A kind of ceramic matrix composite material grid reinforcement component forming mold and preparation method thereof

A technology of composite materials and forming molds, which is applied in the direction of ceramic forming machines, mold auxiliary parts, manufacturing tools, etc., can solve the problems of increased requirements for comprehensive performance of equipment, high pressure requirements for autoclave molding, and small application scale, etc., to achieve Improve molding quality, achieve near-net shape, and improve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

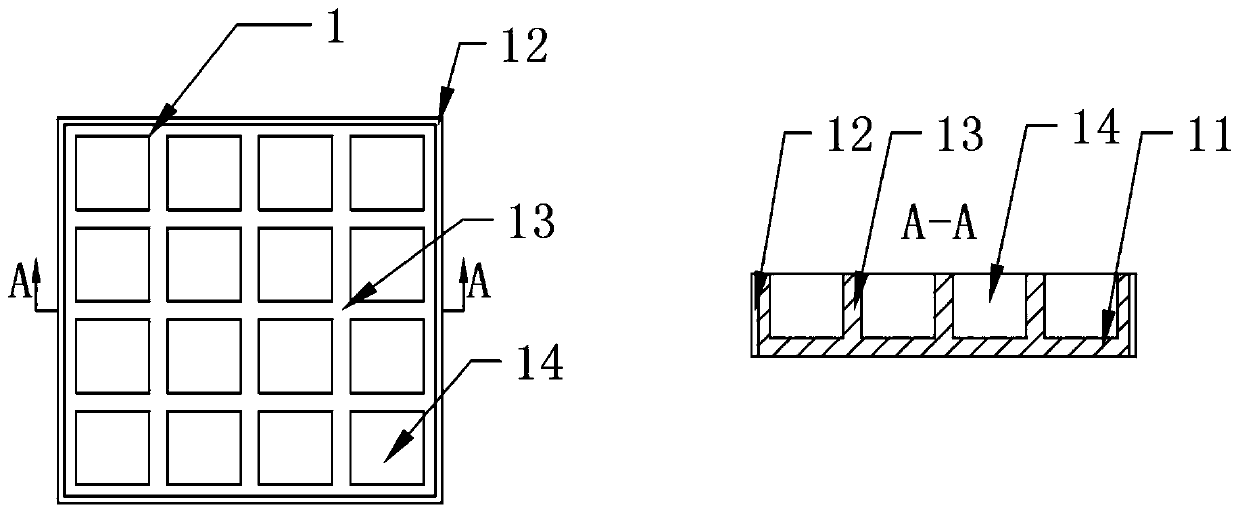

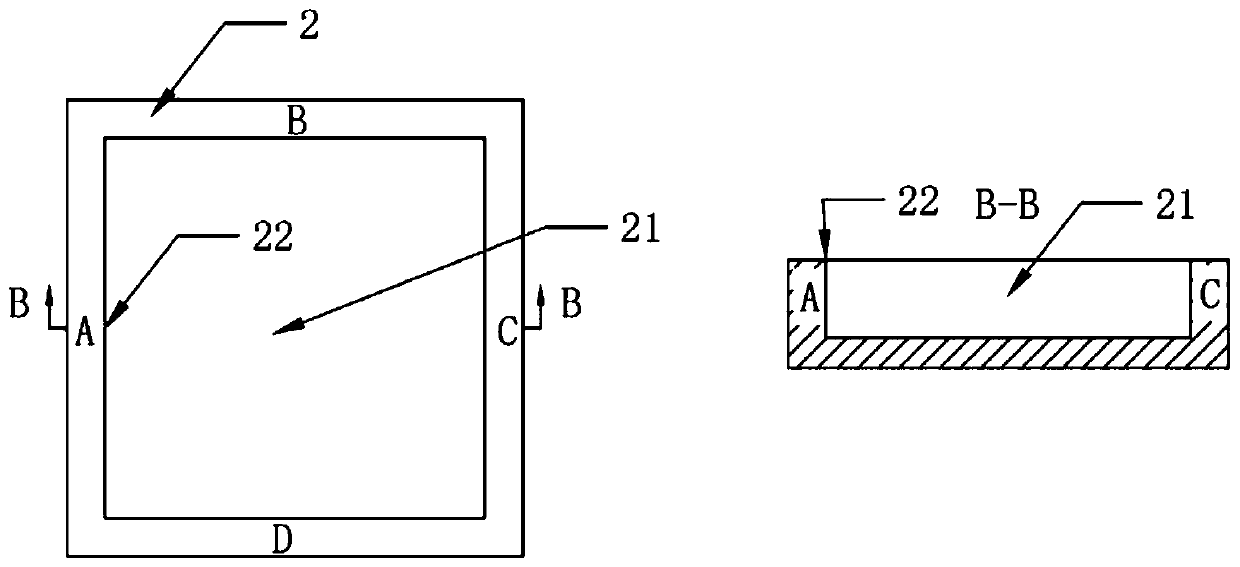

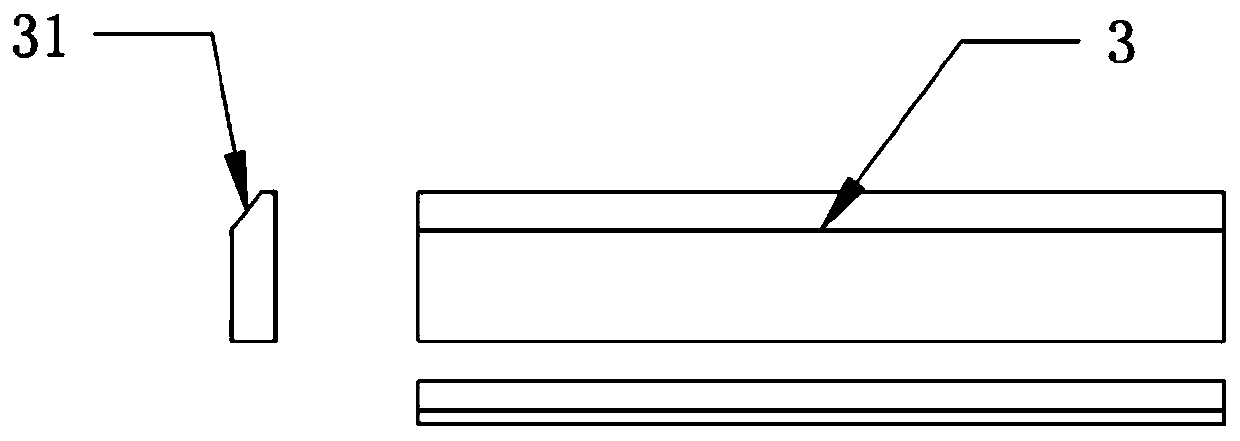

[0049] The mold design and molding method for the co-solidification molding of the grid-reinforced component of ceramic matrix composite material will be described below in conjunction with the accompanying drawings and specific examples.

[0050] In this embodiment, the bottom of the grid reinforcement member 1 is a square plane base 11, and the plane base 11 is surrounded by four sides formed by the skin 12. ×4 grid unit, the space in the grid unit forms a grid unit body 14, the height of the rib plate 13 is flush with the skin 12, and the forming mold for this kind of ceramic matrix composite grid stiffened member includes:

[0051] The female mold 2, the female mold 2 is to process a female mold groove 21 on the metal blank according to the size of the plane base 11 and the skin 12 of the grid reinforcement member 1, and the ribs 22 of the female mold groove 21 are surrounded by ribs 22. The ribs 22 respectively correspond to the four sides of the plane base 11, the length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com