No-rinse pipe type membrane assembly for water treatment

A tubular membrane, flush-free technology, applied in osmosis/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. The film quality is not easy to control, the preparation process is simple, and the production efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

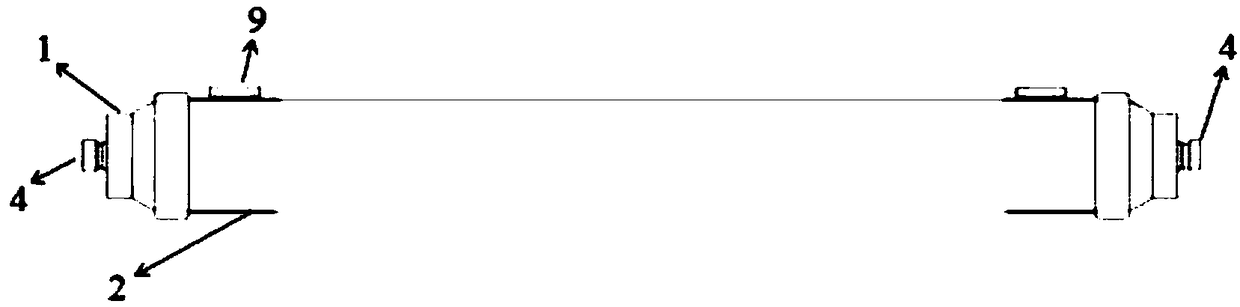

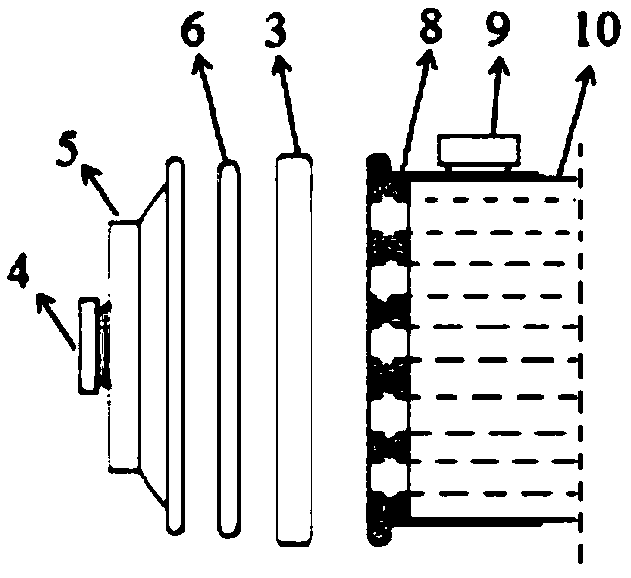

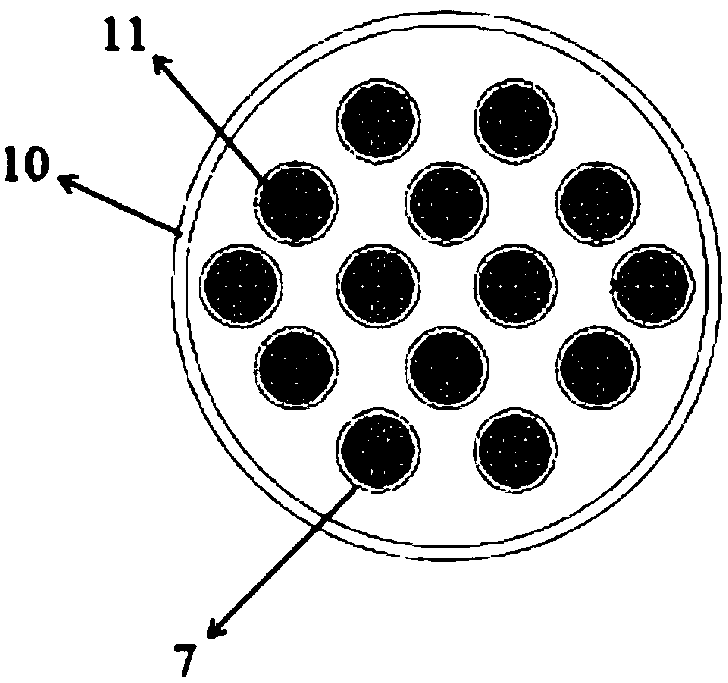

[0020] Specific implementation mode one: as Figure 1 to Figure 5 As shown, a flush-free tubular membrane module for water treatment in this embodiment is composed of a head 1, a membrane tube 2 and a metal clamp 3; the head 1 is composed of a water flow port 4, a head screw cover 5 and The sealing ring 6 is composed of; the membrane tube 2 is composed of several core tubes 7, head screw barrel 8, clear water port 9, membrane shell cylinder 10 and tubular membrane wire 11; the tubular membrane wire 11 is evenly packaged in Inside the core tube 7; the head screw barrel 8 is arranged at both ends of the core tube 7, and the inside of the head screw barrel 8 is provided with reserved channels, and the reserved channels in the head screw barrel 8 at both ends of the core tube 7 are symmetrical The two ends of several core tubes 7 are correspondingly packaged in the reserved channels; the outer side of the head screw barrel 8 is docked with the head screw cover 5, and the head scre...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the tubular membrane filament 11 is a flush-free PVDF tubular microporous membrane prepared by a non-solvent phase inversion method or a low-temperature thermal phase inversion method; The performance of the tubular membrane filament 11: OD / ID is 2.0-8.0mm / 1.4-6mm; the porosity is 70-95%; the membrane monofilament strength is greater than 7N; the rinse-free operation is realized at 0.1-0.3MPa, and the membrane surface The average pore size is controlled at 0.001~0.5μm; the operating flux is 300~2000L / m 2 ·h, wash once after 20-30 days of continuous operation, and the membrane flux recovery rate after cleaning is over 96%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the preparation of tubular membrane filaments by non-solvent phase inversion method is carried out according to the following steps:

[0028] 1. Weigh 10 to 30 parts of PVDF, 50 to 100 parts of dispersion medium, 0.1 to 20 parts of organic additive and 0.1 to 10 parts of inorganic additive in parts by weight; the dispersion medium is N,N-dimethylformamide, One or a mixture of several of N,N-dimethylacetamide, N-methyl-2-pyrrolidone and acetone; the organic additive is polyethylene glycol, polyacrylonitrile PAN, cationic surfactant , anionic surfactants, nonionic surfactants, acetone, ethanol, glycerol and polyvinylpyrrolidone of different molecular weights or a mixture of several of them; the inorganic additives are lithium chloride, ammonium chloride, One or a mixture of zinc chloride, lithium nitrate, lithium perchlorate and water;

[0029]2. Add 10 to 30 parts of PVDF, 0.1 to 20 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com