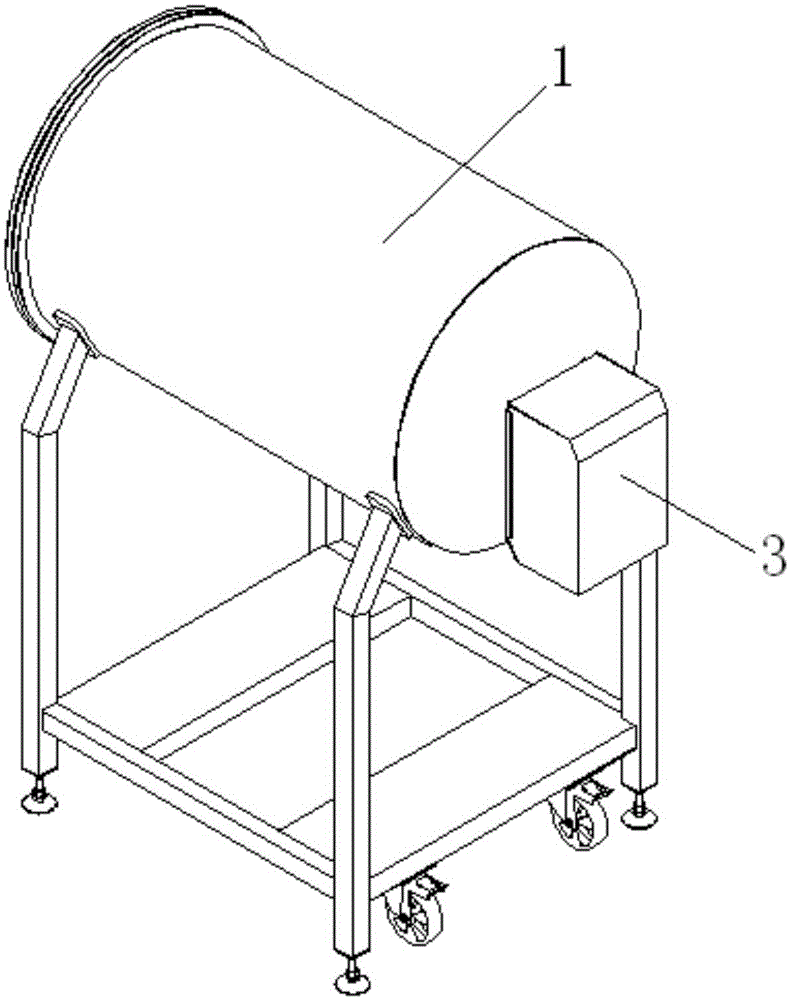

Drum-type economical washing machine

An energy-saving, cleaning machine technology, applied to cleaning methods and utensils, cleaning methods using liquids, heating, etc., can solve the problems of increased workshop costs, longer cleaning time, and waste of cleaning water, so as to improve sanitation and reduce The cleaning time and the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

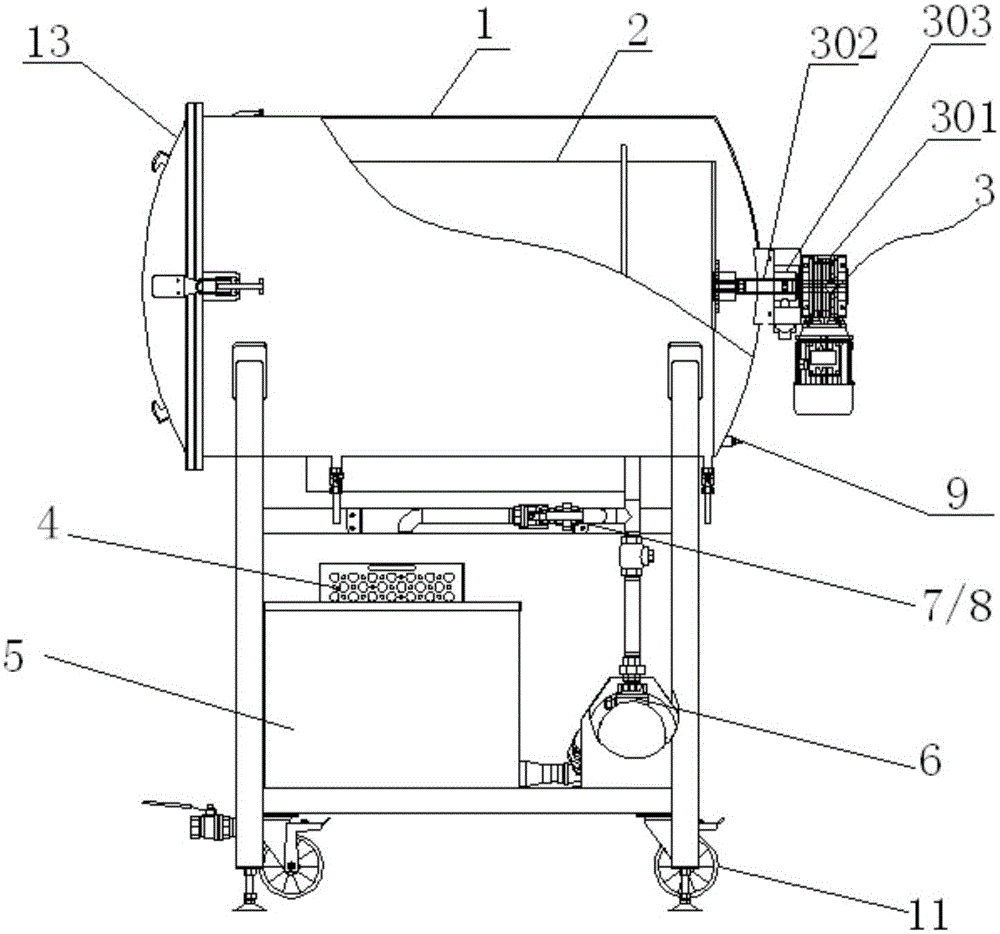

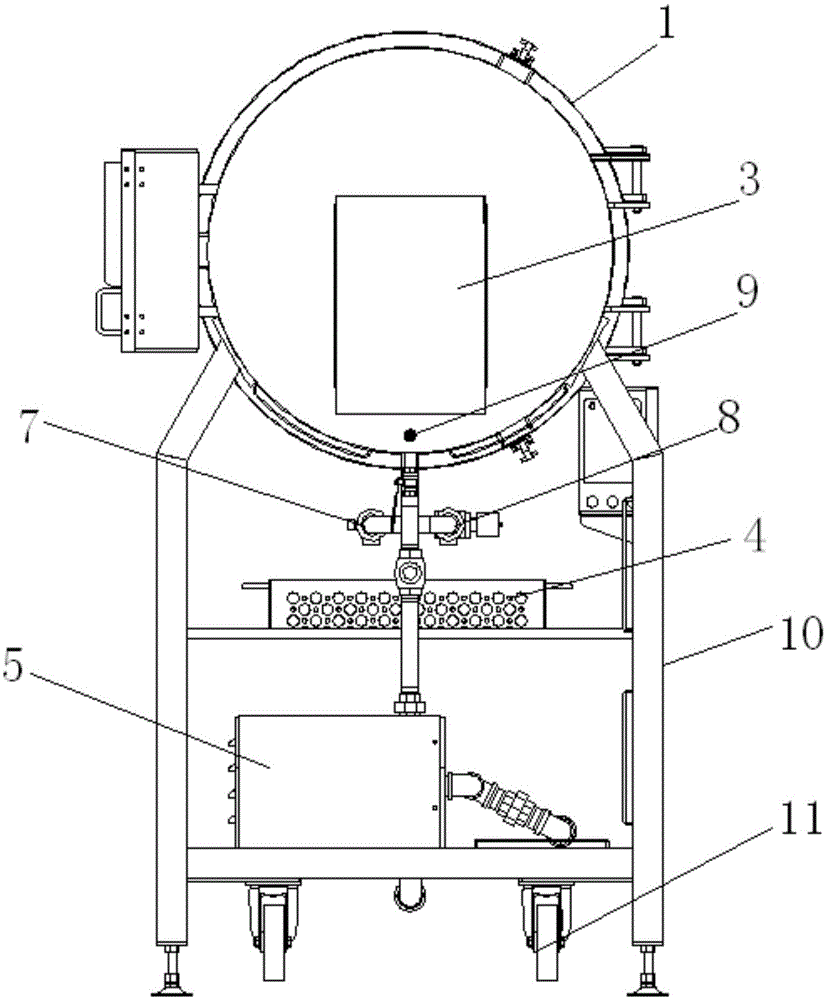

[0033] like figure 2 and image 3 As shown, a drum-type energy-saving washing machine includes an outer cylinder 1 with a closed space, a drum 2 with several through holes on the peripheral side, a power unit 3, a filter 4, a water tank 5 and a water pump 6, and the drum can rotate The power device is arranged inside the outer cylinder, the power device is arranged outside the outer cylinder, and the power output shaft of the power device penetrates into the outer cylinder in a sealed manner, and can drive the roller to rotate relative to the outer cylinder; The water pump pumps the cleaning water in the water tank into the outer cylinder, and the cleaning water discharged from the outer cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com