Hub casting die

A technology for casting molds and hubs, which is applied in the field of hub castings. It can solve the problems of heavy workload, slow progress, and high cost of new mold development, so as to reduce the amount of follow-up processing and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

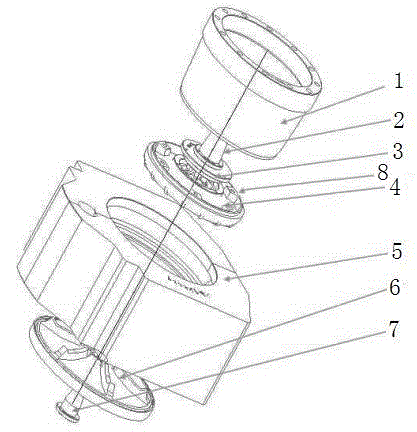

[0013] Such as figure 1 A wheel hub gravity casting mold shown comprises an upper mold, a side mold 5 and a lower mold 6 which are combined to form a wheel hub casting cavity, and the upper mold is composed of an upper mold ring 1 and an upper mold molding block 4 connected to its lower end The connecting ends of the upper mold block 4 and the upper mold ring 1 are respectively provided with a positioning platform 8 and a positioning groove that cooperate with each other, and the riser 2 and the upper mold core 3 are concentrically connected to the upper mold molding block 4 respectively, and the lower iron The core 7 is concentrically connected to the lower die 6 .

[0014] Name and number the upper mold ring 1, riser 2, upper mold core 3, upper mold molding block 4, side mold 5, lower mold 6 and lower iron core 7 according to certain rules, such as: upper mold ring 1 is named UM-A-B-C, where UM means upper mold ring, A means product size, B means side mold width, C means se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com