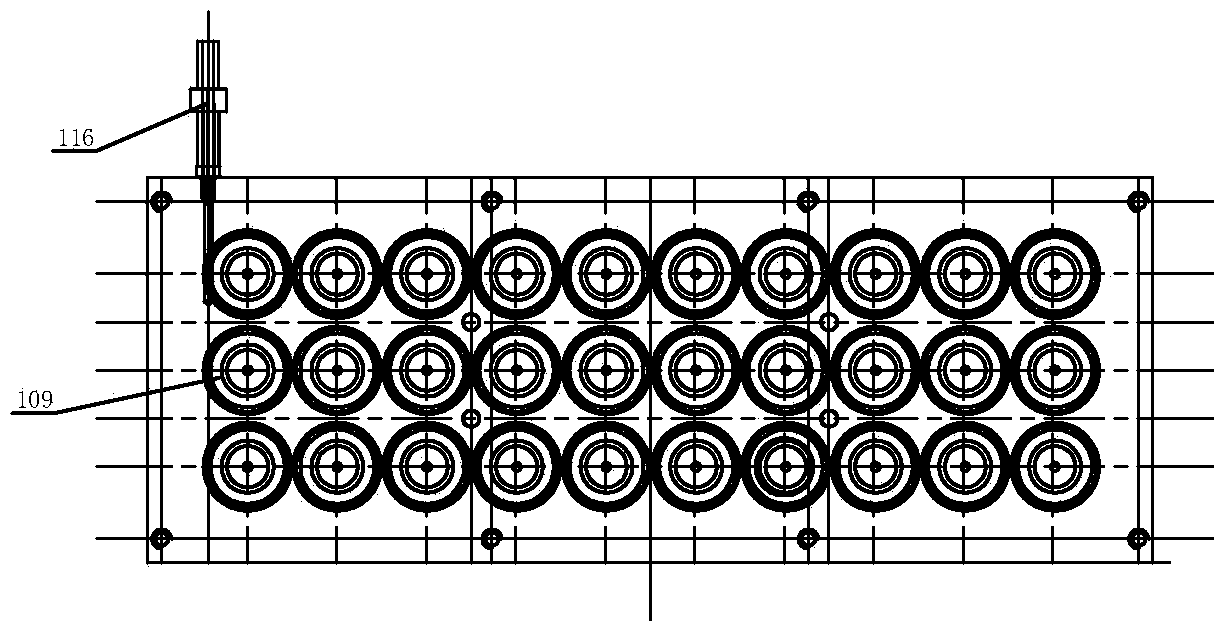

[0042] Such as figure 2 , image 3As shown, the upper mold 1 includes an upper mold 108, an upper mold cover 101, an upper mold 109, a heating d...

Embodiment 2

[0048] Embodiment 2: as Figure 8 As shown, the difference between this example and Example 1 is that the heating device described in this example is for heating the fuel pipeline, such as Figure 9 , Figure 10 Shown, upper mold 1 comprises upper template 108, upper mold 109, upper mold cover 101 and roller connecting device, is provided with a plurality of upper mold fixed pads 107 on described upper template 108, on upper template 108 one end and upper mold The mold fixing pad 107 is connected to a plurality of upper molds 109 at the corresponding positions, and the upper mold cover 101 is installed at the other end, and a staggered fuel circulation pipeline is set in the upper mold 108; the lower mold 2 includes two ends of the lower mold 203 that are matched and connected With a plurality of internal lower templates 205, two adjacent lower templates are connected by small pull shafts 206, and two adjacent small pull shafts 206 are arranged alternately, and each lower tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com