Connection method of transmission axle for precise transmission and bearing support part

A connection method and technology of supporting parts, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increased production cost, unclean welding surface, economic loss, etc., and achieve simple manufacturing process, reduced production steps, and subsequent The effect of small processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

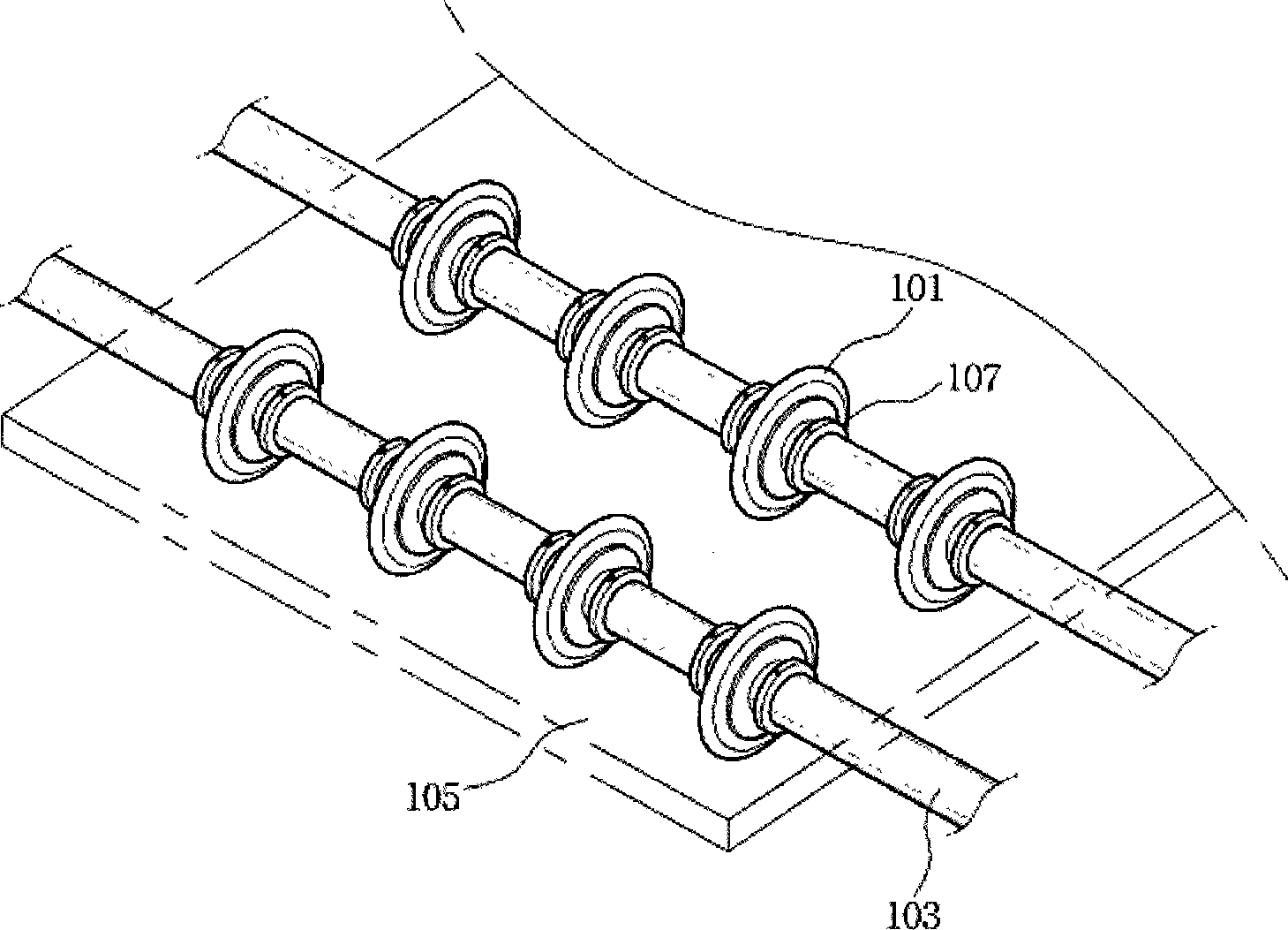

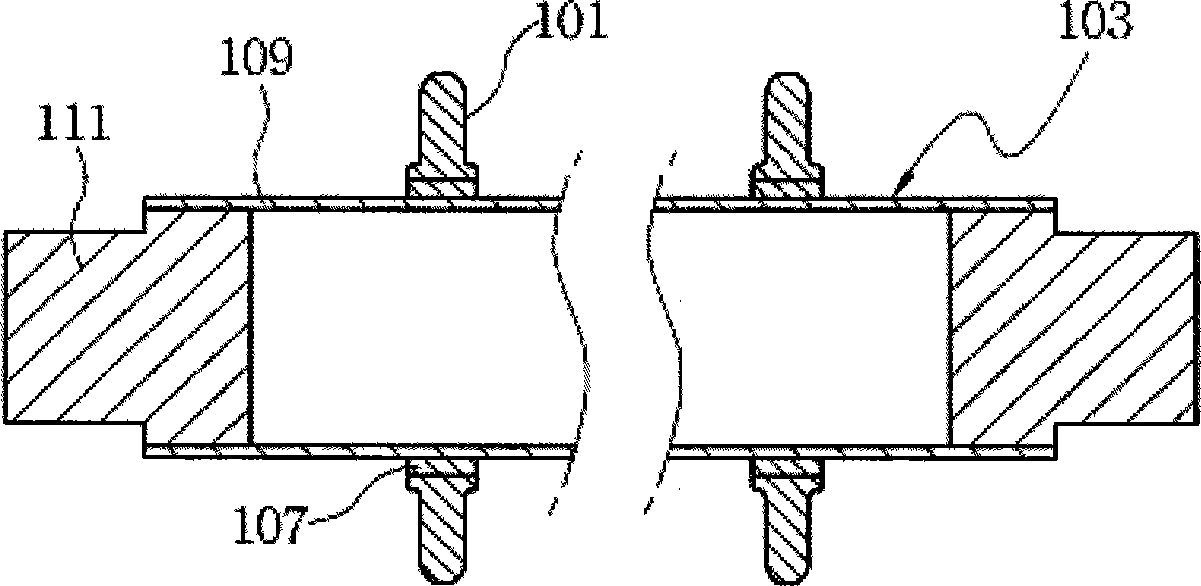

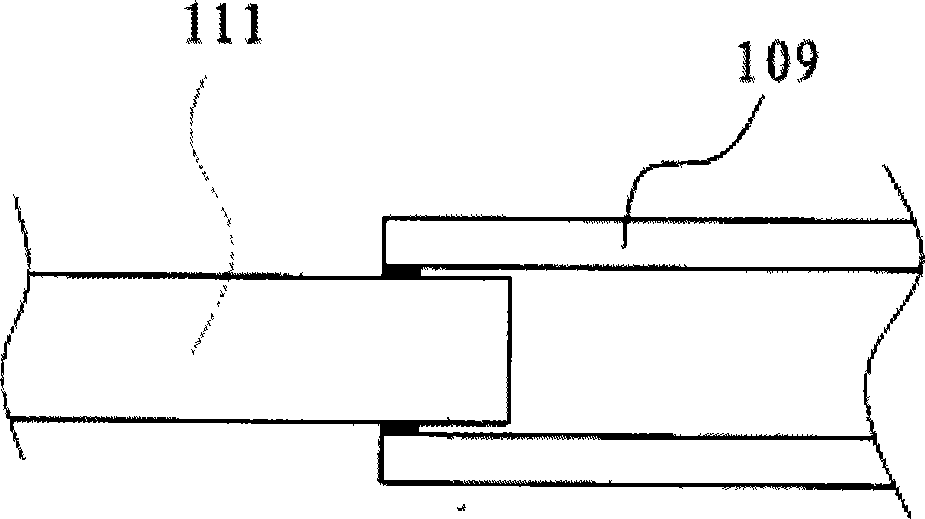

[0027] Combine below Figure 5 , Figure 6 The method for connecting the transmission shaft and the bearing supporting part used for precision transmission in the present invention is described in detail.

[0028] First fix the hollow main body 109 and the cylindrical bearing supporting part 111 on the rotating equipment respectively, and make the hollow main body 109 rotate, and the part of the hollow main body 109 that needs to be connected with the cylindrical bearing supporting part 111 is heated, and the heating depth should be lower than that of the cylindrical bearing supporting part 111. The insertion depth of the body bearing support part 111 is long, and the heating temperature should reach a plastic state that does not change the material properties of the hollow body 109, so that the insertion of the cylindrical bearing support part 111 is easy, and the heating is kept in the same direction to make the hollow body 109 The connecting part 30 is heated evenly; after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com