Mud scraping and cleaning device for well logging cable

A technology for cleaning devices and cables, applied in the directions of drying gas arrangement, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of poor scraping effect and short service life, avoid water infiltration into the cable interior, prolong the Service life, ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

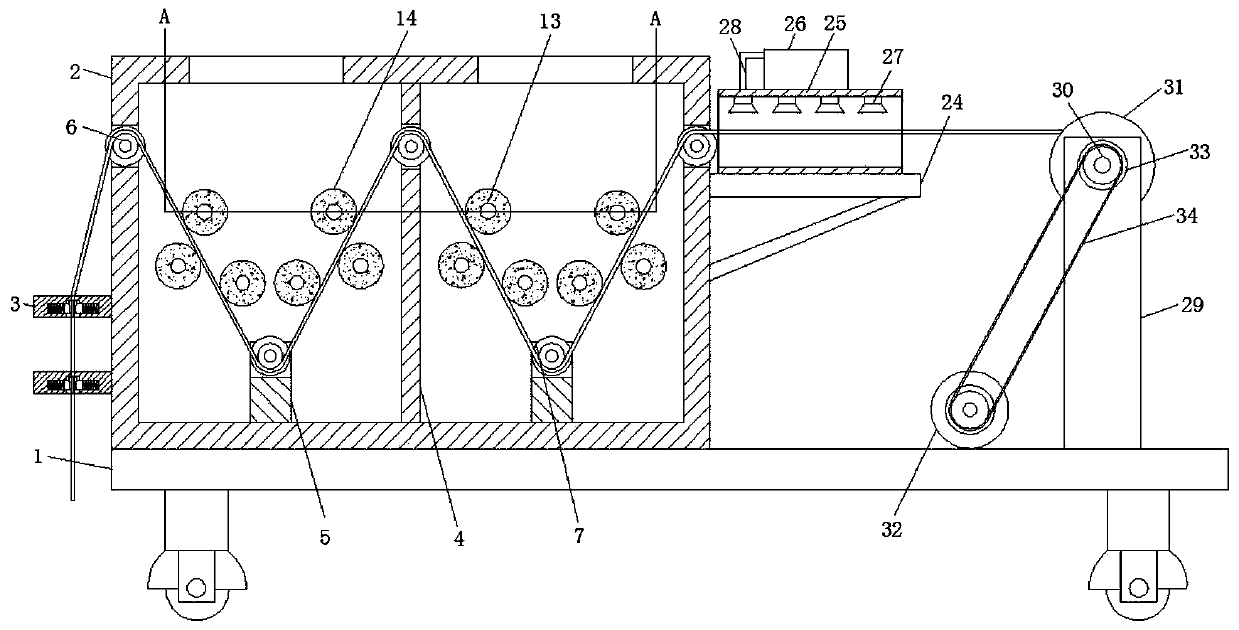

[0029] refer to Figure 1-6, a mud scraping and cleaning device for well logging cables, comprising a workbench 1, four corners of the lower end of the workbench 1 are fixed with support legs by screws, the lower ends of the support legs are equipped with universal wheels, and one side of the upper end of the workbench 1 The cleaning box 2 is fixed by screws, and the side wall of the cleaning box 2 away from the workbench 1 is provided with a mud scraping device 3, and there are two mud scraping devices 3, and the middle part of the inner wall of the cleaning box 2 is fixed by gluing Sealing plate 4, both sides of the inner bottom surface of cleaning box body 2 are all fixedly connected with mounting plate 5 by screws, and the upper ends of mounting plate 5, sealing plate 4 and cleaning box body 2 both side walls are all provided with mounting grooves, the front and rear ends of mounting grooves The side walls are connected with the installation shaft 6 through rolling bearing...

Embodiment 2

[0032] Such as Figure 5 and 6 Shown, this embodiment is basically the same as Embodiment 1. Preferably, the mud scraping device 3 includes a circular plate 301, one side of the circular plate 301 is fixedly connected to the side wall of the cleaning box 2 by screws, and the circular plate 301 A circular groove 302 is provided at the center of the lower end face of the circular groove 302, and a groove 303 is provided inside the both sides of the circular groove 302. The inner wall of the groove 303 is slidingly connected with a mounting block 2 304, between the mounting block 2 304 and the bottom surface of the groove 303 Springs 1 305 are fixedly connected between them, and the end of mounting block 2 304 away from spring 1 305 is fixedly connected with mud scraper 306 by screws, and a through hole 308 is also opened on the top surface of the circular groove 302, and the through hole 308 runs through Circular plate 301 .

[0033] In this embodiment, through the function of...

Embodiment 3

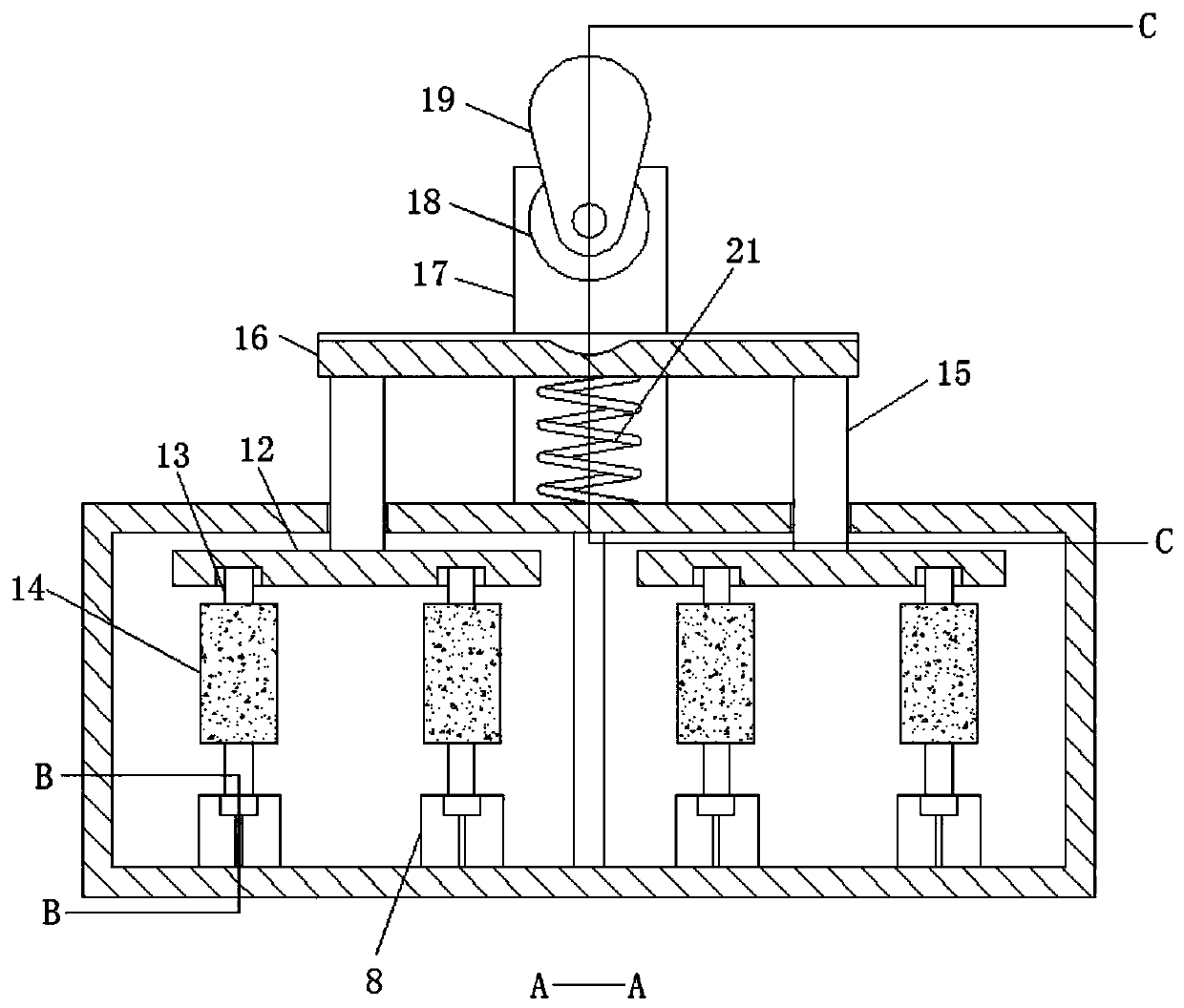

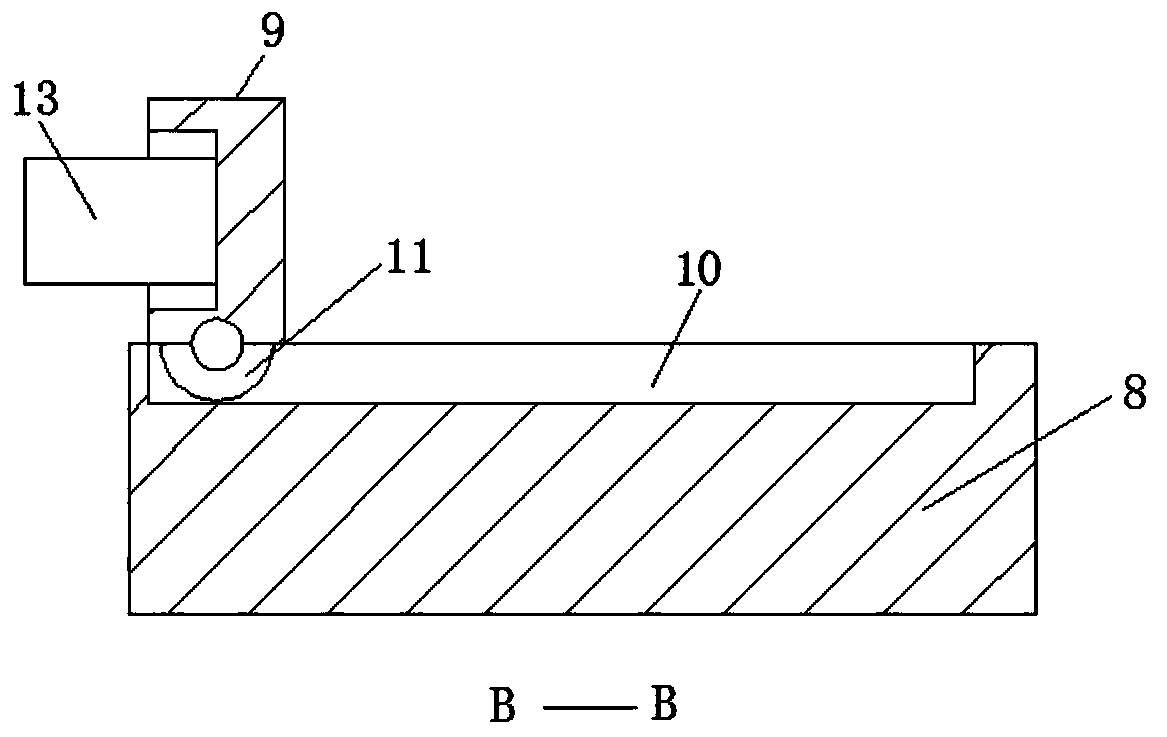

[0035] Such as image 3 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two rolling grooves 10 and two rolling grooves 22 are provided, and two balls one 11 and two rolling grooves 23 are also provided and placed in rolling groove one 10 respectively. and roll groove two 22 inside.

[0036] In this embodiment, two balls one 11 and two balls 23 are provided to ensure that the installation block one 9 and the drive plate 16 operate more stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com