A processing method of a valve seat part

A processing method and valve seat technology, which is applied in the processing field of valve seat parts, can solve the problem that the dimensional accuracy and shape and position tolerance of the valve seat parts cannot meet the overall requirements of the valve seat parts, and the cutting tools are prone to sticking, which affects the processing quality and size and other issues to achieve the effect of reducing the impact of machining accuracy, avoiding assembly errors, and improving the quality of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is basically as attached Figure 1-Figure 5 shown.

[0035] A processing method for a valve seat part, characterized in that: comprising the following steps:

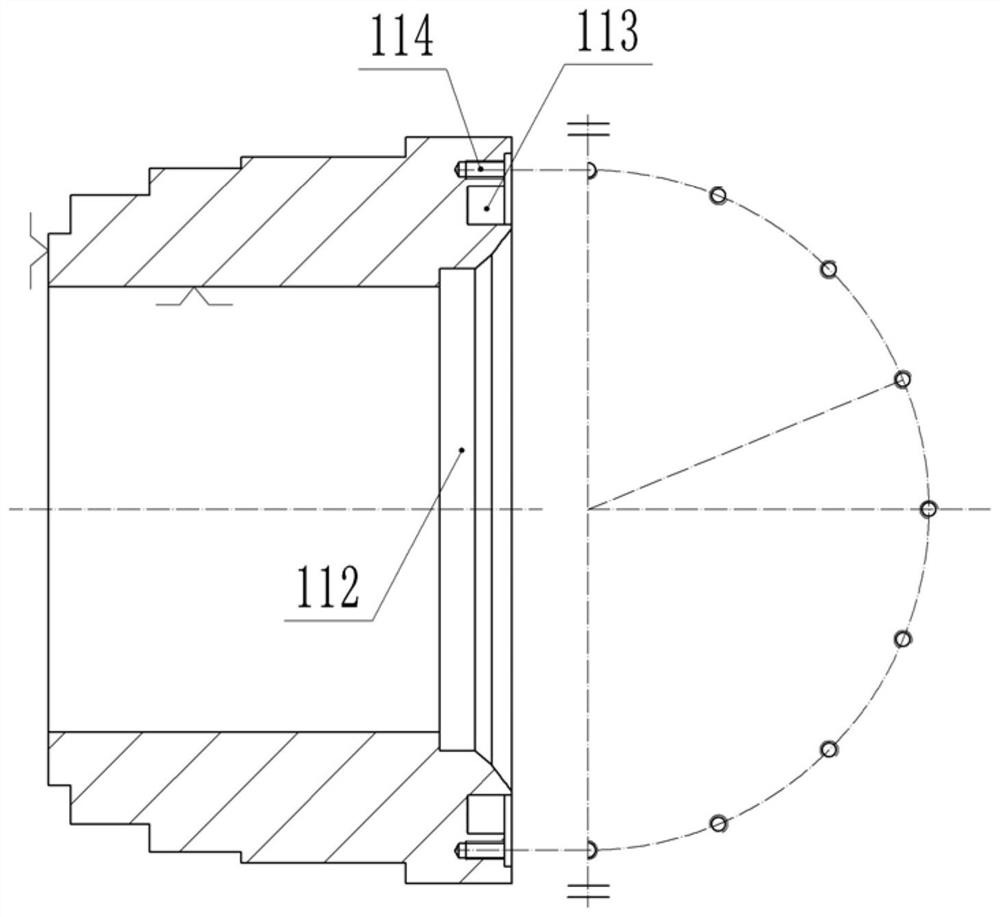

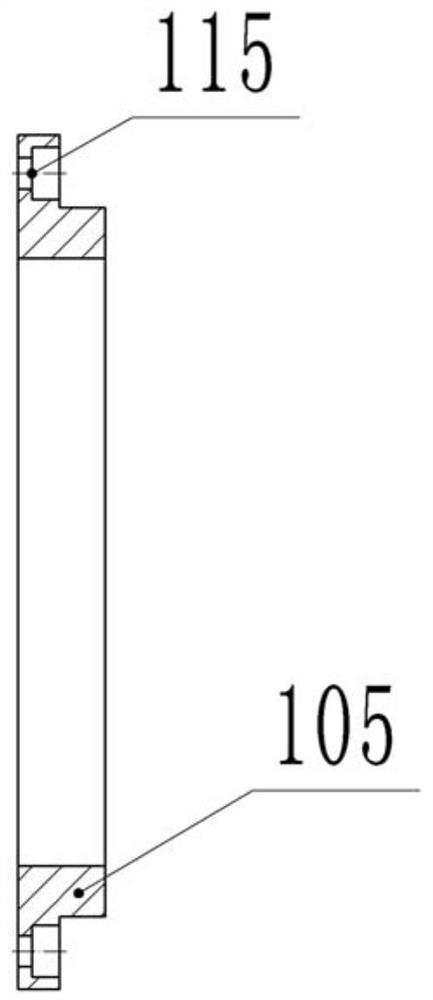

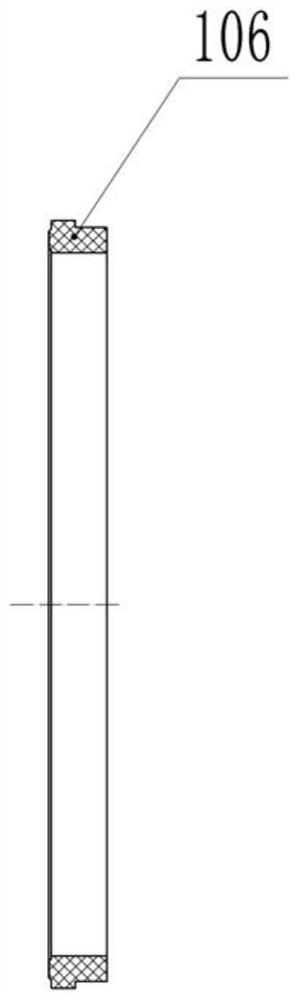

[0036] A, prepare a plurality of parts: prepare as in this embodiment figure 1 Shown valve seat support sleeve 101, figure 2 The seat guide ring 105 shown and image 3 The valve seat ring 106 shown has three parts, and the valve seat ring 106 in this embodiment is a polytrifluoroethylene valve seat ring. The outer circle of the valve seat support sleeve 101 is stepped, the left end of the valve seat support sleeve 101 is the small end, and the right end is the large end, and the right end surface of the valve seat support sleeve 101 is provided with an annular ring groove 113 and a plurality of circles evenly distributed The threaded hole 114. The valve seat guide ring 105 is annular in shape, and the outer wall of the valve seat guide ring 105 protrudes outward to form a ring-shaped connectin...

Embodiment 2

[0047] After step C, D. surface treatment of the valve seat part is also included: treating the surface of the valve seat part to make the surface roughness of the valve seat part meet the requirements.

[0048] The specific surface treatment method in this step is: Figure 6 As shown, before the surface treatment, the overall direction of the clamped workpiece is reversed, that is, the clamping part on the axial pressure plate 107 is clamped by the machine tool, and the dial indicators J01” and J02” are used to assist the clamping correction to maintain the radial direction of the clamping. , The axial precision is controlled within the specified range. Place the surface processor 116 on the tool holder of the machine tool, and place the consumables corresponding to the corresponding surface processor 116: wool wheel, white cleaning cloth wheel, and evenly soak the organic lubricant and auxiliary fine polishing agent.

[0049] During the surface treatment, the valve seat par...

Embodiment 3

[0051] It is easy to understand that in step C or step D, changes can also be made according to the actual situation, such as the determination of the clamping datum and machining datum, the moving direction of the tool, the specific structure of the clamping tool, and the parameter design in the processing process, such as When clamping the valve seat support sleeve 101, the large end of the valve seat support sleeve 101 can be used as the clamping reference for clamping, and at the same time, the valve seat pressure plate at the large end of the valve seat support sleeve 101 is clamped by a machine tool during the overall processing During the surface treatment process, the machine tool is used to clamp the valve seat pressure plate at the large end of the valve seat support sleeve 101, etc.; in step C, the tool can move from right to left, etc. All these minor changes will not affect the main invention points of this solution, and all should fall within the protection scope ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com