Patents

Literature

53results about How to "Reduce the amount of subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

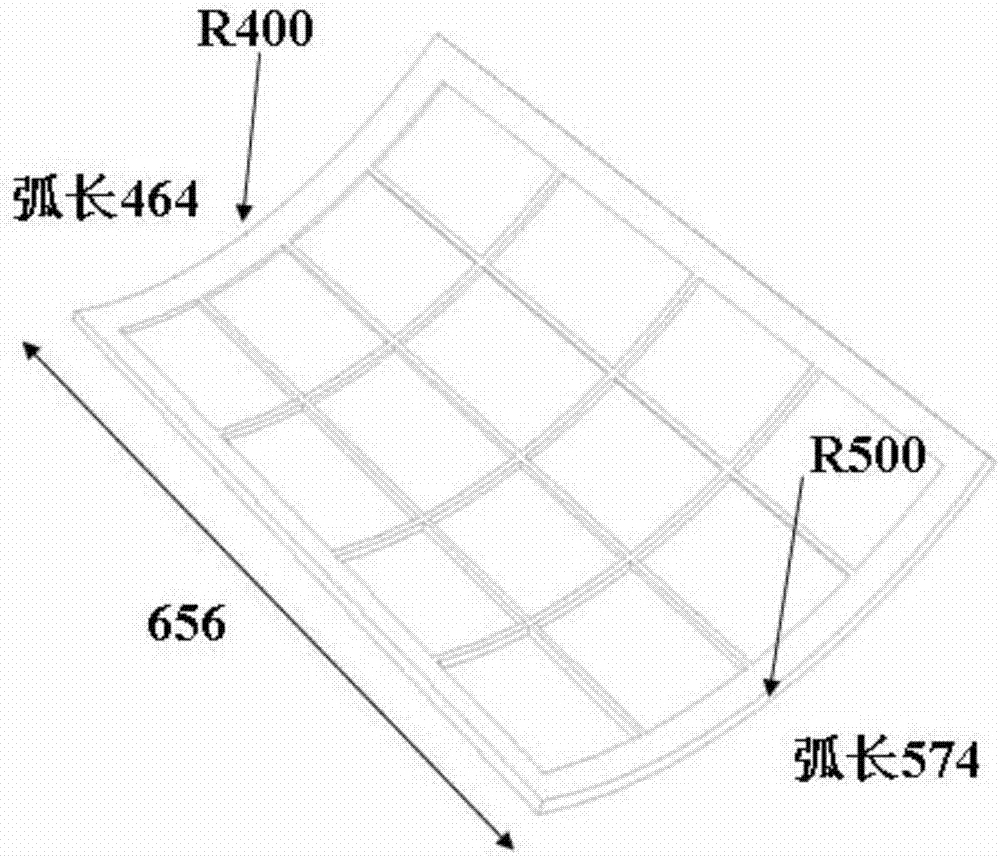

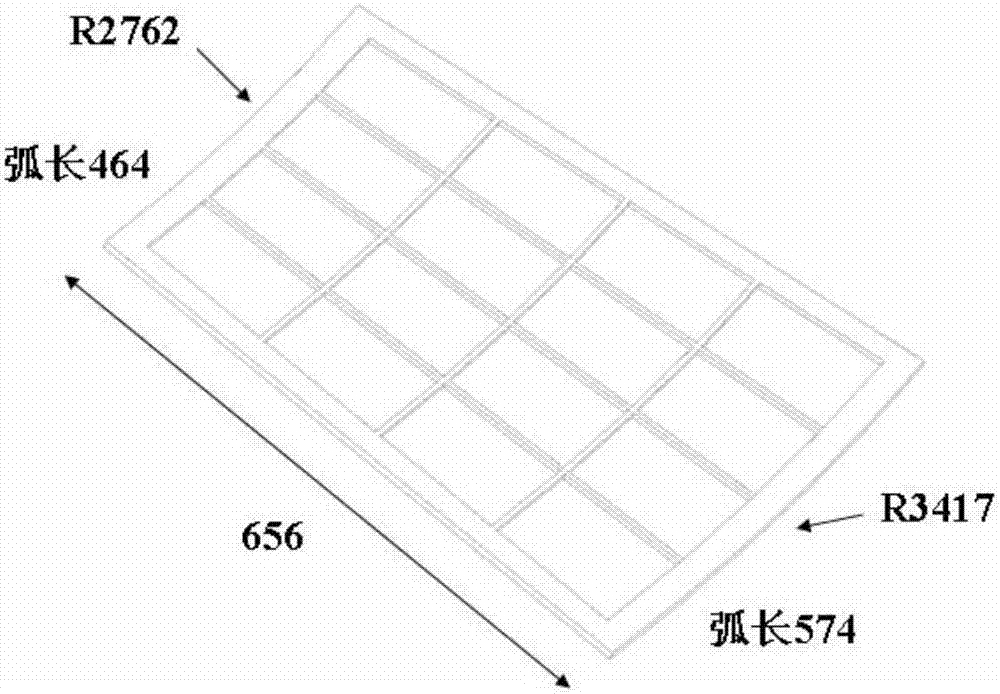

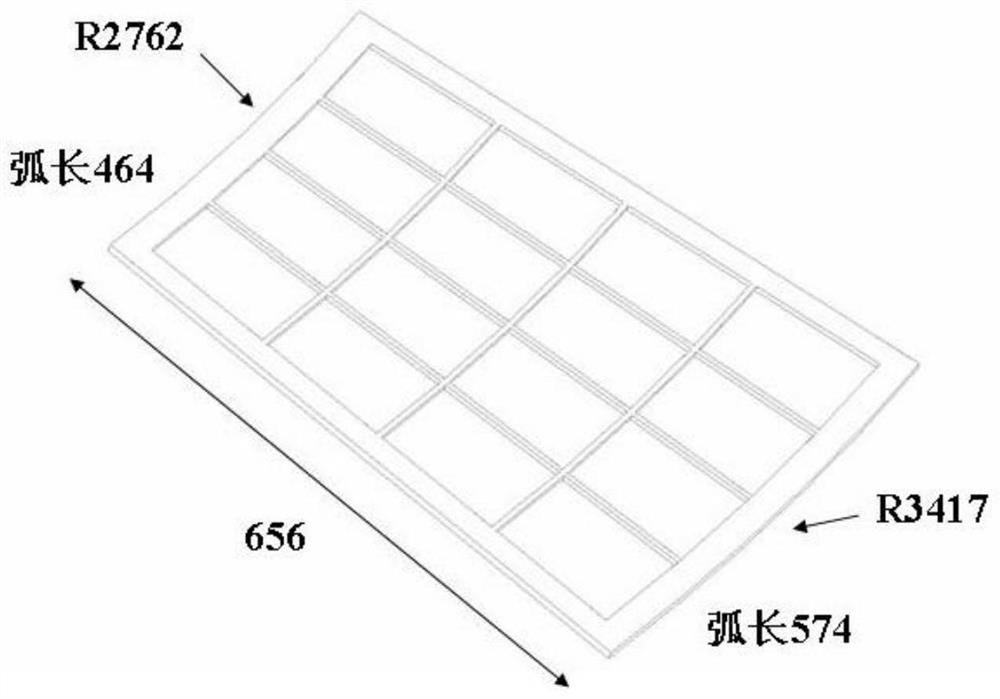

Hot-pressing forming method for aluminum-alloy curved reinforcing rib plate

The invention discloses a hot-pressing forming method for an aluminum-alloy curved reinforcing rib plate. The method comprises the steps of 1, carrying out plane unfolding on the aluminum-alloy curved reinforcing rib plate; 2, preparing corresponding reinforcing ribs on the plate according to the positions of the reinforcing ribs in the plane unfolding diagram; 3, designing and processing a hot-pressing forming die of the aluminum-alloy curved reinforcing rib plate; 4, performing hot-pressing forming on the aluminum-alloy curved reinforcing rib plate; and 5, performing air inflation correction on the aluminum-alloy curved reinforcing rib plate. According to the method, the aluminum-alloy curved reinforcing rib plate is formed by adopting hot-pressing formation and air inflation correction combined technologies, the problem that the size precision and the profile precision of the parts are difficult to control in the conventional cold stamping or machining process is solved, the surface quality of the parts is improved, and the overweight problem in the casting process is avoided; firstly, hot-pressing forming is adopted so that resilience, wrinkling, cracking and other defects in the cold forming process can be effectively avoided; and then air inflation correction is adopted so that the size precision, the profile precision and the surface quality requirements of the parts can be guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

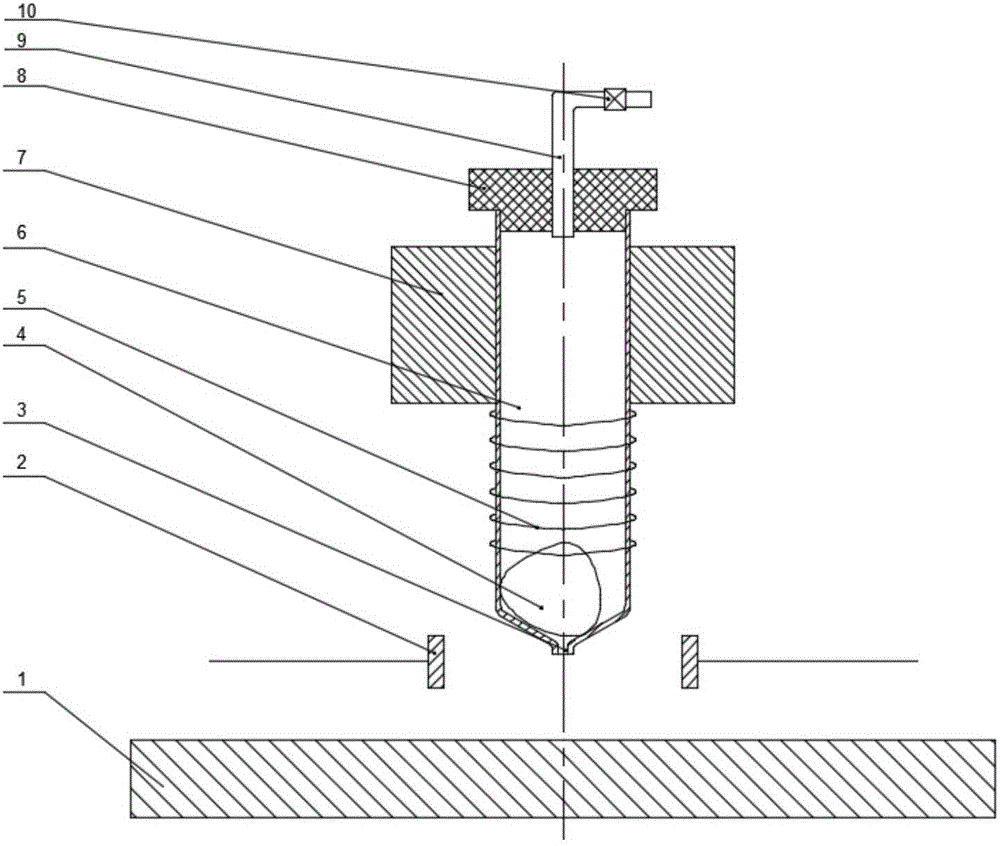

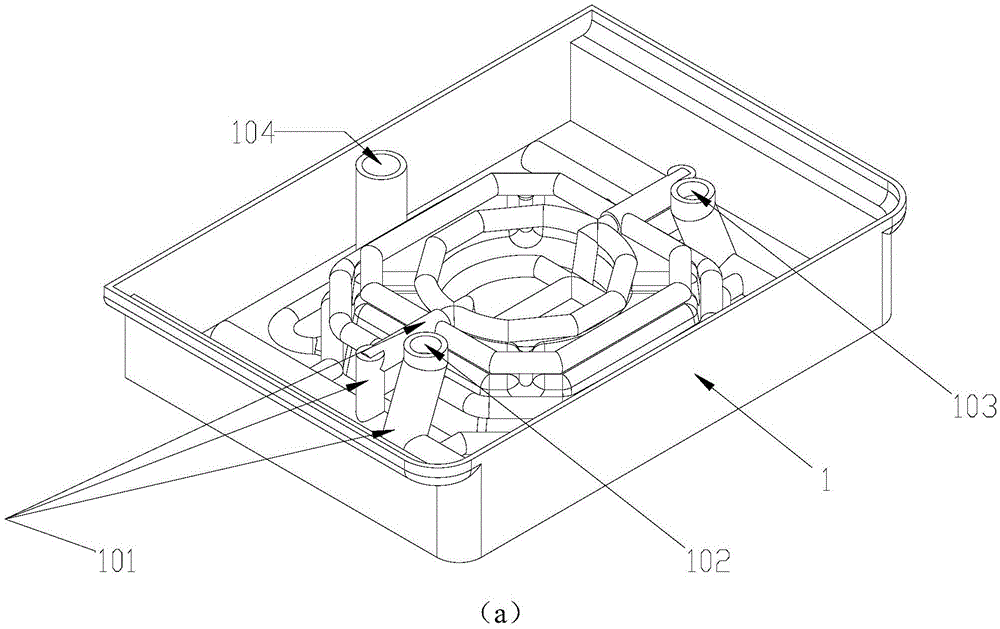

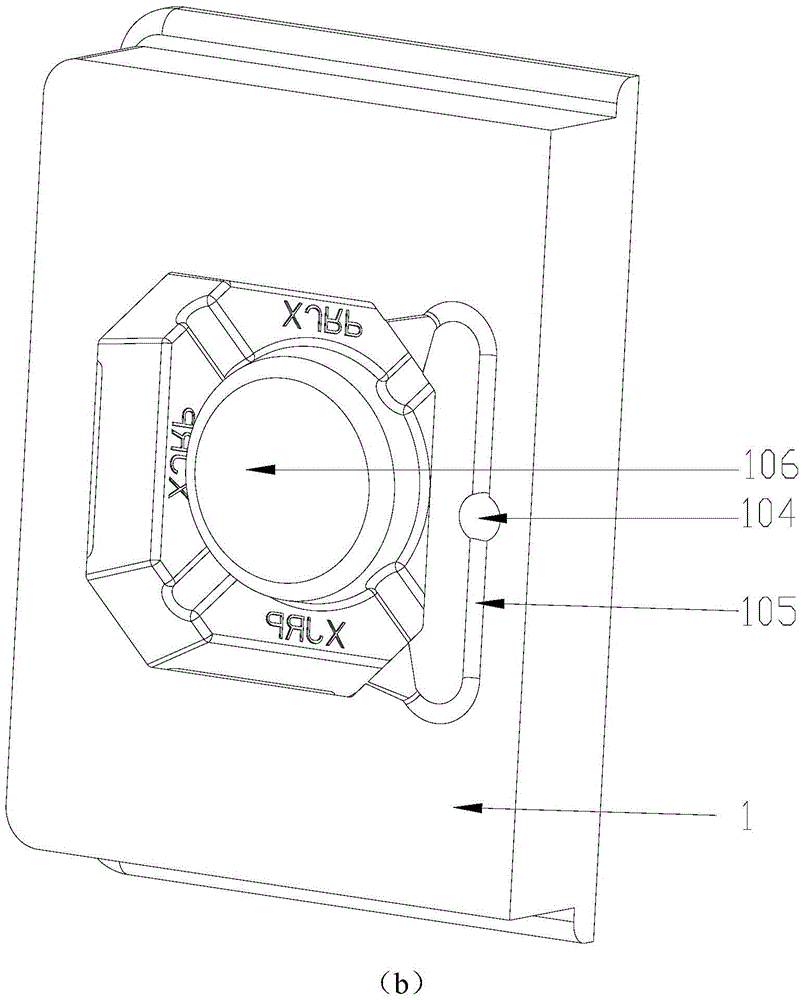

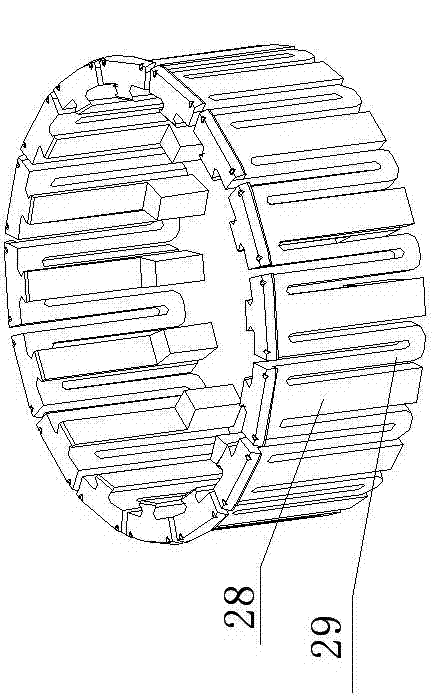

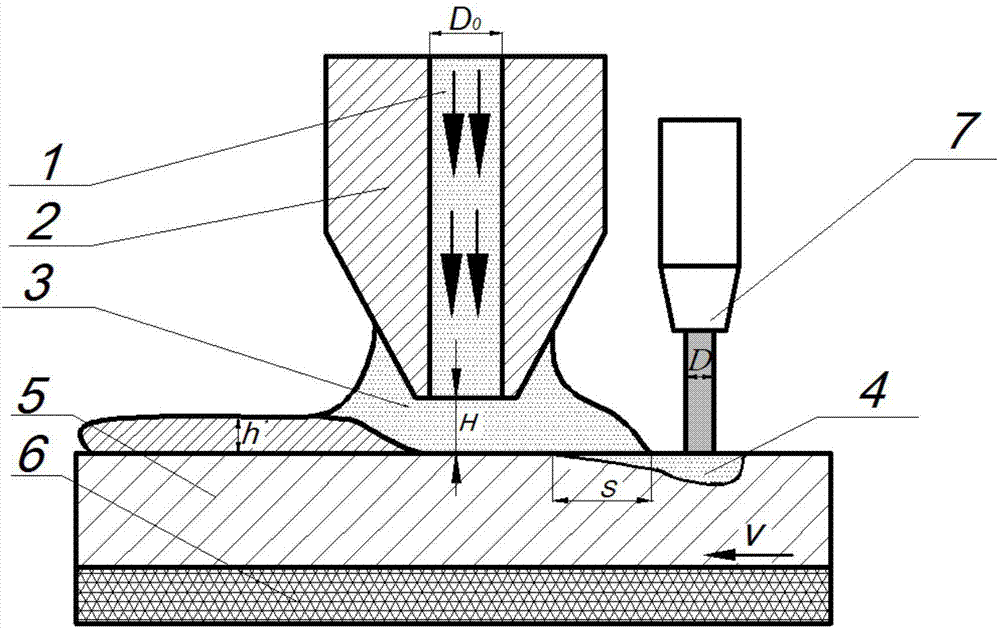

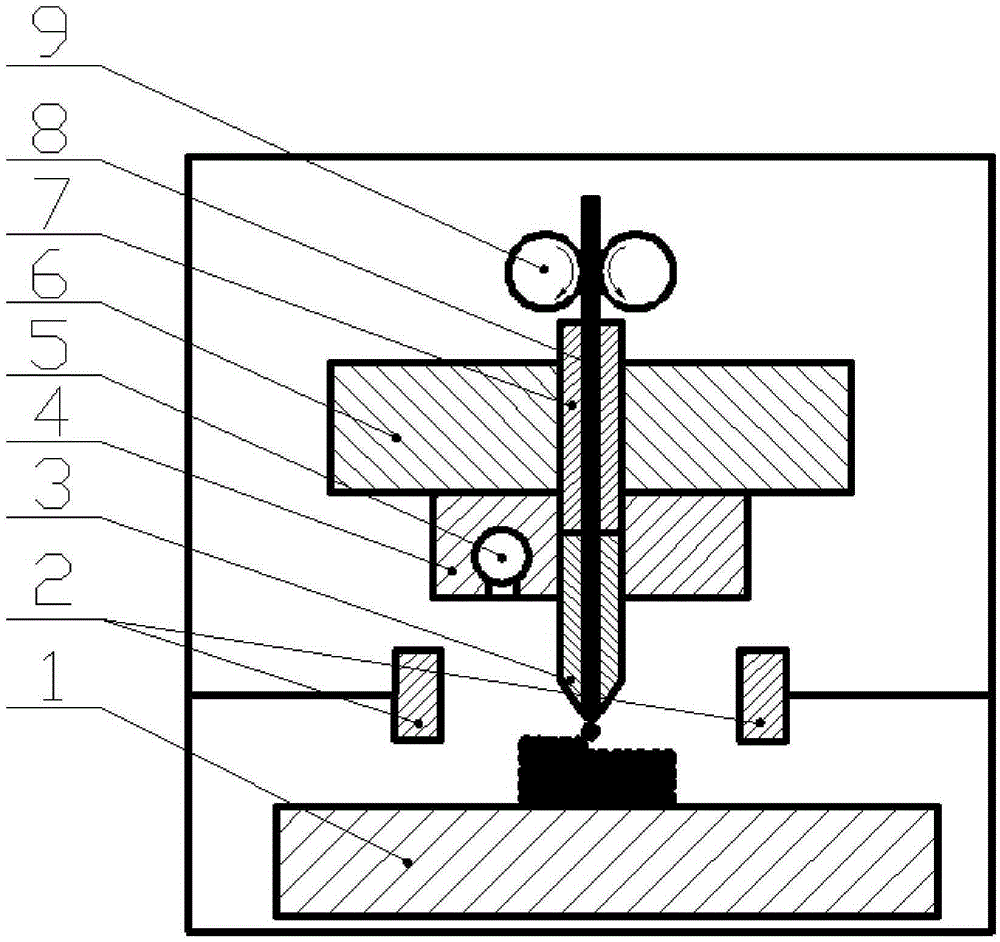

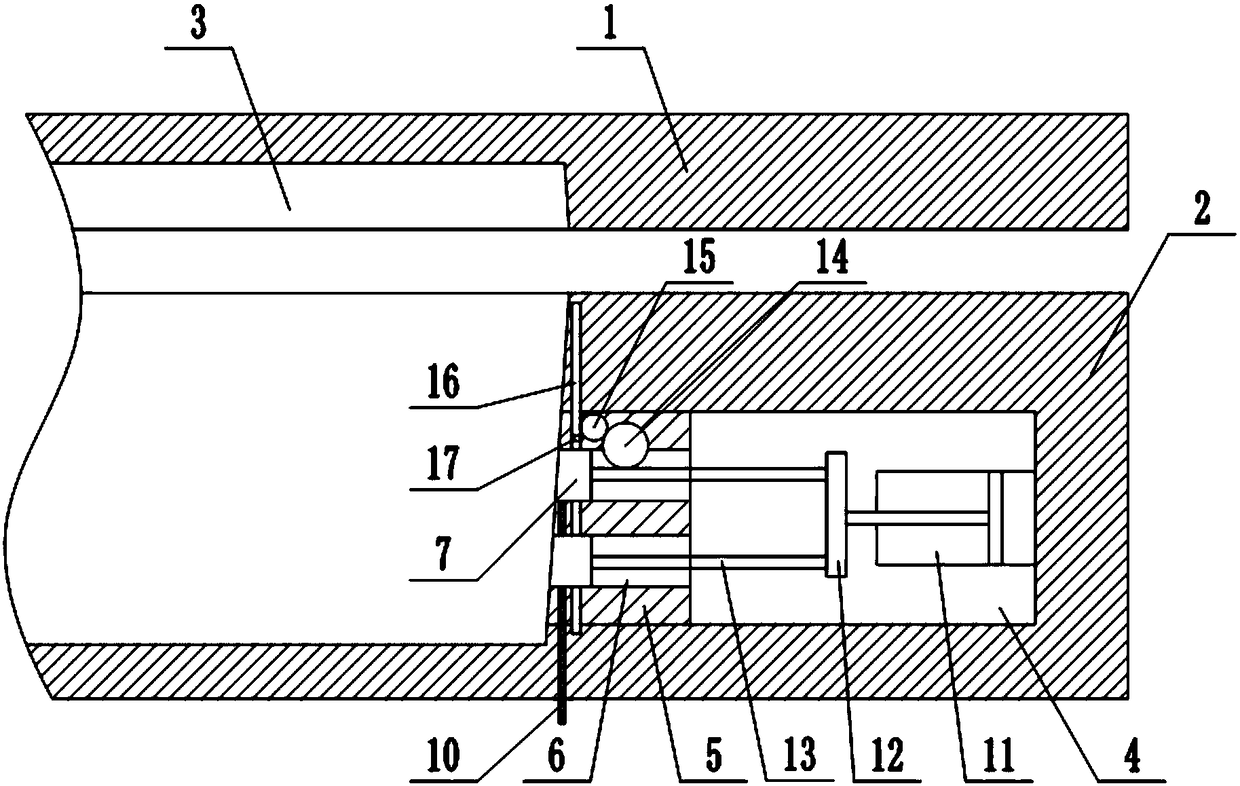

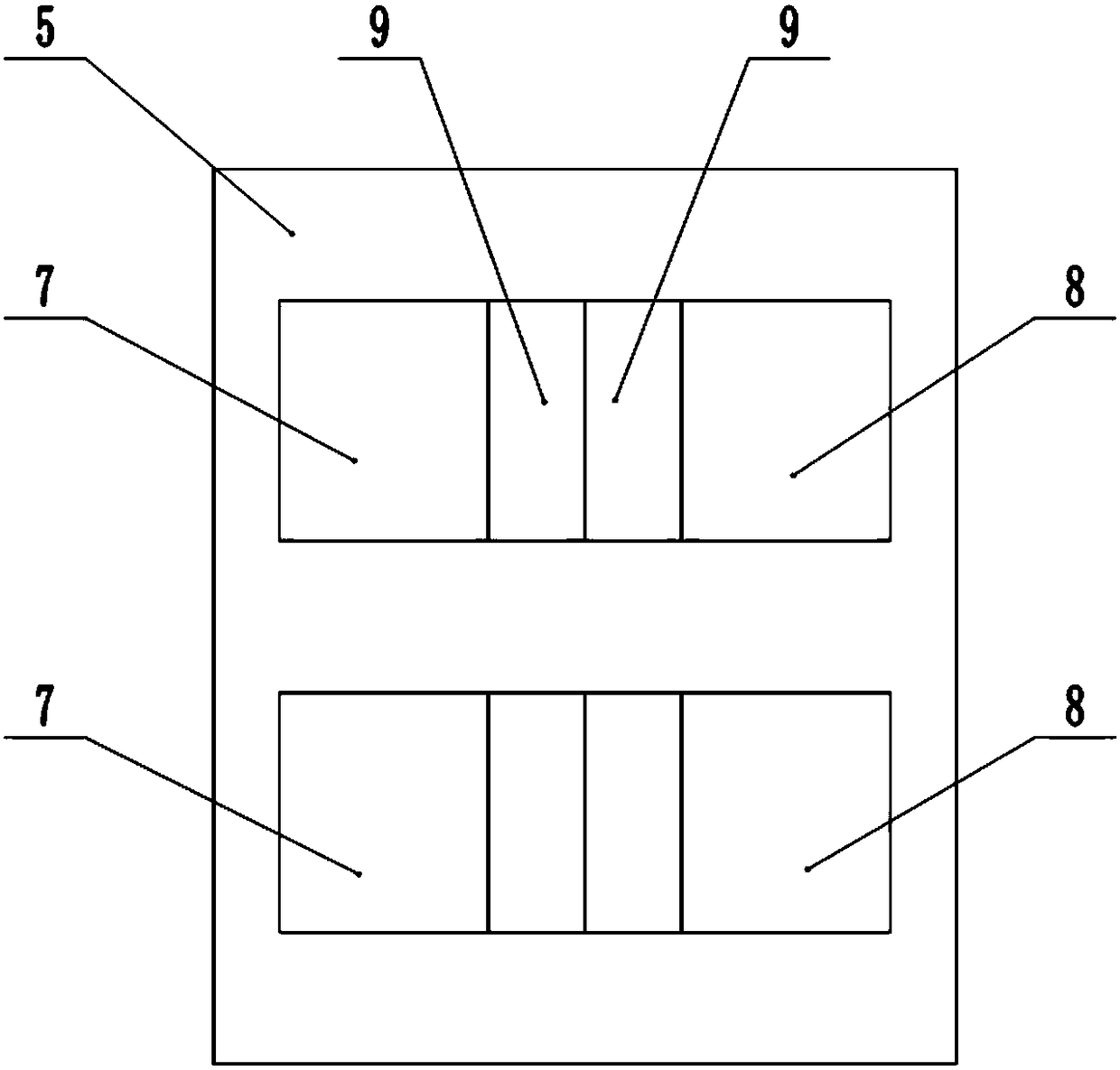

Device and method for rapidly forming metal part through induction heating

InactiveCN105903970AHeating evenlyEven and stable heatingAdditive manufacturing apparatusCrucibleMachining

The invention discloses a device and method for rapidly forming a metal part through induction heating. The device comprises a base plate, a front heating unit and an induction smelting unit. The base plate is located below the induction smelting unit and used as a platform for metal part forming. The front heating unit is located between the base plate and the induction smelting unit and used for forming a uniform temperature field. The induction smelting unit comprises a support and a smelting crucible arranged on the support. An induction coil is arranged on the smelting crucible. The outlet end of the smelting crucible is provided with a smelting crucible nozzle opposite to the base plate. The inlet end of the smelting crucible is connected with an air inlet through a rubber plug and used for providing inert gas for the smelting crucible. The method is used for achieving induction heating and rapid forming of the metal part through the device. The device and method have the advantages of being high in machining flexibility, small in subsequent machining amount and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Zirconia ceramic fingerprint identification sheet and preparing and application method thereof

InactiveCN106495691AHigh dielectric constantSensitive fingerprint recognitionCeramic shaping plantsAuxillary shaping apparatusSolventFingerprint

Owner:HUNAN ZHENGYANG PRECISION CERAMIC

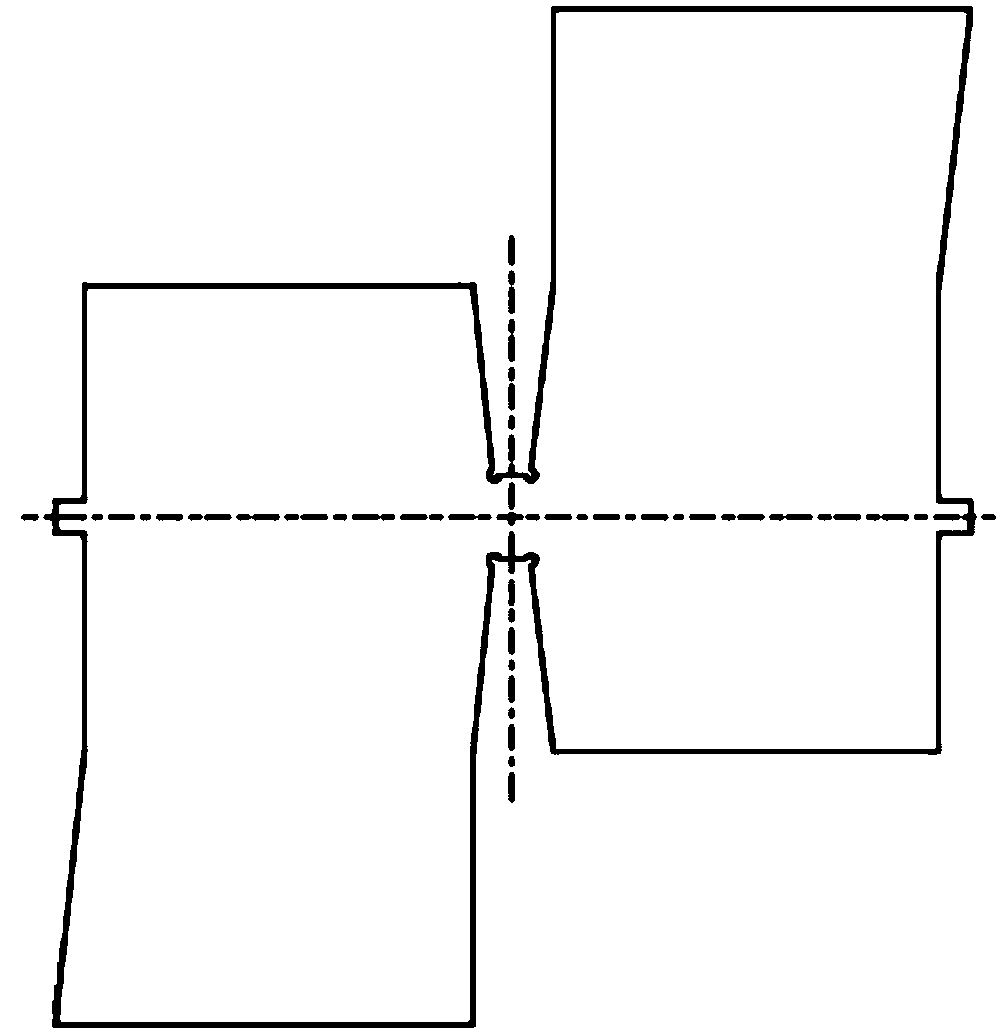

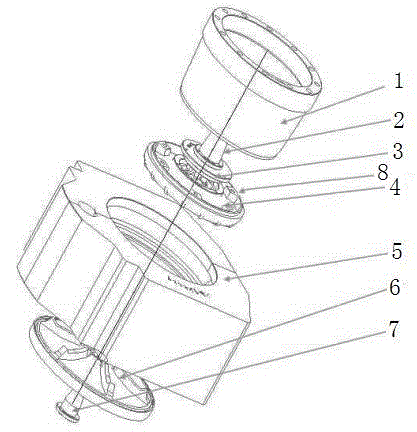

Valve body wax mold of tri-eccentric butt-clamped metal sealing butterfly valve

InactiveCN102107258AHigh dimensional accuracyHigh surface finishFoundry mouldsFoundry coresSurface finishWax

The invention relates to a valve body wax mold of a tri-eccentric butt-clamped metal sealing butterfly valve. The valve body wax mold is characterized by consisting of a front mold shell, a rear mold shell, a left valve body path core, a right valve body path core, a shaft hole core, a plurality of installation hole cores, a baffle plate and a fastening member; the front mold shell and the rear mold shell which are fixed together form a valve body cavity which is matched with the shape of the valve body and comprises a valve body path part cavity, a shaft hole upper end face part cavity, a shaft hole part cavity and an installation hole plate part cavity; the left valve body path core and the right valve body path core pass through the left sides and the right sides of the front mold shell and the rear mold shell so as to be penetrated and fixedly inserted into the path part cavity together; the shaft hole core is inserted into the shaft hole part cavity; the plurality of installation hole cores are respectively inserted into the installation hole part cavity; the baffle plate is covered on the shaft hole end face part of the valve body cavity; and a pouring hole is formed corresponding to shaft hole end face part. The valve body wax mold of the tri-eccentric butt-clamped metal sealing butterfly valve has the advantages of increasing the size precision and the surface finishment of the valve body, reducing the manufacturing cost and improving the production efficiency.

Owner:天津市大站阀门总厂

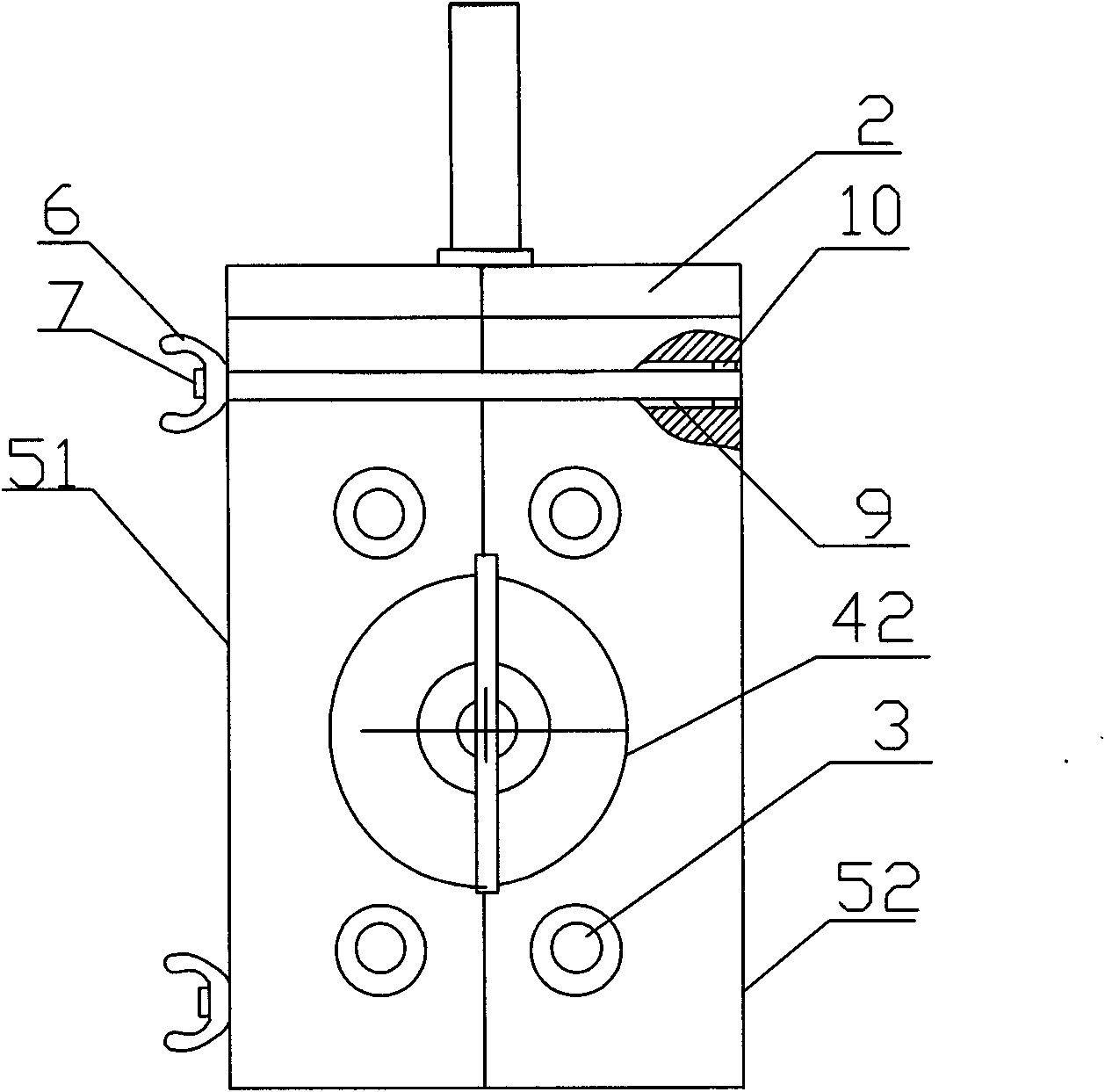

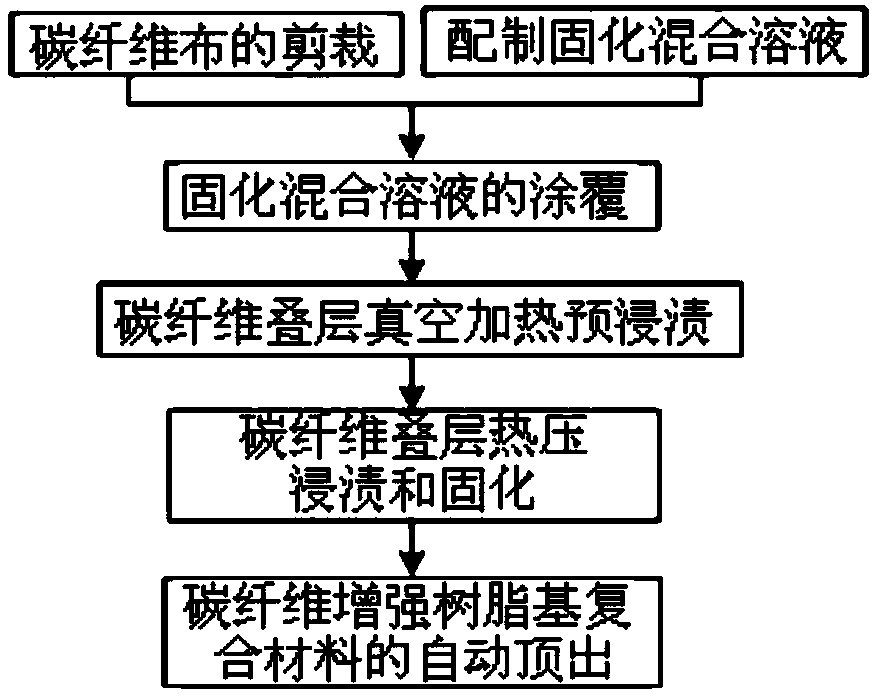

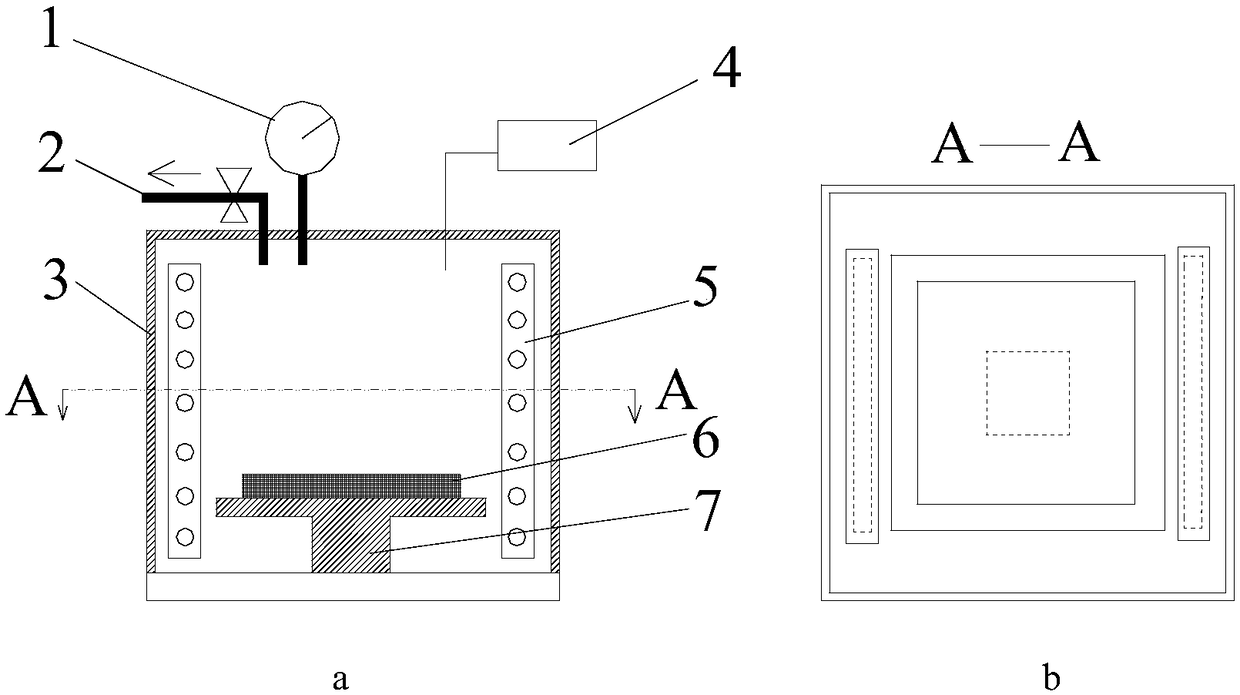

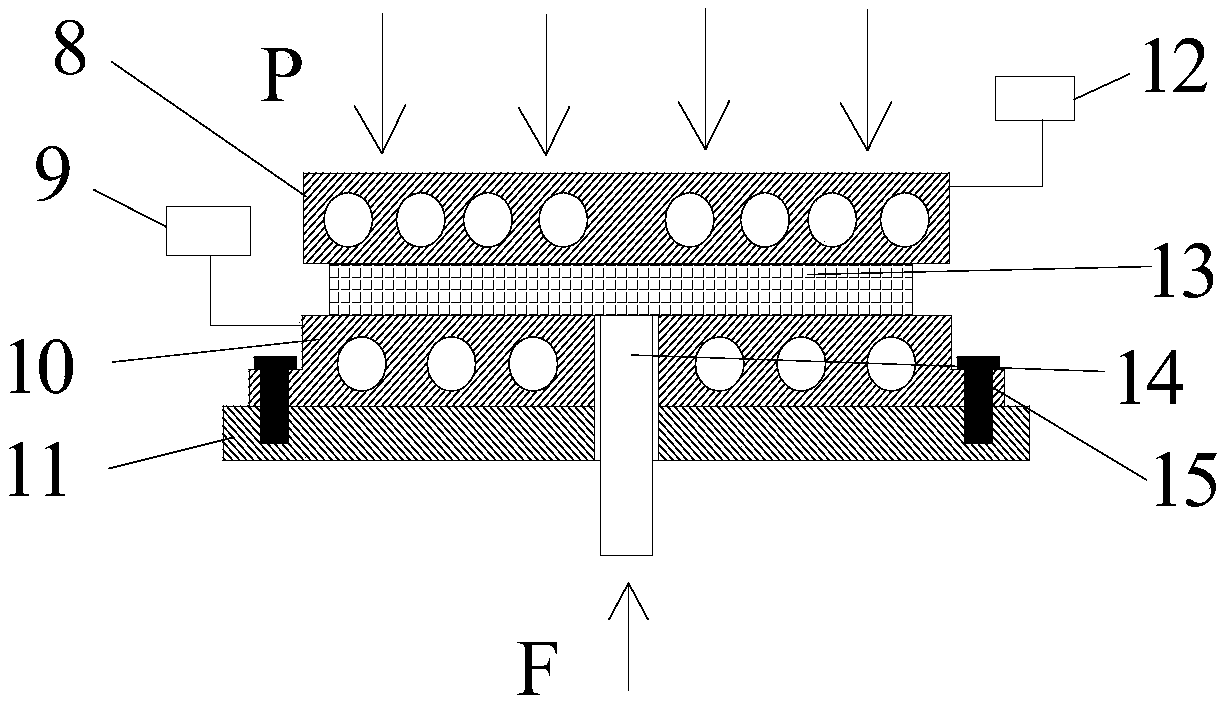

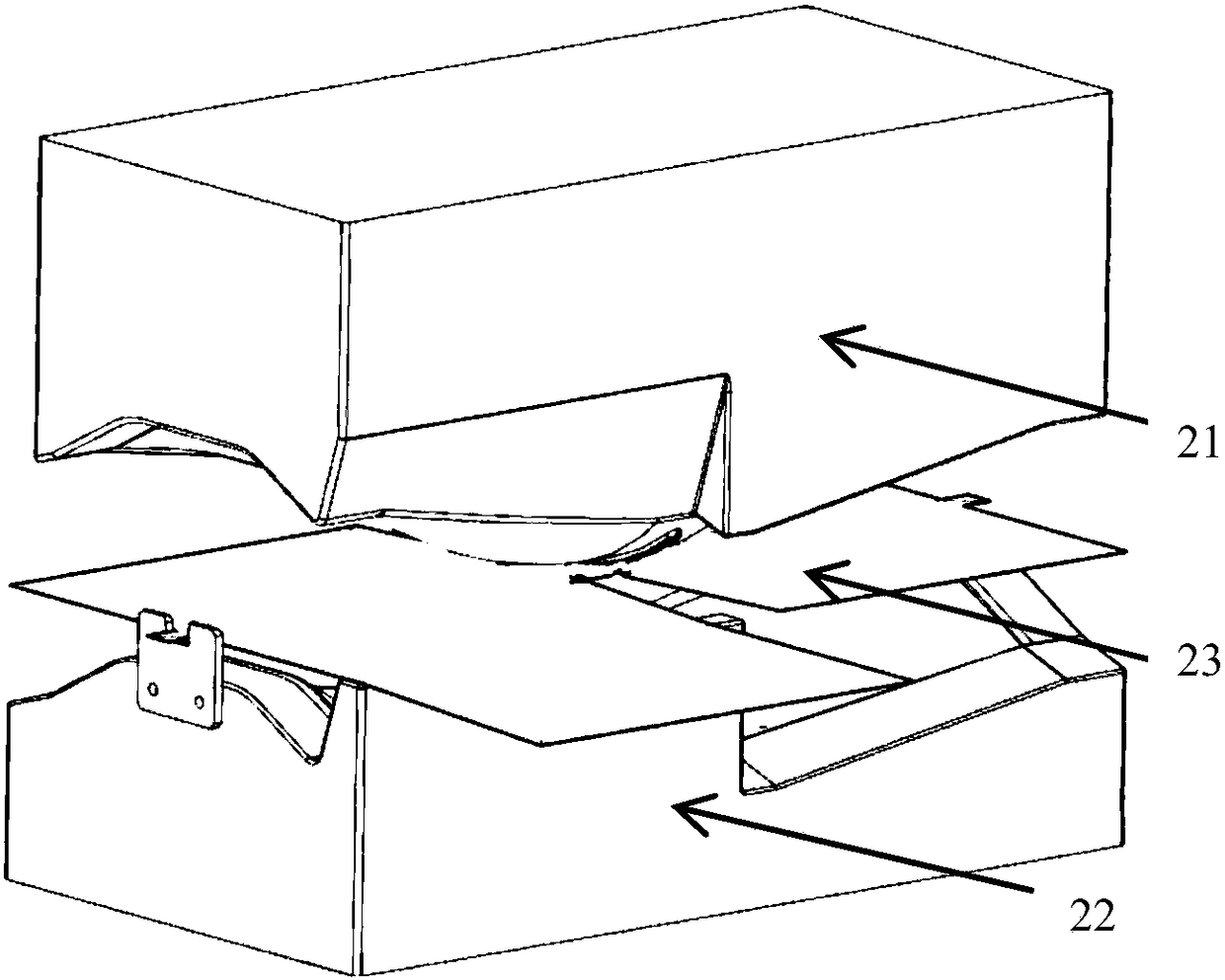

Vacuum impregnation and hot-press curing molding method for carbon fiber composite material

The invention relates to a vacuum impregnation and hot-press curing molding method for a carbon fiber composite material. The vacuum impregnation and hot-press curing molding method comprises vacuum heating and pre-dipping and hot-pressing dipping and curing forming, heating and dipping and extrusion forming of the composite material are achieved through a vacuum heating dipping device and a pressing and dipping and curing device, so that the gas impurities in the carbon fiber cloth laminated layer can be discharged in time, the defect of vacuum impregnation can be made up, so that the curingsolution can be better filled into the gap of the carbon fiber cloth, the defects of pores, shrinkage cavities and shrinkage porosity of the extruded composite material can be obviously reduced, the density is obviously improved, and then the performance of the composite material is improved. According to the vacuum impregnation and hot-press curing molding method, the composite materials with different shapes and sizes can be formed in a near-net mode according to the shape matched with the upper die and the lower die.

Owner:XIDIAN UNIV

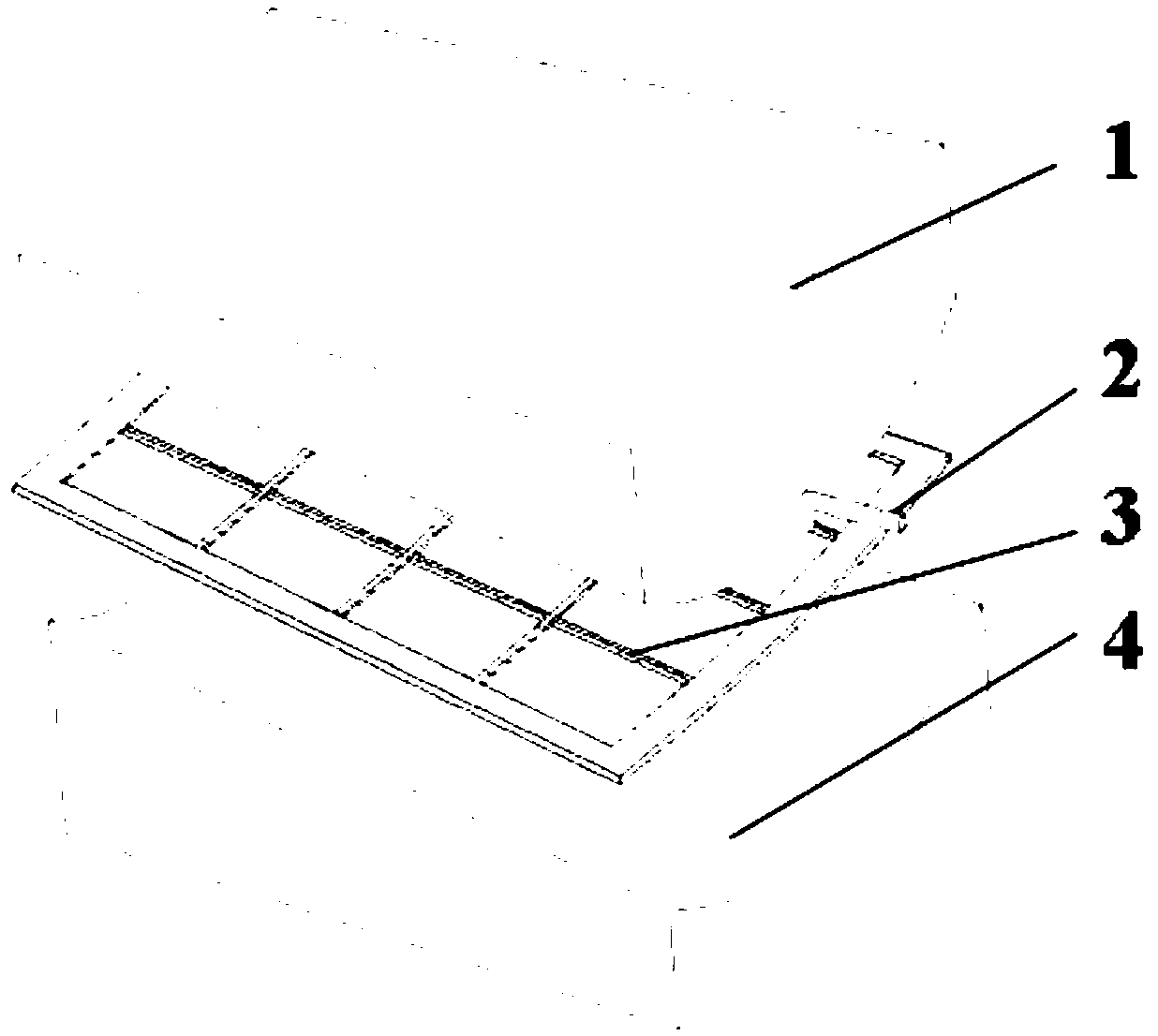

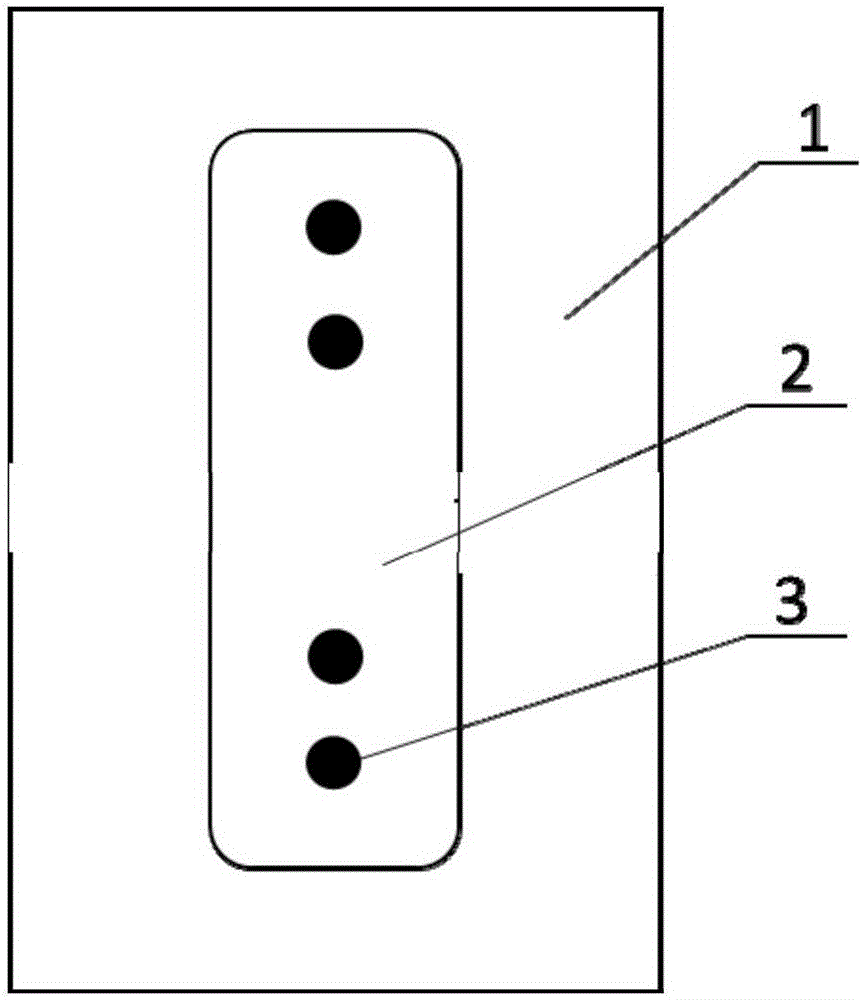

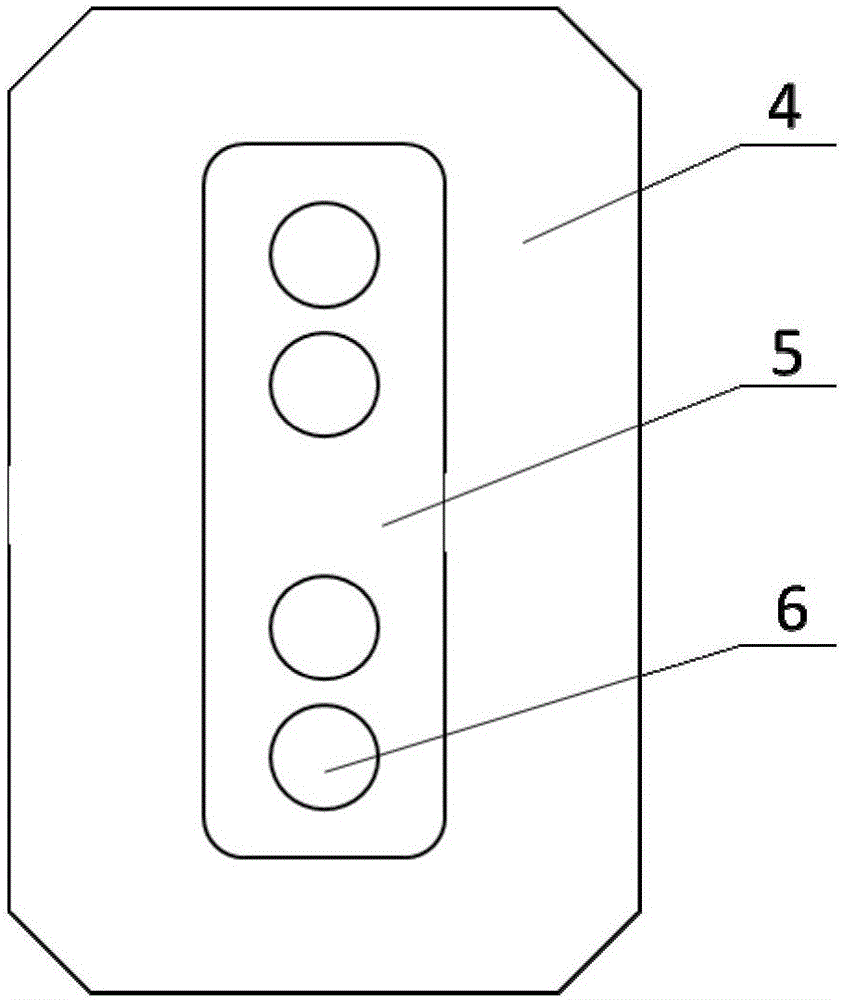

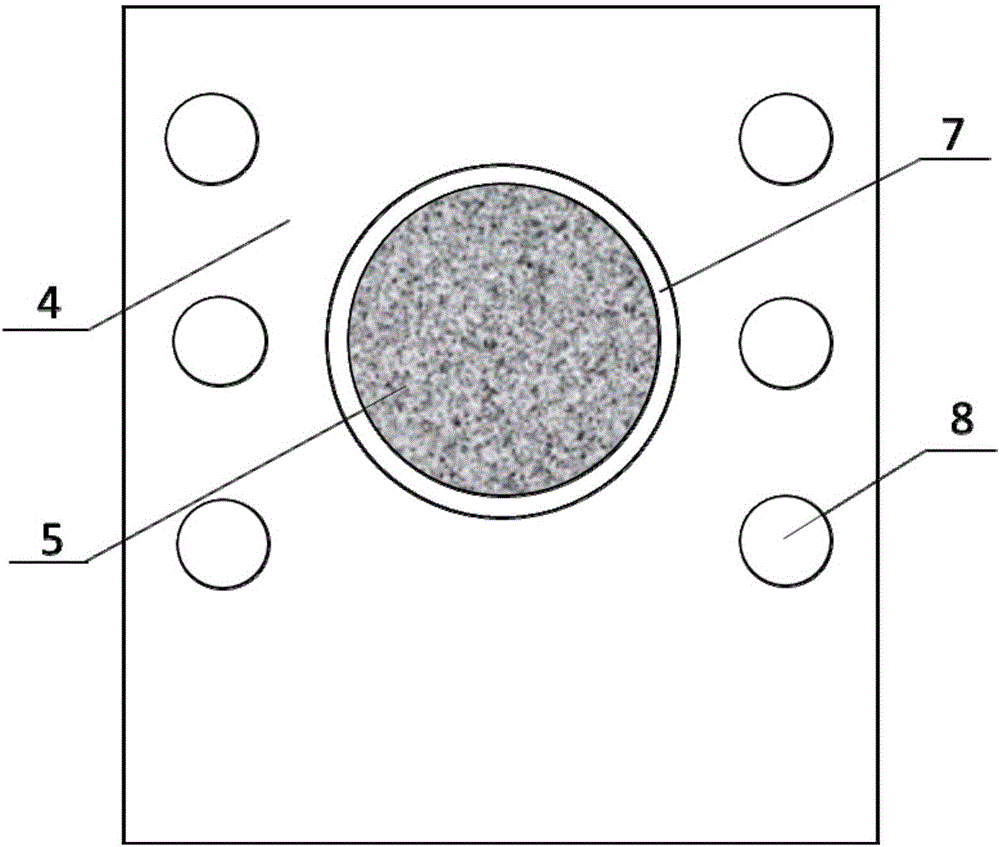

Light curing injection mold cores and manufacturing method thereof

InactiveCN105599178AReduce the amount of subsequent processingShorten the production cycleAdditive manufacturing apparatusMaterials scienceRapid manufacturing

The invention discloses light curing injection mold cores and a manufacturing method thereof. The light curing injection mold cores comprise a fixed mold core and a movable mold core. The manufacturing method includes the following steps that firstly, layering is conducted on the designed fixed mold core or the movable mold core which is subjected to shelling and comprises a pouring system and a conformal cooling channel with layering software, the layered fixed mold core or movable mold core is loaded to a rapid light curing forming machine, and a shell of the fixed mold core or the movable mold core is manufactured; then a backfilling material is manufactured, vacuum stirring processing is conducted on the backfilling material with a vacuum casting machine, a shell pouring cavity of the fixed mold core or the movable mold core is filled till the shell pouring cavity is fully filled, curing is conducted at the room temperature for 10-24 hours, and the light curing injection mold cores are obtained. The light curing injection mold cores which are manufactured in a light curing mode and provided with the conformal cooling channel and subjected to backfilling are short in manufacturing cycle, low in manufacturing cost and applicable to rapid manufacturing of medium or small batches of injection products and rapid trial-manufacture and performance detection of new products and the like.

Owner:XI AN JIAOTONG UNIV +1

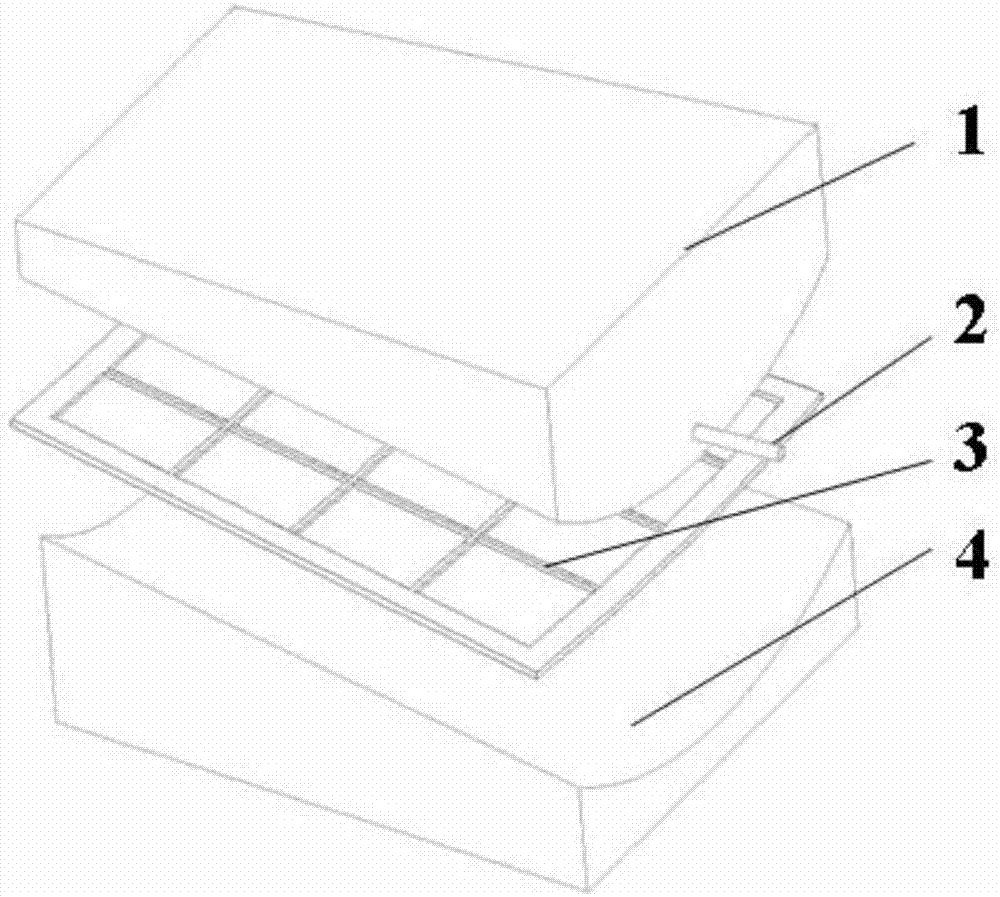

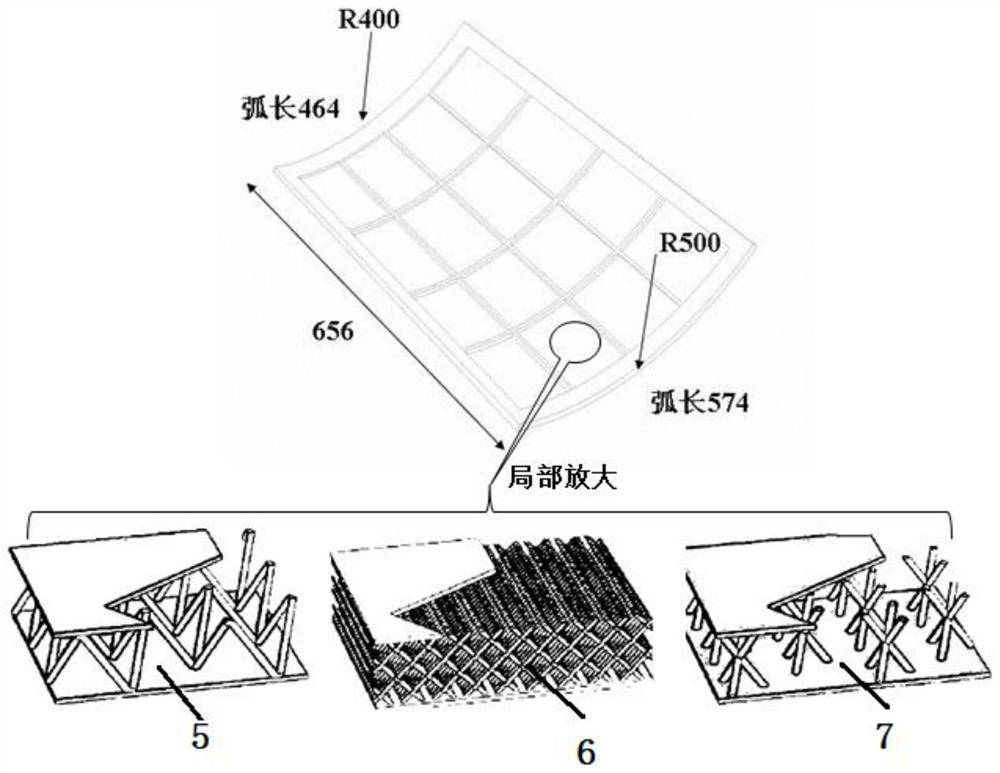

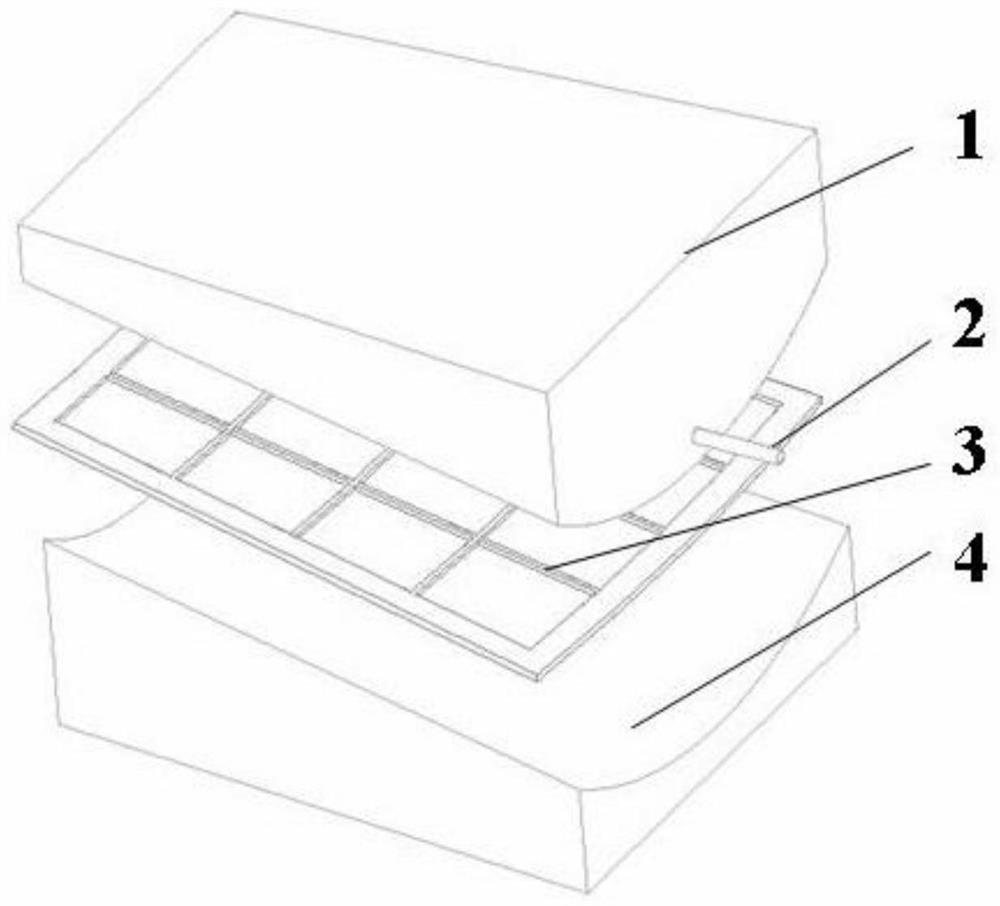

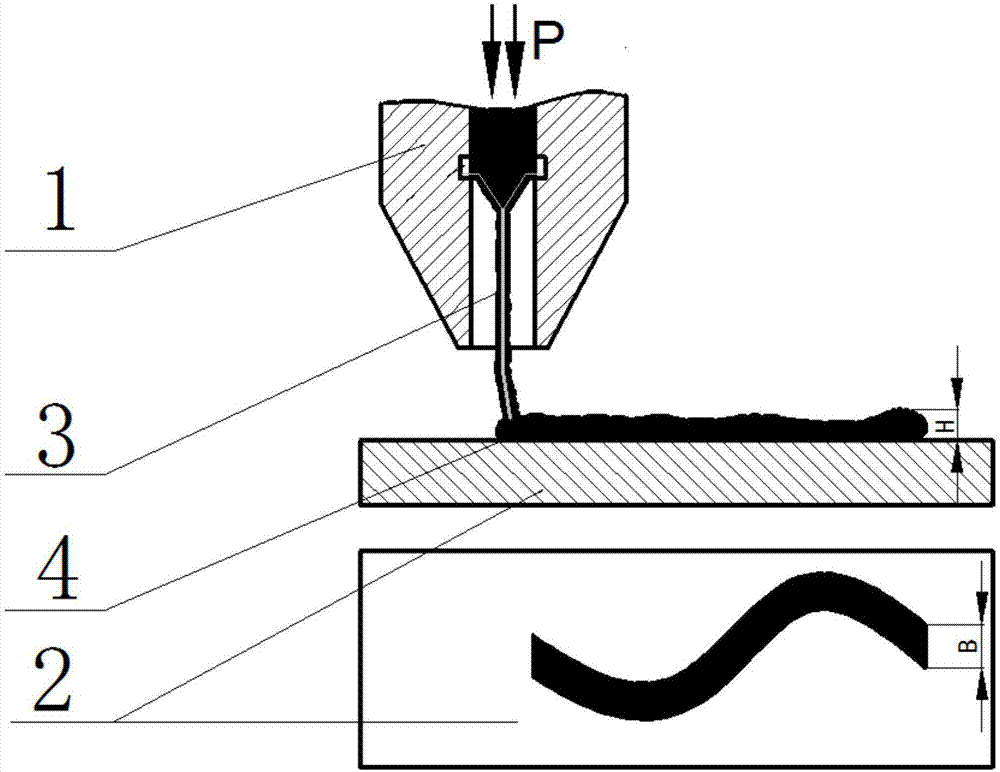

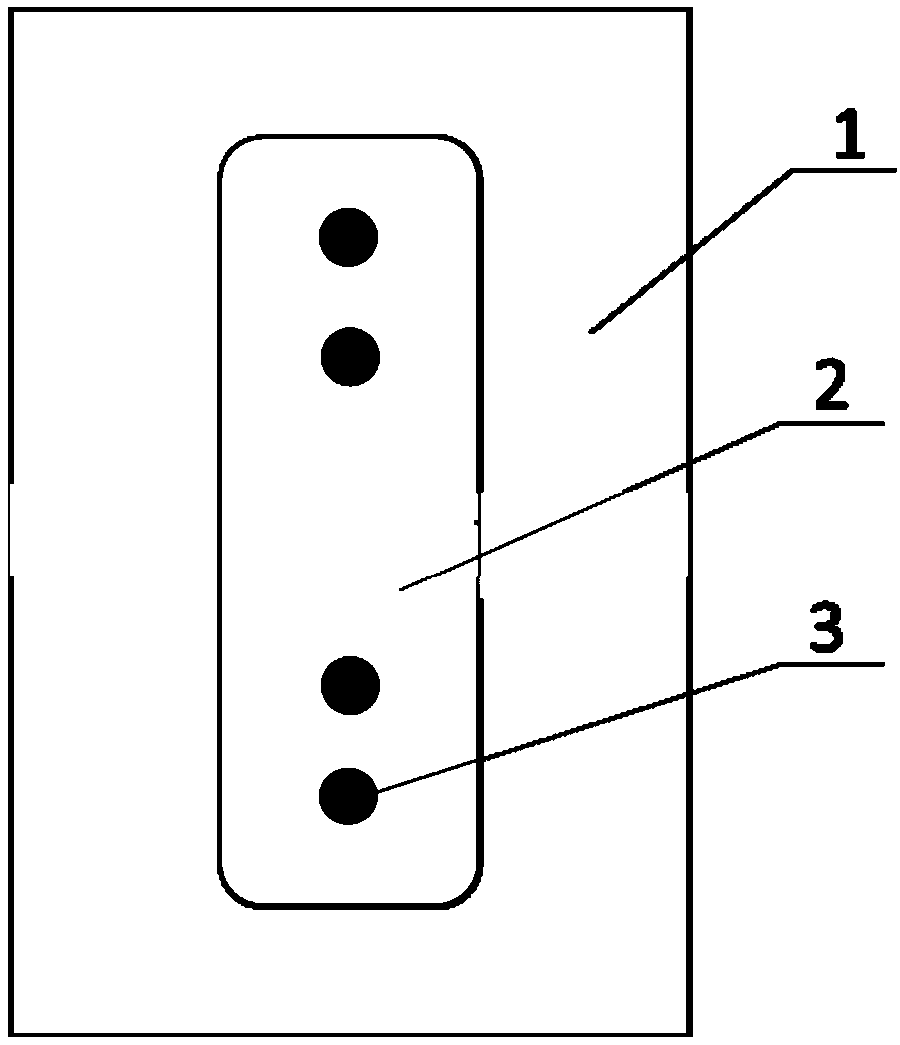

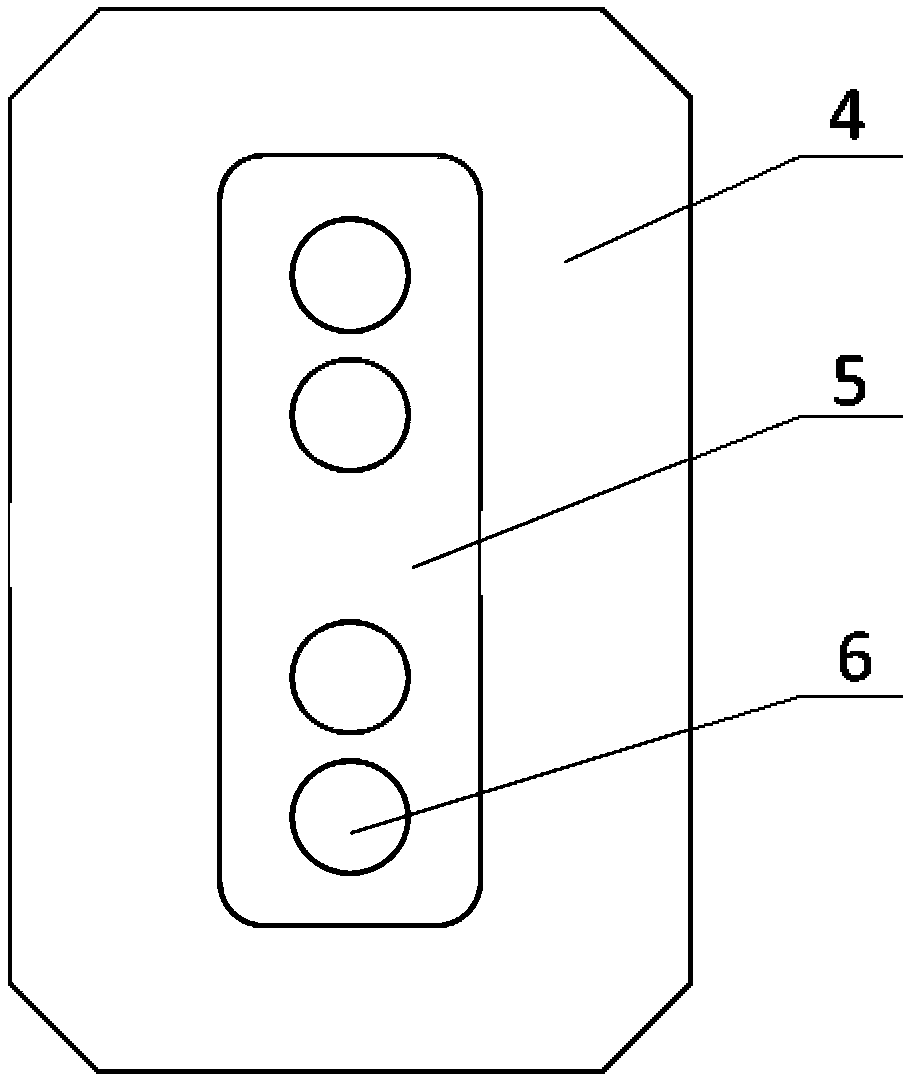

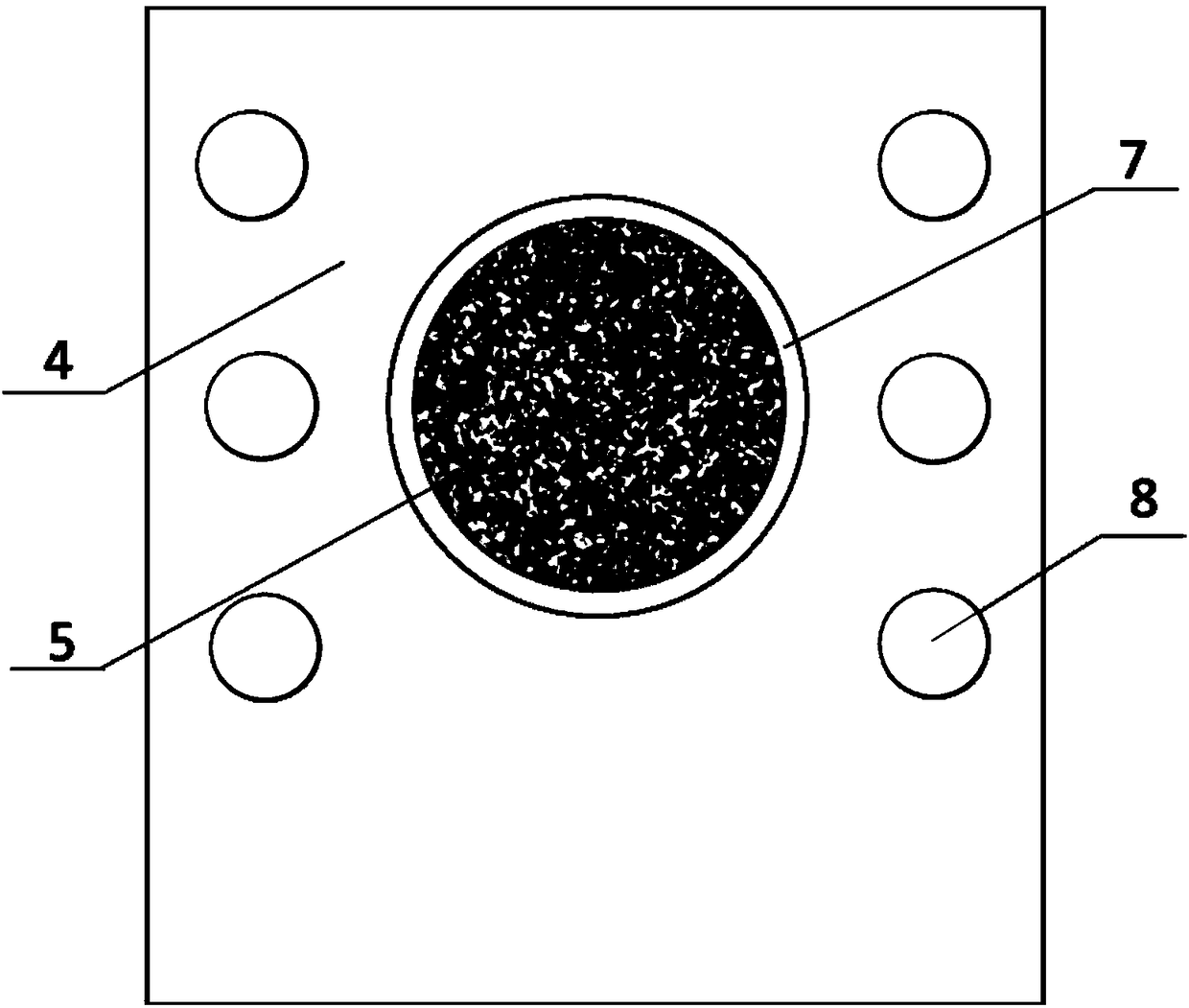

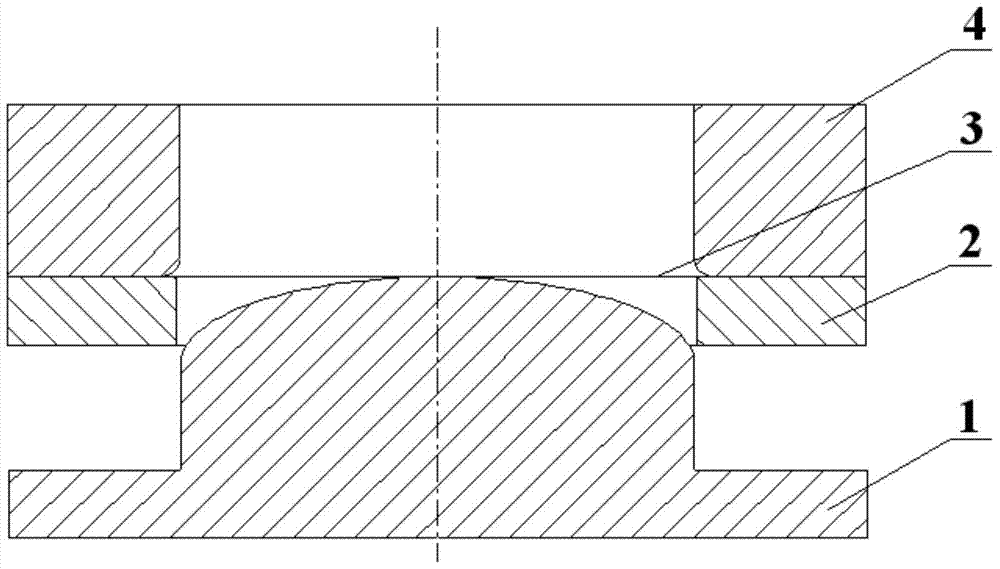

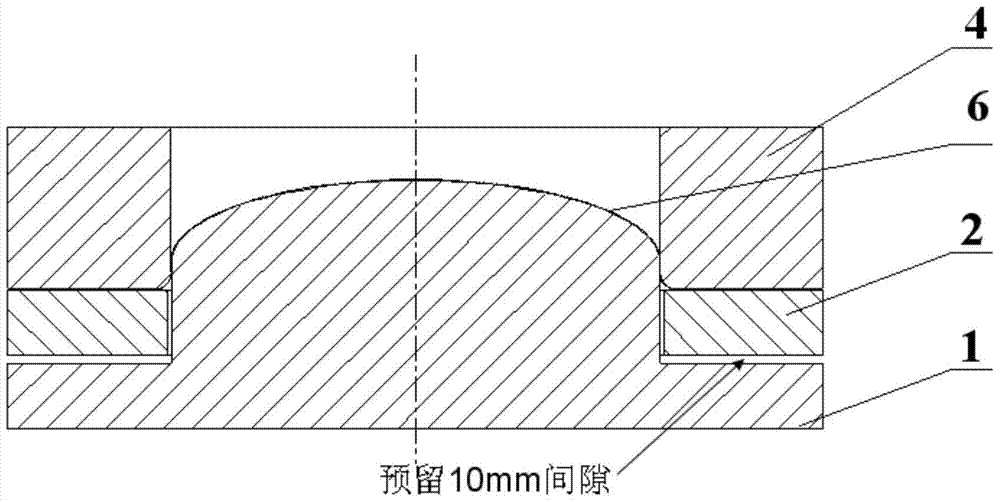

Additive hot-pressing inflatable composite forming method for topological structure wallboard

ActiveCN111744983AImprove integrityImprove surface qualityShaping toolsIncreasing energy efficiencyStructural engineeringClosed cavity

The invention discloses an additive hot-pressing inflatable composite forming method for a topological structure wallboard, belongs to the technical field of precision sheet metal processing, and solves the defects of poor integrity, difficulty in appearance precision control or higher cost in existing technical processing. The forming method comprises the following steps of step 1, determining positions of reinforcing ribs and a topological structure of a topological structure wallboard blank required by hot-pressing forming; step 2, preparing the topological structure wallboard blank by an additive; step 3, manufacturing a hot-pressing forming die of the topological structure wallboard; step 4, placing the topological structure wallboard blank in a cavity of a hot-pressing forming die, and performing hot-pressing forming on the topological structure wallboard blank; and step 5, forming a closed cavity between the topological structure wallboard blank and an upper die, communicating the closed cavity with an external gas source through a vent hole, and performing ventilation and pressurized correction on the closed cavity in order to enable a curved surface part between the reinforcing ribs of the topological structure wallboard to form a smooth curved surface. According to the method, the surface quality of parts is improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

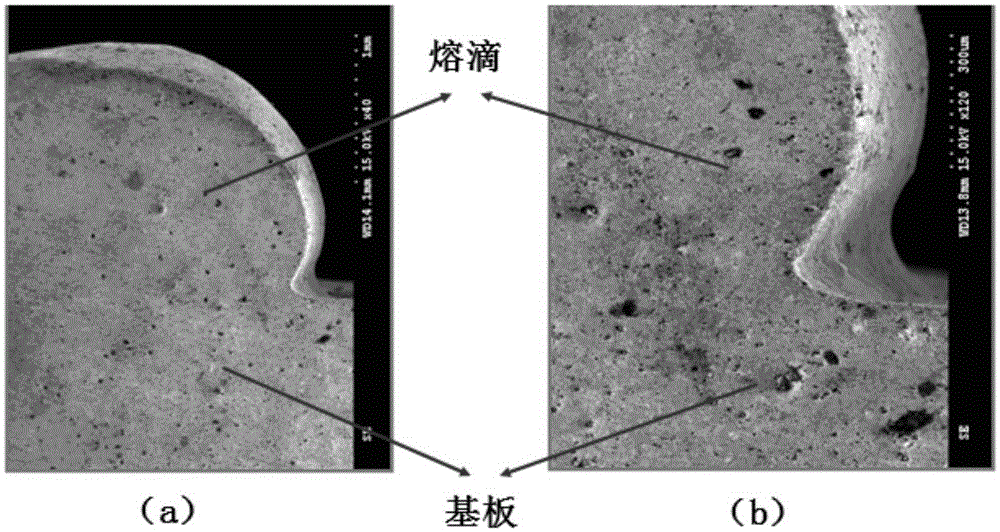

Forming device and method for guiding molten metal coating by using metal wire

InactiveCN104762585AImprove machining accuracyIncrease forming rateMolten spray coatingMetallurgyMolten metal

The invention discloses a forming device and a method for guiding molten metal coating by using a metal wire. The forming device comprises a base plate, a spray head, a 3D displacement platform and the metal wire, wherein the base plate is fixed on the 3D displacement platform; the upper end of the metal wire is inserted into a nozzle at the bottom of the spray head and is fixed on the inner side surface of the nozzle, the lower end of the metal wire is suspended in the air, and the included angle between the lower end of the metal wire and the base plate is 90-95 degrees; and the spray head and the metal wire are positioned above the base plate. By adopting the forming device and the method disclosed by the invention, the strain deformation of a pair, caused by the stress, can be effectively reduced, and the accuracy of a formed part is ensured.

Owner:XI AN JIAOTONG UNIV

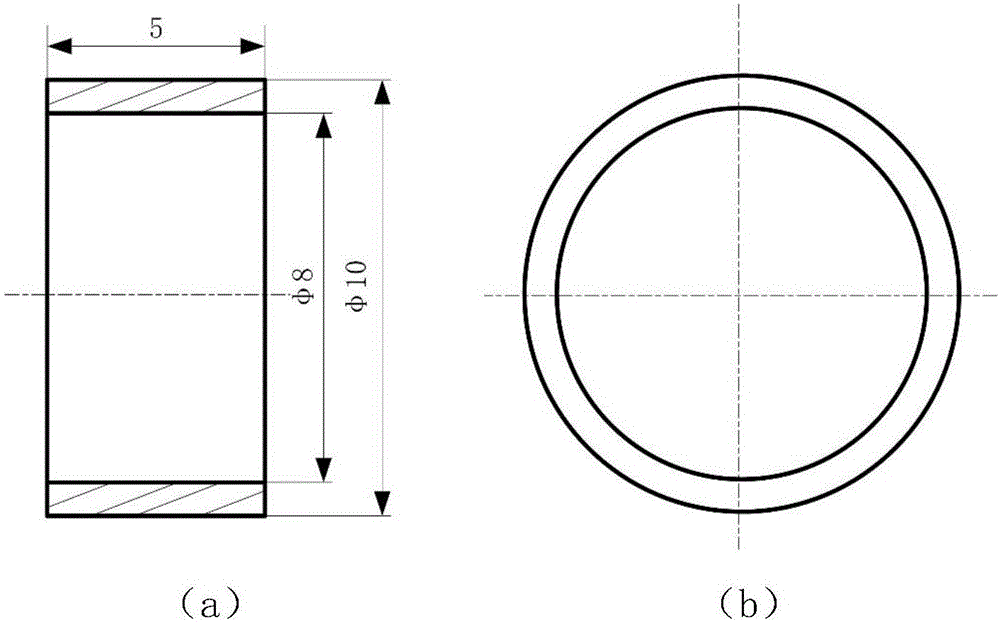

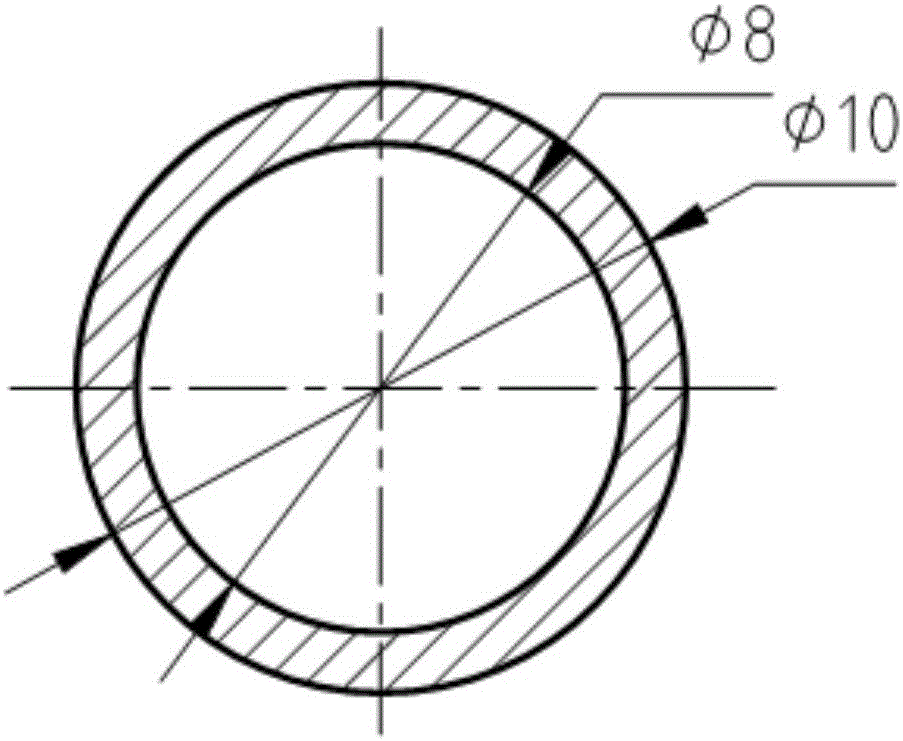

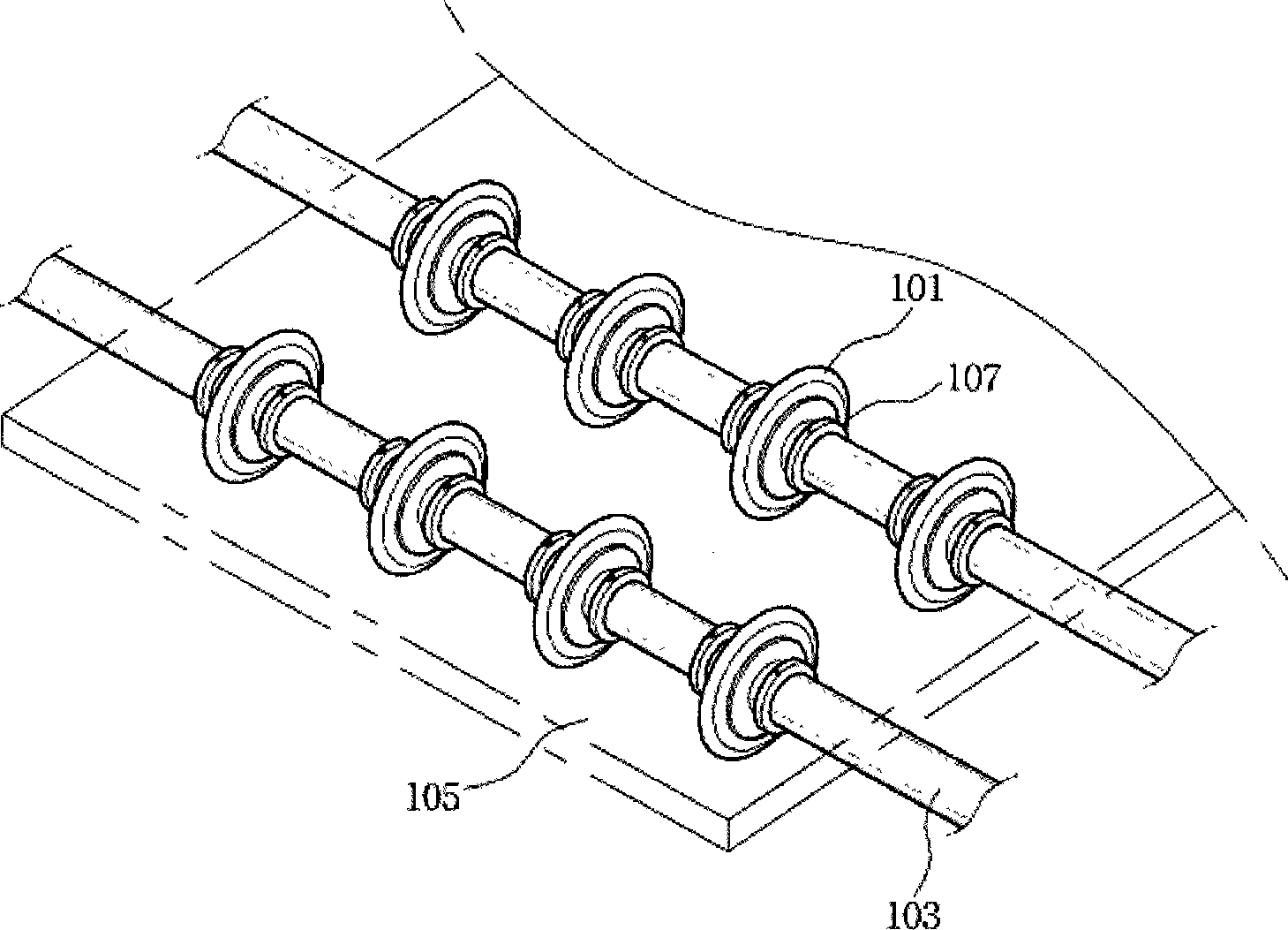

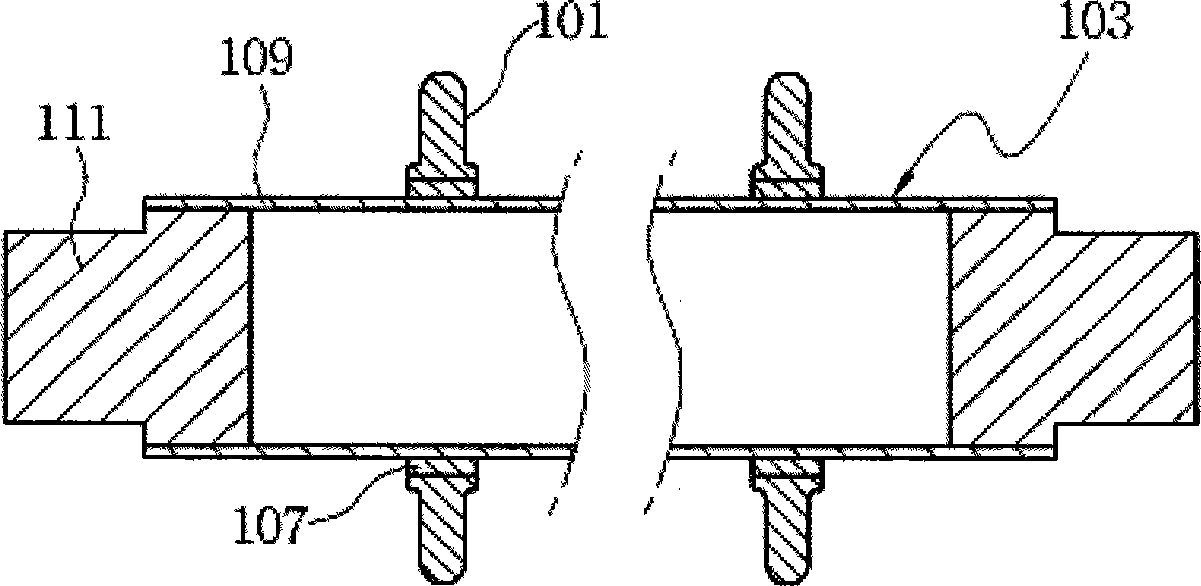

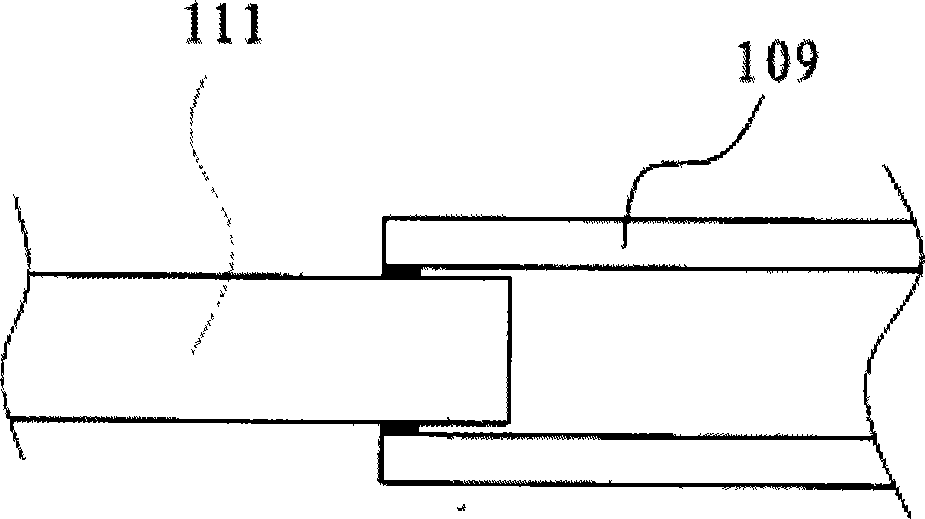

Connection method of transmission axle for precise transmission and bearing support part

InactiveCN101362274AReduce production stepsSimplify the manufacturing processMetal working apparatusCentre of rotationStructural engineering

The invention discloses a method for the connection of a conveying shaft used for precision conveying and a bearing supporting part. The method comprises the following steps: (1) a hollow main body is fixed on rotating equipment; (2) the connecting part of the hollow main body is heated; (3) the cylindrical bearing supporting part is inserted into the hollow main body; (4) after the cylindrical bearing supporting part is inserted into the hollow main body, the cylindrical bearing supporting part and the hollow main body rotate together to form a central rotating shaft; (5) the hollow main body inserted into the cylindrical bearing supporting part is cooled down together, and after cooling, gapless matching is formed between the cylindrical bearing supporting part and the hollow main body; and (6) the outer surface of the connecting part of the hollow main body is processed. The hollow main body of the conveying shaft is connected with the cylindrical bearing supporting part without welding, so that the production steps are reduced; rotating insertion is adopted, so that the hollow main body of the conveying shaft and the cylindrical bearing supporting part have identical central shaft, the production process is simple, the subsequent processing amount is small, and the cost is low.

Owner:宋晓光

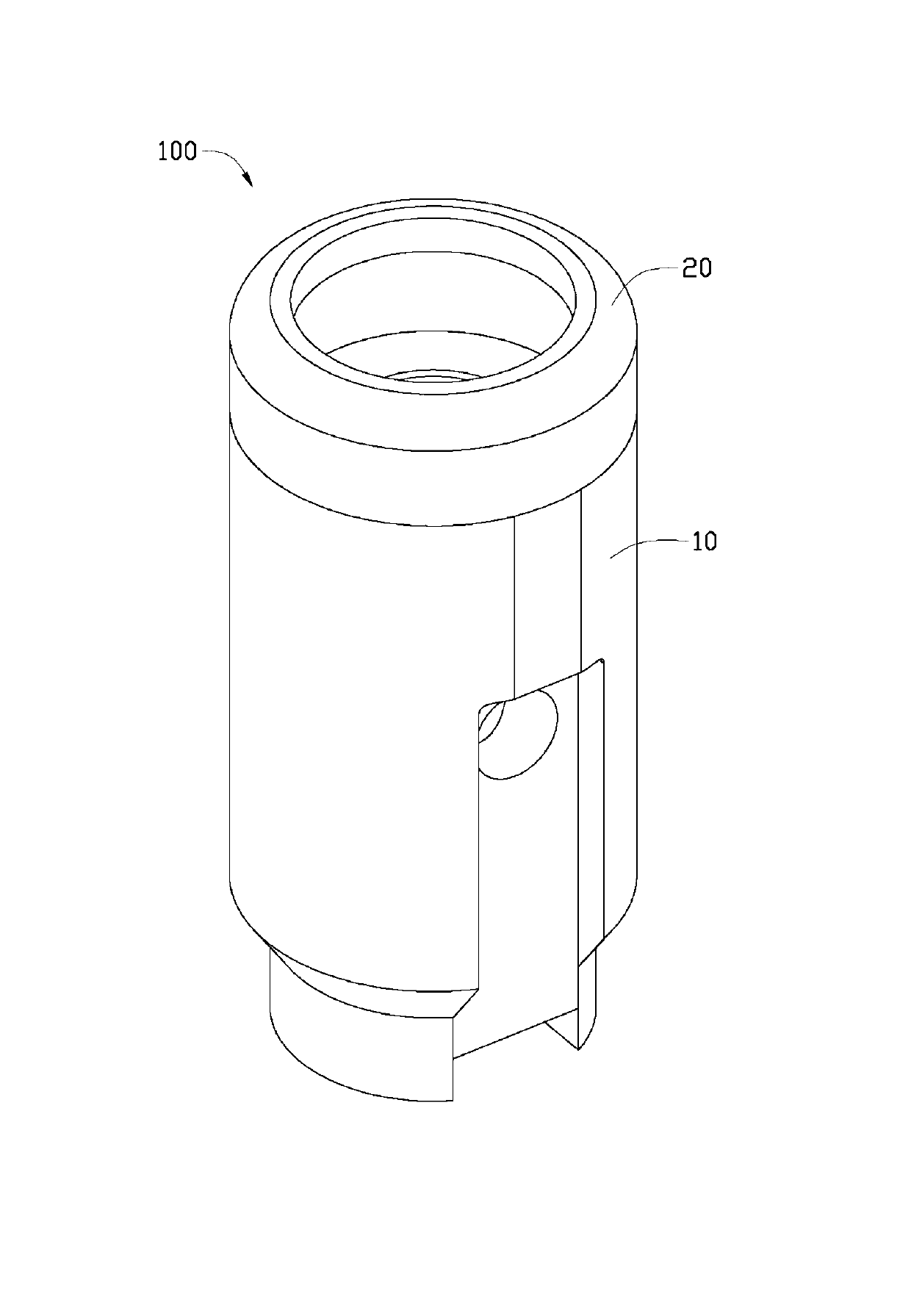

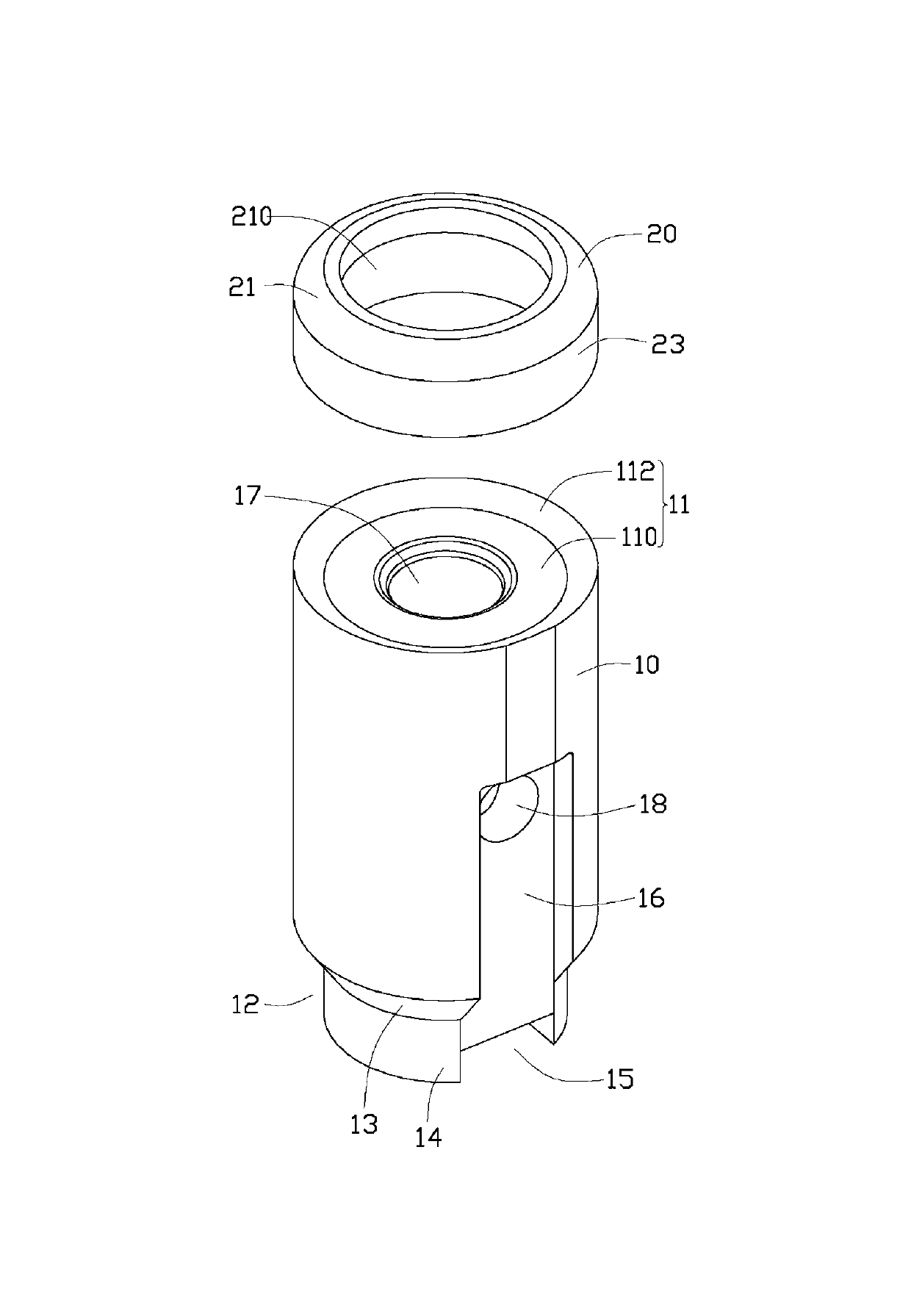

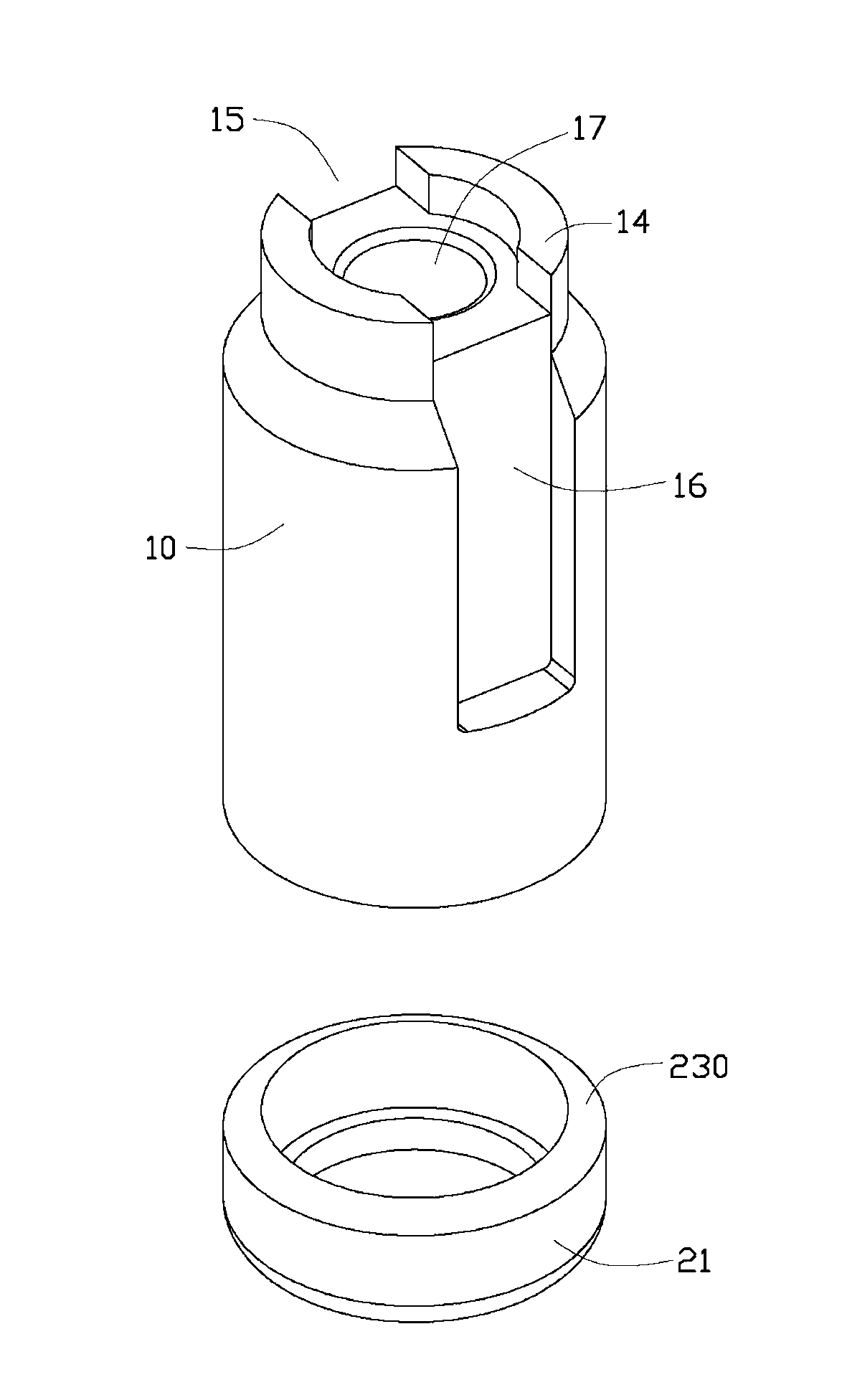

Production method of bearing device

A production method of a bearing device comprises the steps as follows: providing a bearing mold; injecting a mixture of metal powder and a fusion binder into the bearing mold in an injection molding mode to form a bearing body blank and an upper cover blank respectively; removing the binder in the bearing body blank and the upper cover blank; sintering the bearing body blank and the upper cover blank to produce a bearing body and an upper cover; and assembling the upper cover on the bearing body to form the bearing device. The production method of the bearing device reduces follow-up processing amount effectively and can produce parts with high melting point, high strength and complex shape more conveniently compared with other molding modes.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

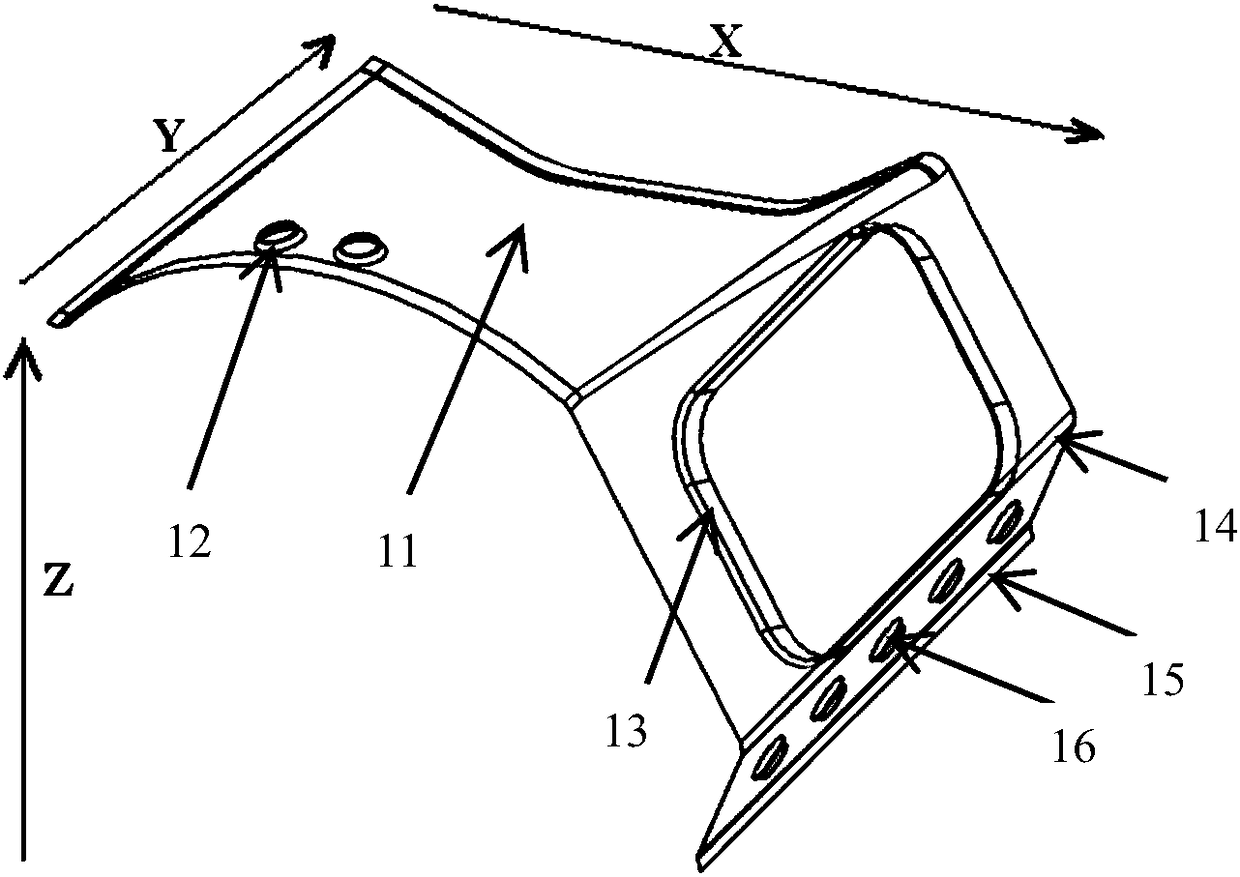

Precise plastic formation method for aluminum alloy complicated special-shaped curved structure part

The invention provides a precise plastic formation method for an aluminum alloy complicated special-shaped curved structure part and belongs to the field of precise sheet metal machining. The preciseplastic formation method is applicable to the aluminum alloy complicated special-shaped curved structure part which has relatively high requirements on dimensional precision, profile surface precisionand surface quality after formation. The method provided by the invention comprises the following steps of: (1) designing and manufacturing an aluminum alloy special-shaped curved thermo-forming mold, a flanging-hole flanging mold and a right side window thermal-flanging mold; (2) calculating the boundary dimension of a blank material and carrying out blanking; (3) carrying out top special-shapedcurved thermo-formation; (4) removing the process allowance and forming a flanging-hole flanging bottom hole and a flanging window flanging front window; (5) carrying out flanging formation of a flanging hole; (6) carrying bending formation of a bent edge; and (7) carrying thermo-flanging formation of the window. The method provided by the invention can overcome the shortcomings that a part machined by the prior art is poor in integrity, difficult in boundary dimension control or the cost is relatively high, and can effectively guarantee precise formation of the aluminum alloy complicated special-shaped curved structure part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Process for machining farm truck tensioner casing

InactiveCN1569390AReduce the amount of subsequent processingImprove toughnessOther manufacturing equipments/toolsPunch pressEngineering

The invention is farm car tensed wheel shell processing craft, relating to processing method. The steps are; selecting steel pipe, and cutting the pipe according to the length demanded; then, the cut semi finished articles steel pipe is processed on the punching machine, forms the outwards edges of the steel pipe, the height is 0.3-1cm; then carries on process to the internal apertures at two ends through punching bed or lathe, makes the internal radius of the shell engaged with the external radius of the bearing. The invention is simple and the cost is low.

Owner:王之中

Hub casting die

InactiveCN104889340AGuaranteed qualityPrecise positioningFoundry mouldsFoundry coresMachiningMaterials science

The invention discloses a hub casting die. The hub casting die comprises an upper die, a side die and a lower die, and the upper die, the side die and the lower die are combined to form a hub casting cavity. The upper die in a split structure consists of an upper die ring and an upper die modeling block connected with the lower end of the upper die ring, simultaneous standard machining of accessories of the die is realized, only the upper die modeling block and / or the lower die need to be replaced when hub types change, and only the upper die ring and the side die need to be replaced when rim widths of the hubs change, so that a traditional method of making a new die for each type of new products is effectively changed, idle die amount and capital input are greatly reduced for enterprises, and utilization rate of die accessories is effectively increased. In addition, workload and cost for development of new dies are greatly reduced, and die development schedule is accelerated while new product launch time is shortened.

Owner:宿迁英挪唯铝业有限公司

A kind of hot pressing forming method of aluminum alloy curved surface stiffener plate

The invention discloses a hot-pressing forming method for an aluminum-alloy curved reinforcing rib plate. The method comprises the steps of 1, carrying out plane unfolding on the aluminum-alloy curved reinforcing rib plate; 2, preparing corresponding reinforcing ribs on the plate according to the positions of the reinforcing ribs in the plane unfolding diagram; 3, designing and processing a hot-pressing forming die of the aluminum-alloy curved reinforcing rib plate; 4, performing hot-pressing forming on the aluminum-alloy curved reinforcing rib plate; and 5, performing air inflation correction on the aluminum-alloy curved reinforcing rib plate. According to the method, the aluminum-alloy curved reinforcing rib plate is formed by adopting hot-pressing formation and air inflation correction combined technologies, the problem that the size precision and the profile precision of the parts are difficult to control in the conventional cold stamping or machining process is solved, the surface quality of the parts is improved, and the overweight problem in the casting process is avoided; firstly, hot-pressing forming is adopted so that resilience, wrinkling, cracking and other defects in the cold forming process can be effectively avoided; and then air inflation correction is adopted so that the size precision, the profile precision and the surface quality requirements of the parts can be guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

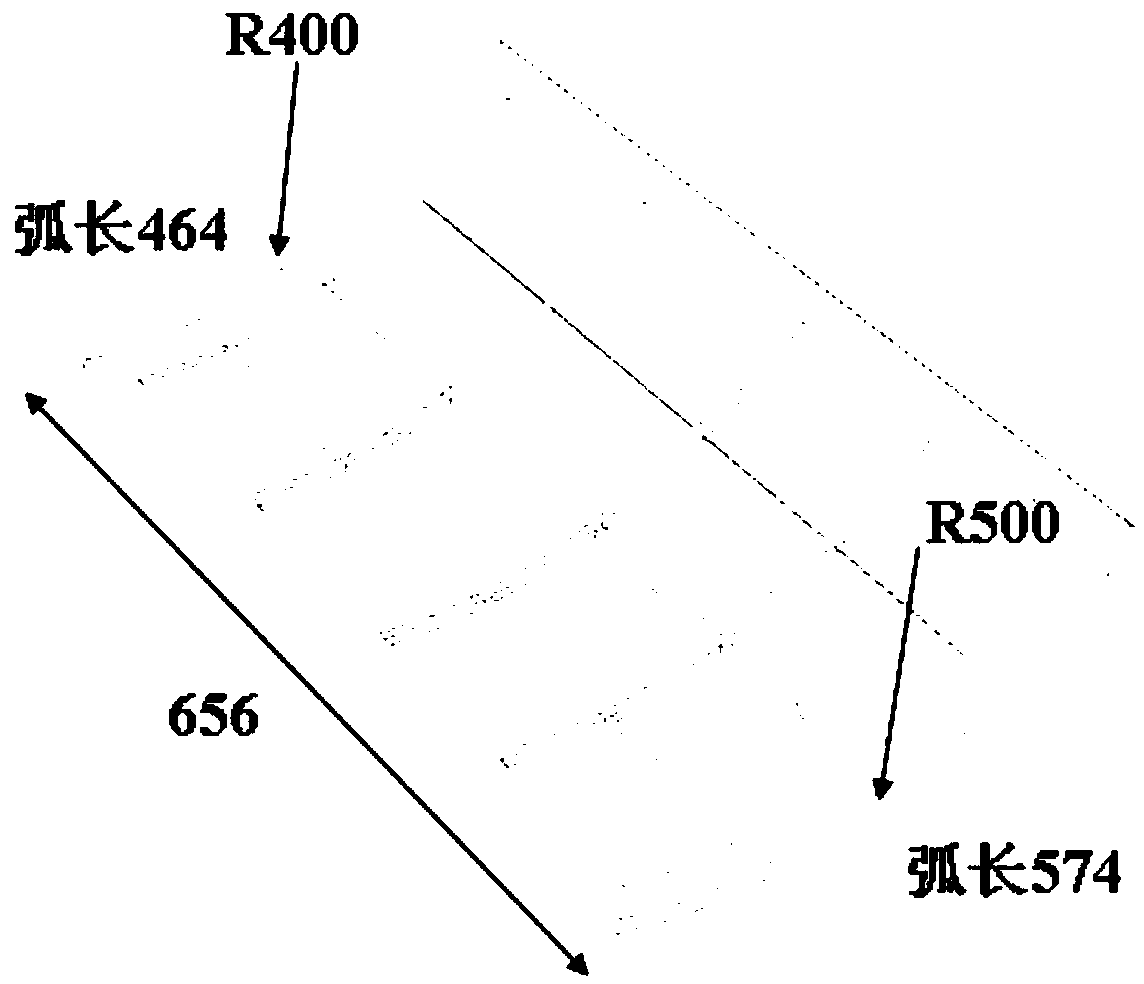

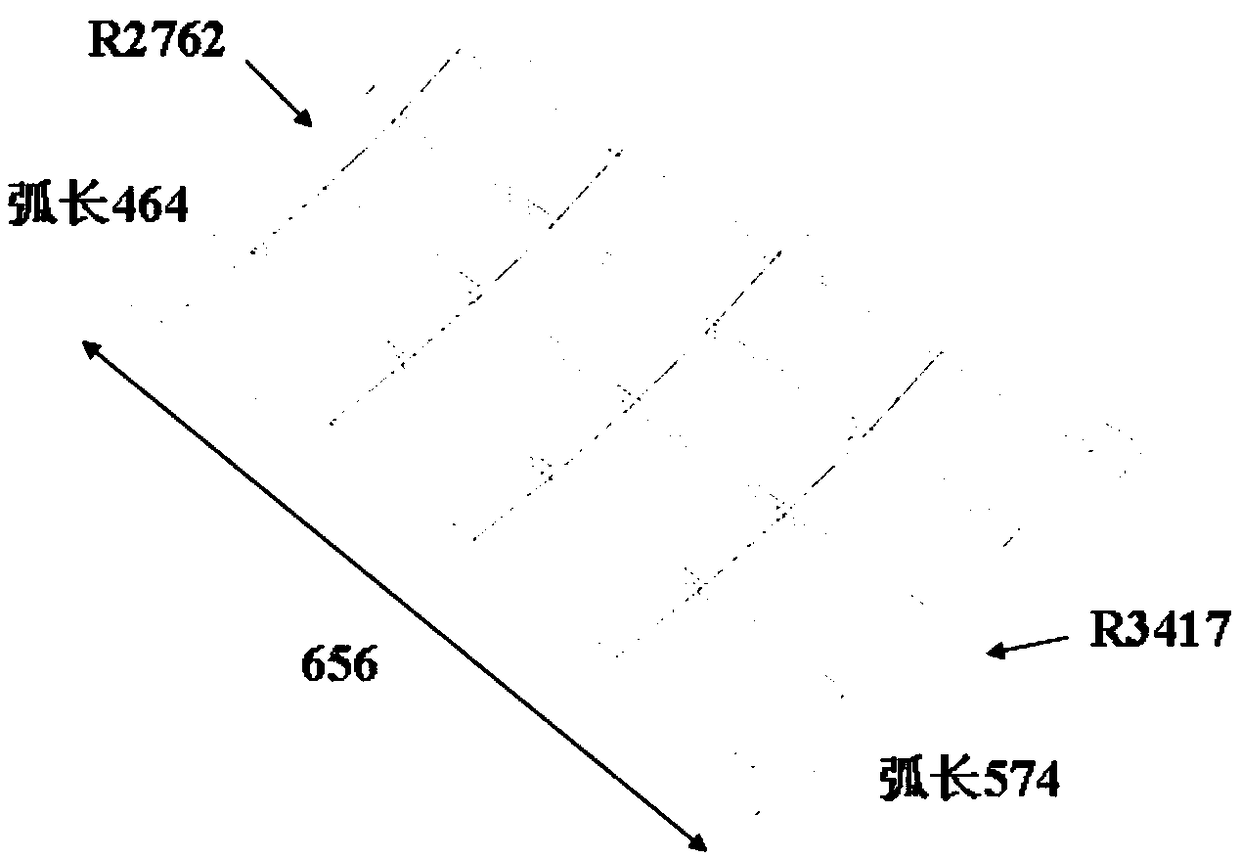

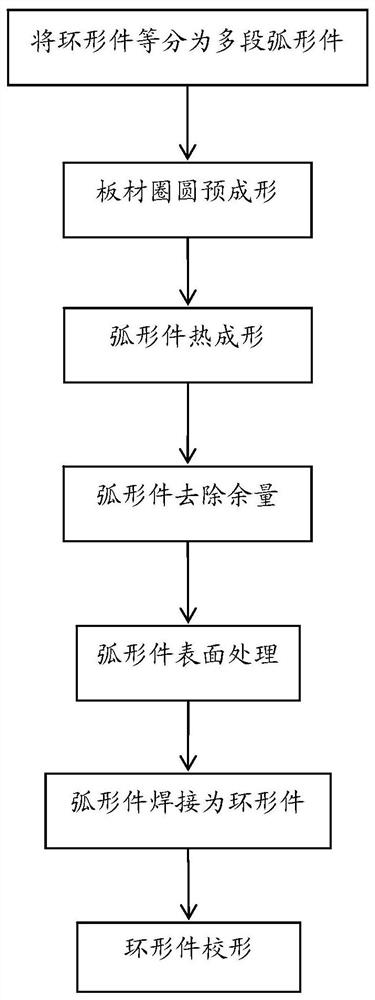

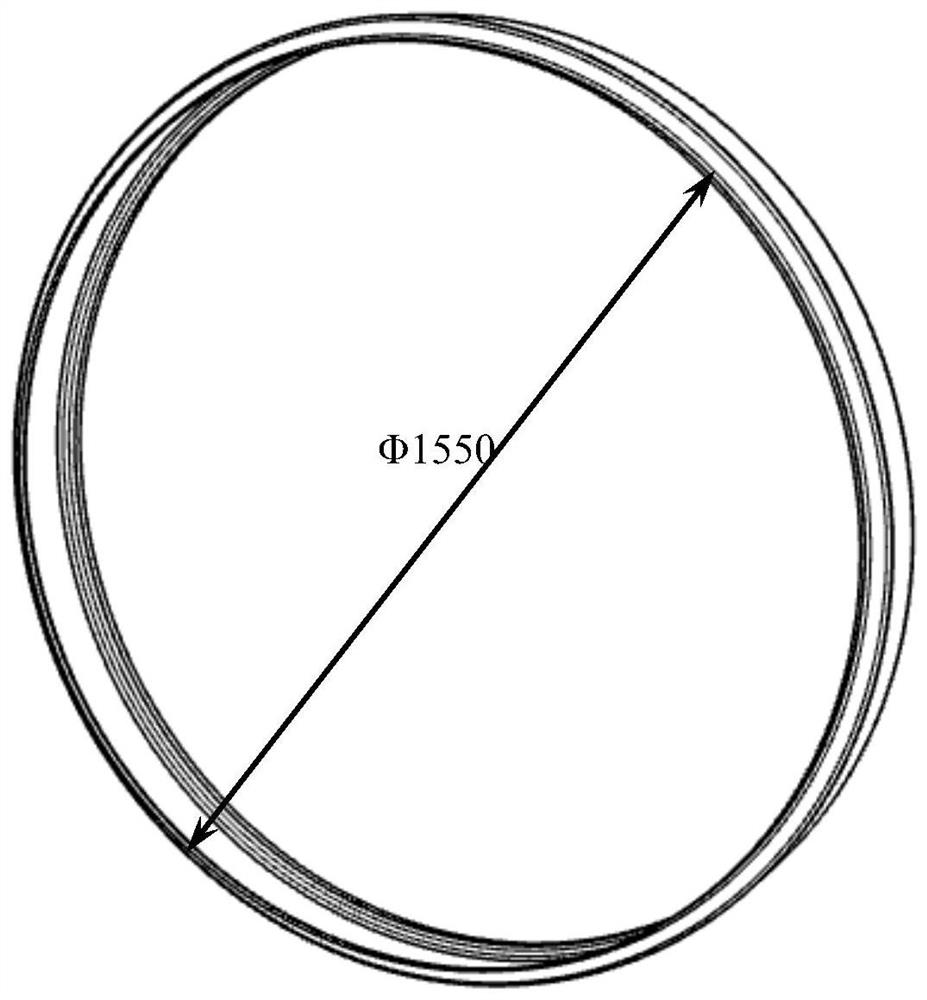

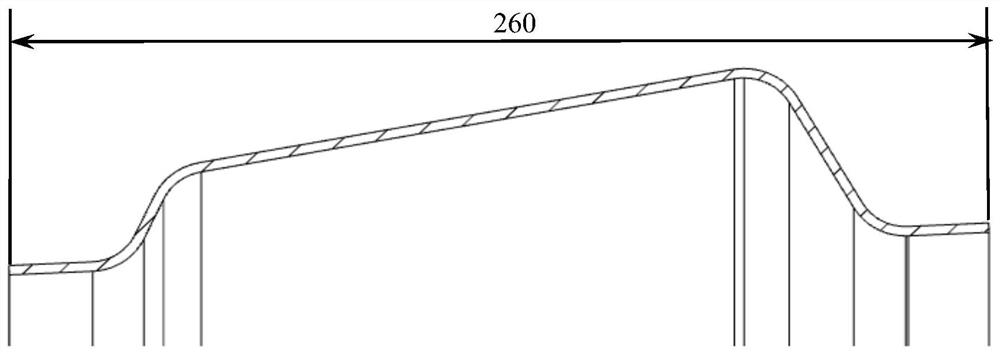

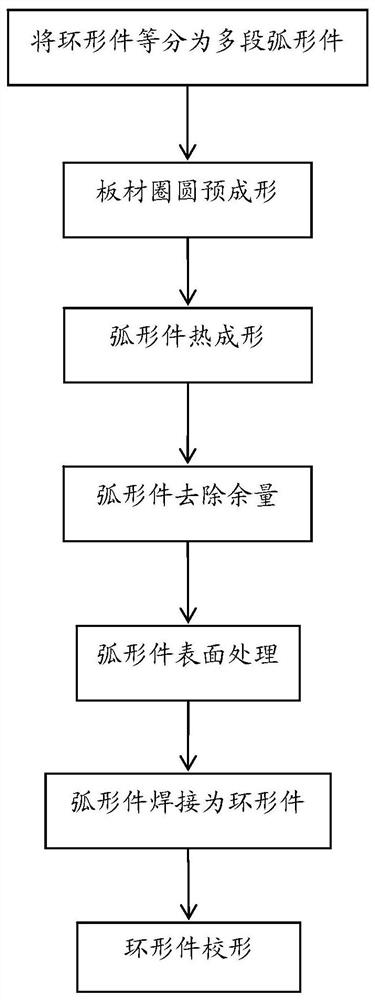

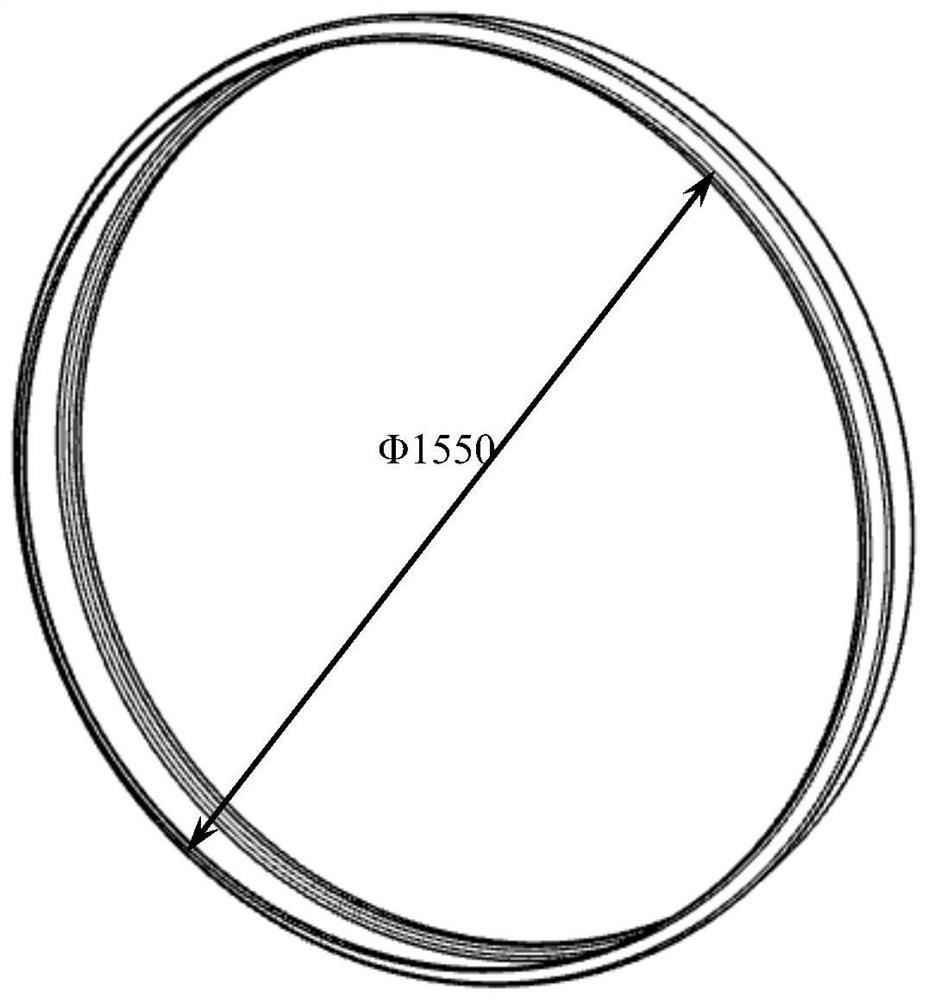

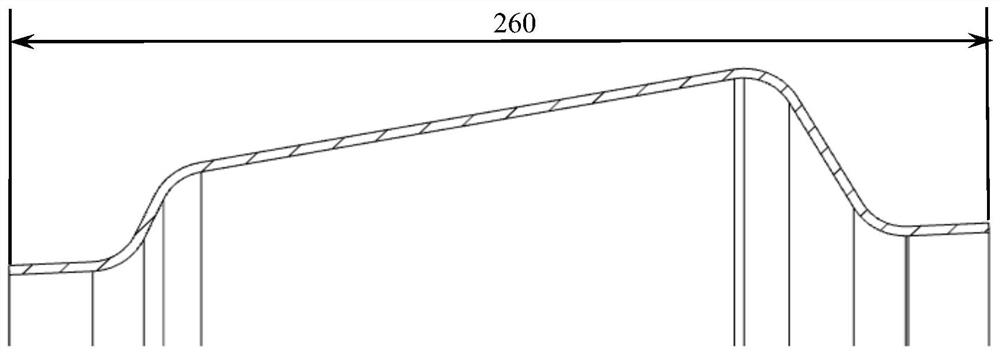

Forming method of large-size thin-wall complex curve section annular part

ActiveCN112676779AGuarantee product qualityReduce processing difficultyStructural engineeringMachining

The invention provides a forming method of a large-size thin-wall complex curve section annular part. The method comprises the following steps of dividing an annular part model into N arc-shaped part models in a circumferential direction according to a model size of the annular part; designing a hot forming process part and designing a hot forming die; determining a size of a needed blank, conducting blanking, conducting circle preforming on the blank obtained through blanking, and preparing a circle preformed part; conducting hot forming on the circle preformed part through the hot forming die to obtain the hot forming process part; removing a process allowance of the hot forming process part to prepare an arc-shaped part; conducting surface treatment on the N arc-shaped parts; assembling and welding the N arc-shaped parts subjected to surface treatment to obtain the annular part; and correcting the shape of the welded annular part. According to the method, a metal plate preforming plus hot forming plus welding composite forming technology is adopted, the most suitable forming technology is adopted for different portions, and therefore precise forming of parts is integrally achieved, the subsequent machining amount can be effectively reduced, subsequent manual shape correction is avoided, the efficiency is improved, and the cost is reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y

InactiveCN108588503AAvoid corrosionReduced service lifeHot-dipping/immersion processesAlloyDip-coating

The invention discloses a novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y. The alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Na,1.5-1.8% of Ti, 0.4-0.8% of Ca, 15.0-22.0 % of Sn, 0.2-0.4% of Y, 0.3-0.5% of Yb, 0.1-0.2% of P and the balance aluminum. By means of the hot dip coating aluminum tin alloy, the key problems that thetechnology in the present hot dip coating alloy field lags behind, product quality is poor, the product cost is high, energy consumption is large, and the like are solved, and in the near future, thealloy will be applied to more fields more widely.

Owner:GUANGZHOU YUZHI TECH CO LTD

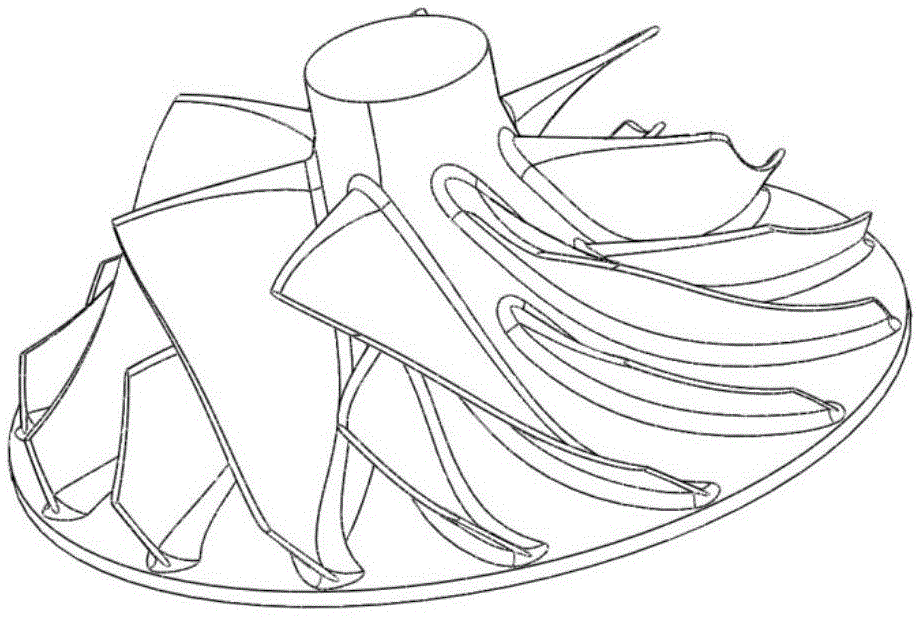

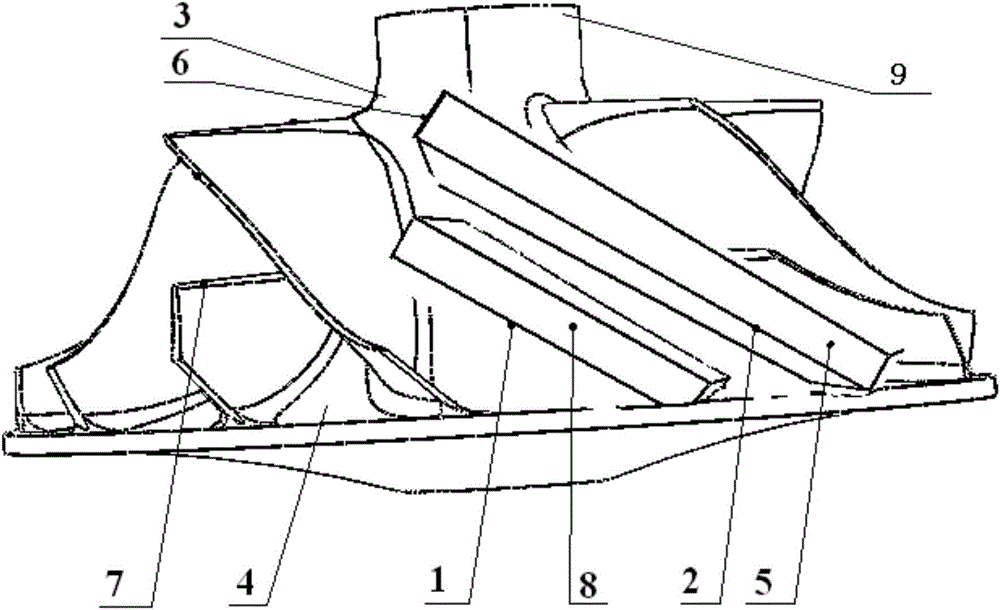

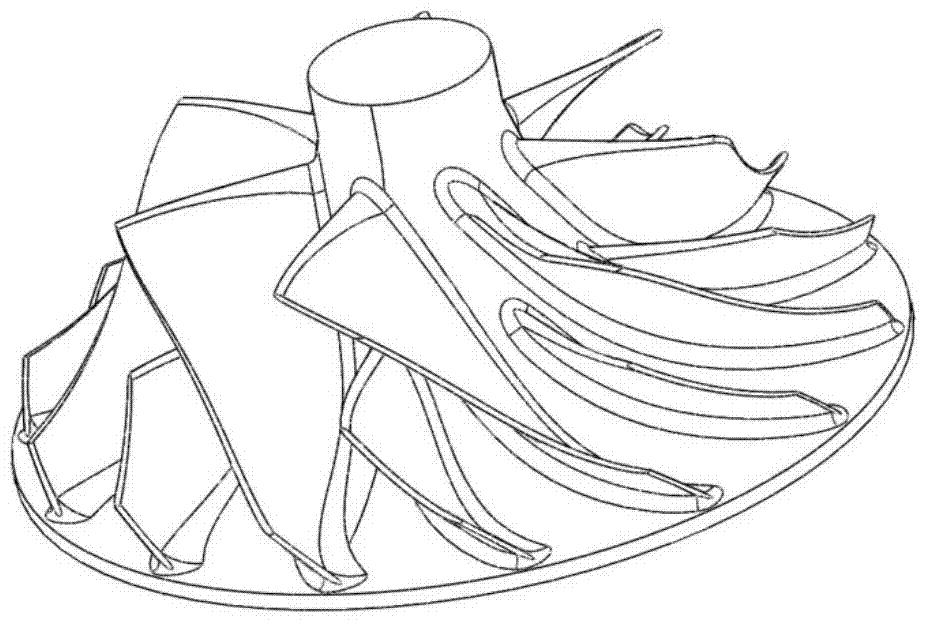

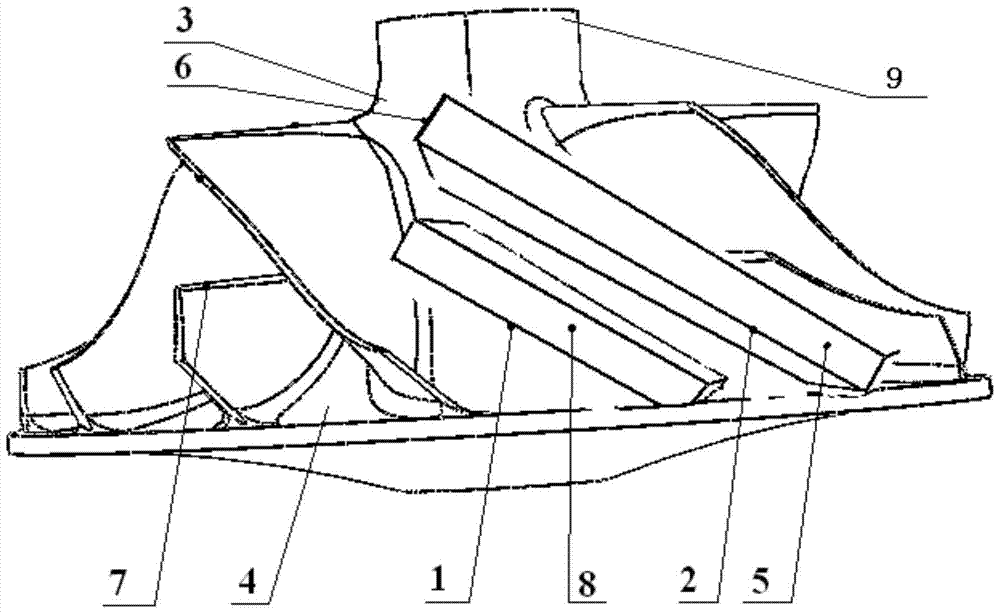

Casting method for compression impeller

ActiveCN105710315ARealize automatic demouldingQuick disassemblyFoundry mouldsFoundry coresImpellerEngineering

The invention belongs to the technical field of complex part forming, and relates to a casting method for a compression impeller. According to the casting method for the compression impeller, when a compression impeller casting die is manufactured, the size of a compression impeller product is regarded as the datum; each primary blade of the compression impeller casting die is a hexahedron which can accommodate a primary blade of the compression impeller product, and the upper surface, the lower surface and the marginal surface which is not combined with a compression impeller hub of each primary blade are all planes. Each secondary blade of the compression impeller casting die is a hexahedron which can accommodate a secondary blade of the compression impeller product, and the upper surface, the lower surface and the marginal surface which is not combined with a compression impeller hub of each secondary blade are all planes. The follow-up machining amount of a compression impeller casting obtained through the casting method for the compression impeller is far smaller than that of a compression impeller rotating body which is directly formed through forging, automatic die releasing of the die can be achieved, and on the premise of guaranteeing the excellent performance, the follow-up machining amount and machining cost are lowered.

Owner:GRIMAT ENG INST CO LTD

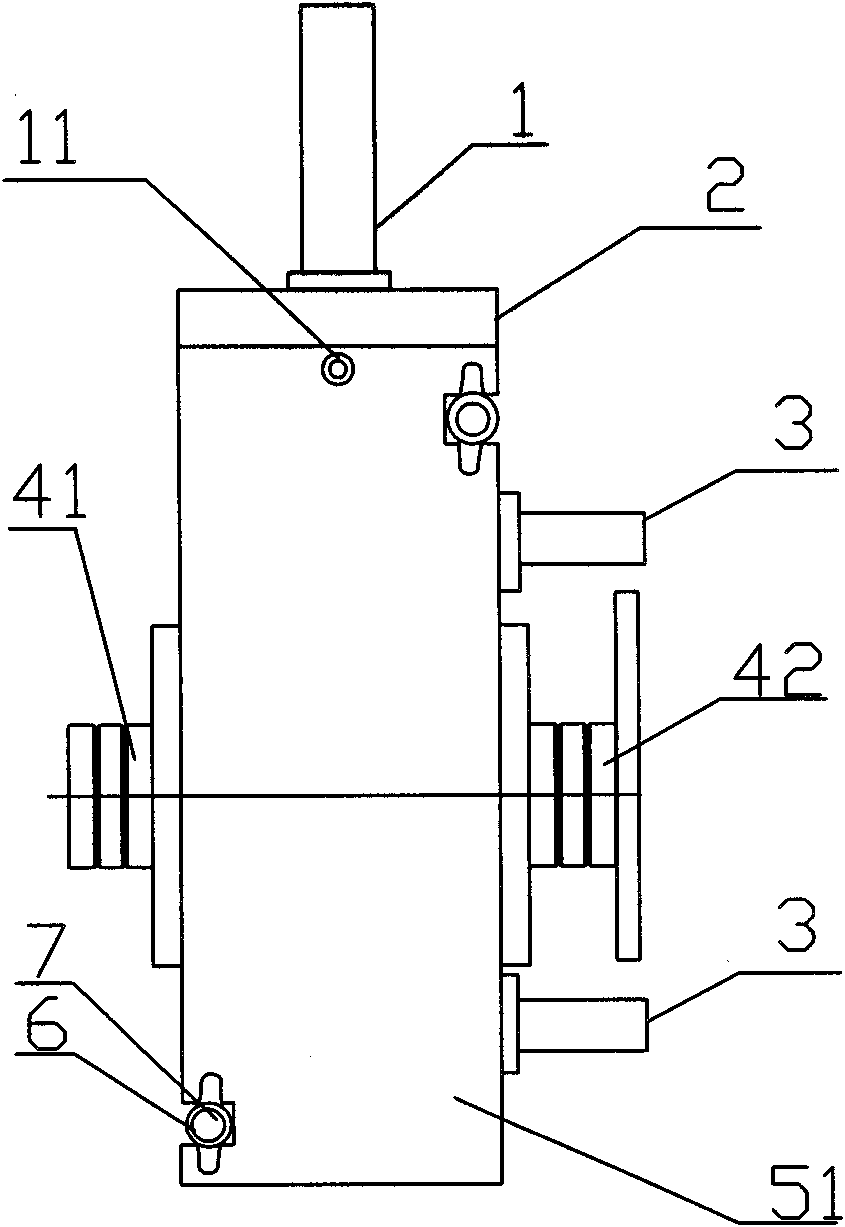

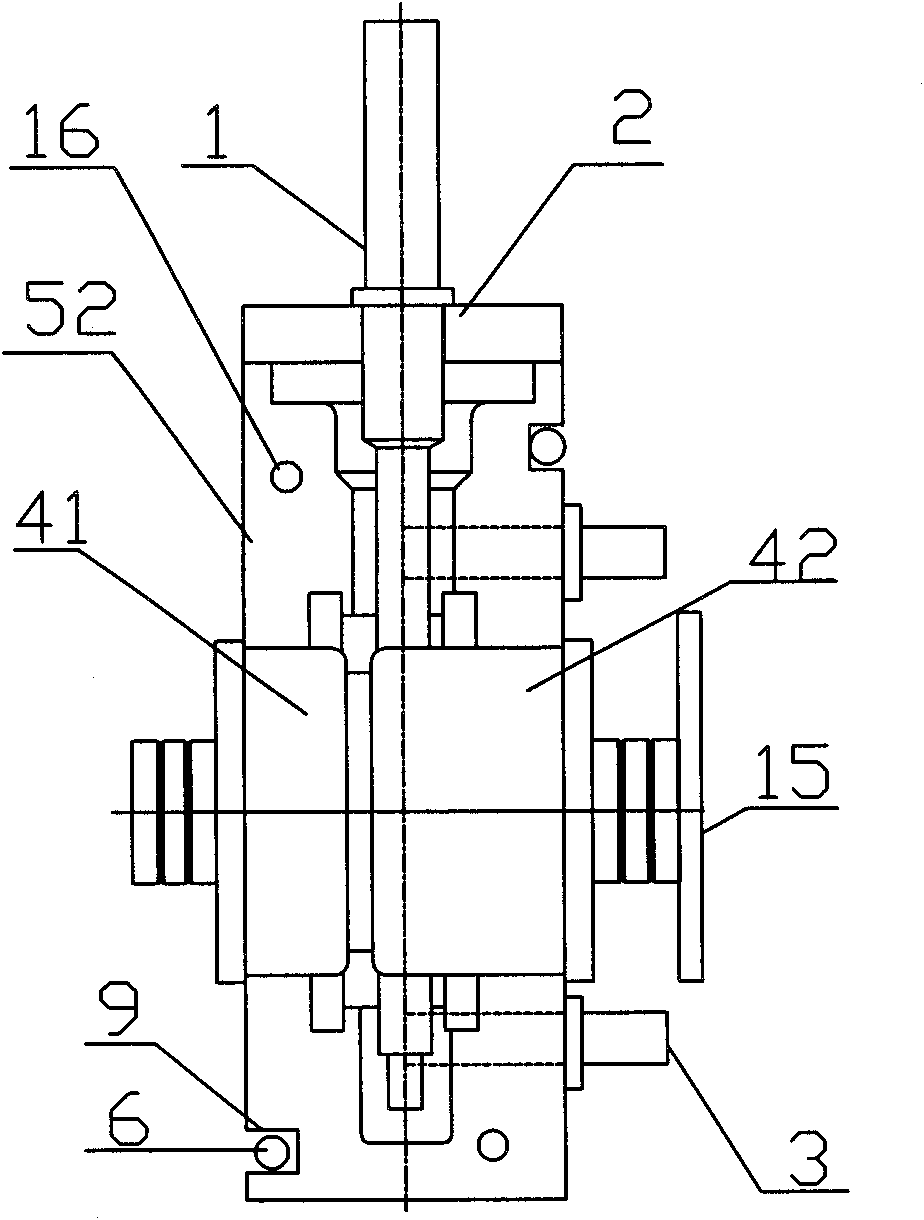

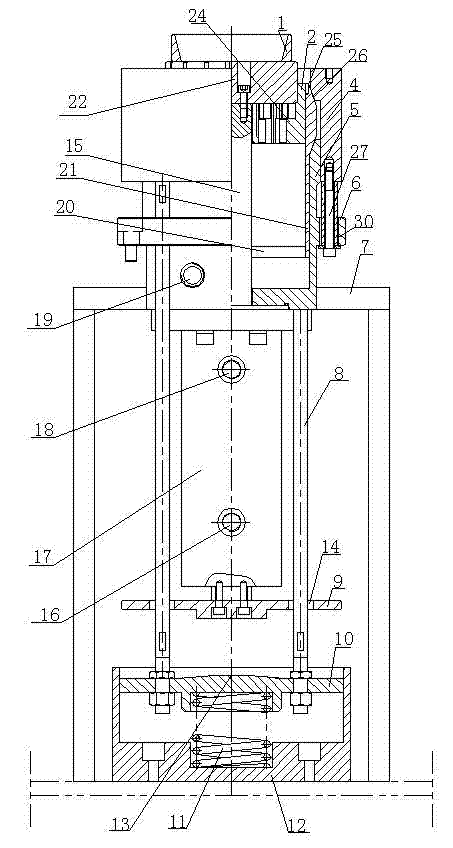

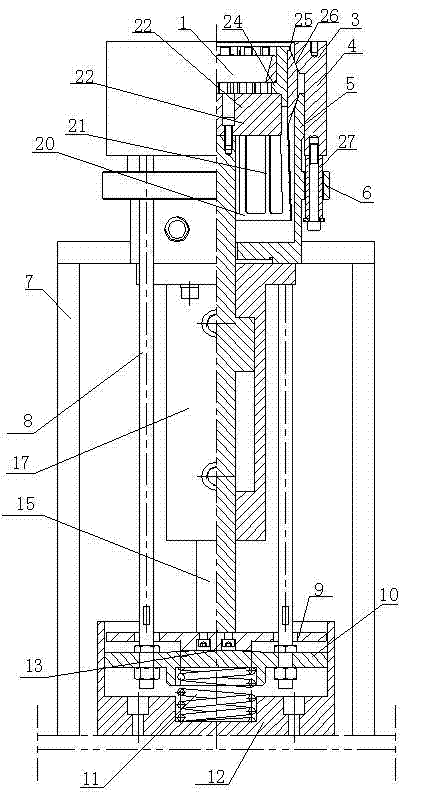

Spring-type quenching clamp assembly

ActiveCN103114189ARealization of type-limited quenchingEasy to replaceFurnace typesHeat treatment furnacesEngineeringFlange

The invention relates to a clamp assembly which is used for quenching a workpiece and in particular relates to a spring-type quenching clamp assembly. The spring-type quenching clamp assembly comprises a rack, an outer sleeve, an inner sleeve, a limiting clamp and a clamping body, wherein the inner sleeve is arranged below the outer sleeve; a quenching oil hole is formed on the inner sleeve; the extending end of the inner sleeve is arranged on the inner part of the outer sleeve; an inclined surface structure which is fitted with the outer sleeve and the inner sleeve is arranged on a branch structure, respectively; an annular flange for supporting the limiting clamp is supported at the top end of the branch structure; a boss is arranged in the limiting clamp; the limiting clamp is supported by a bracket and arranged on the inner part of the inner sleeve; and the bracket is connected with a drive device. Compared with the prior art, the spring-type quenching clamp assembly has the advantages of reducing the deflection after quenching, reducing the subsequent processing amount and the processing amount of the early process, and reducing the cost; the spring-type quenching clamp assembly can be fitted to various associated equipment and can be used for realizing various working modes such as a continuous working mode, a single-step working mode, and the like; moreover, the optional range is large and the production efficiency is greatly improved; the limited-type quenching of the workpieces with different sizes can be realized by changing the clamping body; and the mould is simple and convenient to change.

Owner:亚捷(无锡)热工科技有限公司

Novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance

InactiveCN108588507AImprove corrosion resistanceUniform compositionHot-dipping/immersion processesCorrosionChloride sodium

The invention discloses a novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance. The aluminum alloy comprises the following components in percentage by weight: 0.1-0.2 wt.% of Ba, 0.3-0.5 wt.% of Hf, 0.4-0.6 wt.% of Ca, 1.2-1.5 wt.% of Bi, 0.2-0.4 wt.% of Sc, 0.1-0.2 wt.% of Eu, 0.2-0.3 wt.% of S, and the balance aluminum. The aluminum alloy solves the current situation of backward technologies in the national hot dipping aluminum alloy field at present, and breaks through the bottleneck of restricting the development of hot dipping aluminum steel plate production technologies and equipment in the national high-end field through technology innovation and optimal design. In the near future, the material can be widely applied to more fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

High power density substrate inlaid with diamond copper and preparation method thereof

ActiveCN106801158ALow densityHigh thermal conductivitySoldering apparatusWelding/soldering/cutting articlesSemiconductor materialsAlloy

The invention provides a high power density substrate inlaid with diamond copper and a preparation method thereof. A substrate body comprises a diamond copper composite material portion, a tungsten copper and molybdenum copper alloy or an oxygen-free copper portion. The alloy portion is inlaid on the composite material or the composite material is inlaid on the alloy, and the two portions are in metallurgical bonding or welding bonding; by means of a vacuum pressure infiltration process, newly net forming can be directly performed. The substrate has heat conductivity which is higher than that of alloys such as tungsten copper alloy; the coefficient of thermal expansion is matched with that of a semiconductor material; the substrate is likely to be machined, and is better than a pure diamond copper material in machinability; the substrate is small in relative mass and moderate in price and convenient to popularize and use, and can meet the heat-dissipating demands of a high power electronic apparatus, so that the heat-dissipating problem restricting high power and miniaturized development of the electronic apparatus is solved.

Owner:GRIMAT ENG INST CO LTD

Metal micro-coating forming system and method thereof

The invention discloses a metal micro-coating forming system and a method thereof. The system comprises a base plate, a heating device and a fixed feeder, wherein the base plate is fixed on the heating device, the fixed feeder is arranged above the base plate, a gap is formed between the fixed feeder and the base plate, and a molten metal channel is formed on the fixed feeder along the vertical direction. The stress-strain transformation of the formed parts can be effectively reduced and the precision of the shaped parts can be increased.

Owner:XI AN JIAOTONG UNIV

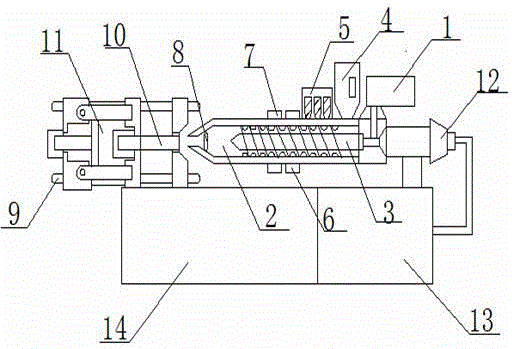

Full-automatic injection molding machine

The invention provides a full-automatic injection molding machine and belongs to the field of industry machinery. The full-automatic injection molding machine is composed of a drive screw engine, a cylinder, a screw, a hopper, a paint hopper, a heater, a humidity measurer, a filter membrane, a pull rod, a pouring path, a die assembling device, an injection cylinder, an oil cylinder and a hydraulic engine, wherein the drive screw engine is connected with the screw; the screw is arranged in the cylinder; the front end of the cylinder is provided with an opening; the hopper and the paint hopper communicate with the cylinder; the heater and the humidity measurer are both arranged on the cylinder; the filter membrane is arranged at the opening of the cylinder; the pouring path and the die assembling device are connected to the pull rod; the pull rod is arranged at the front end of the cylinder; one end of the injection cylinder is connected with the screw, and the other end of the injection cylinder is connected with the oil cylinder; the other end of the oil cylinder is connected with the hydraulic engine. According to the full-automatic injection molding machine provided by the invention, plastic molds in various colors can be injection-molded; the humidity of the equipment can be checked at any time, so loss caused by dampness of electric appliances is avoided; the filter membrane is capable of preventing impurities from entering the die assembling device, so the production quality is improved.

Owner:ZHEJIANG DIYE AGRI EQUIP

High-efficiency reducing furnace electrode repairing method

InactiveCN110923692ASolve production inefficienciesImprove cleanlinessPressure inorganic powder coatingMachiningBonding strength

The invention discloses a reducing furnace electrode repairing method. The reducing furnace electrode repairing method comprises the following steps that firstly, cleaning and grinding treatment is conducted on the surface of a to-be-repaired area on a reducing furnace electrode; secondly, inert gas is used for loading to-be-sprayed particles, and after heating is conducted to 200-800 DEG C, the to-be-sprayed particles are sprayed to the surface of the to-be-repaired area; and thirdly, mechanical machining is conducted on a reducing furnace electrode surface coating according to the actual usage size, and a repaired reducing furnace electrode is obtained. According to the reducing furnace electrode repairing method, a repairing body can be dense, and the bonding strength between the repairing body and an electrode base body material is high; based on the electrode component shape, the electrode material deposition precision can be optimized by controlling the nozzle size, spraying parameters, tracks and the like, and the subsequent machining amount is reduced; the thickness and the shape of the repairing body are not limited, and the reducing furnace electrode repairing method canbe used for repairing of electrodes different in damage degree; applicable materials are wide, a base body and the coating can be repaired at the same time, and efficiency is high; and the spraying process is simple, heat treatment is not needed, cost is low, and the production efficiency is high.

Owner:GUANGDONG INST OF NEW MATERIALS

Apparatus and method for forming thin-walled structural parts by metal fusion deposition

InactiveCN103752825BSolve the problem that the molten state is difficult to controlReasonable structureHeat-affected zoneMetallurgy

The invention discloses a device and a method for utilizing molten metal deposition to form a thin wall structural member. The device comprises a metal wire and a wire feeding roller, a nozzle conducts x-y planar motion according to the section outline information of the thin wall structural member, meanwhile extrudes molten metal and controls the molten metal flow to enable the molten metal to be evenly deposited on a substrate, and the molten metal is quickly cooled to form the section outline of a thin wall part. After one layer is formed, the substrate descends for the height of a section layer to conduct deposition of the next layer, and the process is circulated to finally obtain a product prototype of the metal thin wall structural member. The device and method has the advantages of being high in machining flexibility, stable in product quality, small in heat affected zone, small in workpiece heat deformation and small in follow-up machining quantity, effectively improves manufacturing efficiency and performance of the thin wall structural member, greatly reduces manufacture cost and improves the batch production probability through the molten metal deposition method.

Owner:XI AN JIAOTONG UNIV +1

Machining process for reducing side wall shrinkage of shell cast parts

InactiveCN108247005AReduce wall thicknessDense internal organizationDie castingUltimate tensile strength

The invention relates to the technical field of metal casting and particularly discloses a machining process for reducing side wall shrinkage of shell cast parts. The process comprises the following steps of (1) preparing dies; (2) assembling the dies, specifically, the movable die and the fixed die are assembled through a die assembly press, and a die cavity for cast part forming is formed; (3) preheating the dies, specifically, the movable die and the fixed die are preheated to be 170-220 DEG C; (4) performing filling, specifically, a high-temperature liquid material is pressed into the diecavity from a pouring opening at the pressure intensity of 100-130 MPa till completely filling the die cavity; (5) performing die-cast formation; and (6) taking out the cast parts, specifically, the die assembly press is started, the movable die and the fixed die are separated, and the cast parts are taken out. By means of the machining process for reducing side wall shrinkage of the shell cast parts, the wall thickness of the cast parts can be reduced, the strength of the cast parts is improved while the weight of reduced, shrinkage is reduced at the same time, the qualified rate of the castpart products is improved, raw materials are saved, and the production cost is reduced.

Owner:CHONGQING BAIJI SIXING DIE CASTING

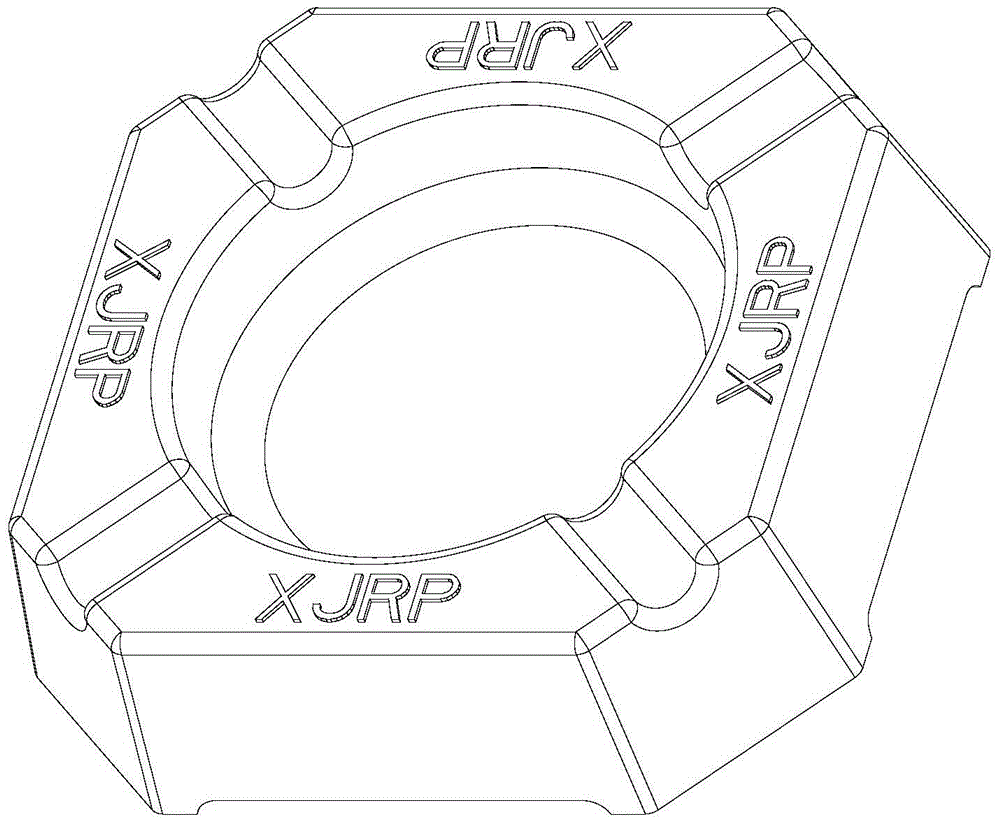

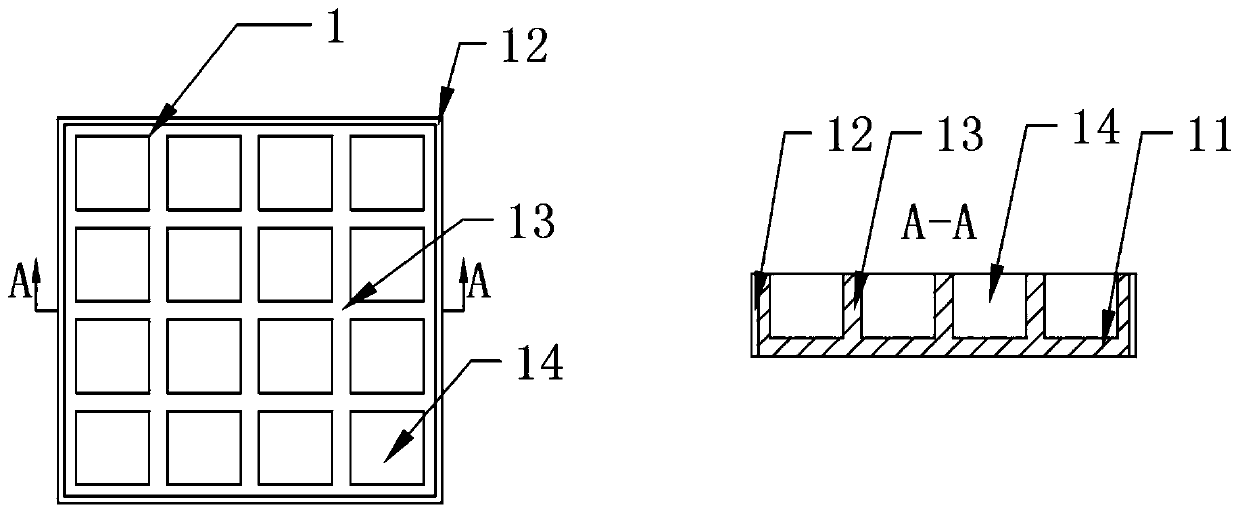

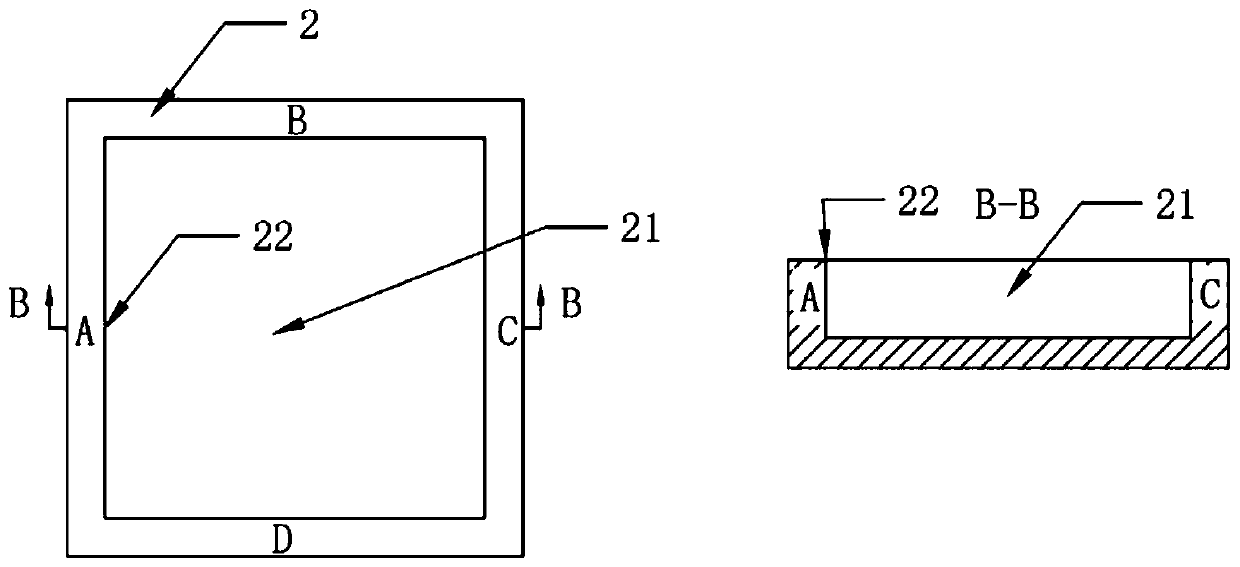

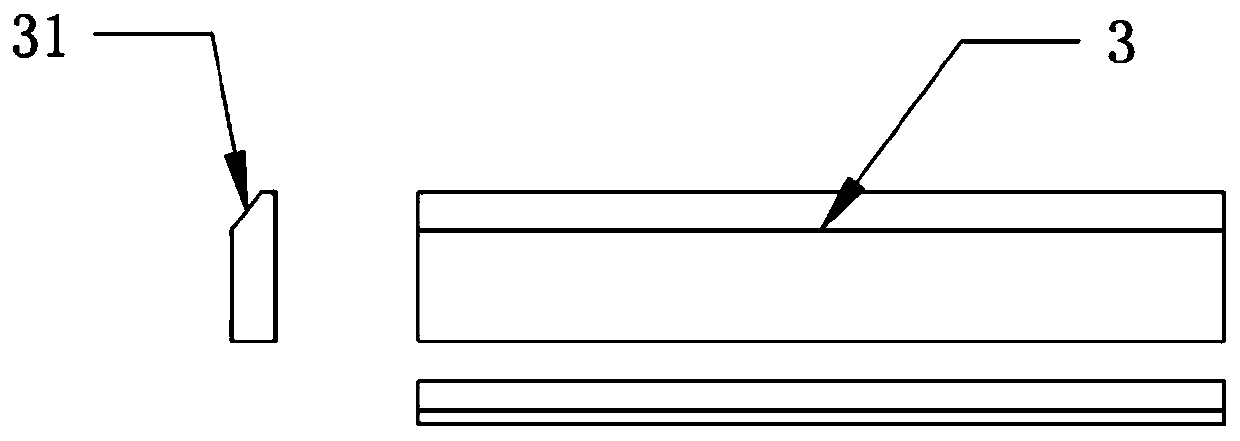

A kind of ceramic matrix composite material grid reinforcement component forming mold and preparation method thereof

ActiveCN109397494BImprove molding efficiencyGuaranteed forming positionMould auxillary partsCeramic matrix compositeForming processes

The invention relates to a forming mold and a preparation method of a ceramic-based composite material grid reinforcement component. The mold comprises a female mold, a male mold, a skin forming sliding block, a rib plate forming pressing strip and a rib plate forming sliding block. According to the technical scheme of the mold and the preparation method, uniform and sufficient forming pressure can be provided for a prepreg in the forming process; the prepreg can be greatly contracted in the thickness direction of a rib plate in the forming process; it is guaranteed that the component is uniformly pressed at all positions in the forming process, and the forming defects of the component are avoided, damage to fibers at the reinforcement structure caused by shearing of the prepreg through the mold in the forming process is avoided, the integral forming of the component is realized; and meanwhile, the forming position and the thickness of the grid rib plate are guaranteed through formingline by line, the forming quality of the component is effectively improved while the size of the component is ensured.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A high power density substrate embedded with diamond copper and its preparation method

ActiveCN106801158BLow densityHigh thermal conductivitySoldering apparatusWelding/soldering/cutting articlesSemiconductor materialsMaterials science

The invention provides a high power density substrate embedded with diamond copper and a preparation method thereof. The substrate body includes a diamond copper composite material part and a tungsten copper, molybdenum copper alloy or oxygen-free copper part. The alloy part is inlaid on the composite material or the composite material is inlaid on the alloy, the two parts are metallurgically bonded or welded together, and the vacuum pressure impregnation process can be used to directly form near-finish. The substrate has a higher thermal conductivity than alloy materials such as tungsten copper; the thermal expansion coefficient matches that of semiconductor materials; it is easy to machine and has better machinability than pure diamond copper materials; the relative mass is small and the price is moderate, which is convenient for popularization and use , can meet the heat dissipation requirements of high-power electronic devices, and solve the heat dissipation problem that restricts the development of electronic devices to high power and miniaturization.

Owner:GRIMAT ENG INST CO LTD

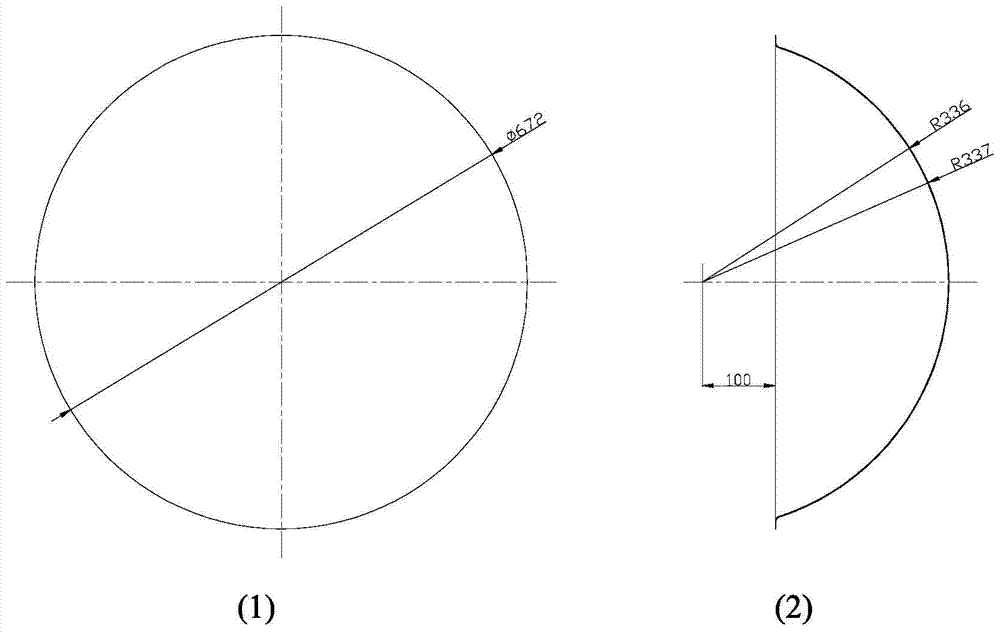

Integral Forming Method of Aluminum Alloy Thin-walled Spherical Head

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A method for forming large-scale thin-walled ring parts with complex curved sections

The invention provides a method for forming a large-scale thin-walled ring with a complex curve section, which includes: dividing the ring model into N arc-shaped models along the circumference according to the model size of the ring; designing the thermoforming process part, and Design a thermoforming mold; determine the size of the required blank and blank it, and preform the blank circle obtained by blanking to prepare a circle preform; use a thermoforming mold to perform thermoforming on the circle preform to obtain a hot Forming process parts; remove the process margin of thermoforming process parts, and prepare arc-shaped parts; surface treat N arc-shaped parts; assemble N surface-treated arc-shaped parts, and weld them to obtain ring parts; weld The final ring is shaped. The present invention adopts sheet metal preforming + thermoforming + welding composite forming technology, and adopts the most suitable forming technology for different parts, so as to realize the precision forming of parts as a whole, which can effectively reduce the amount of subsequent processing, avoid subsequent manual shape correction, improve efficiency and reduce costs .

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Casting method of a pressure impeller

ActiveCN105710315BRealize automatic demouldingQuick disassemblyFoundry mouldsFoundry coresImpellerEdge surface

The invention belongs to the technical field of complex parts forming, and relates to a casting method of an impeller. The casting method of the pressure impeller provided by the present invention is based on the size of the pressure impeller product when manufacturing the pressure impeller casting mold. The edge face that is plane and not combined with the impeller hub is a plane hexahedron. The secondary blade of the impeller casting mold is a hexahedron capable of containing the secondary blade of the impeller product, the upper surface and the lower surface are plane, and the edge surface not combined with the hub of the impeller is a plane. The amount of follow-up processing required for the impeller casting obtained by the casting method of the impeller provided by the present invention is far less than the amount of follow-up processing required for the rotary body of the impeller directly forged, and the automatic demoulding of the mold can be realized, ensuring excellent Under the premise of high performance, the amount of subsequent machining can be reduced, and the cost of machining can be reduced.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com