Hot-pressing forming method for aluminum-alloy curved reinforcing rib plate

A technology for hot press forming and stiffening rib plate, which is applied in the field of hot pressing of aluminum alloy curved stiffening rib plate and aluminum alloy curved stiffening rib plate, can solve the problems of high cost, difficult shape accuracy control, poor integrity of parts, etc. Efficiency, avoidance of manual shape correction, profile accuracy and the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

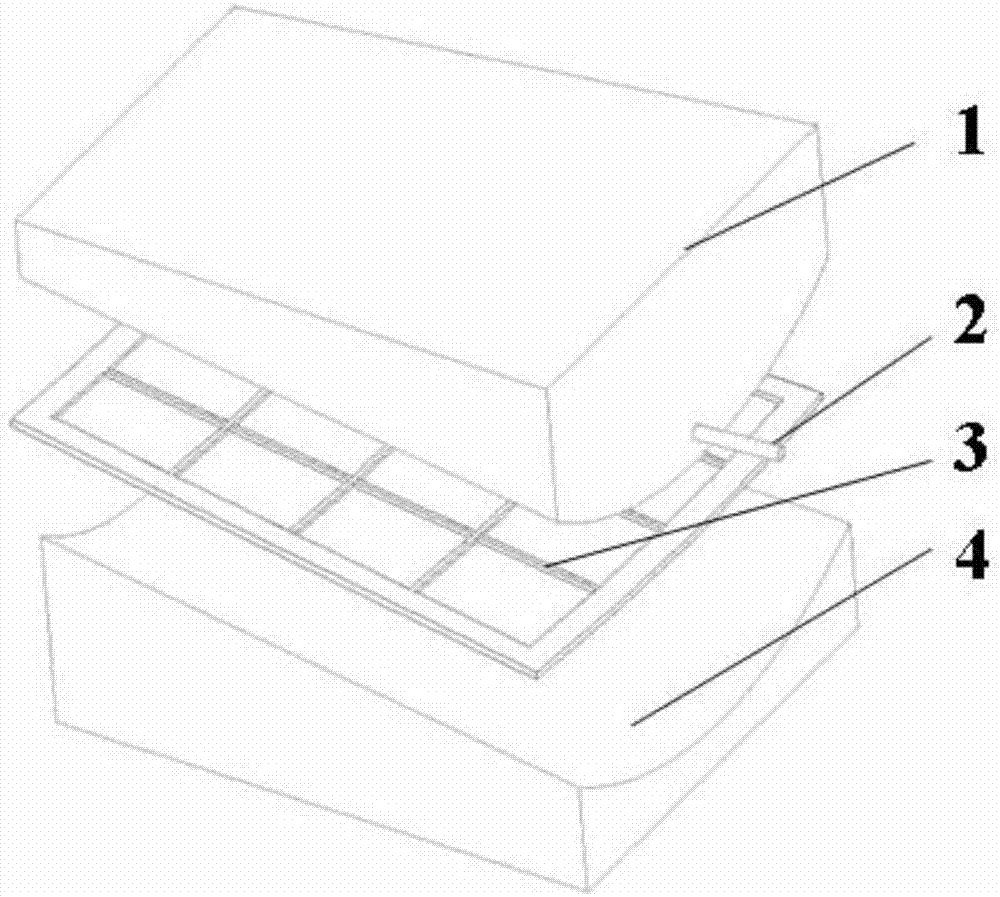

[0024] The preferred embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

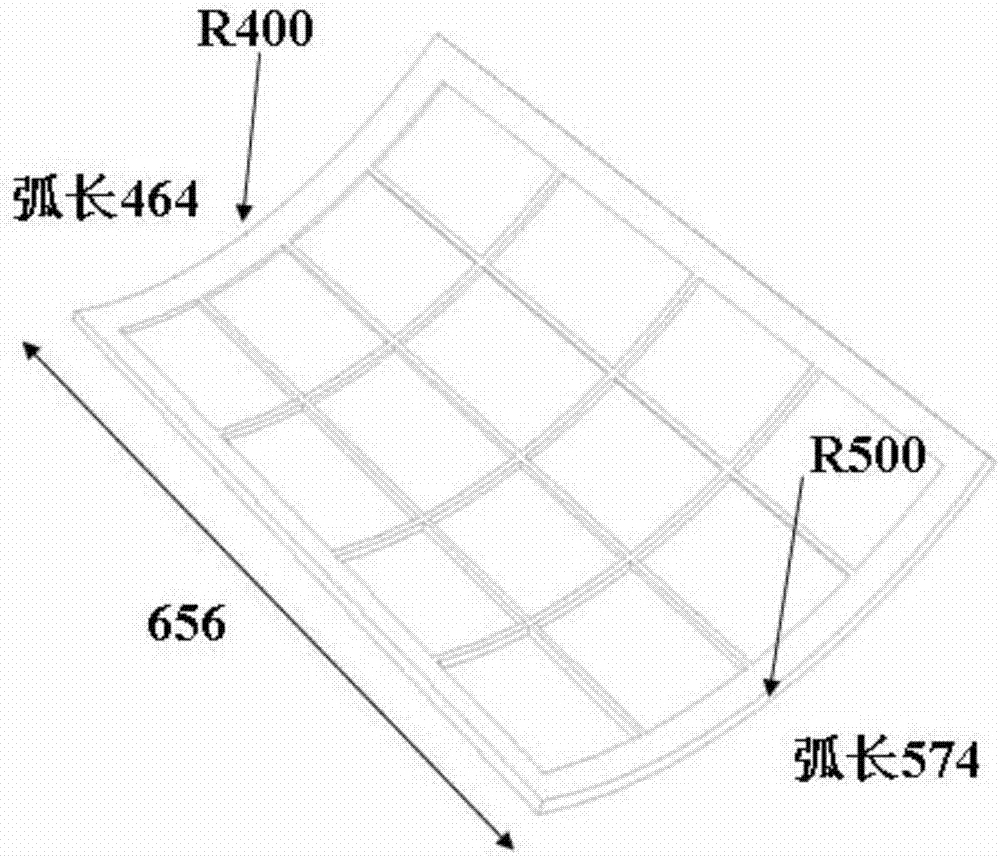

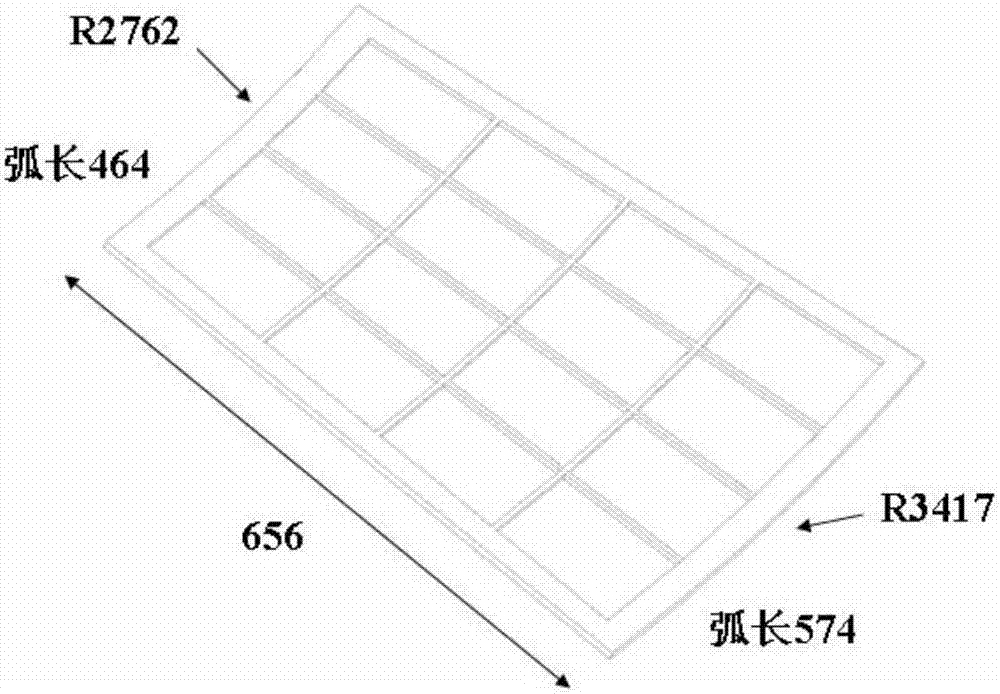

[0025] The invention belongs to the field of precision sheet metal processing, and relates to a hot-press forming method for an aluminum alloy curved-surface stiffener plate, which is suitable for forming an aluminum alloy curved-surface stiffener plate with high requirements for forming dimension accuracy, surface precision and surface quality. The method is as follows: ① Plane unfold the aluminum alloy curved rib plate; ② Prepare the corresponding rib on the plate according to the position of the rib in the plane unfolded diagram; ③ Design and process the hot-press forming mold for the aluminum alloy curved rib plate ; ④ hot-press forming the aluminum alloy curved surface stiffener plate;

[0026] The invention adopts the combination process of hot pressing forming + air-inflating shape correction to form the aluminum alloy curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com