Large alloy steel part cutting method through diamond wire saw

A diamond wire saw and alloy steel technology, applied in metal sawing equipment, sawing machine devices, metal processing equipment and other directions, can solve the problems of difficult execution, low cutting accuracy, high labor intensity, etc. The effect of reduced processing volume and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

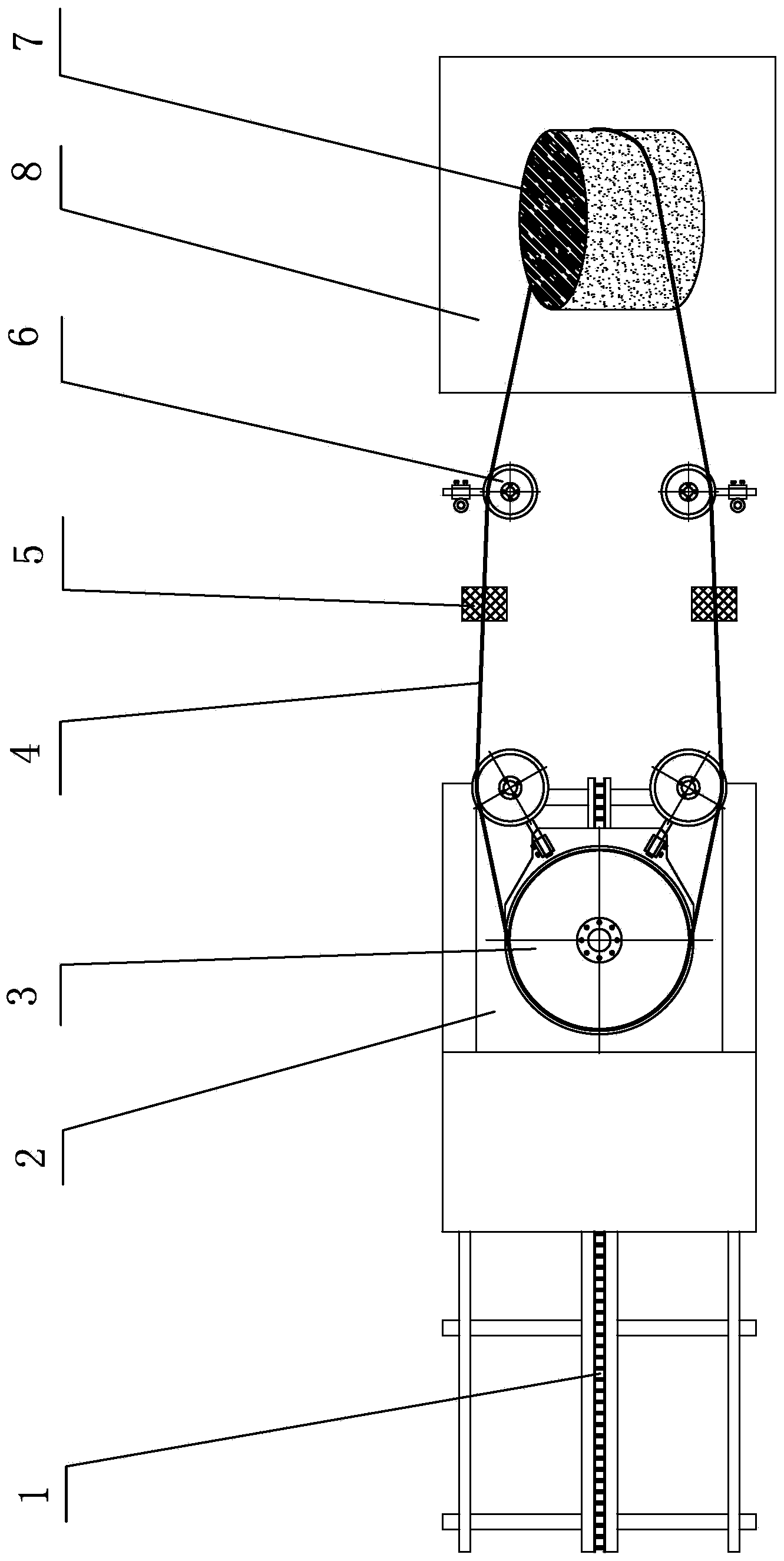

[0041] The technical solution of the present invention will be further described below in conjunction with the processing methods shown in the accompanying drawings.

[0042] The method that the present invention adopts diamond wire saw to cut large-scale alloy steel parts is to adopt wire saw machine 2 to cut large-scale alloy steel parts 7, and the schematic diagram of processing is as follows figure 1 As shown, its technological process is:

[0043] 1. Lay and fix the guide rail 1 on the cutting site, and set up a horizontal cutting table 8 in front of the guide rail 1. The wire saw machine 2 is placed on the guide rail 1 and can move forward and backward along the guide rail 1.

[0044] 2. Lift the large alloy steel piece 7 to be cut by a crane or transport it to the cutting workbench 8 with a forklift, and fix the large alloy steel piece 7 on the cutting workbench 8 with a pressure plate so that it is as close as possible to the cutting workbench. The workbench 8 is kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com