Spring-type quenching clamp assembly

A technology of assembly, limit fixture, applied in the direction of manufacturing tools, furnace types, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

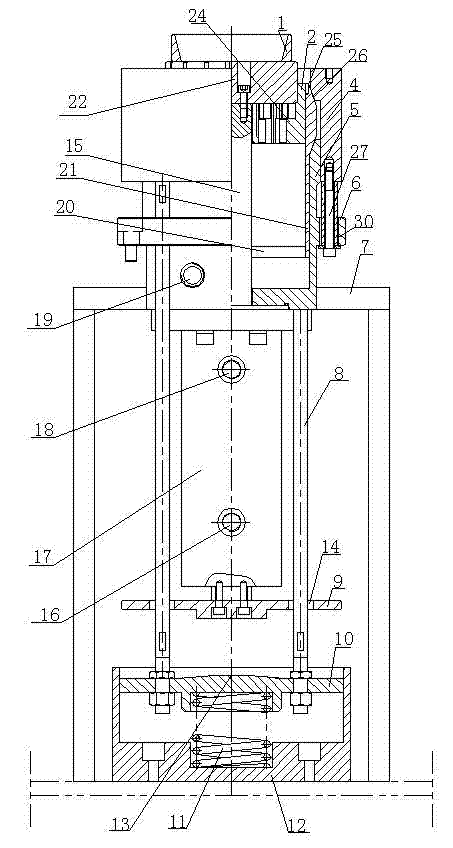

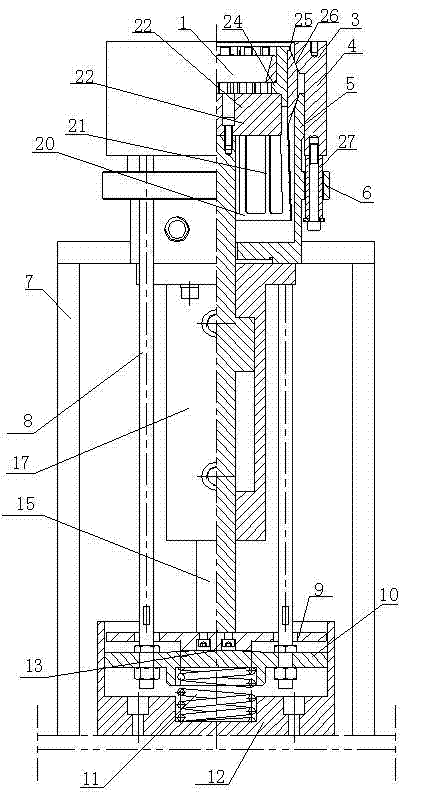

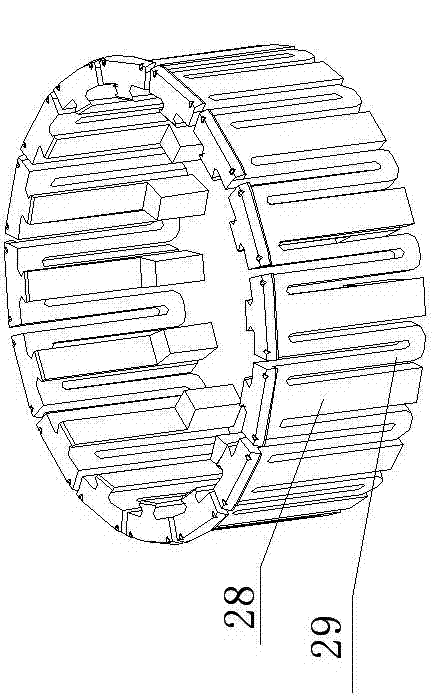

[0026] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0027] A spring type quenching fixture assembly, see attached figure 1 To attach Figure 5 , in the figure: workpiece 1, limit fixture 2, clamping body 3, outer sleeve 4, inner sleeve 5, shoulder structure 6, bracket 7, connecting rod 8, pressure plate 9, pressure sleeve 10, compression spring 11, bottom sleeve 12 , Protruding structure 13, Through hole 14, Piston rod 15, Second oil hole 16, Oil cylinder housing 17, First oil hole 18, Quenching oil hole 19, Ring chassis 20, Branch structure 21, Bracket 22, Boss 24 ; annular flange 25 ; slope structure 26 , guide column 27 , bar 28 , U-shaped structure 29 , guide hole 30 , and extension plate 31 .

[0028] In this example, see the attached figure 1 to attach Figure 5 The clamping body 3 is composed of the lower annular chassis 20 and the upper branch structure 21; the inner sleeve 5 is placed under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com