Patents

Literature

117results about How to "Does not affect thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

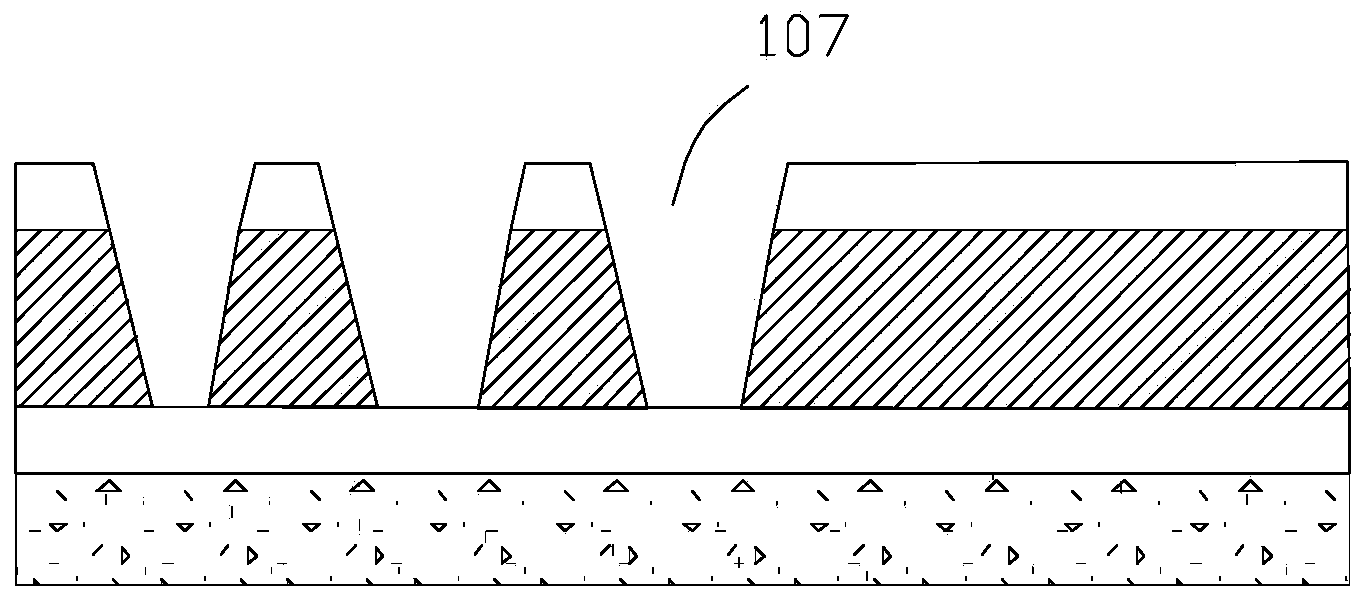

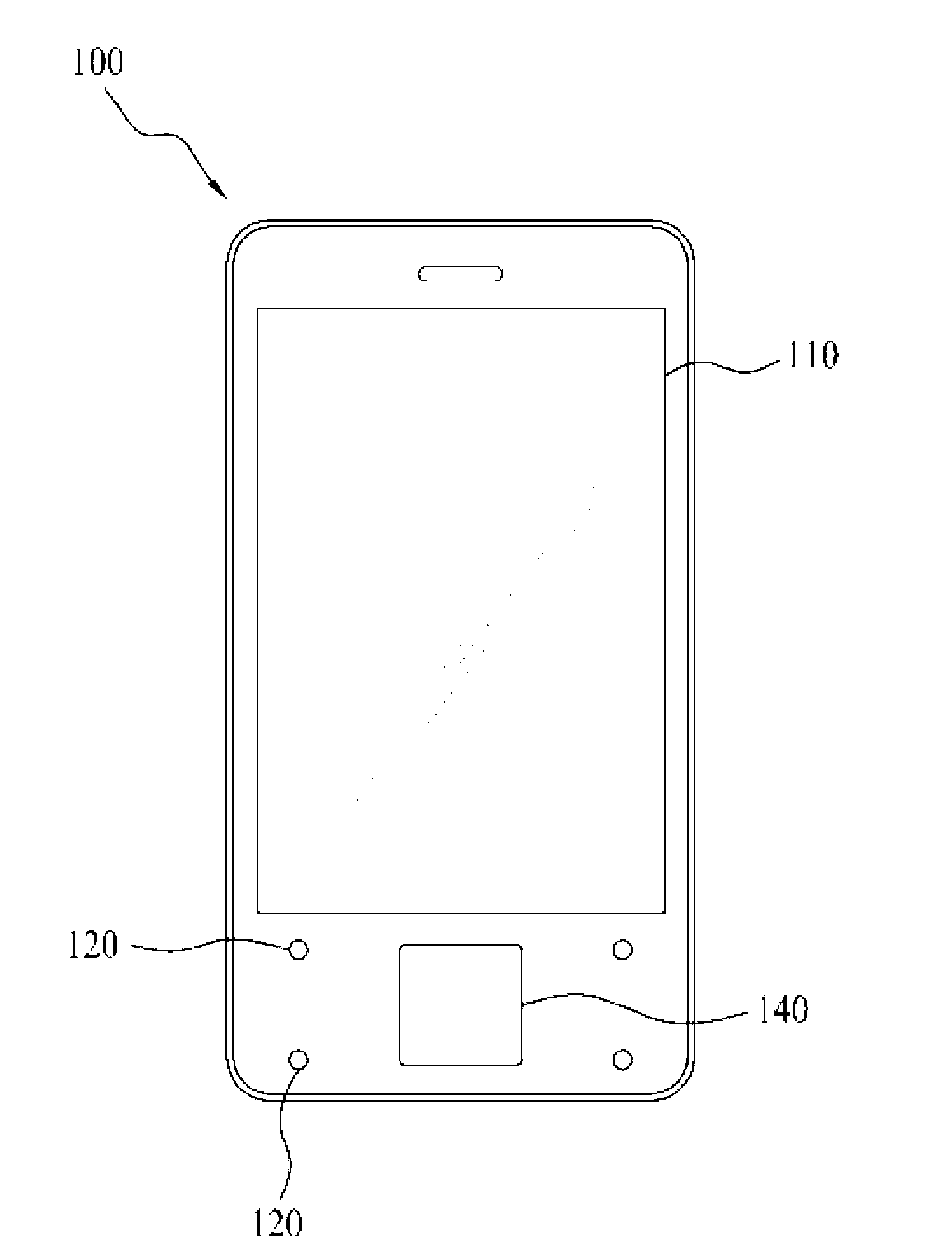

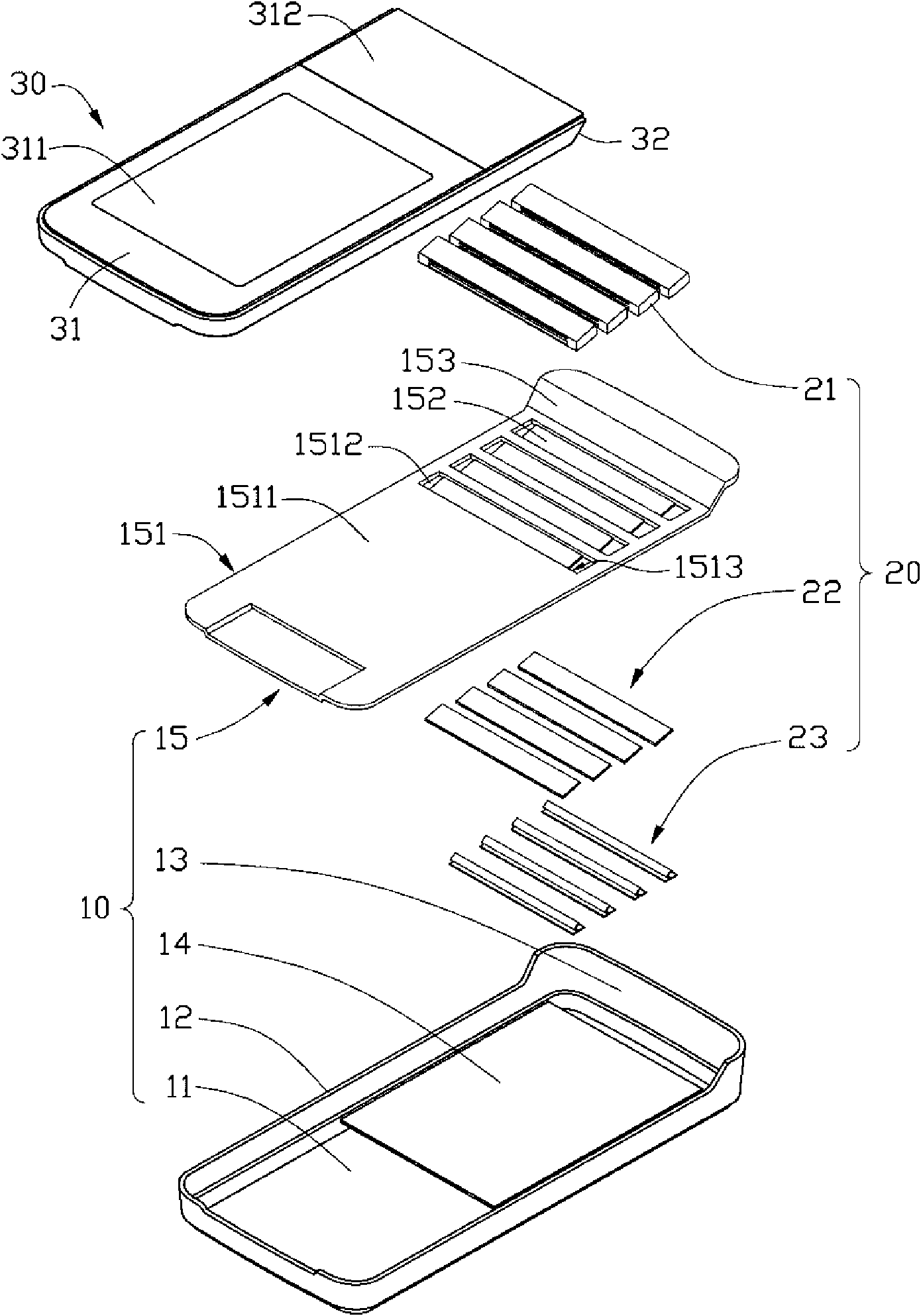

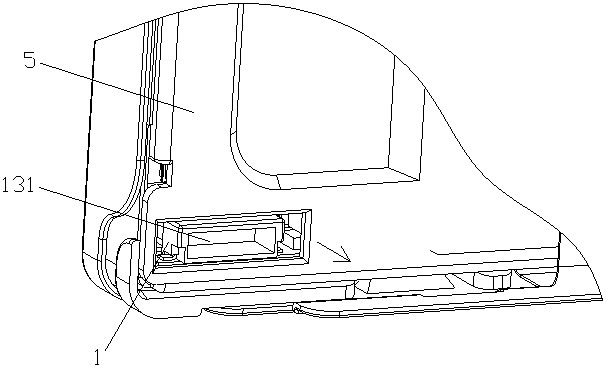

Fingerprint recognition sensor packaging structure, electronic device and method for manufacturing fingerprint recognition sensor

ActiveCN103793689ADoes not affect thicknessDoes not affect thickness designCharacter and pattern recognitionDielectricGlass cover

The invention relates to a fingerprint recognition sensor packaging structure and an electronic device with the fingerprint recognition sensor packaging structure. The fingerprint recognition sensor packaging structure comprises a control button and a fingerprint recognition sensor arranged below the control button, wherein the control button comprises a glass cover plate and a thin film which coats the surface of the glass cove plate and is made of non-anisotropic dielectric materials. The mode of combining the glass cover plate and the coated film is adopted by the control button, the hardness of the control button is ensured, meanwhile, cost is reduced, in addition, the thickness of the fingerprint recognition sensor packaging structure is not affected, and when the fingerprint recognition sensor packaging structure is embedded into the electronic device, the thickness design of the electronic device is not affected.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

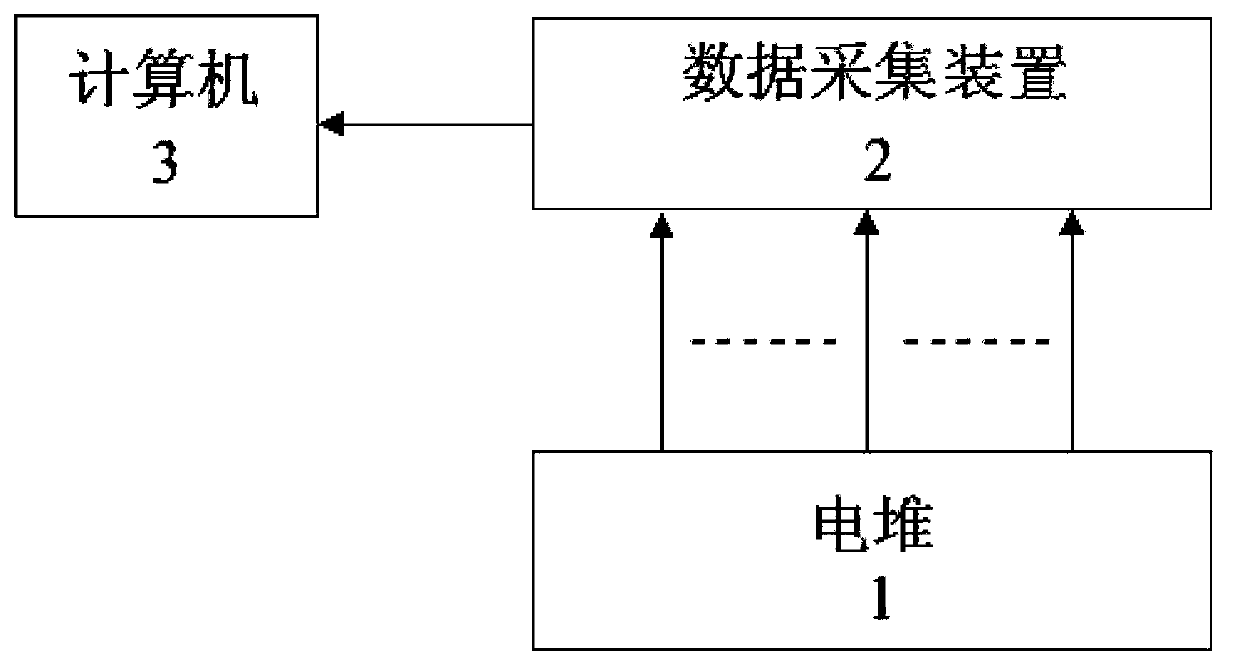

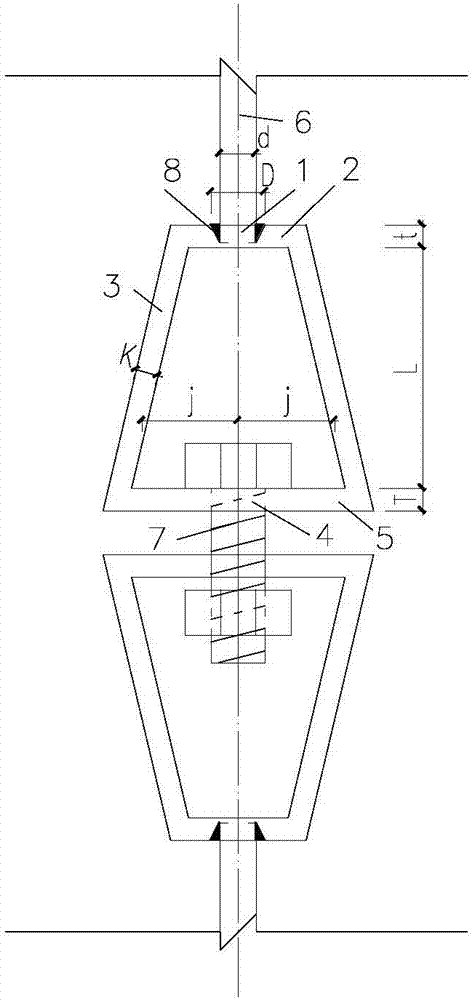

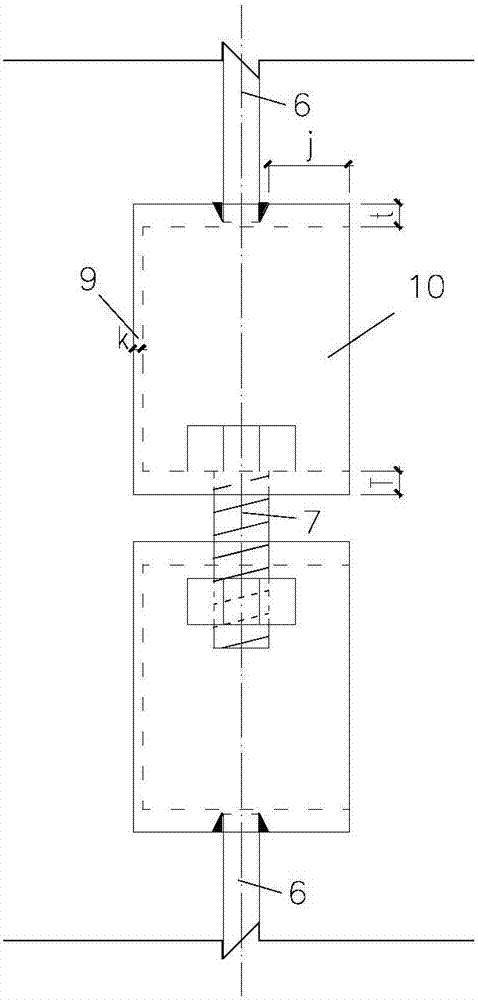

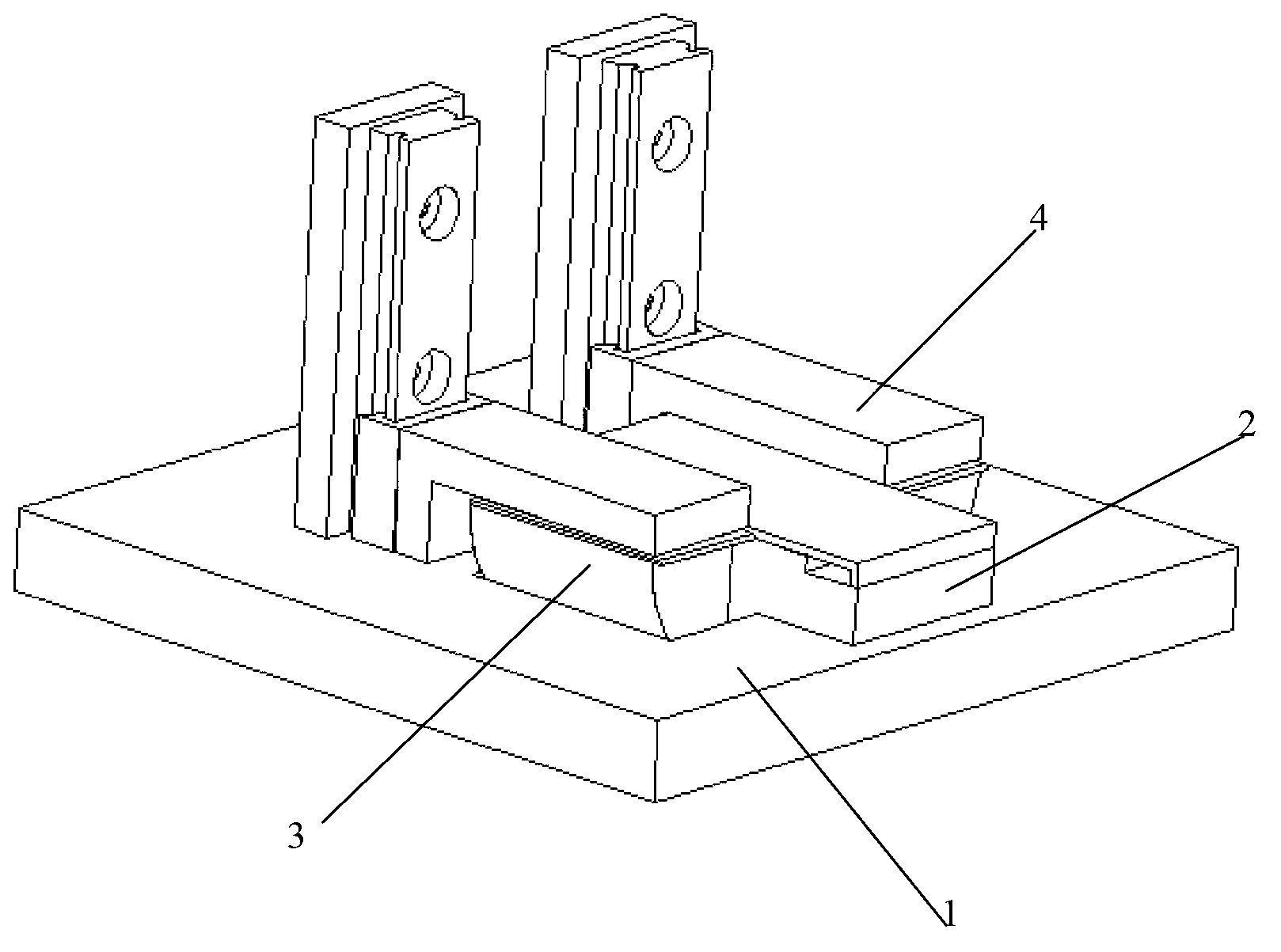

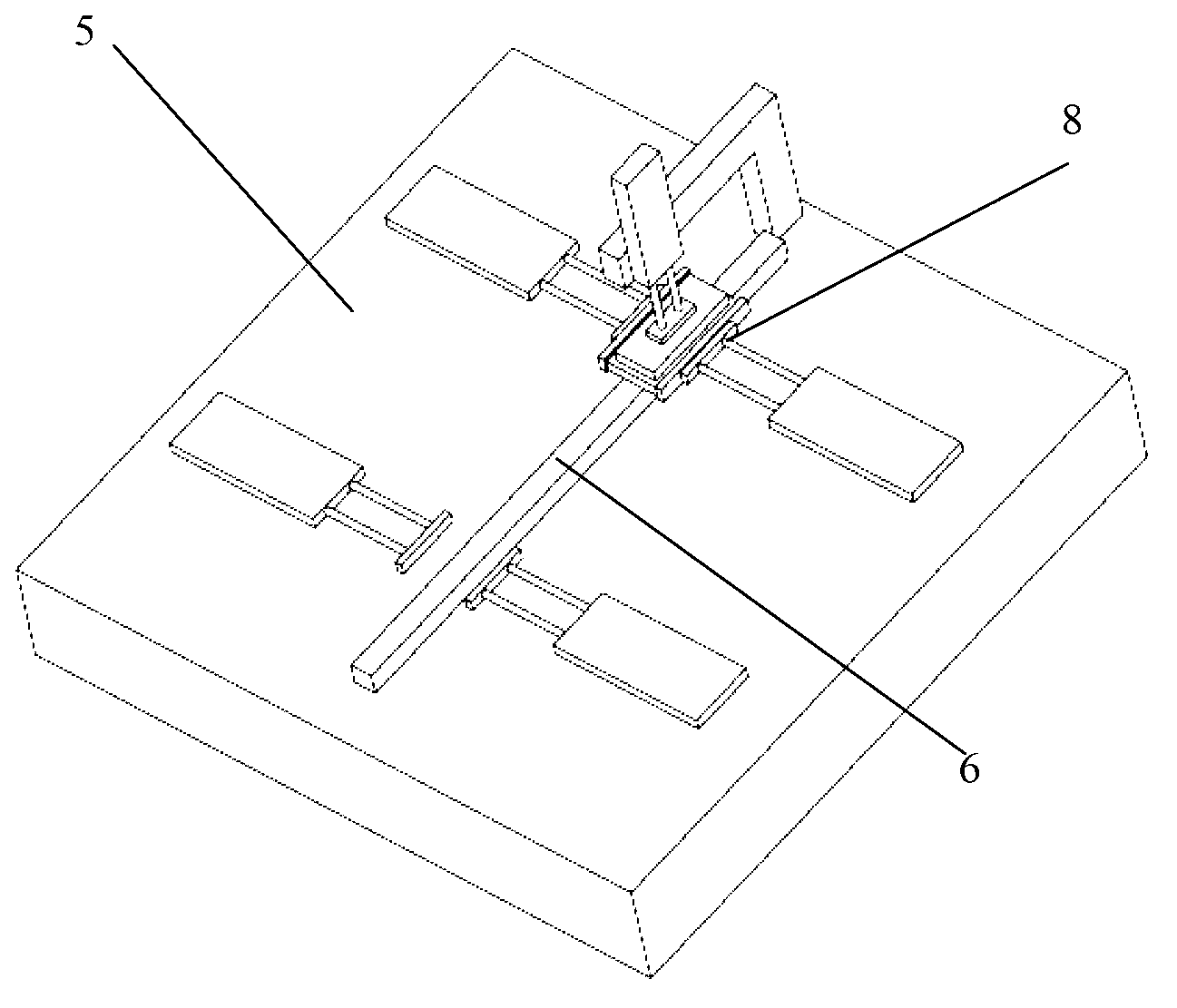

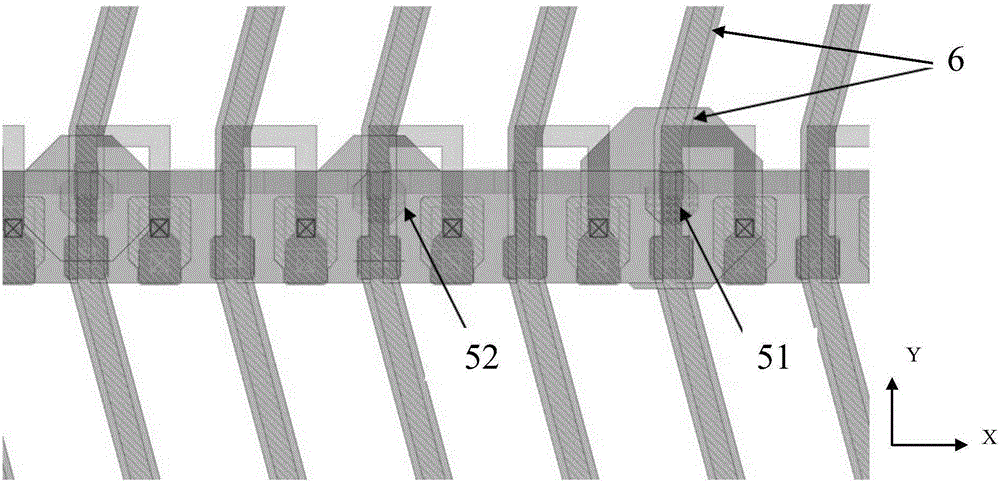

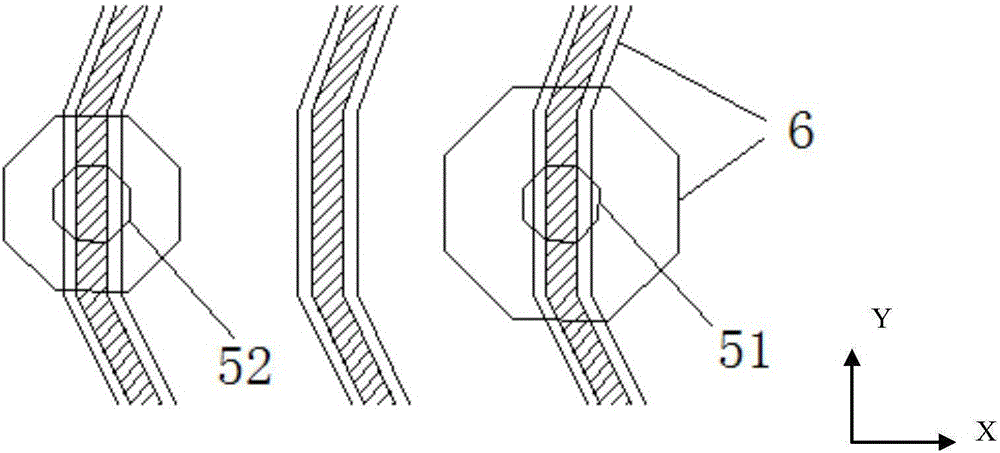

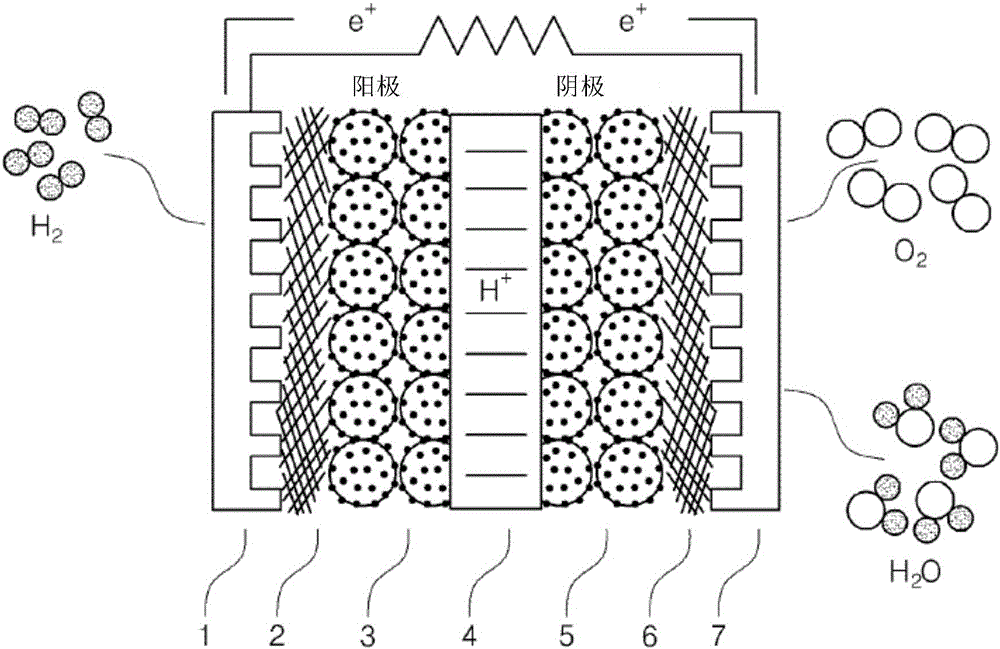

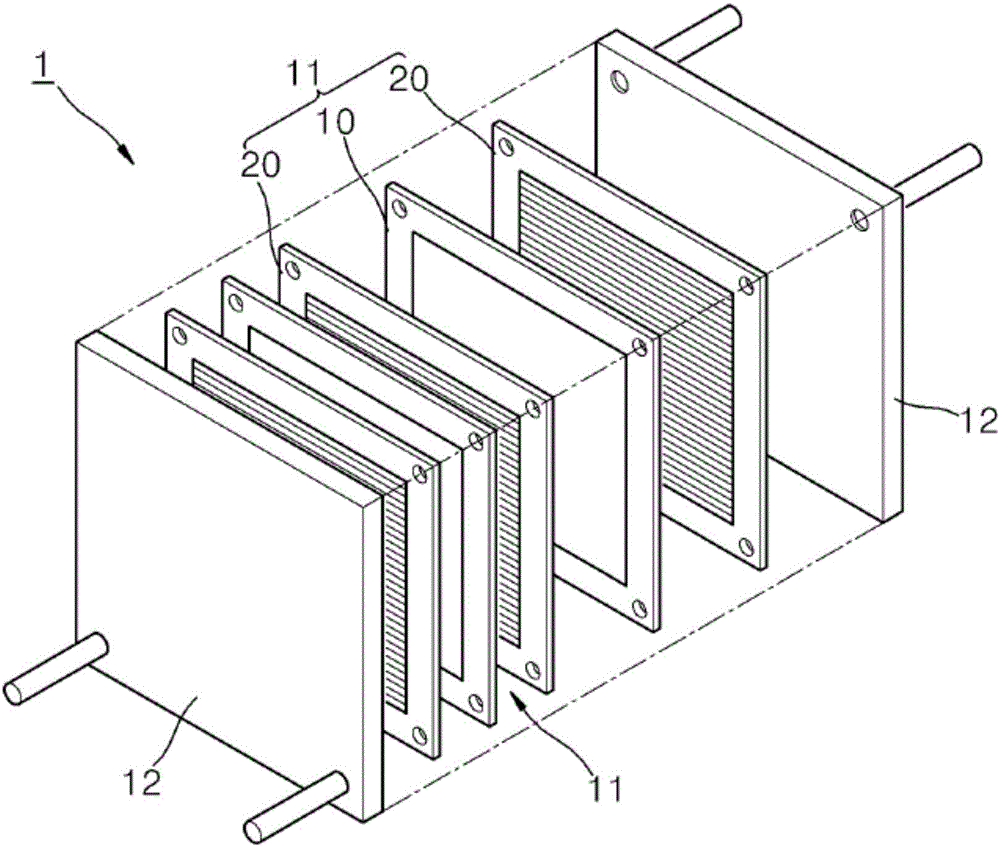

Fuel cell pile online regional detection system and method

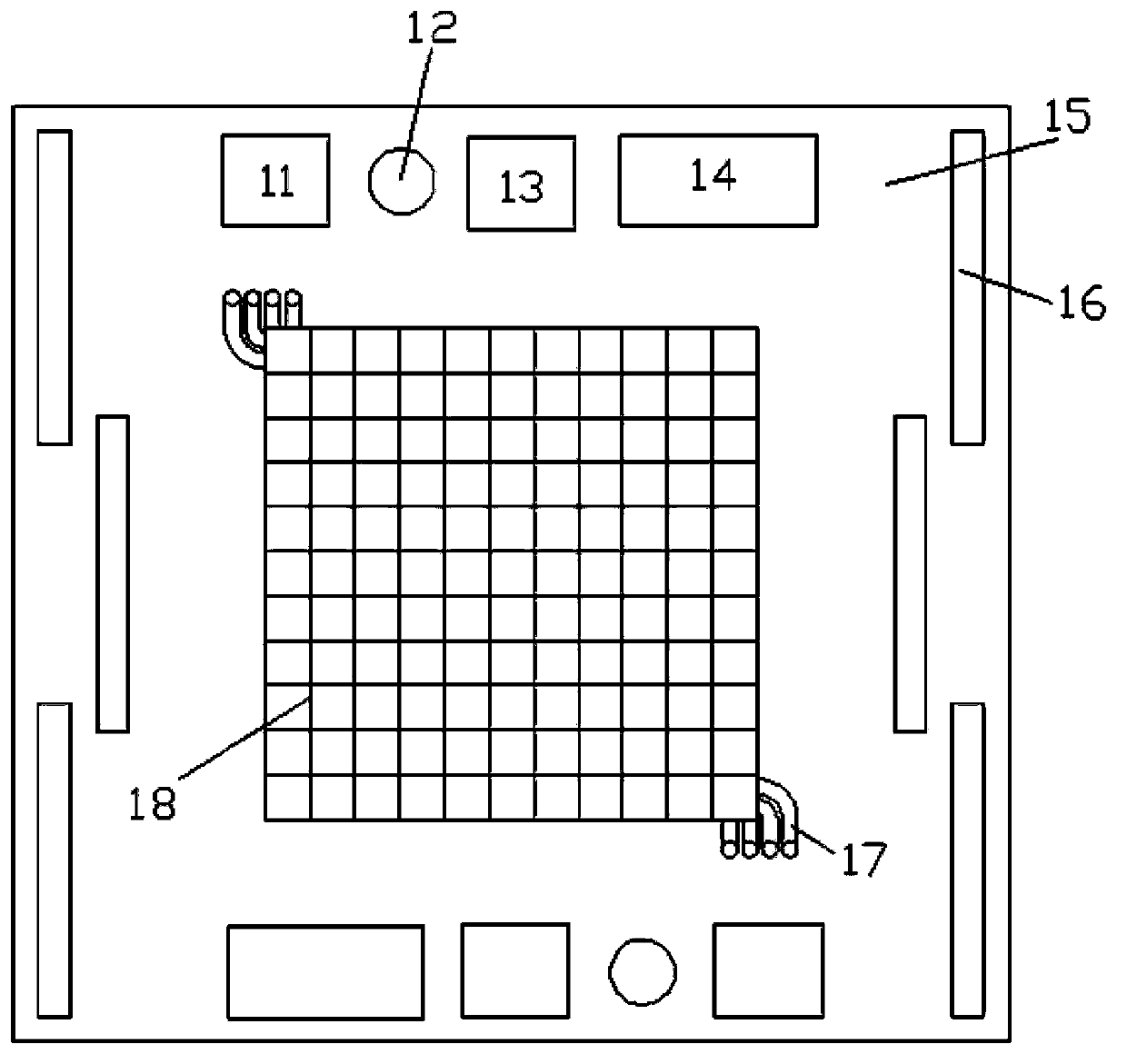

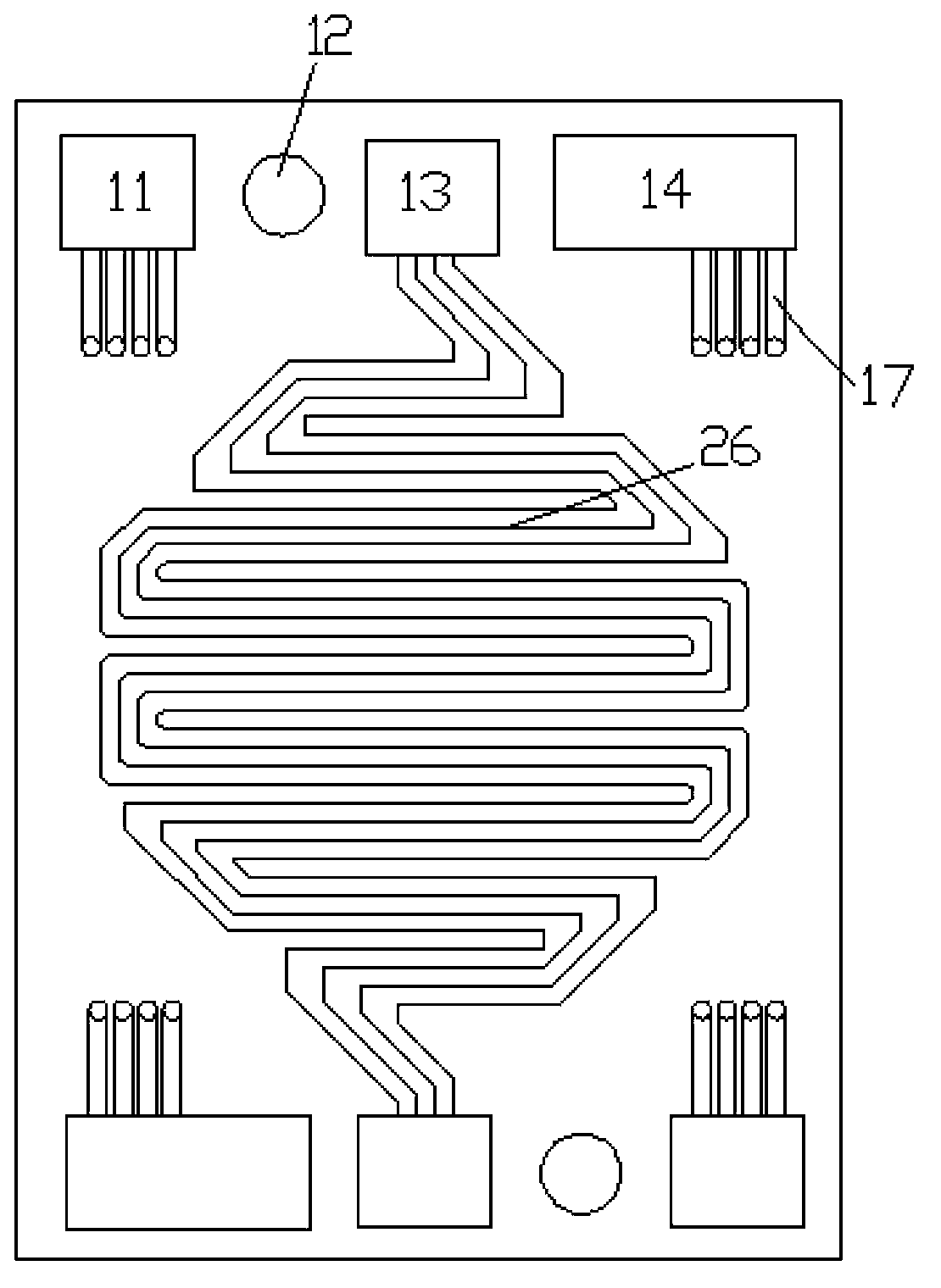

The invention relates to a fuel cell pile online regional detection system and a fuel cell pile online regional detection method. The detection system comprises piles, PCBs, a data acquisition device and a computer; the PCBs are arranged in the piles; the input end of the data acquisition device is connected with the PCBs; and the output end of the data acquisition device is connected with the computer. The detection method comprises the following steps that: a plurality of PCBs are adopted to replace single-body anode boards, and sealing is performed; hydrogen, air and water are led into the piles, so that the piles can work normally; after the piles can work normally, regional current density signals, temperature signals and single-body voltage signals measured by the PCBs are acquired by the data acquisition system, and data processing results are transmitted to the computer; and the computer converts received data into a two-dimensional distribution graph and displays the graph, and therefore, regional properties of the piles can be detected in an online manner. Compared with the prior art, the fuel cell pile online regional detection system and method of the invention are advantageous in basic avoidance of pile structure modification, a large number of detected performance parameters, intuitive display of measurement results, wide application and the like.

Owner:TONGJI UNIV

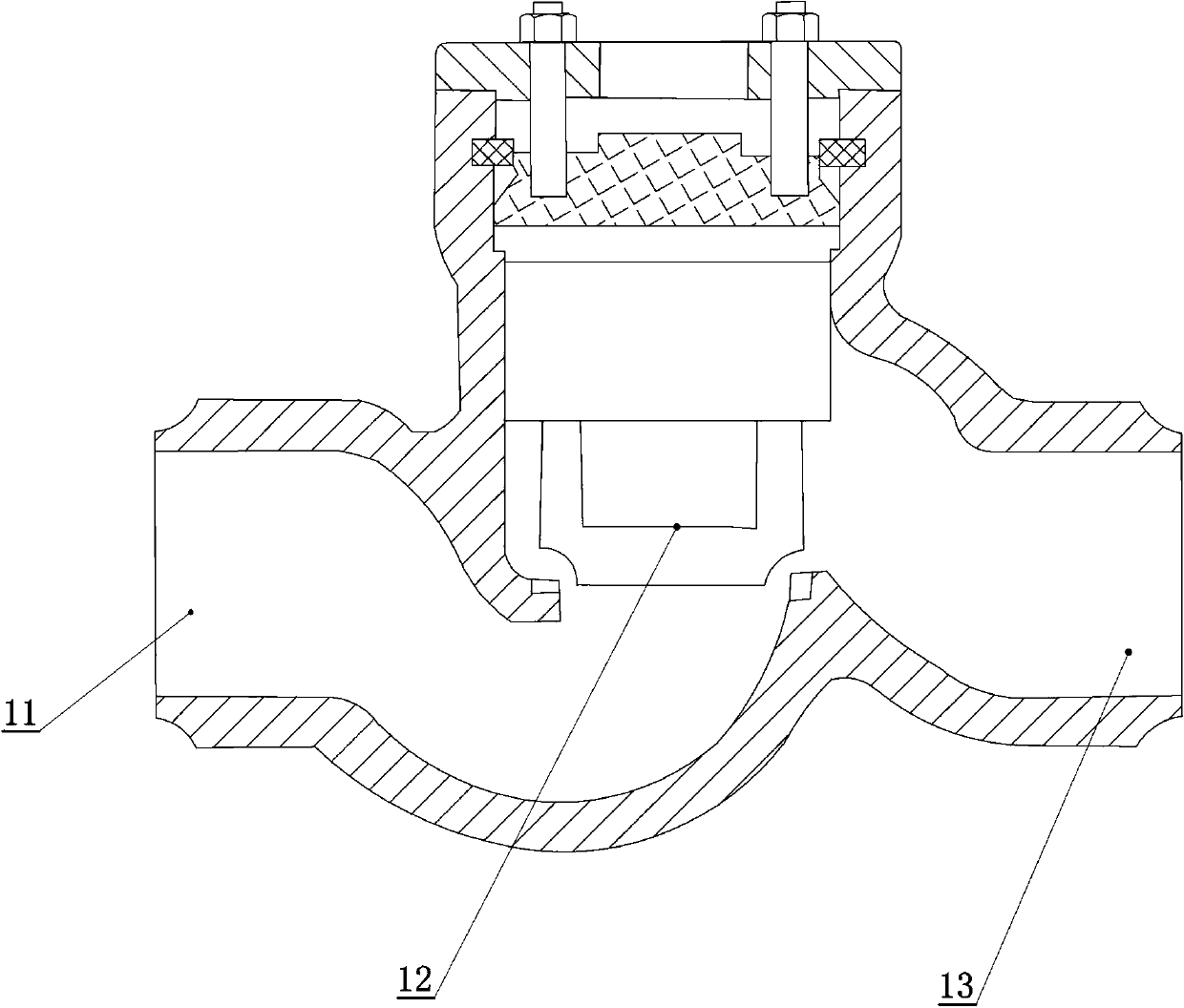

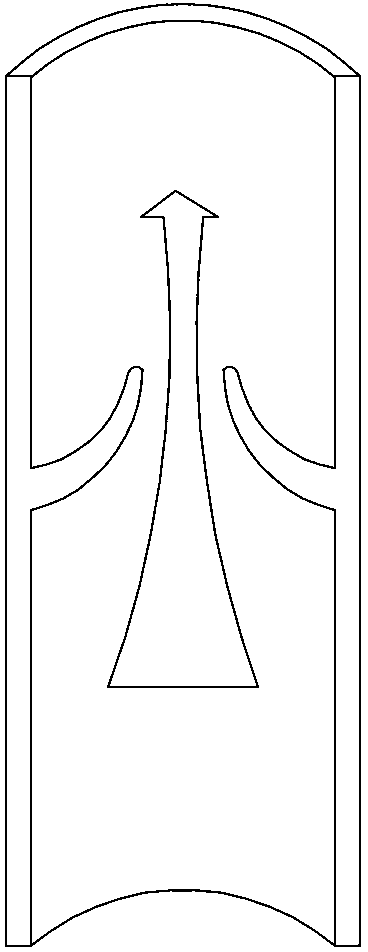

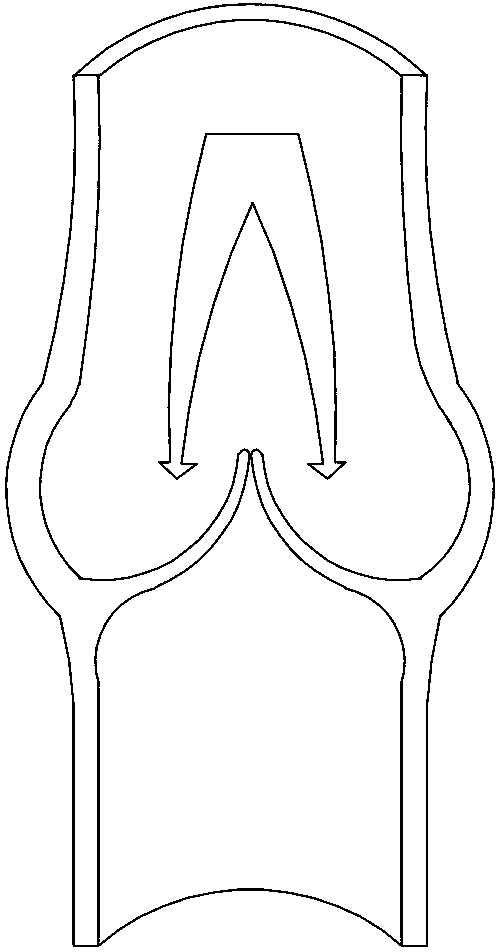

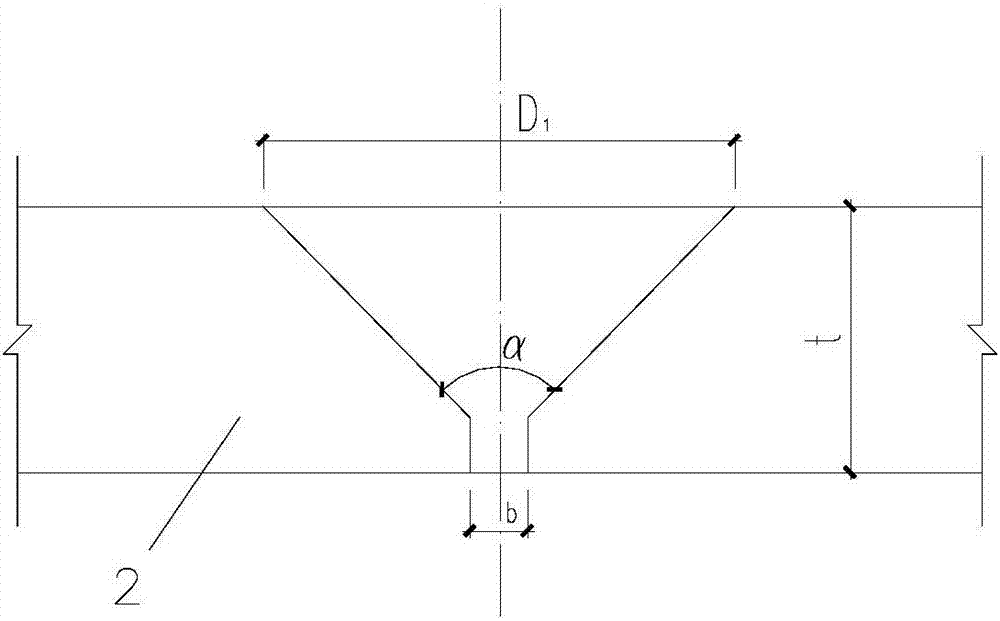

Black-flow preventer valve in pipeline

The invention discloses a back-flow preventer valve in a pipeline. The back-flow preventer valve in the pipeline comprises a pipe body and valves, wherein the valves are arranged in a pipe cavity. Two valves are designed in the pipe cavity, the width of the middle parts of the valves is greater than the radius of the pipe cavity, and is 1.5-2.5 times the radius of the pipe cavity; the root parts of the valves are thicker than other parts, are arc-shaped and connected with the inner wall of the pipe cavity; free edges of the upper valve and the lower valve face towards the flow direction of the fluid; the valves are light films with elasticity and toughness; and the pipe body is transparent, and the two valves are provided with different colors. The back-flow preventer valve in the pipeline has the advantages that: 1, the two valves are simple and practical, satisfy biomechanics, and can be arranged at a plurality of positions in the same pipe body; 2, down-flow is not affected when the back-flow is prevented; 3, convection of liquid and gas in a drainage pipeline is prevented; and 4, the structure of the pipeline is not affected when the back-flow preventer valve is widely applied to any part of various pipe cavities and pipelines in medical science or non-medical life.

Owner:于秀月 +2

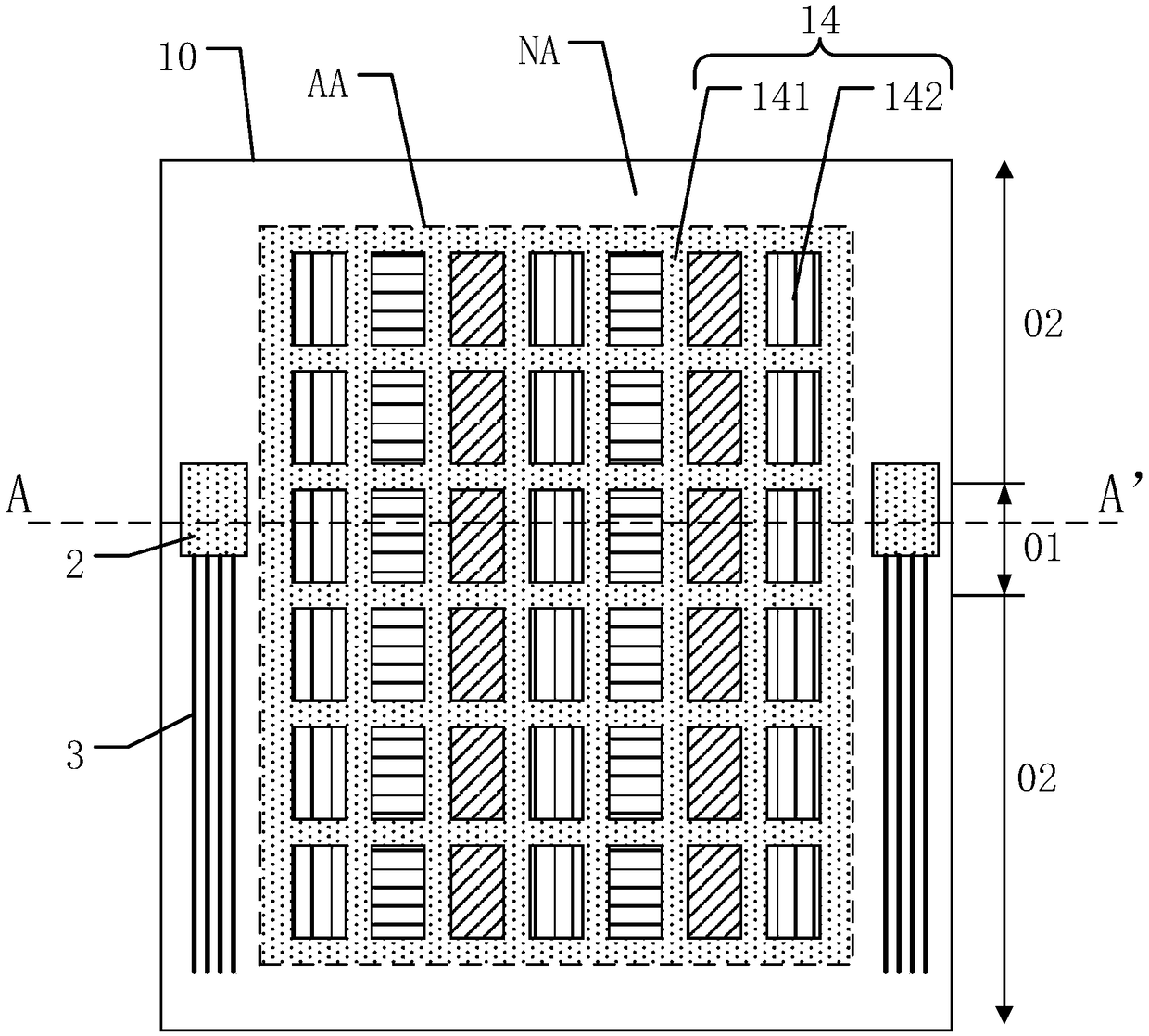

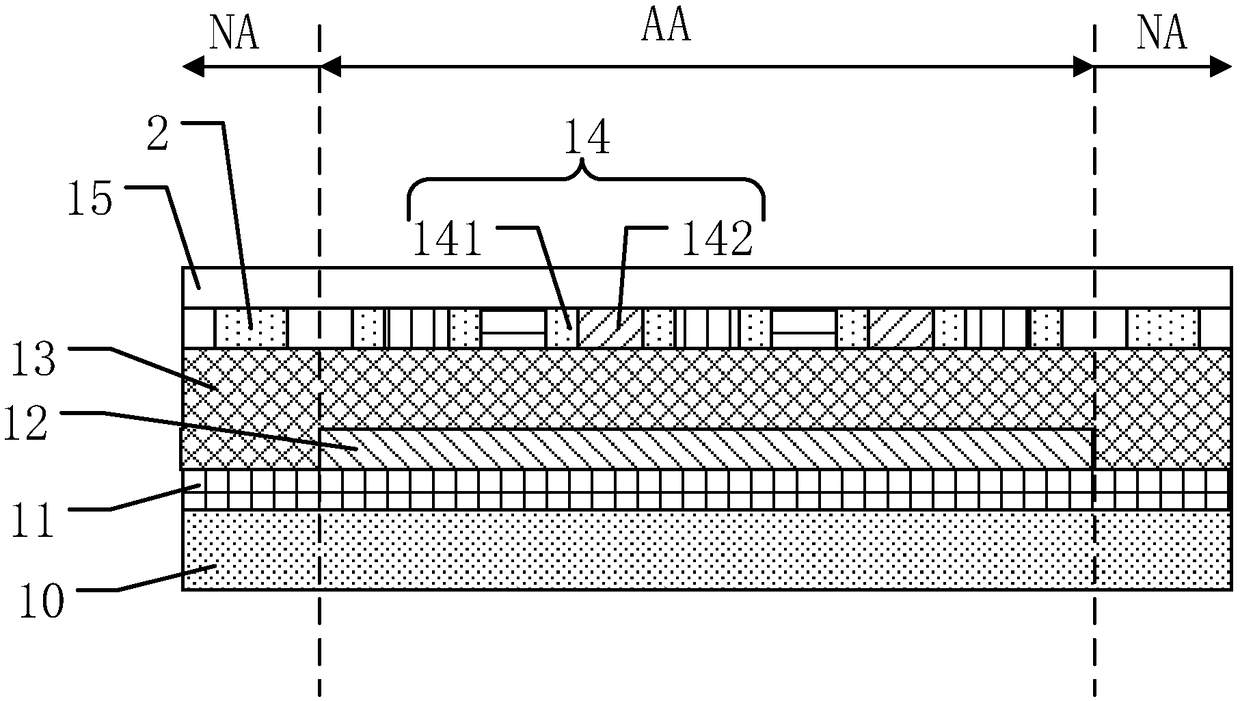

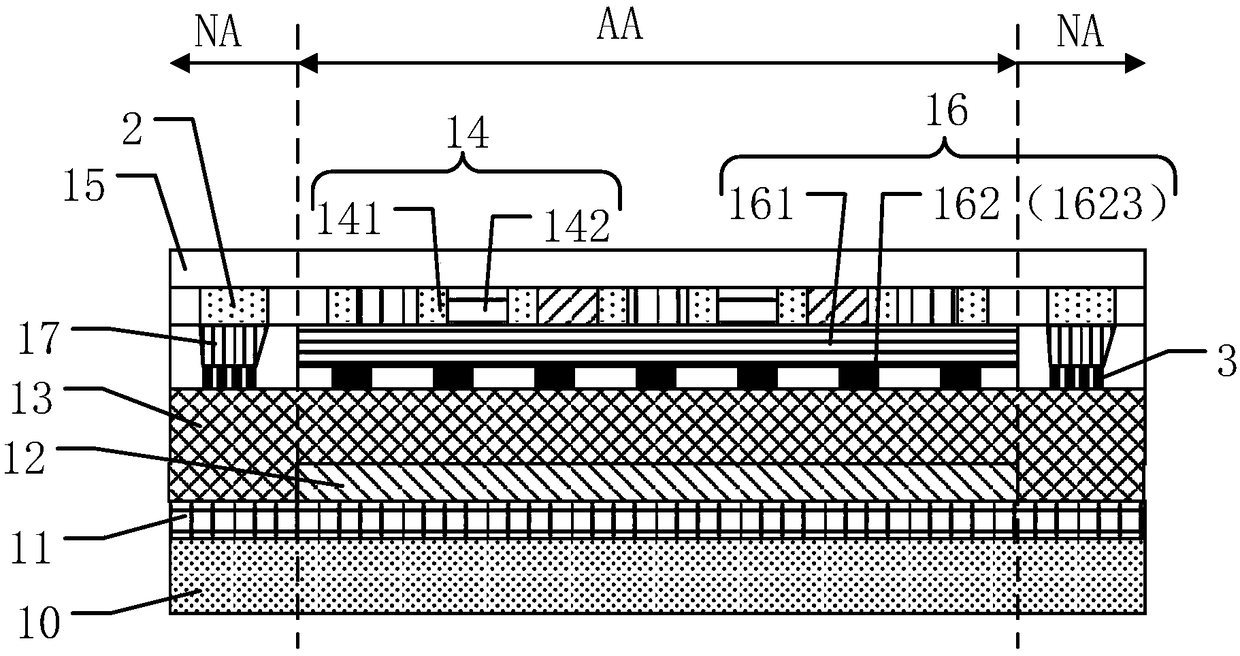

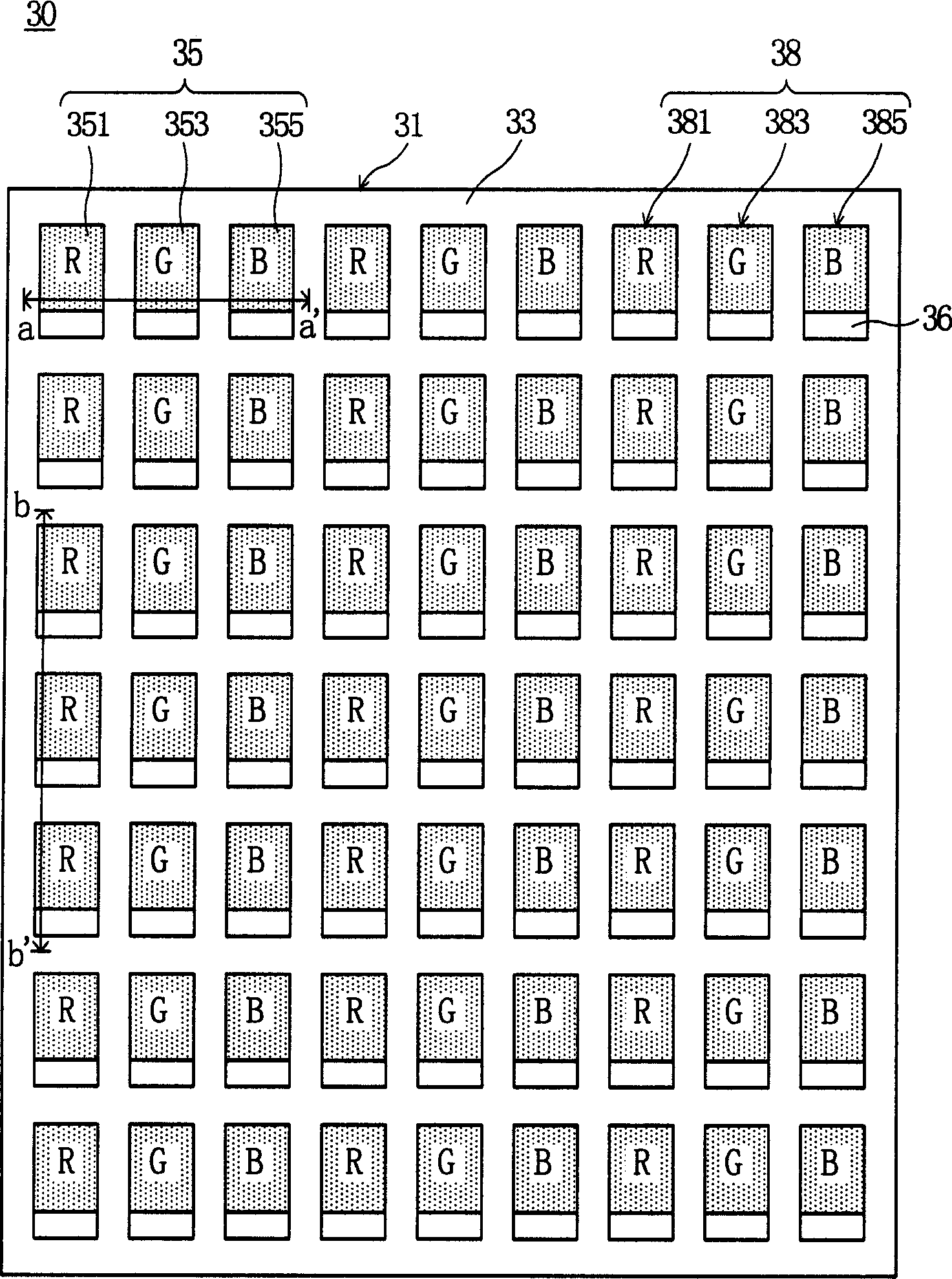

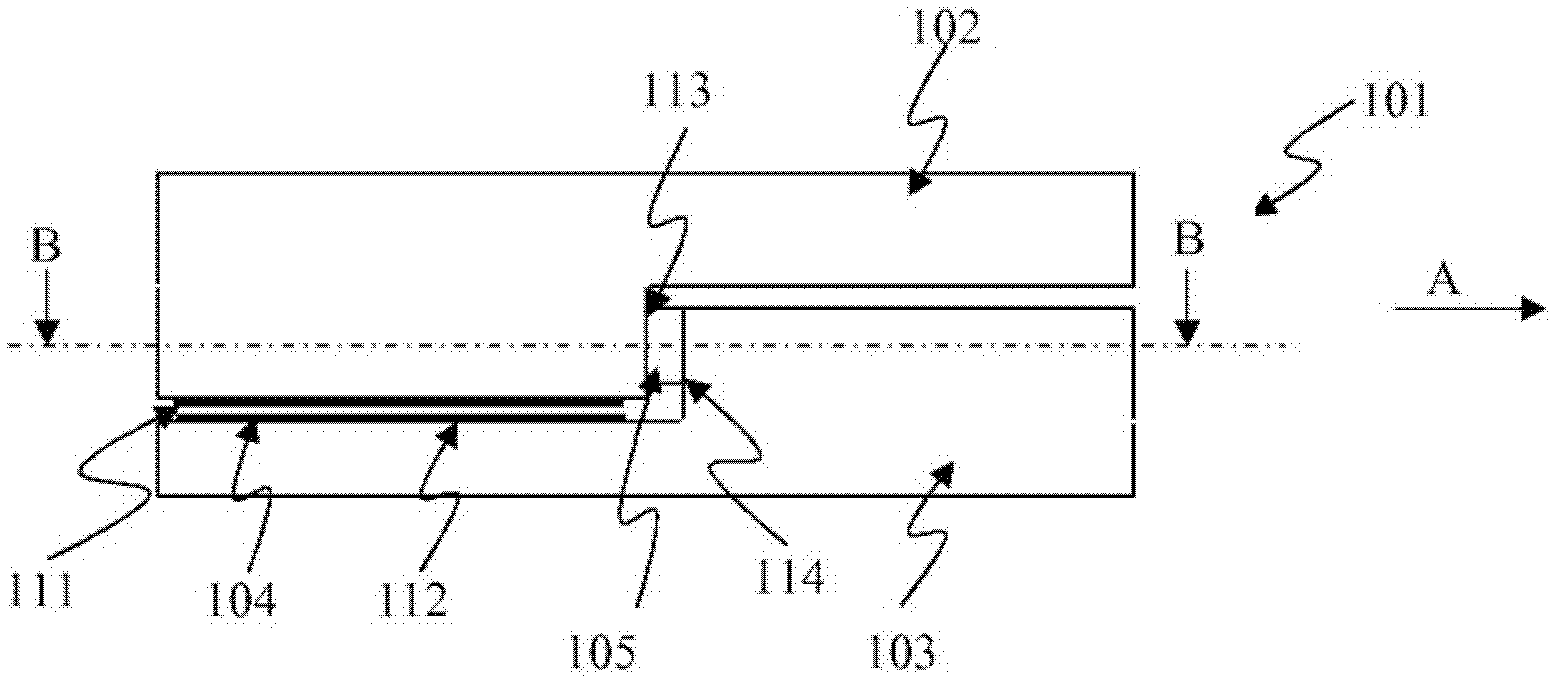

Flexible display panel and display device

ActiveCN109285864ADoes not affect thicknessDoes not affect border sizeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmBridge type

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a display area, a non-display area, a flexible substrate, an array layer, an organic light-emitting layer, a thin-film packaging layer, a color film structure layer and a flexible protection layer, wherein the color film structure layer includes a light-shading organic film layer and a plurality of color resistors arranged in an array mode; the non-display area includes at least two bridge-type bending inductors and a plurality of metal wires, the bridge-type bending inductors are electrically connected with the metal wires, and the bridge-type bending inductors are arranged in the same layer as the light-shading organic film layer; and the display panel comprises at least one bending area and a non-bending area, and the bridge-type bending inductors are at least partially located in the bending area. The display device comprises the flexible display panel. The flexible display panel not only can reduce the process difficulty and the process steps, but also can be conducive to the development of the display panel towards a thinning and frame narrowing trend.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

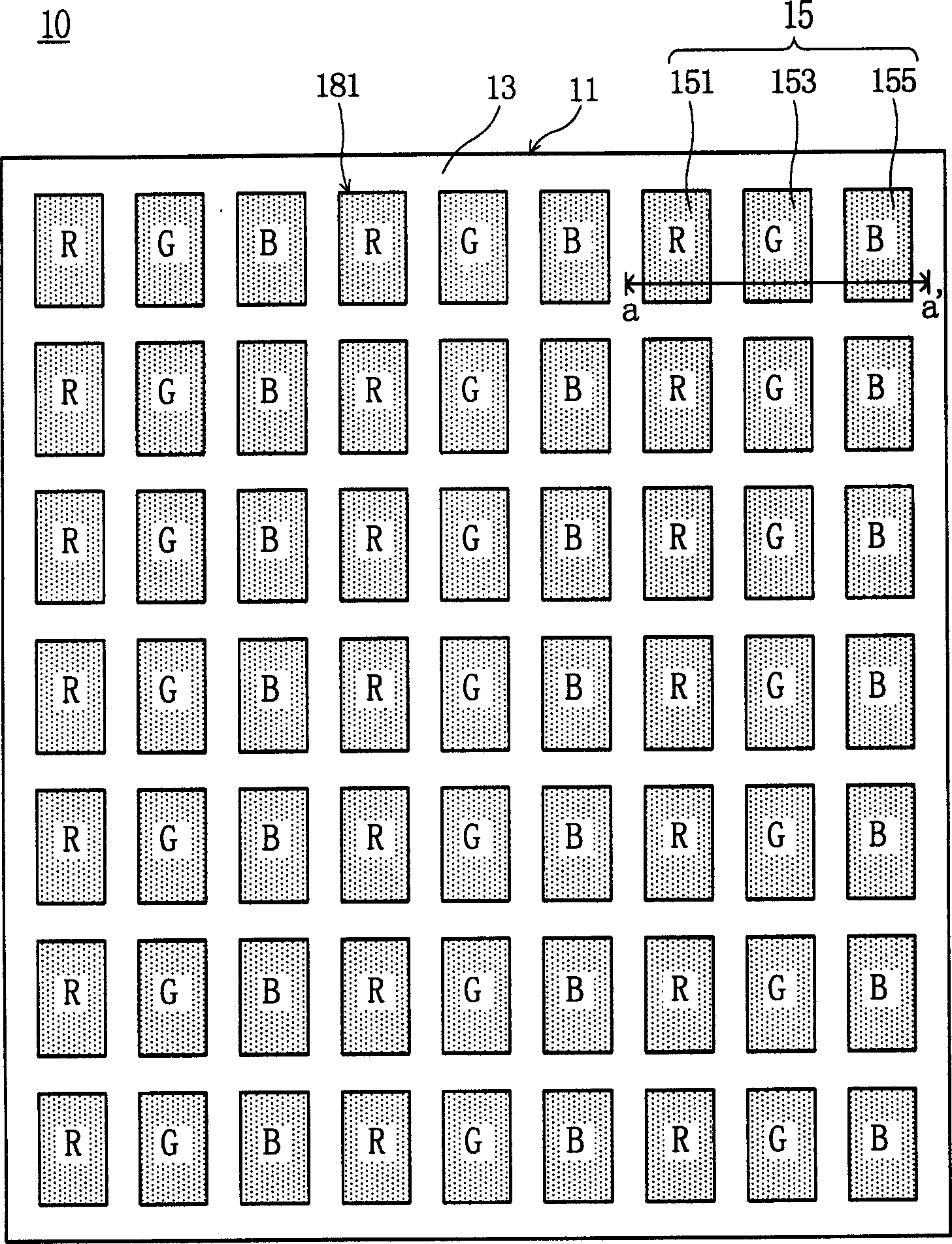

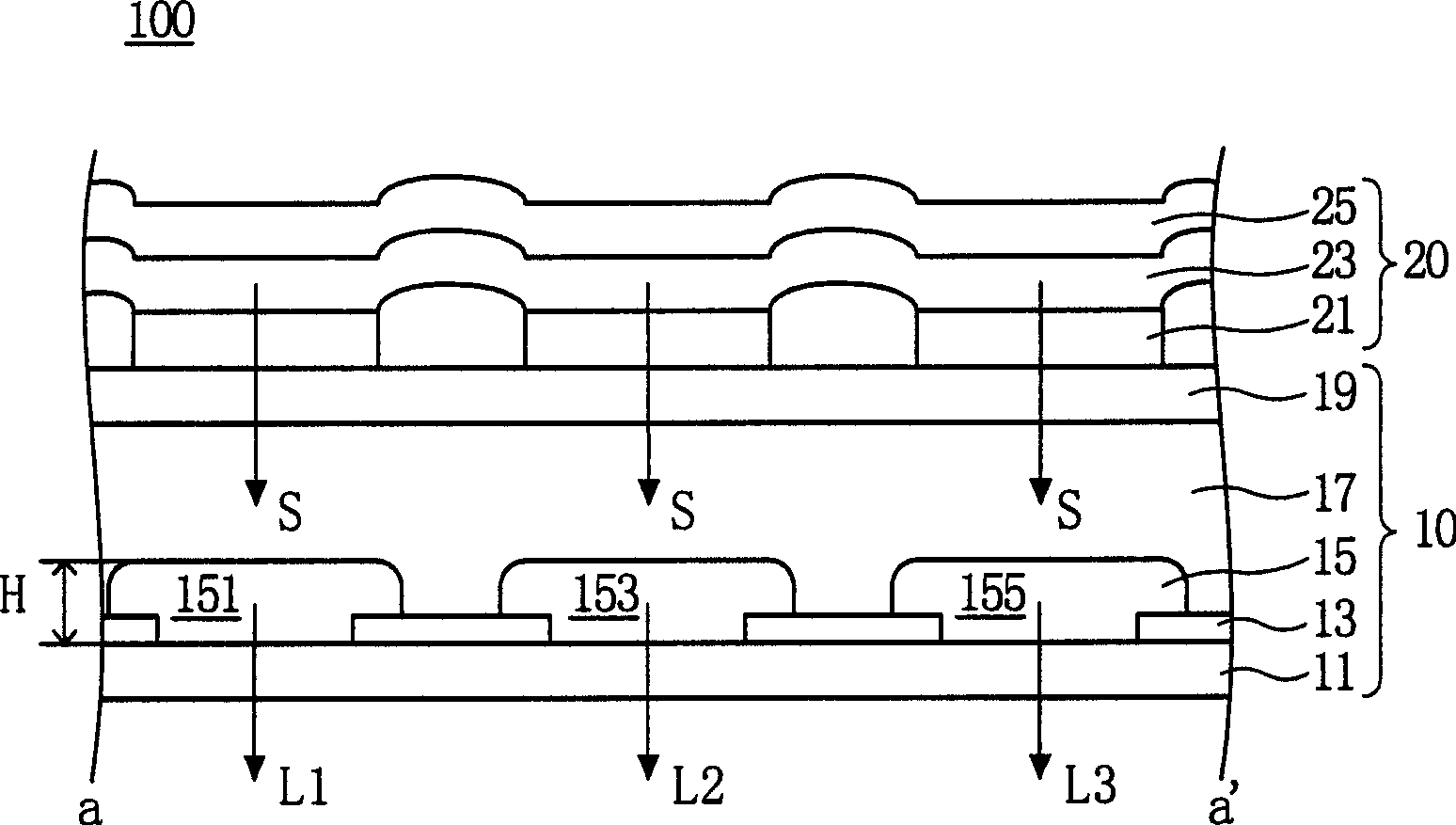

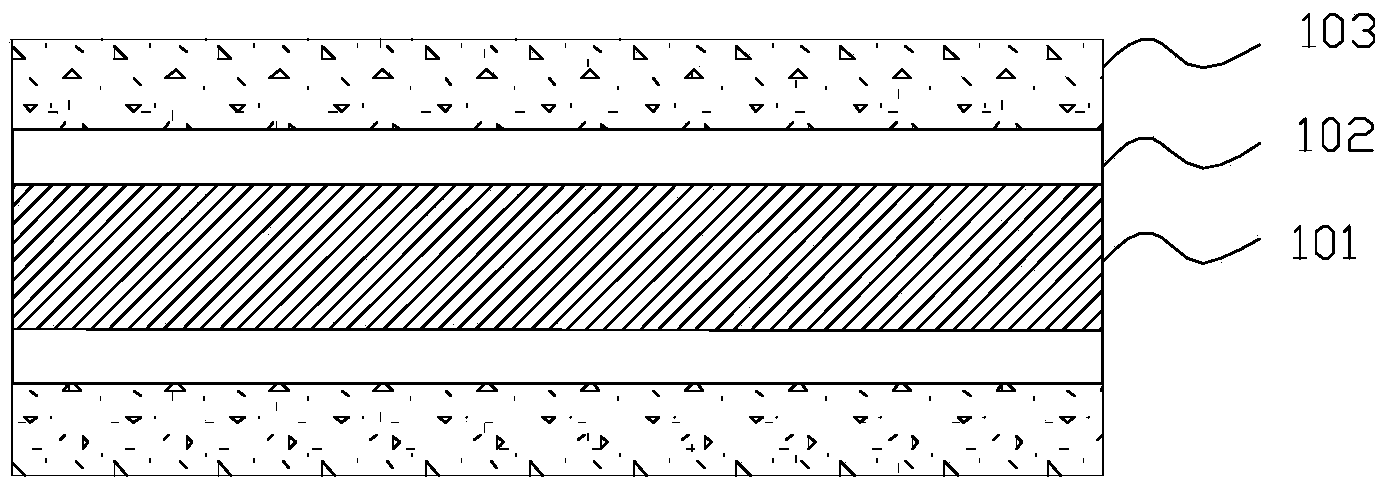

Colour filter concurrently having luminous brightness and photochromic contrast

InactiveCN1776467AIncrease brightnessDoes not affect thicknessNon-linear opticsOptical elementsLight filterTranslight

In the invention, a black matrix is setup on partial upper surface of a transparent base plate so as to define out multiple pixels. At least a color photoresistive and a hollowing out part are respective setup inside each pixel. Without influence on brightness of penetration light source, the hollowing out part reaches purpose of raising photochromic contrast of penetration light source.

Owner:彭冠璋

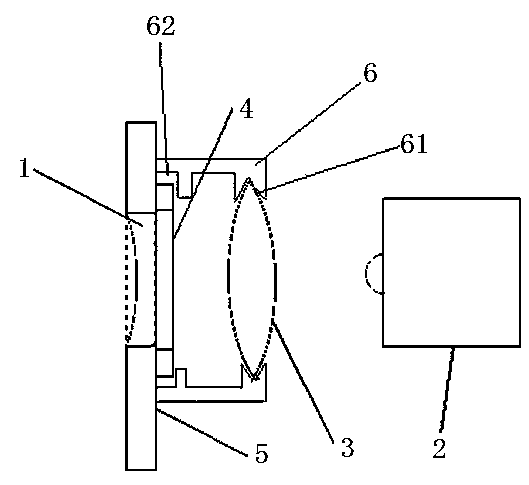

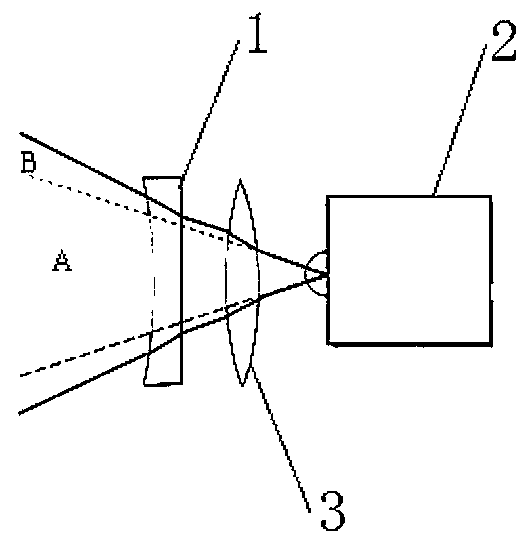

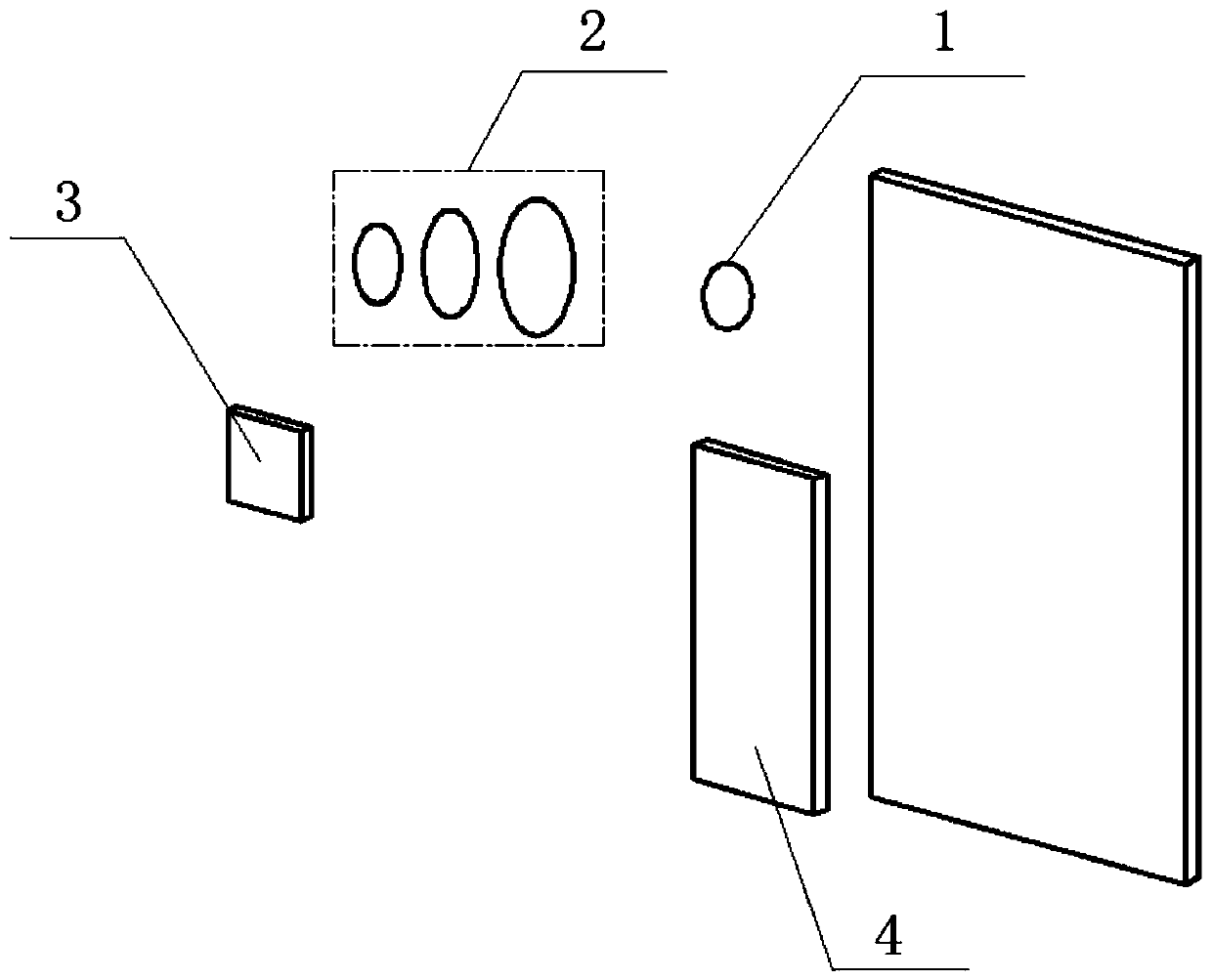

Wide-angle lens of mobile terminal camera

InactiveCN104062737AImproved wide-angle performanceDoes not affect thicknessMountingsCamera body detailsCamera lensCamera module

The invention discloses a wide-angle lens of a mobile terminal camera. The wide-angle lens comprises a first lens, a camera module, a second lens, a diaphragm and a fixing component, wherein the first lens is embedded into a mobile terminal shell, the camera module is connected with a circuit board of a mobile terminal and aligns with the first lens, the second lens is arranged between the first lens and the camera module, the diaphragm is arranged between the first lens and the second lens, and the fixing component is connected with the mobile terminal shell and used for fixing the second lens and the diaphragm. The lens wide-angle performance of the module is improved through the set of lens with positive and negative diopter, the requirement for an ultrathin mobile terminal at present is met, the performance of the lens wide angle of the mobile terminal camera is added, the shooting field angle of the mobile terminal is increased, and much experience is acquired while the scenery and the like are shot.

Owner:PHICOMM (SHANGHAI) CO LTD

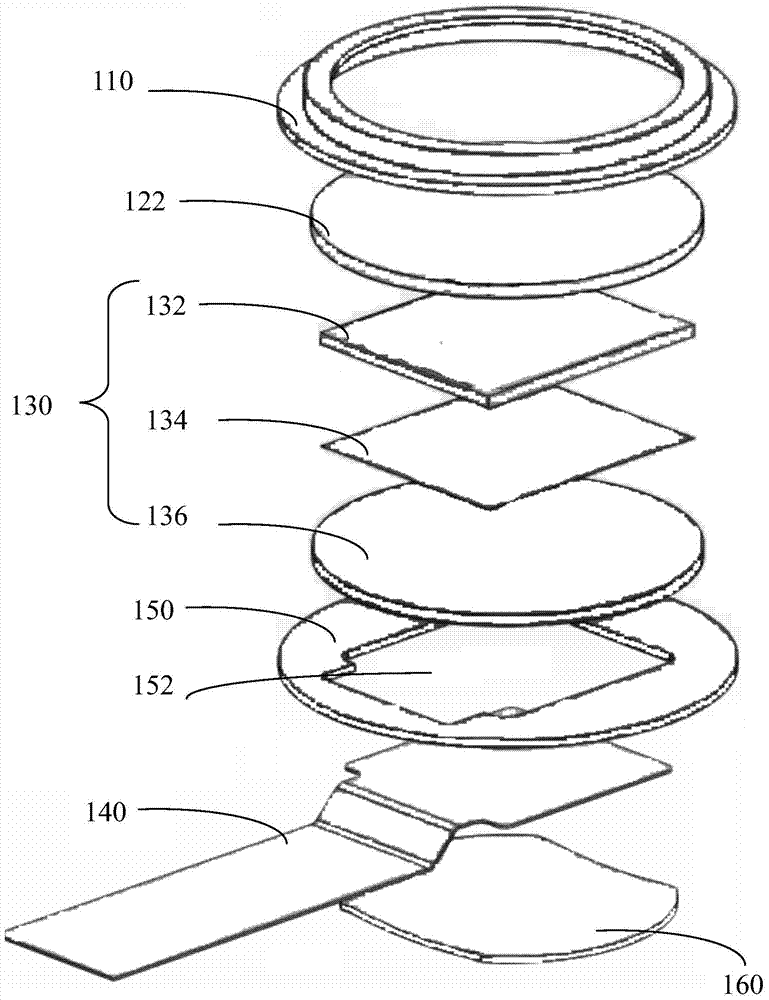

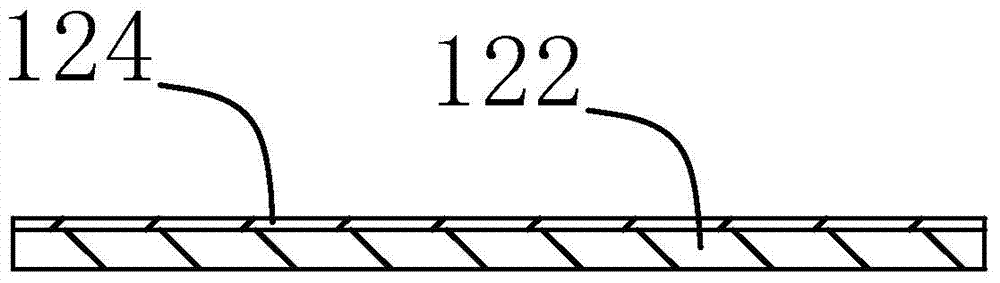

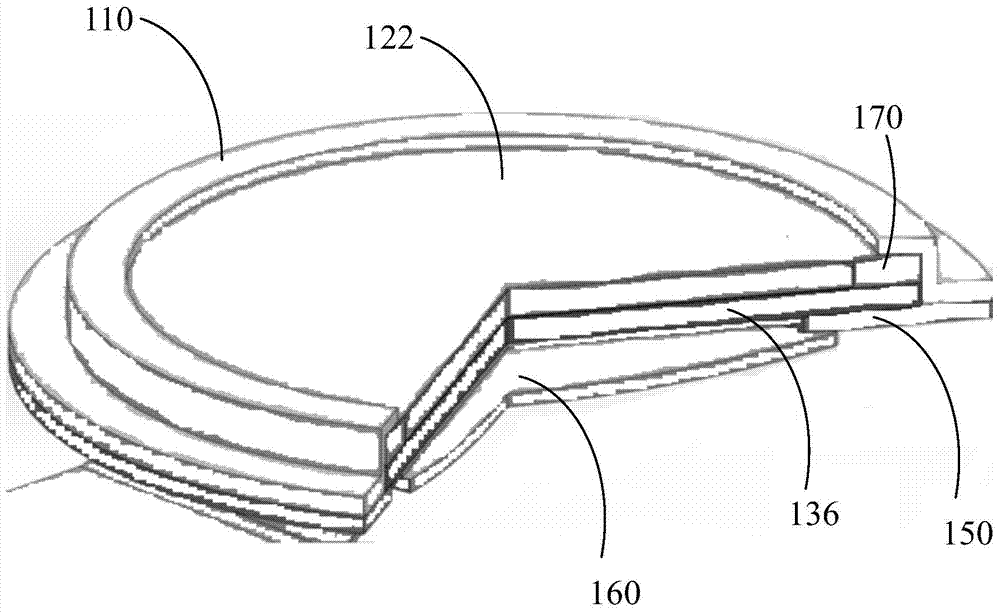

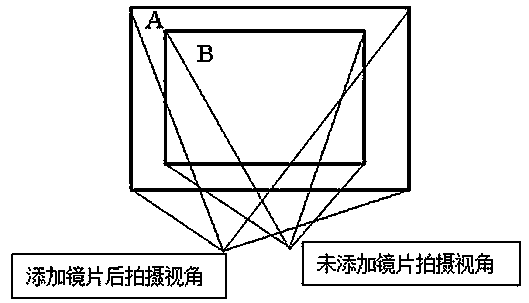

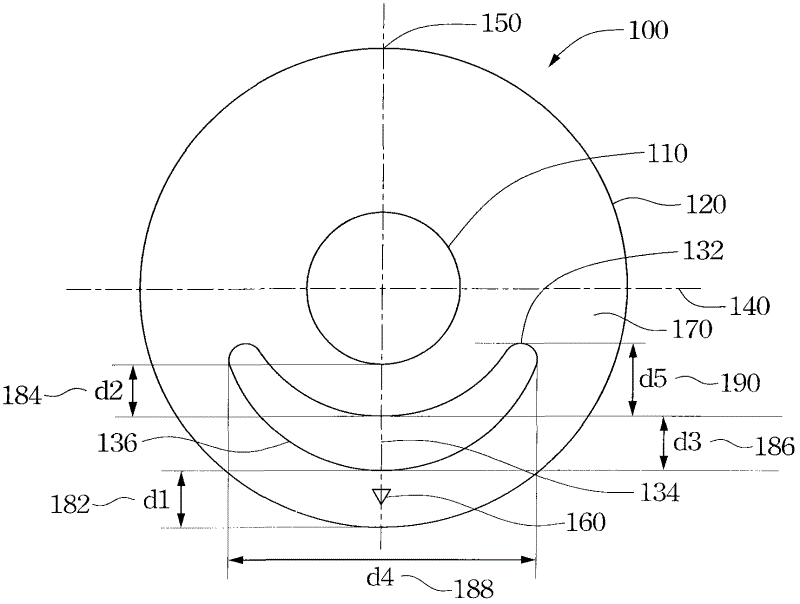

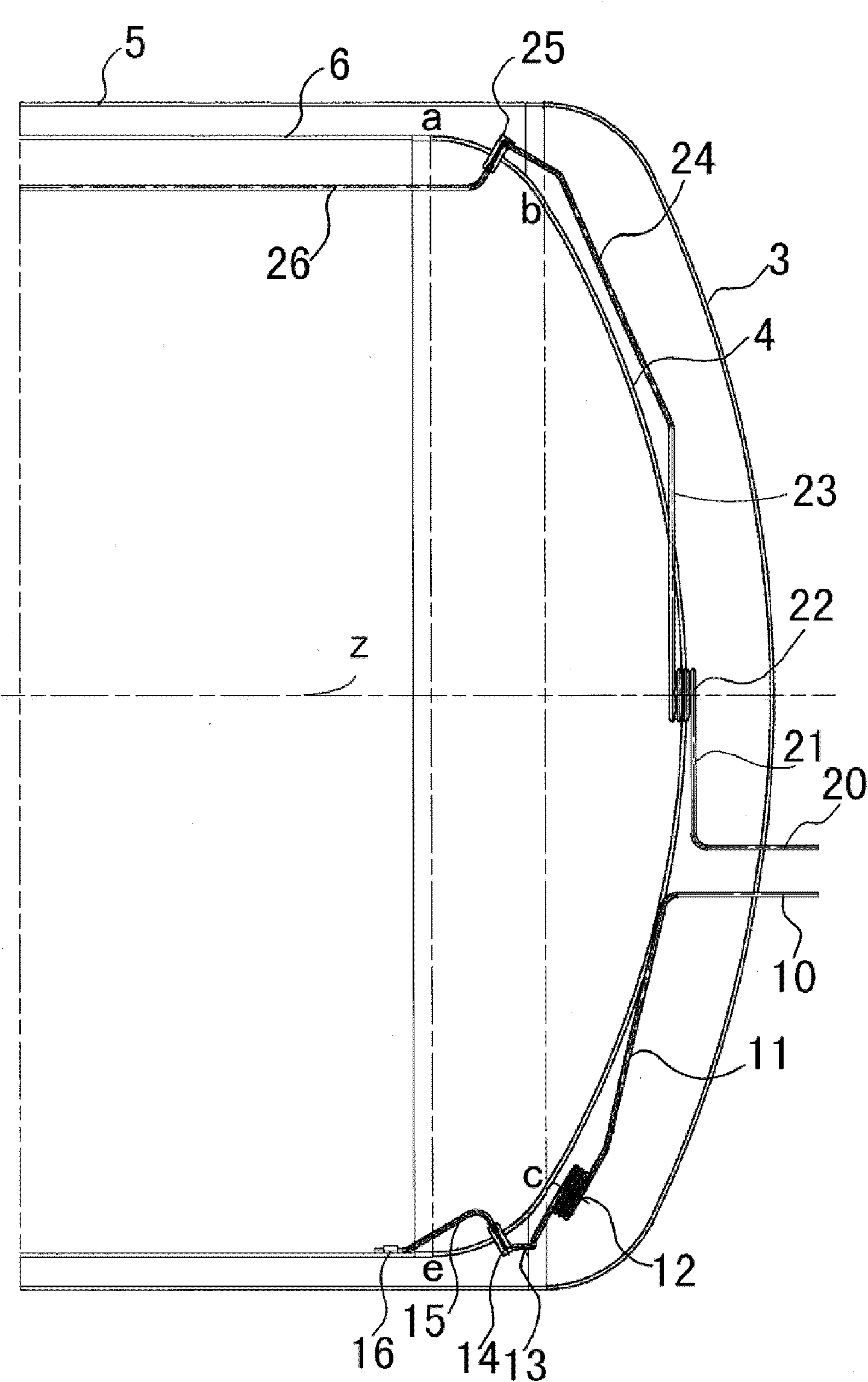

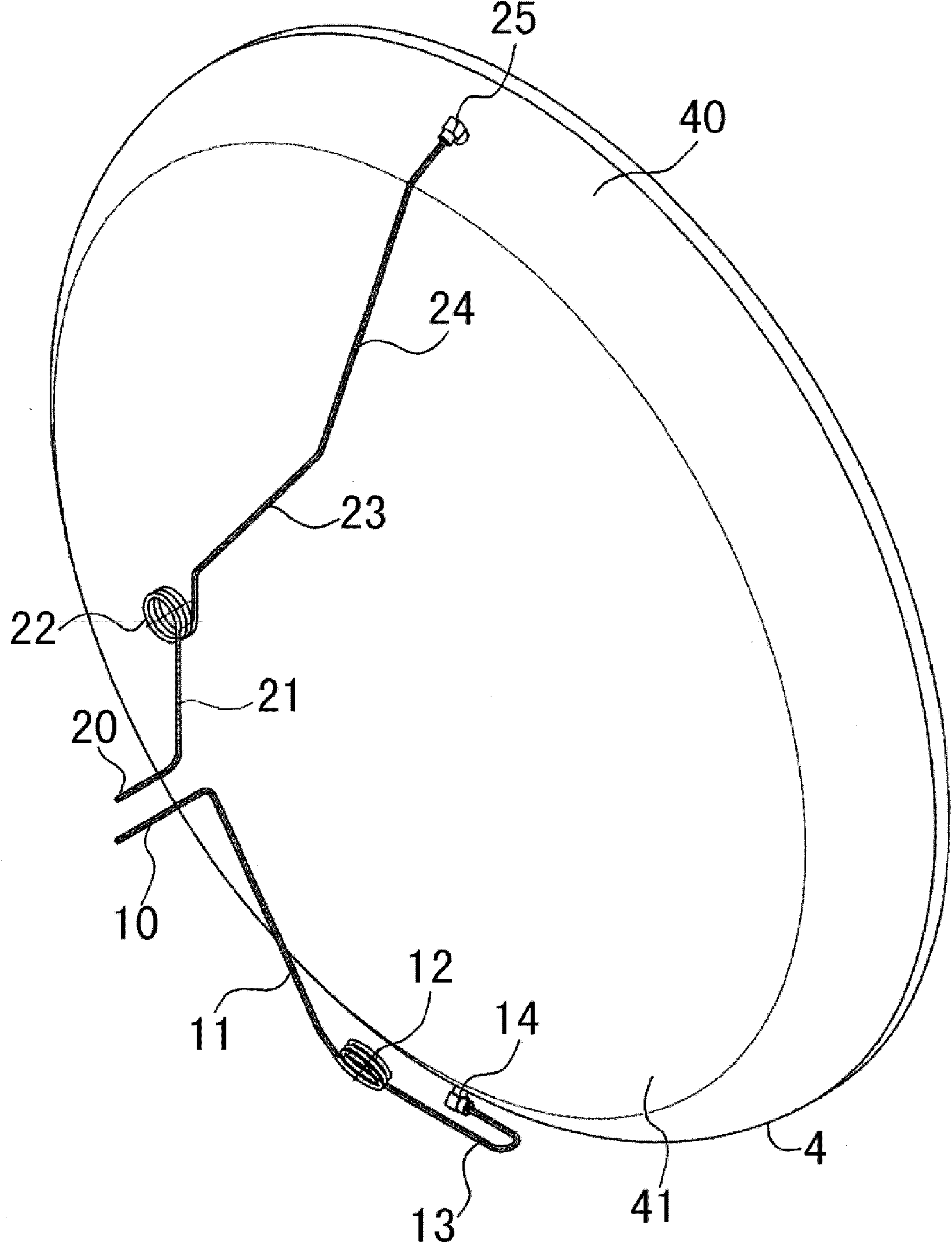

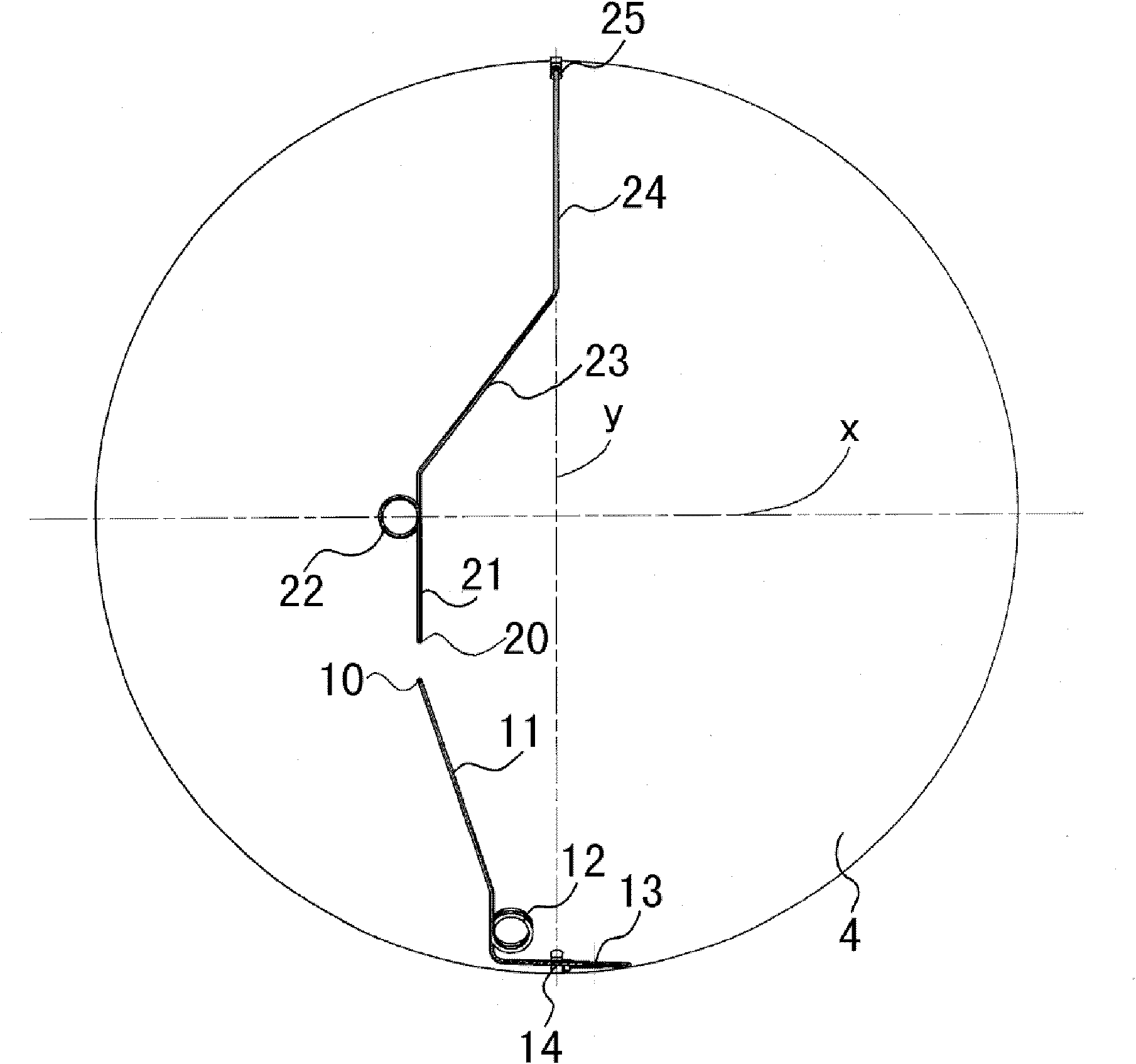

Segmented delta toric lens

A segmented delta toric lens is described. The segmented delta toric lens includes an optical area, a circumference area surrounding the optical area and a segmented delta protrusion formed on the circumference area. The segmented delta protrusion is located apart from the optical area and the edge of the circumference area. The segmented delta toric lens can further include a mark to indicate a direction of the segmented delta toric lens.

Owner:PEGAVISION CORP

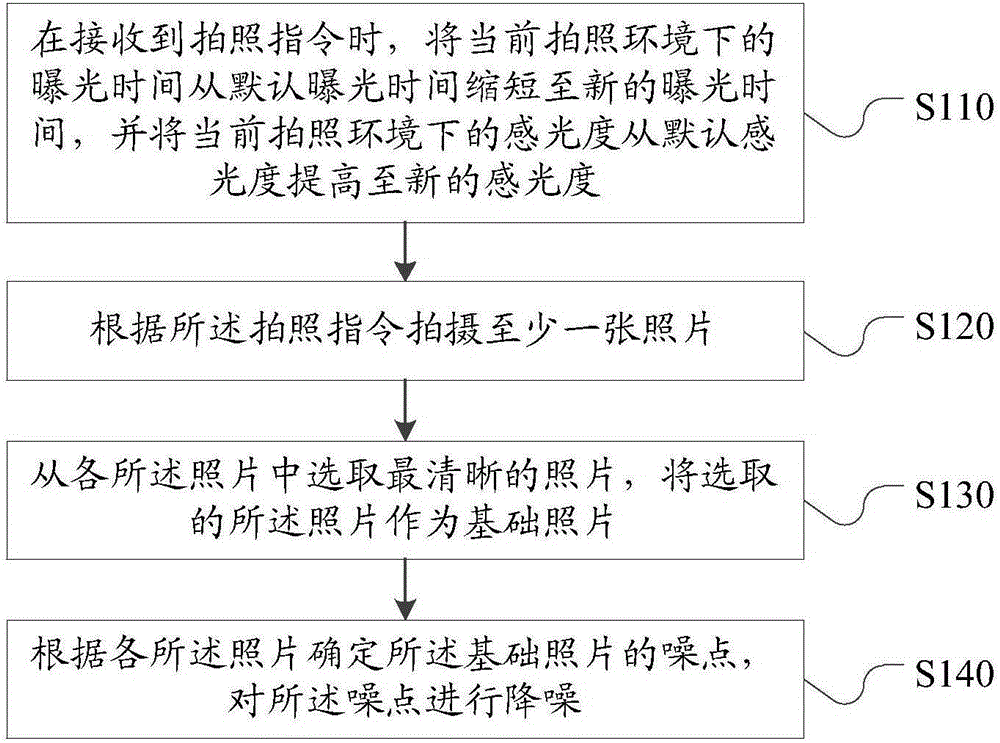

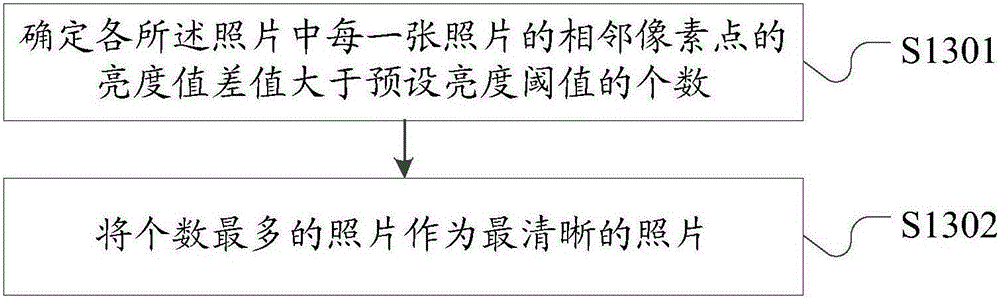

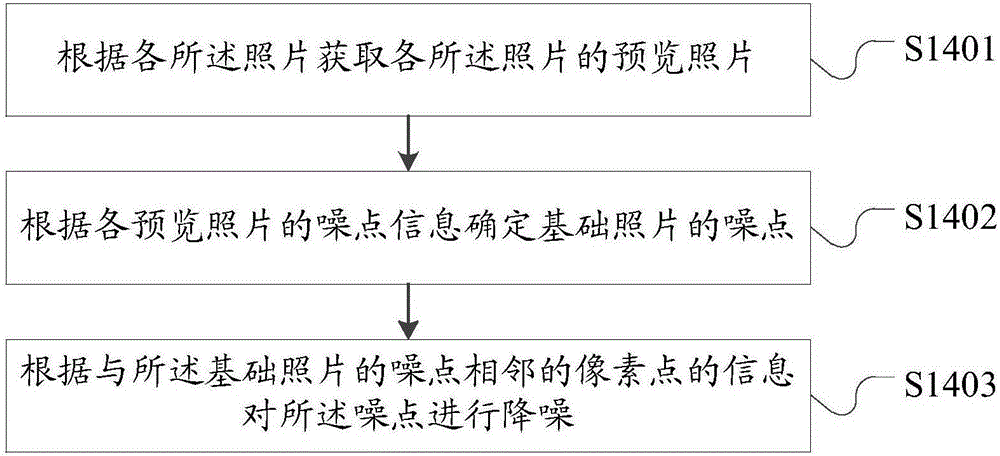

Shooting method and device

ActiveCN105187728ADoes not affect thicknessDoes not affect industrial design stylingTelevision system detailsColor television detailsComputer graphics (images)Simulation

The invention relates to a shooting method and device. The method comprises the steps of: reducing the exposure time under a current shooting environment to a new exposure time from a default exposure time when receiving a shooting instruction, and increasing the light sensitivity under the current shooting environment to a new light sensitivity from a default light sensitivity; shooting at least one photograph according to the shooting instruction; selecting a clearest photograph from all photographs to be used as a basic photograph; and determining the noise of the basic photograph according to the photographs, and reducing the noise. The shooting method and device are realized by employing software, can effectively solve the problem of fuzzy shooting under light and dark light environments, especially under the dark light environment, do not influence camera module thickness and an intelligent terminal industrial design molding, and reduce costs.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

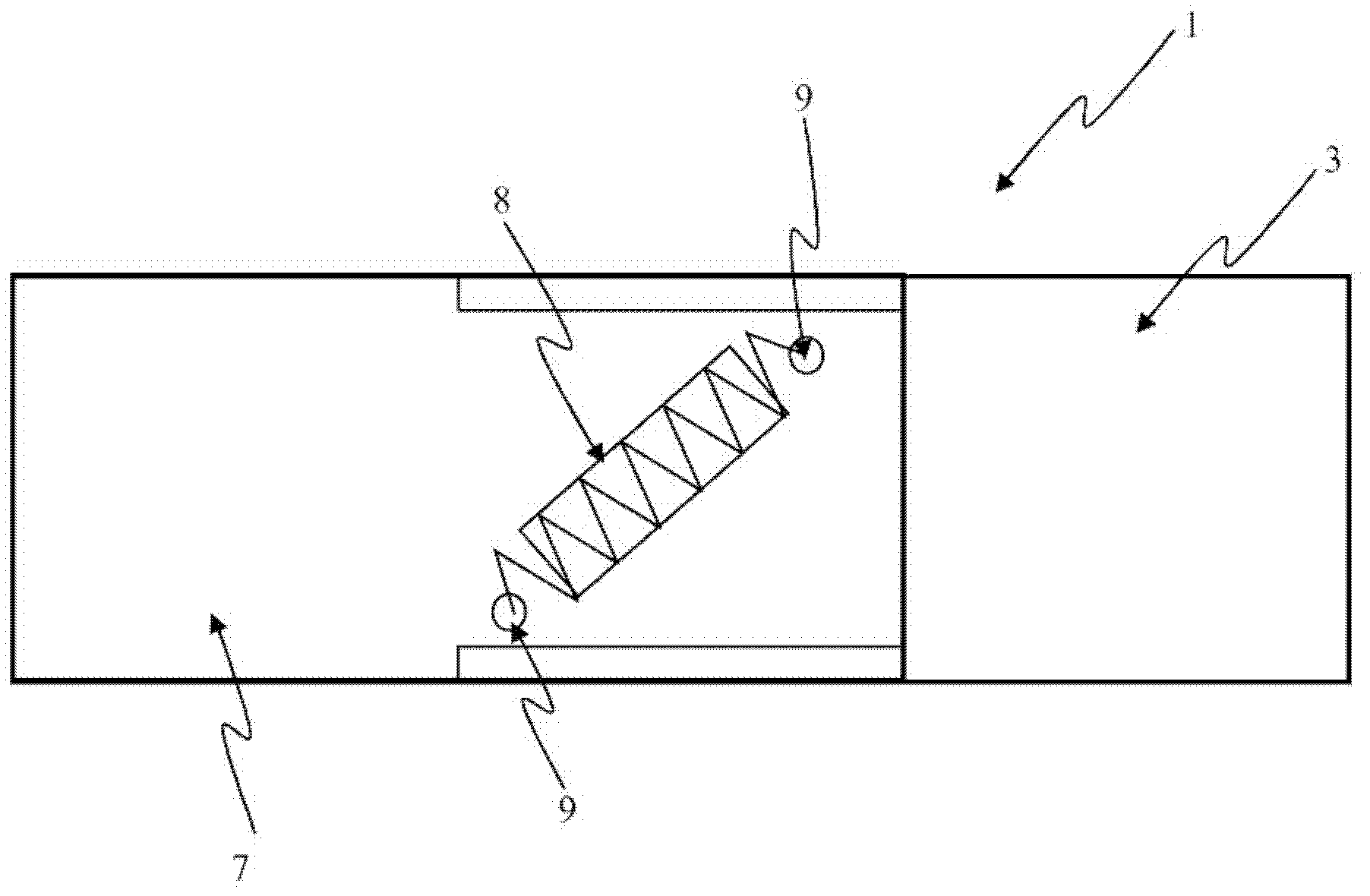

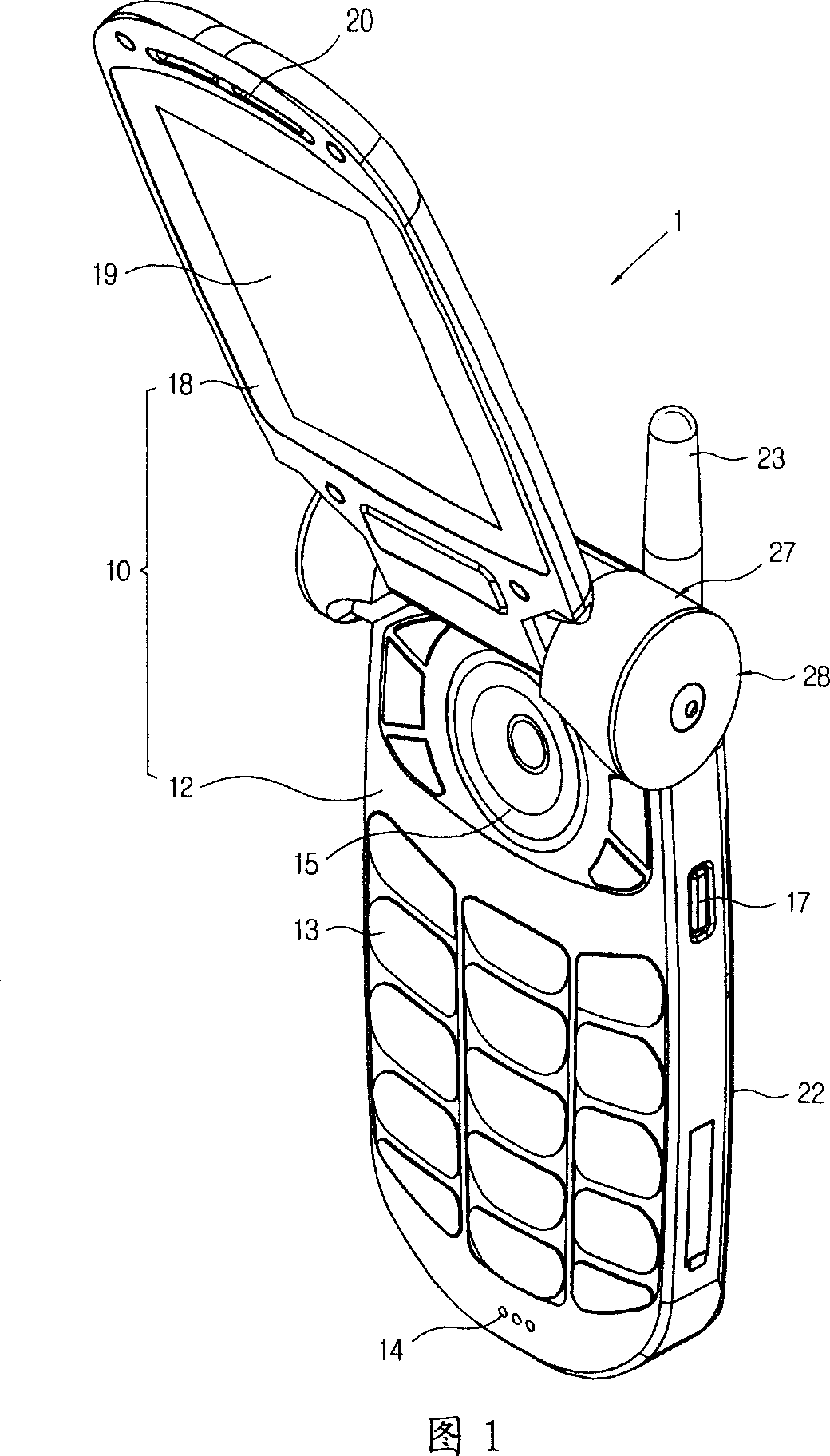

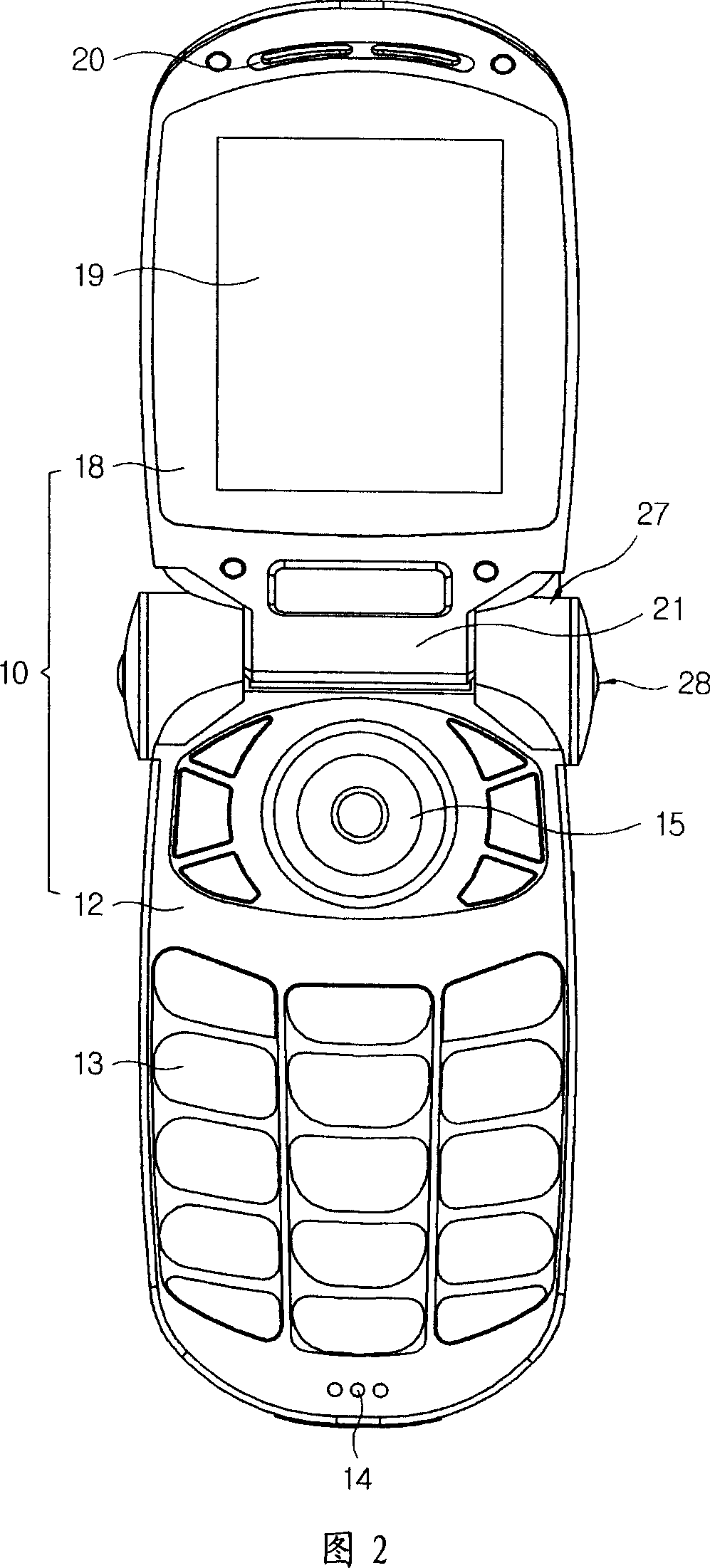

Mechanism for radio communication terminal

InactiveCN102342082ADoes not affect thicknessReduce complexityTelephone set constructionsComputer terminalElectrical and Electronics engineering

Owner:SONY ERICSSON MOBILE COMM AB

High-density package substrate on-hole disk product and preparation method thereof

ActiveCN104270888AImproved dimensional stabilityOptimizing the Laser Processing ProcessPrinted circuit aspectsElectrical connection printed elementsCopper foilEtching

The invention discloses a high-density package substrate on-hole disk product and a preparation method of the high-density package substrate on-hole disk product. The preparation method comprises the following steps of drying a substrate, manufacturing locating holes, conducting laser drilling, conducting micro-etching, conducting copper plating, conducting pattern transfer, conducting electroplating for hole filling and conducting film stripping and etching, and then the high-density package substrate on-hole disk product is obtained. According to the method, under the effect of protective film layers of the thin copper substrate, the problem that copper foil at the bottom is cut through in the thin copper processing process in the past is solved, and a complete half-through hole structure is made on the thin copper substrate; meanwhile, the direct laser processing technology is adopted, the thickness of the copper foil can not be influenced, and through good matching between the direct laser processing technology and the MSAP process, a high-density Flip-chip product with the high-flatness on-hole disk structure can be manufactured.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Acrylic acid grafted polyvinyl alcohol enhancer, and preparation method and application thereof

The invention discloses an acrylic acid grafted polyvinyl alcohol enhancer, and a preparation method and application thereof. The preparation method comprises the following steps: adding 0.1-1 part of polyvinyl alcohol into 4-10 parts of water, and heating at 60-90 DEG C for 1-5 hours to gelatinize the polyvinyl alcohol; and adding 1-5 parts of acrylic acid, adding alkali to regulate the pH value to 7-8, adding 0.01-0.1 part of initiator, and reacting at 60-90 DEG C for 2-6 hours to obtain the acrylic acid grafted polyvinyl alcohol enhancer. The polyvinyl alcohol chain used as the framework is grafted with the polyacrylic acid branched chain with certain flexibility to form the block macromolecular structure with branched chain, so that the prepared enhancer has better enhancement effect; and the nano glaze slip with the enhancer can not easily crack after being applied to the ceramic billet surface. The enhancer has small influence on the viscosity and flowability of the glaze slip, so the glaze thickness on the billet surface can not be influenced when the traditional glazing method is adopted.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

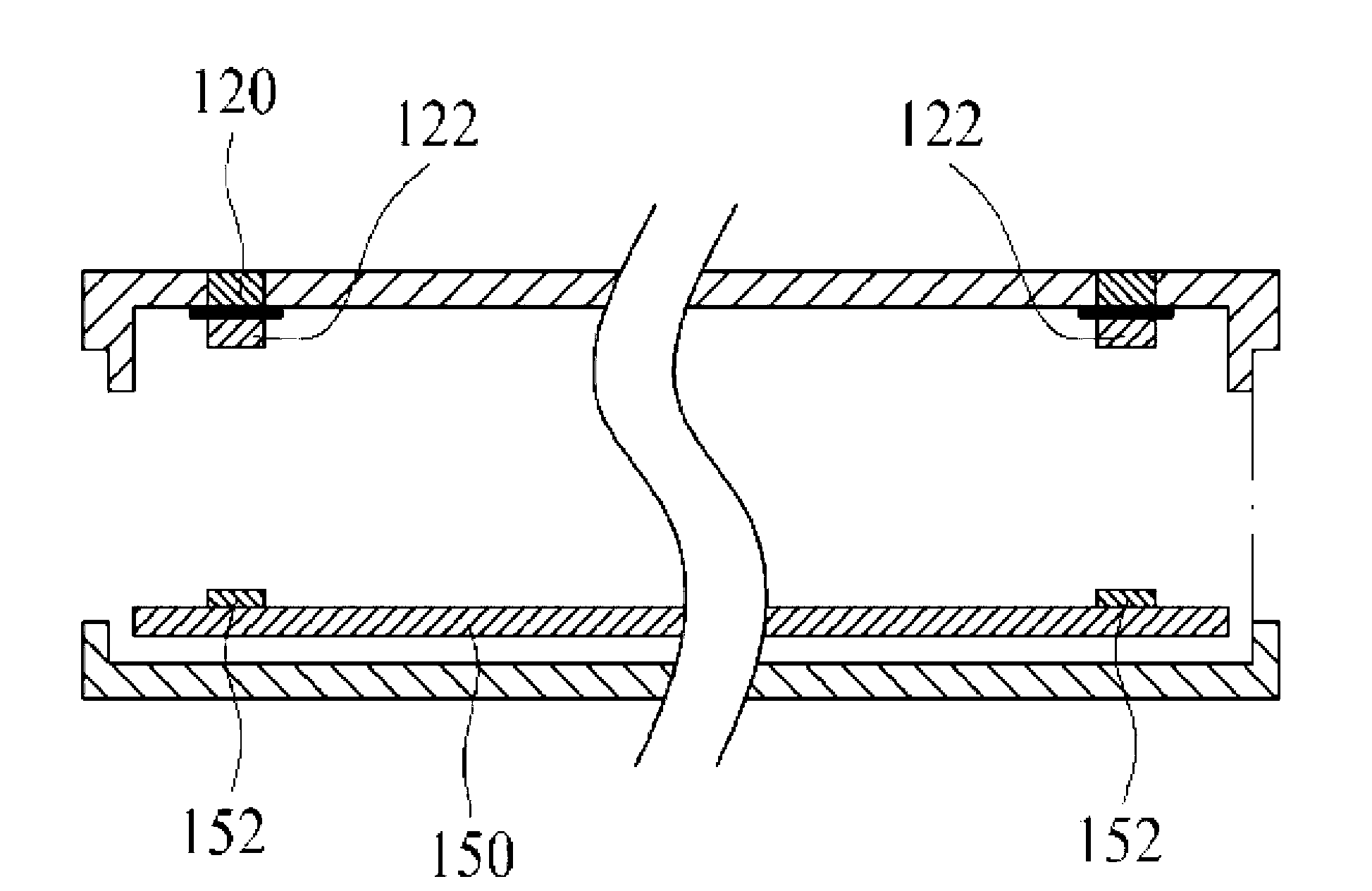

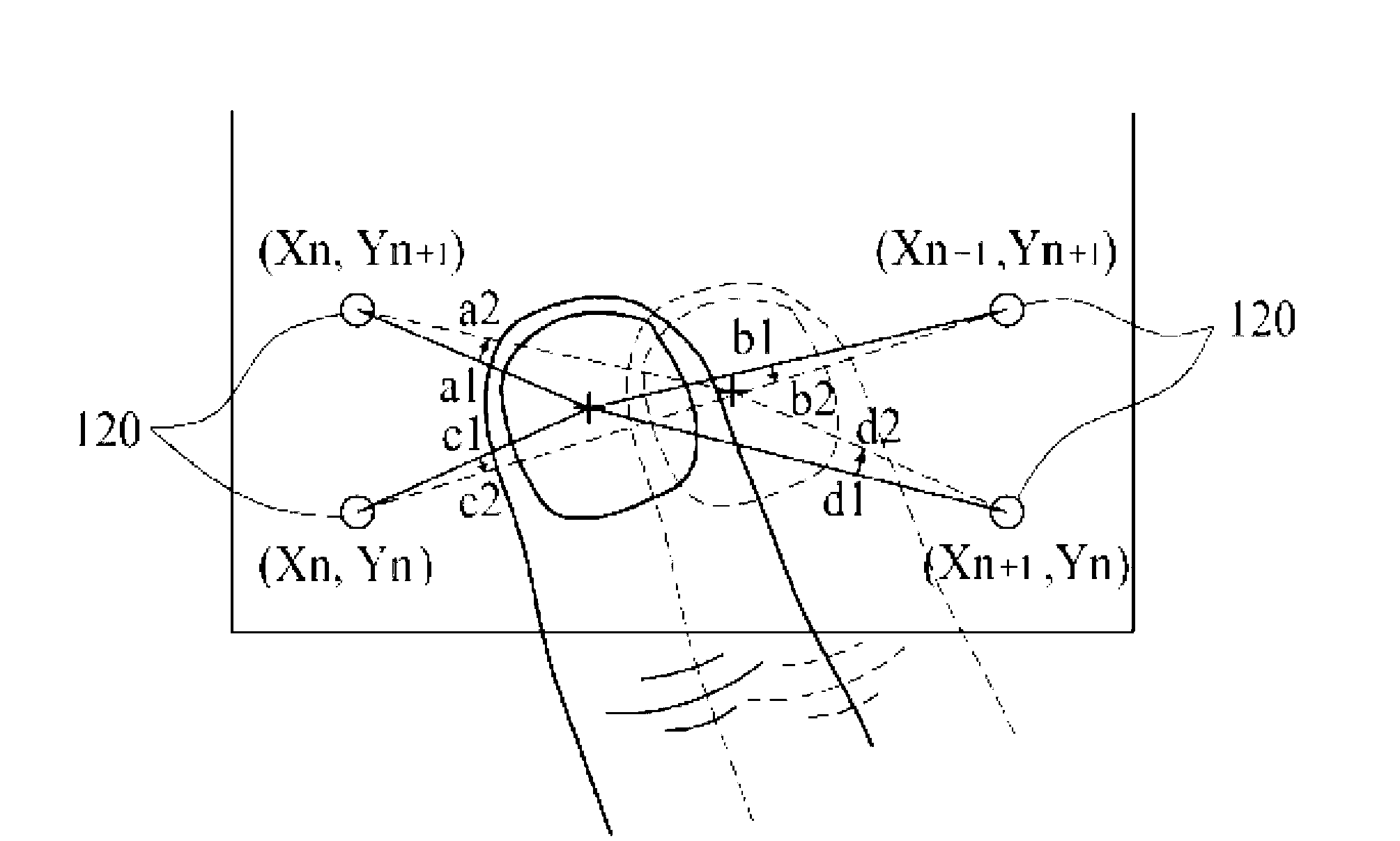

Device and method for detecting movement using proximity sensor

InactiveCN103052929AEasy to makeEasy to designInput/output for user-computer interactionProximity sensorTime difference

A device for detecting movement for detecting the movement of an object on a touch area comprises: three or more proximity sensors, which are two-dimensionally and separately arranged on the touch area, each of the proximity sensors for measuring electric scalars which correspond to the distance to the object on the touch area; and a control unit for calculating the vector of a second touch position, which is modified in relation to a first touch position, using a first electric scalar and a second electric scalar that are measured with a predetermined time difference therebetween, thereby calculating the movement of the object in terms of the vector to generate a movement signal.

Owner:EUMPLUS

Prefabricated concrete structure connecting method

InactiveCN107254912ADoes not affect thicknessReduce decreaseBuilding reinforcementsRebarInternal forces

The invention relates to a prefabricated concrete structure connecting method, which comprises the following steps that (1) a steel bar internal force converter is manufactured; (2) a steel bar is connected with one end of the steel bar internal force converter; (3) the steel bar and the steel bar internal force converter are positioned in a component according to design requirements; an anti-shearing groove is formed in the connecting end surface of the component; and concrete is cast to form a prefabricated component; (4) a connecting screw bolt between the steel bar internal force converters is selected; (5) when the manufacturing of the prefabricated components is completed and the prefabricated components are conveyed to a construction site to be installed, the connecting end surfaces of the two prefabricated components are attached and aligned; and at the time, the end surfaces of the steel bar internal force converters on the two prefabricated components are all attached and aligned; and (6) the screw bolt passes through a screw bolt connecting hole formed in each steel bar internal force converter and is tightened to the preset torque; and after all steel bar internal force converters are sequentially connected through the screw bolt, the two prefabricated components are also connected together. The invention provides the prefabricated concrete structure connecting method with the advantages that the process is simplified, and the reliability is high.

Owner:应义淼

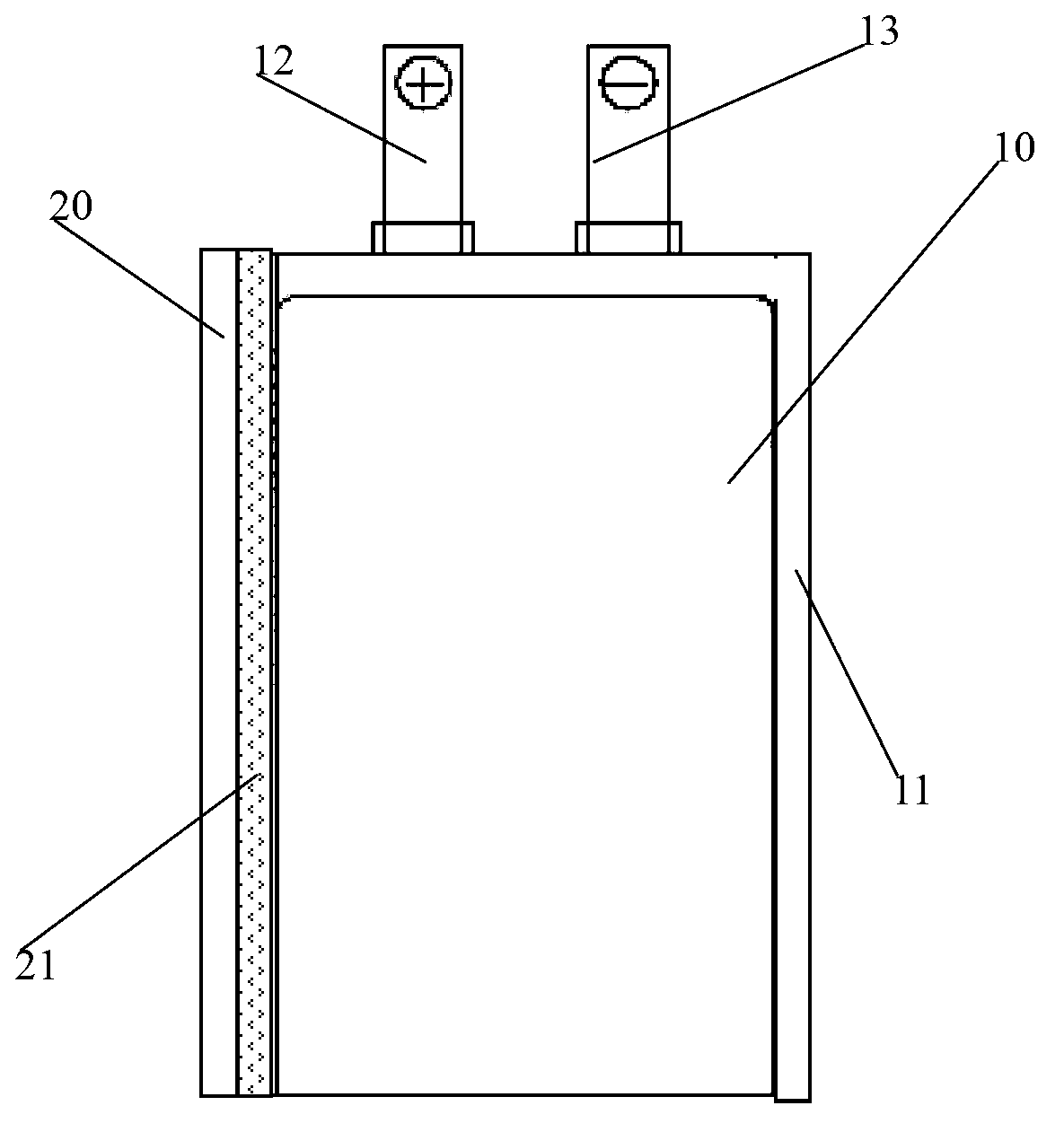

Portable electronic device

InactiveCN101888420ADoes not affect thicknessGood touchEmergency casingsElectric switchesCantileverElectrical and Electronics engineering

The invention provides a portable electronic device which comprises a body, a key structure and a cover body, wherein the cover body is slidably installed on the body, the key structure comprises at least one key, the key comprises a touch surface, the body is provided with a through slot for containing the key and a cantilever arranged in the through slot, the cantilever is used for elastically clamping the key in the through slot, and the touch surface is formed in the way that when the cover body slides relative to the body, the key slides in the through slot in the direction vertical to the sliding direction of the cover body, so that the key extends out of or is contained in the body.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

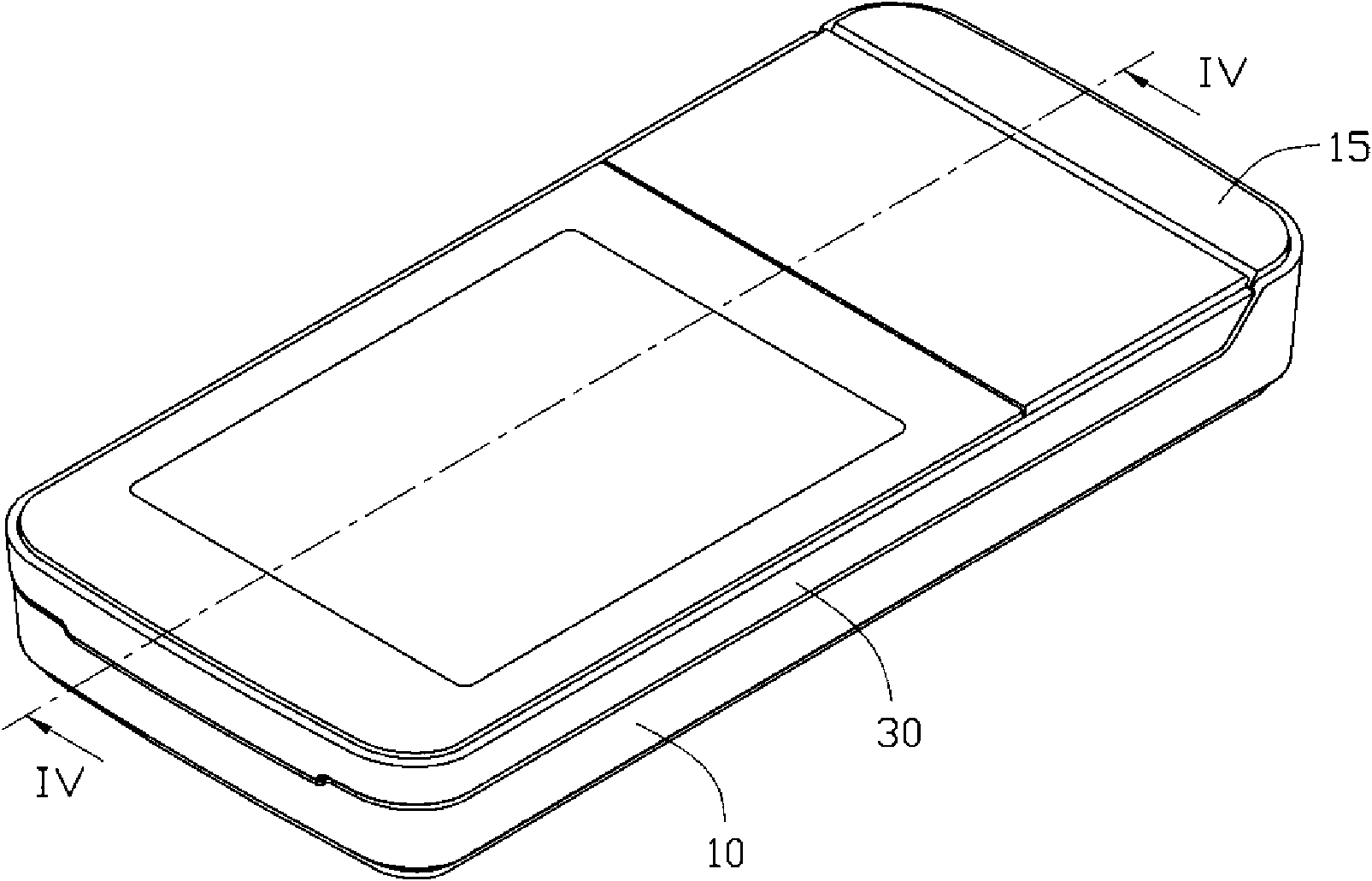

Side edge folding method of lithium ion battery

InactiveCN103022567ASmall sizeIncrease energy densityFinal product manufactureElectrolyte accumulators manufactureEnergy densityLithium electrode

The invention discloses a side edge folding method of a lithium ion battery. The side edge folding method comprises the following steps of: 1) adhering a side edge adhesive tape on the upper surface of the side edge of the lithium ion battery; 2) bending the single-side wrapped adhesive tape downwards to the lower surface of the side edge of the lithium ion battery so as to wrap the cross section of the side edge of the battery; 3) rolling the side edge adhesive tape adhered to the upper and lower surfaces of the side edge of the battery so as to eliminate bubbles in the adhesive tape; 4) respectively preheating the upper and lower surfaces of the side edge of the battery by using upper and lower preheating blocks; 5) rotating the lower preheating block so as to vertically bend the side edge of the battery towards a battery body, and adhering a double-surfaced adhesive tape to the side edge of the battery body; and 6) performing hot ironing on the two side surfaces of the battery, and performing the battery side edge treatment after the hot ironing is accomplished. By utilizing the side edge adhesive tape adhering process of the lithium ion battery, the side edge is firmly adhered to the battery body, so that the battery is prevented from opening when being stored and used, and moreover, an aluminum plastic shell is prevented from metal leakage; and not only is the size of the battery in the thickness direction saved, but also the energy density of the battery is increased.

Owner:TIANJIN LISHEN BATTERY

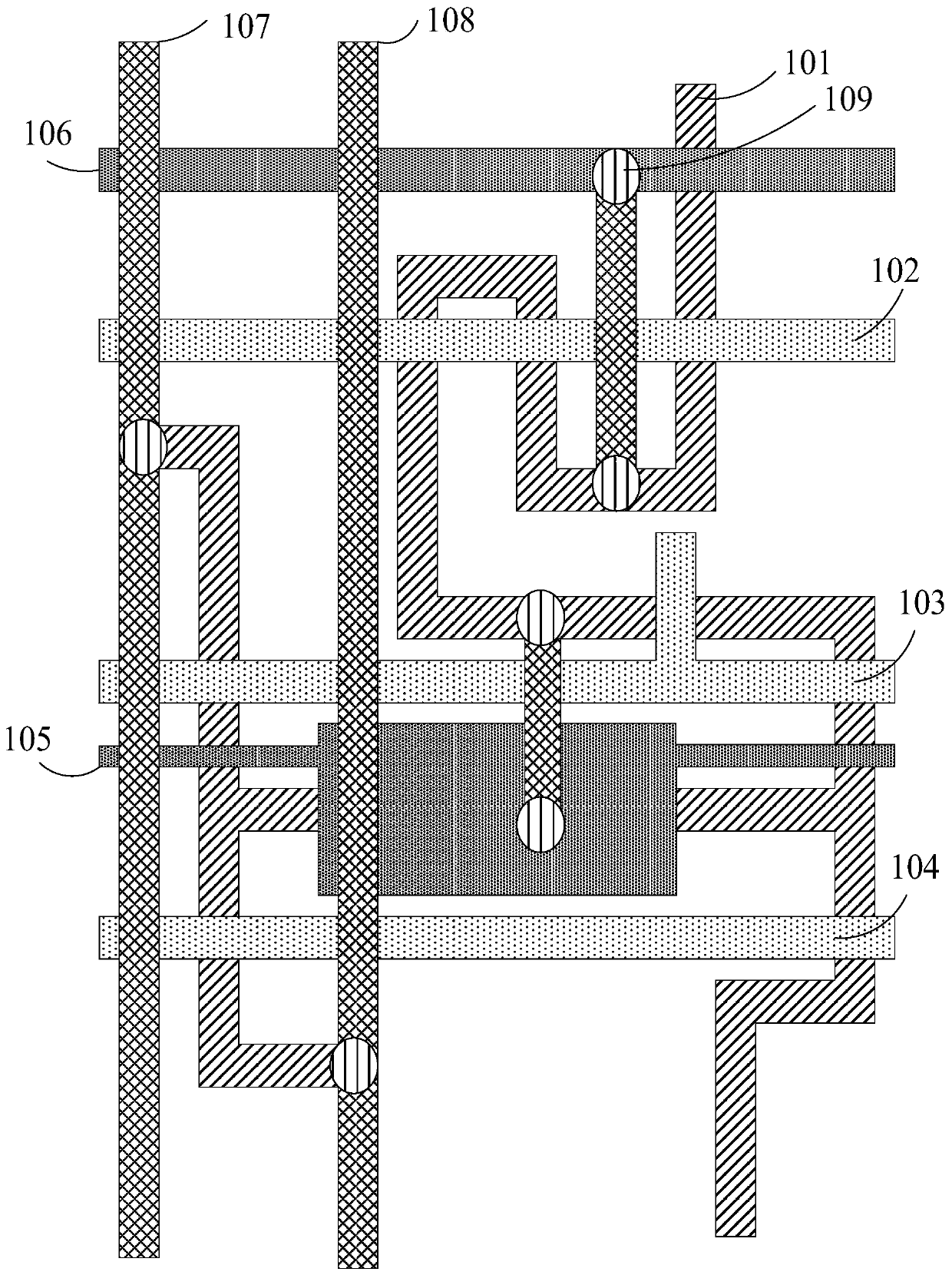

Array substrate and display panel

PendingCN111129093ADoes not affect thicknessAlleviating technical problems of uneven brightnessSolid-state devicesSemiconductor devicesVoltage dropEngineering

The invention provides an array substrate and a display panel. According to the array substrate, a first power supply voltage line is formed on a second metal layer of the array substrate, a first viahole is formed in the interlayer insulating layer, a first power supply voltage line on the second metal layer is connected with a second power supply voltage line of the source-drain electrode layerthrough a first via hole, at least two connections exist between the first power supply voltage line and the second power supply voltage line, parallel connection of the first power supply voltage line and the second power supply voltage line is ensured, therefore, the impedance of the power supply voltage line is reduced, the problem of voltage drop on the power supply voltage line is relieved,a film layer does not need to be added, the thickness of the display panel is not influenced, and the technical problem of uneven brightness of the display panel due to the voltage drop on the power supply voltage signal line of an existing display panel is relieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Dry unilateral-stretching production technology of lithium battery separator

InactiveCN111391267AHigh crystallinityHigh tensile strengthCell component detailsPhysical chemistryPolypropylene

The invention relates to the technical field of lithium battery separators and provides a dry unilateral-stretching production technology of a lithium battery separator. The dry unilateral-stretchingproduction technology of the lithium battery separator solves the problem that the hole size distribution of a lithium battery separator produced in the prior art is uneven. The dry method unilateralstretching production technology of the lithium battery separator comprises the following steps of (1) preparing materials, wherein polypropylene and ethylene-propylene copolymer are used as raw materials, pre-dried respectively and then put into a high-speed mixer to be stirred to uniform; (2) conducting melt extrusion, wherein the evenly mixed raw materials are fed into an extrusion machine andplastified into uniform melt, and the uniform melt is extruded from a slit die; (3) conducting tape casting film formation, wherein the melt undergoes tape casting and then forms a polypropylene basefilm, and the polypropylene base film undergoes traction and coiling; (4) conducting annealing treatment, wherein the coiled polypropylene base film is placed in a drying box to undergo annealing treatment; (5) conducting unilateral stretching, wherein the annealed polypropylene base film undergoes cold stretching and hot stretching; and (6) conducting heat setting, wherein heat setting is conducted on the polypropylene base film completing unilateral stretching, and after cooling and coiling, the lithium battery separator is obtained.

Owner:石狮申泰新材料科技有限公司

Corrosion-resistant treatment process of outer surface of nodular cast iron pipe

ActiveCN104214469AAvoid damageAvoid destructionCorrosion preventionPipe protection against corrosion/incrustationCement mortarZinc

The invention discloses a corrosion-resistant treatment process of an outer surface of a nodular cast iron pipe, particularly relates to a corrosion-resistant treatment process of an outer surface of a nodular cast iron pipe, and aims at providing the corrosion-resistant treatment process of the outer surface of the nodular cast iron pipe with the advantages of improvement of corrosion-resistant property of the outer surface of the nodular cast iron pipe and prolonging of the service life of a pipeline. The corrosion-resistant treatment process of the outer surface of the nodular cast iron pipe comprises the following steps of annealing, finishing and grinding, water pressure test, coating of a cement mortar lining, steam curing of the cement mortar lining, grinding of the cement mortar lining, preheating of the pipeline, treatment of the outer surface of the pipeline, spraying of a sacrifice anode protecting coating, sealing of holes and spraying of a finishing layer, solidifying of the finishing layer, spraying of markers, and packaging and shipping. The new process has the beneficial effects that the problems of damage to the sacrifice anode protecting coating in the production procedure and consumption of active metal of the coating caused by the steam curing are solved, the attaching capability of the sacrifice anode protecting coatings, such as zinc layers, is improved, the corrosion-resistant property of the outer surface of the nodular cast iron pipe is improved, and the service life of a pipeline is prolonged.

Owner:XINXING DUCTILE IRON PIPES CO LTD

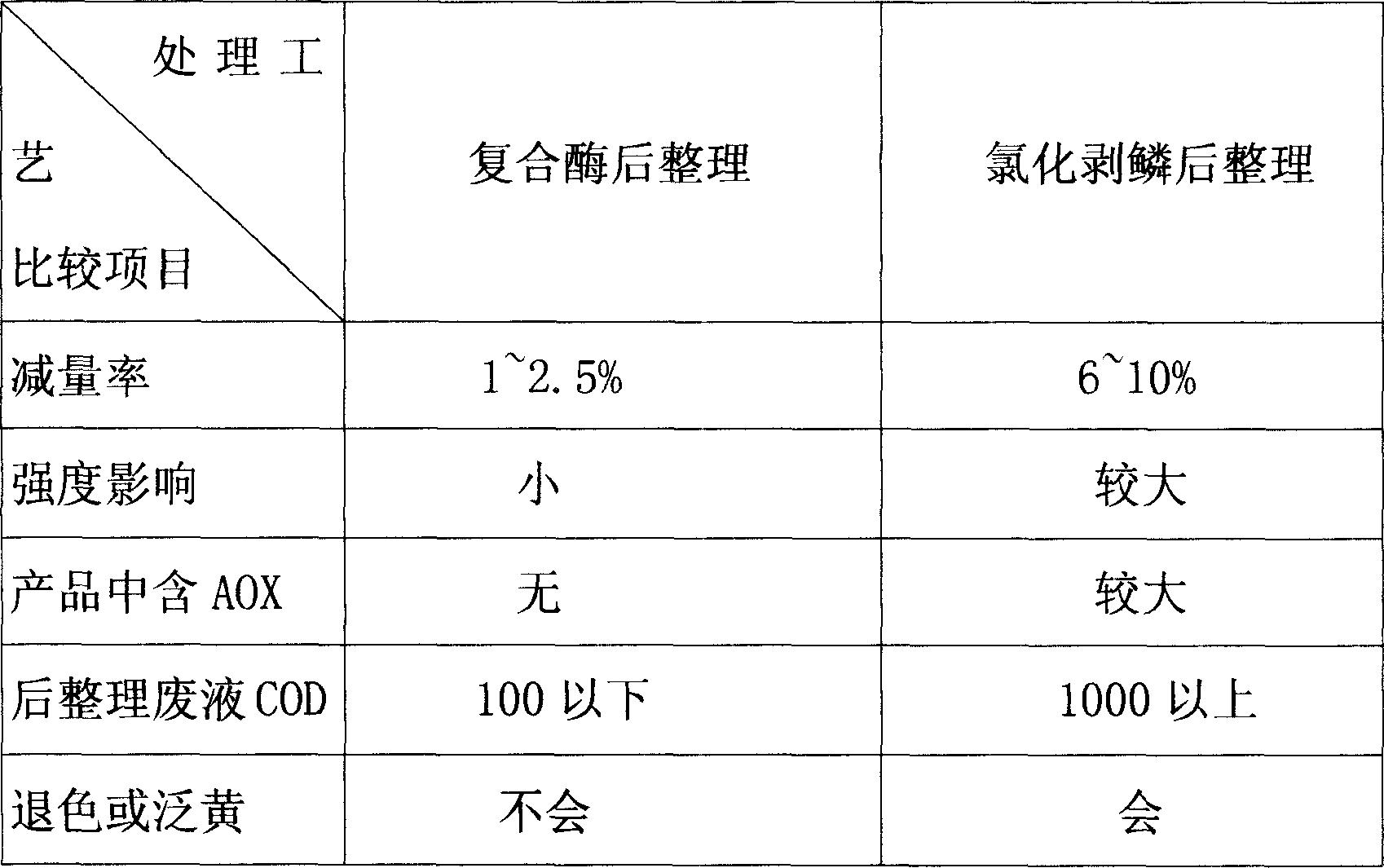

Method for preparing complex enzyme for wool fabric post-treatment

InactiveCN1710070AIn line with the development trend of green finishingDoes not affect strengthEnzymesFermentationEnzyme

The invention involves the preparation method of the compound enzyme tidy up wool fabric which is made through slant culture, fermentation, shocking culture and filtering. Because the enzyme is a kind of biological enzyme preparation, so the wool sweater after being scaled will not contain AOX. As it has good specifity to wool protein, so the wool reduction quantity is just 1-2.5% which basically not influence the intensity and thickness of the wool sweater. Using the compound enzyme to scale under pH=3.0-5.0 acid conditions, the wool sweater will not fade and become yellow.

Owner:浙江雀屏纺织化工有限公司

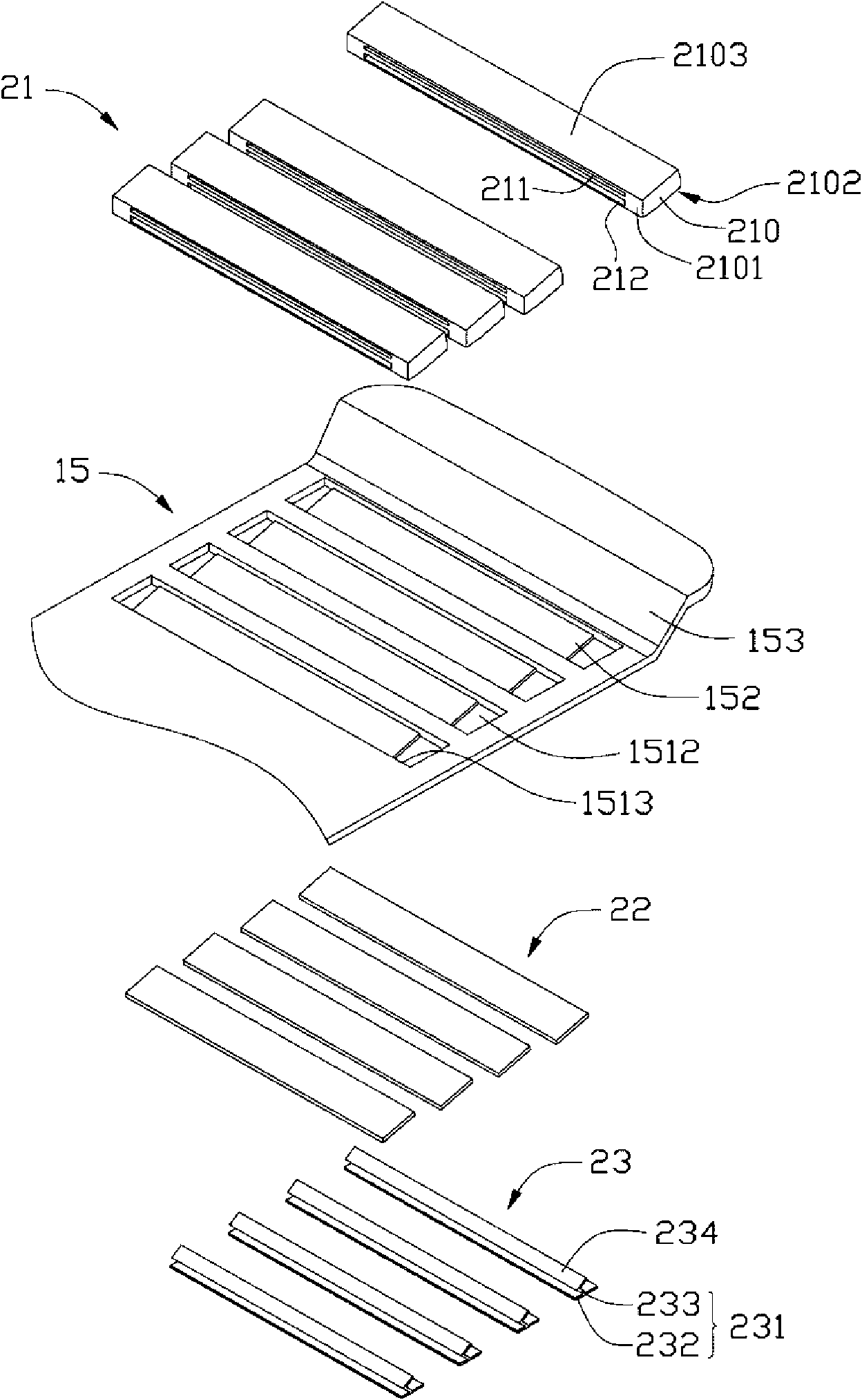

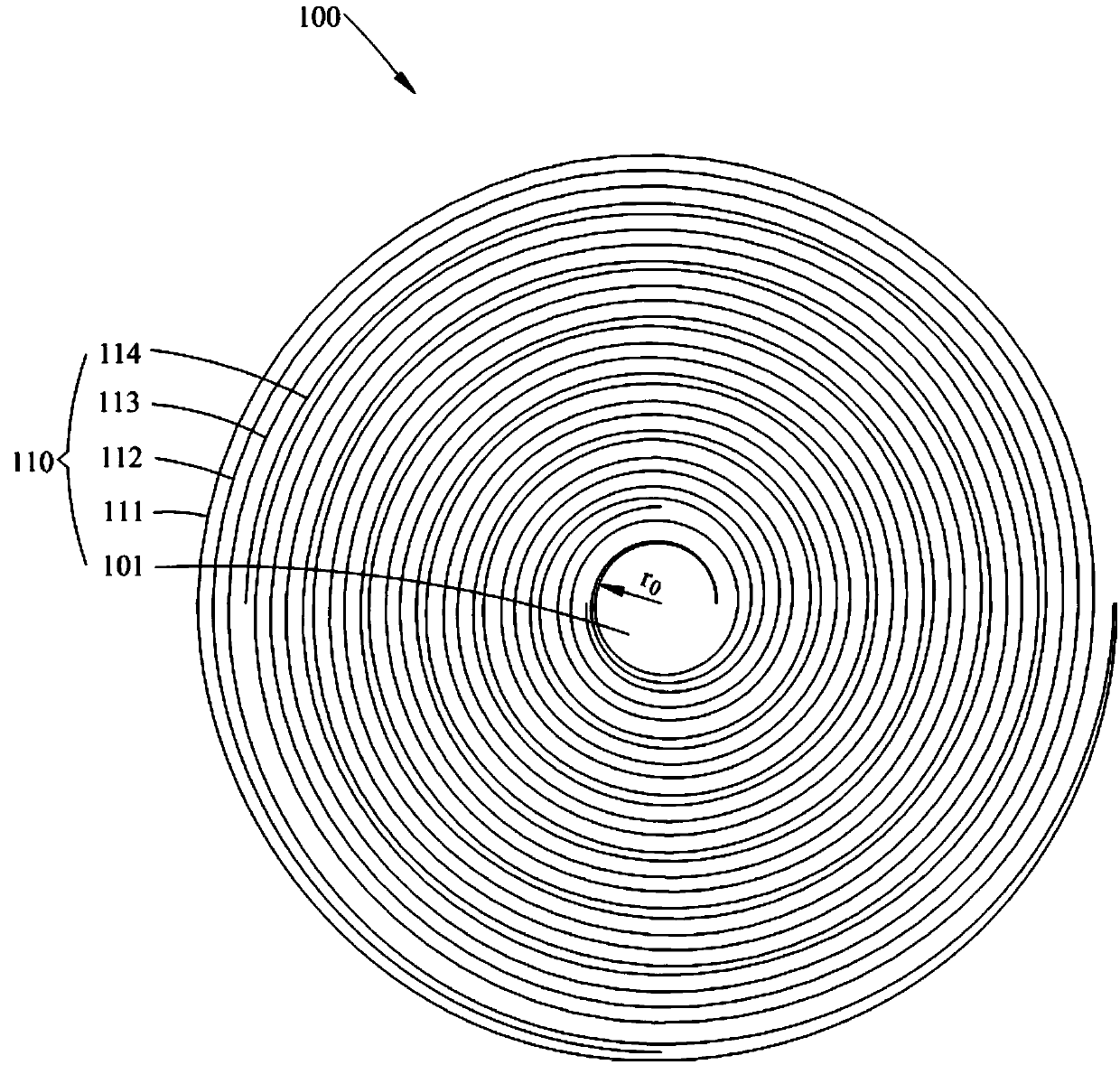

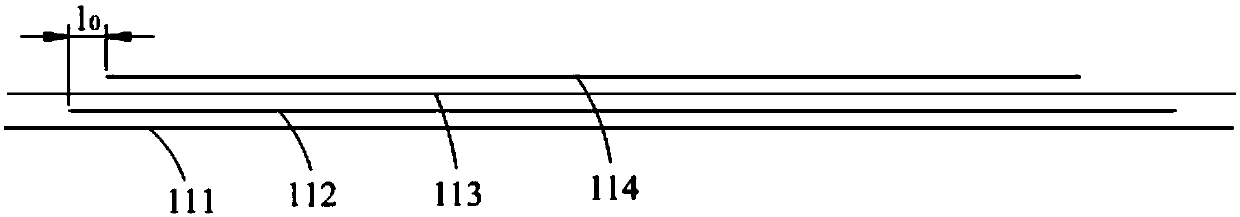

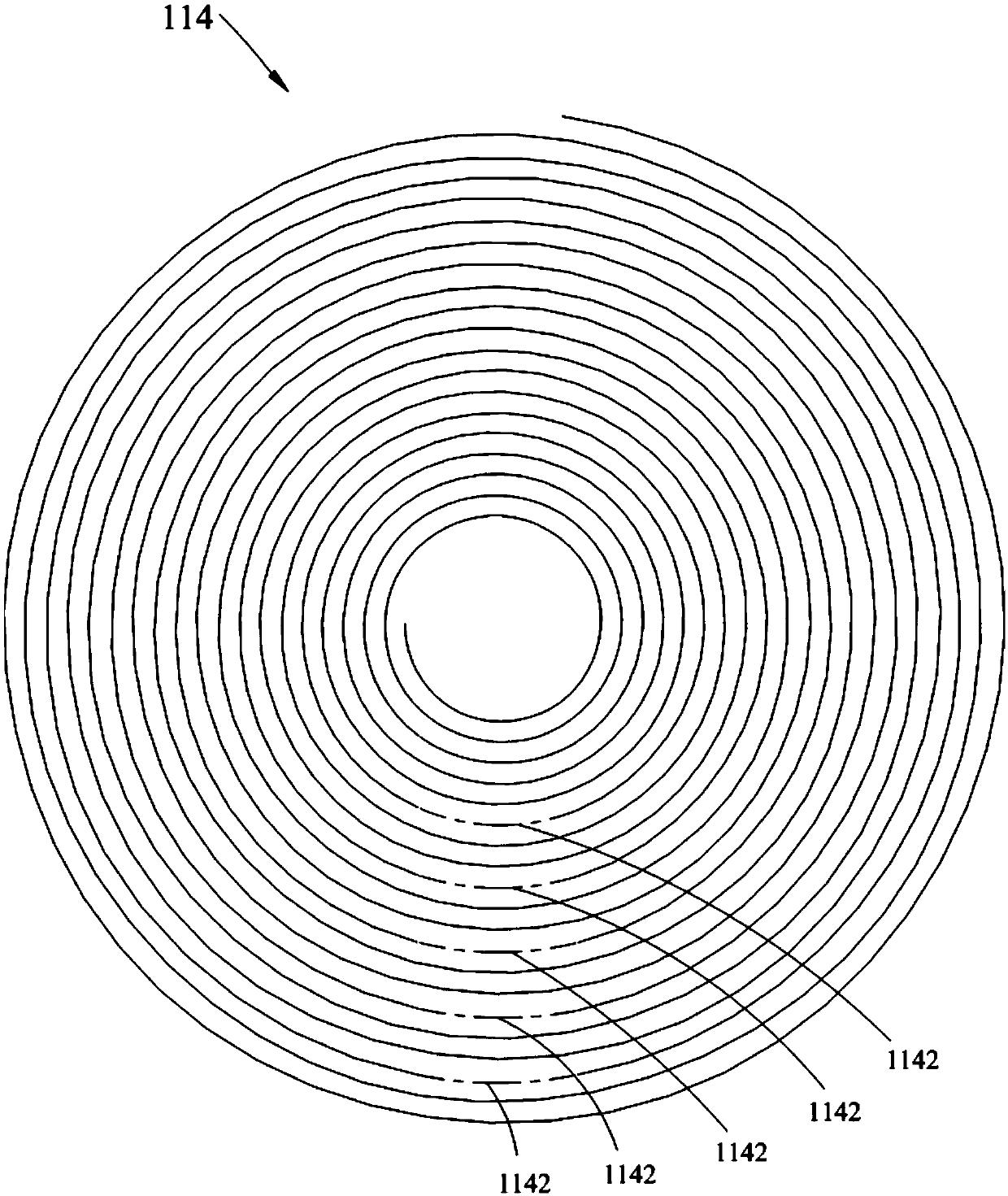

Battery core and method for manufacturing battery core, and lithium ion battery

PendingCN109659480AImprove cylindricityMeet the requirements of high rate charge and discharge performanceFinal product manufactureSecondary cellsEngineeringLithium-ion battery

The invention is applicable to the field of lithium ion batteries, and discloses a battery core and a method for manufacturing a battery core, and a lithium ion battery. The battery core comprises a core body having a hollow inner hole, and the core body comprises a first diaphragm, a negative electrode sheet, a second diaphragm and a positive electrode sheet. The positive electrode sheet comprises a positive electrode metal substrate, positive electrode ears and a positive electrode coating layer coating the positive electrode metal substrate. The negative electrode sheet comprises a negativeelectrode metal substrate, negative electrode ear and a negative electrode coating layer coating the negative electrode metal substrate. There are at least two positive electrode ears and negative electrode ears, and the positive electrode ears are located at the same side of the hollow inner hole in the radial direction of the core body, the negative electrode ears are located at the same side of the hollow inner hole in the radial direction of the core body, each positive electrode ear is integrated with the positive electrode metal substrate, and each negative ear is integrated with the negative electrode metal substrate. The coating areas of the coating layers on the pole sheets are added to improve the capacity of the lithium ion battery and improve the cylindricity of the battery core.

Owner:SHENZHEN ZHUONENG NEW ENERGY TECH

Novel smart phone with imaging spectrum detection function and spectrum detection method thereof

InactiveCN111464700AReal-time online detectionFast online detectionColor/spectral properties measurementsTelephone set constructionsEngineeringPhotoelectric conversion

The invention discloses a novel smart phone with an imaging spectrum detection function and a spectrum detection method. The novel intelligent mobile phone with the imaging spectrum detection functioncomprises a light source, an optical lens, an imaging spectrum module, an electronic assembly, a transmission assembly and a PCB mainboard which are arranged in a mobile phone shell, wherein the light source is electrically connected with the PCB mainboard, the PCB mainboard is electrically connected with the transmission assembly, the transmission assembly is electrically connected with the electronic assembly, the electronic assembly is electrically connected with the imaging spectrum module, the optical lens is clamped on the imaging spectrum module, and the imaging spectrum module comprises a micro lens array, a spectrum modulation film layer and a photoelectric conversion part. The spectrum modulation film and the photoelectric conversion part are combined to form the imaging spectrum module, real-time, rapid and online detection of the spectrum of the to-be-detected substance is achieved through the smart phone, operation is easy in the detection application process, operation of professional technicians is not needed, and the system reliability is high.

Owner:JILIN QS SPECTRUM DATA TECH CO LTD

Horizontal low temperature container and liquid level measurement device thereof

ActiveCN103148910AVacuum interlayer thickness is smallIncrease volumeMachines/enginesLevel indicatorsExternal LiquidEngineering

The invention discloses a horizontal low temperature container and a liquid level measurement device thereof. The liquid level measurement device comprises a liquid-phase pipeline and a gas-phase pipeline, wherein the liquid-phase pipeline is divided into an external liquid-phase pipeline and an internal liquid-phase pipeline through a first leading-out joint; and the gas-phase pipeline is divided into an external gas-phase pipeline and an internal gas-phase pipeline through a second leading-out joint, the first leading-out joint is arranged in a position which is in the vertical central line of a rear sealing head of an inner container of the horizontal low temperature container and close to the lowest point, and the second leading-out joint is arranged in a position which is in the vertical central line of a rear sealing head of the inner container of the horizontal low temperature container and close to the highest point. By utilizing the liquid level measurement device, the thickness of a vacuum interlayer can be reduced, and the reading of a liquid level meter is more accurate.

Owner:ZHANGJIAGANG CIMC SANCTUM CRYOGENIC EQUIP +1

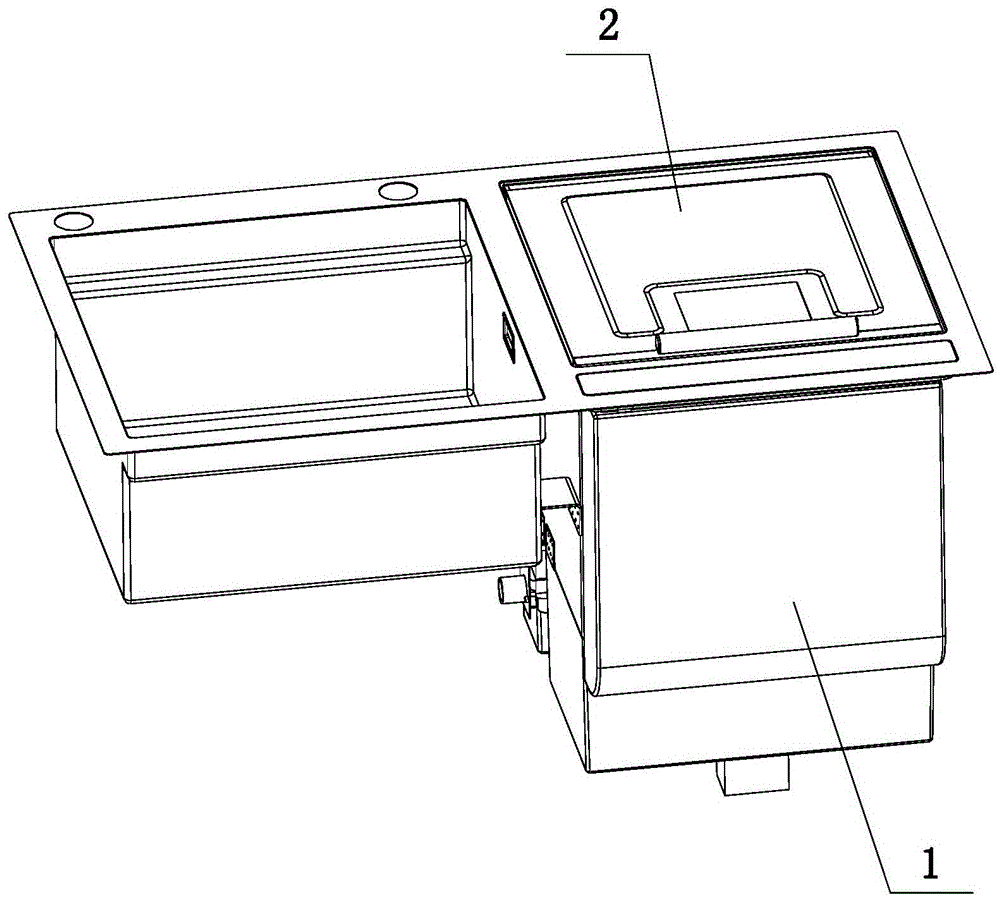

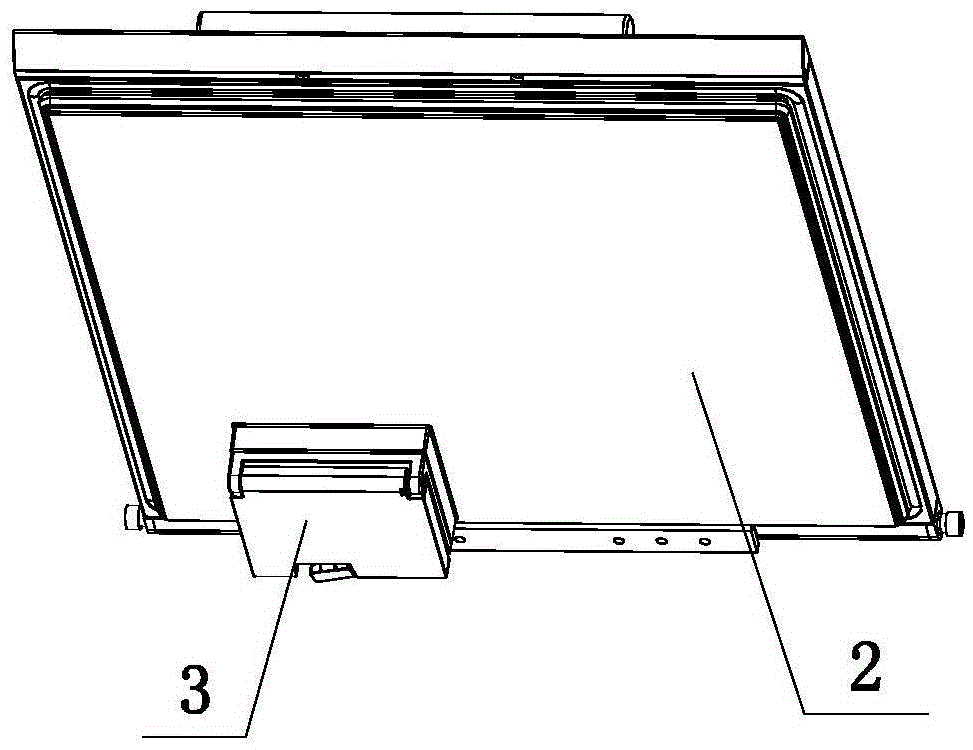

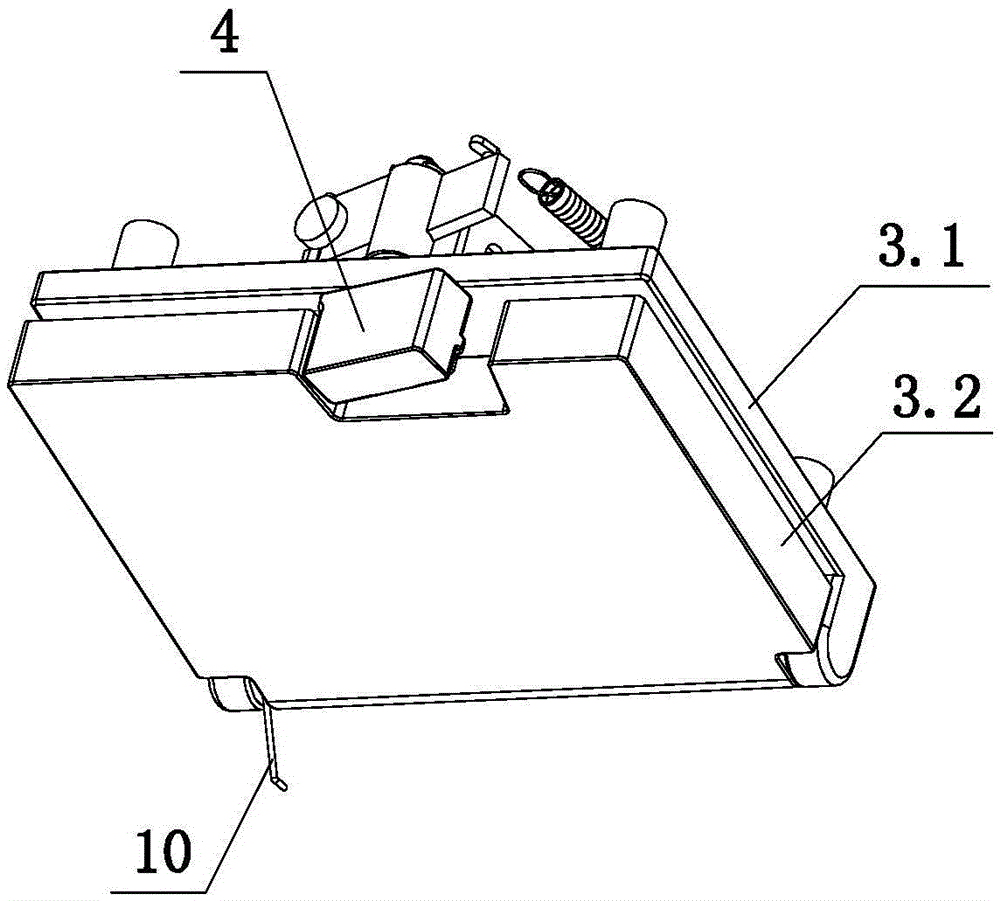

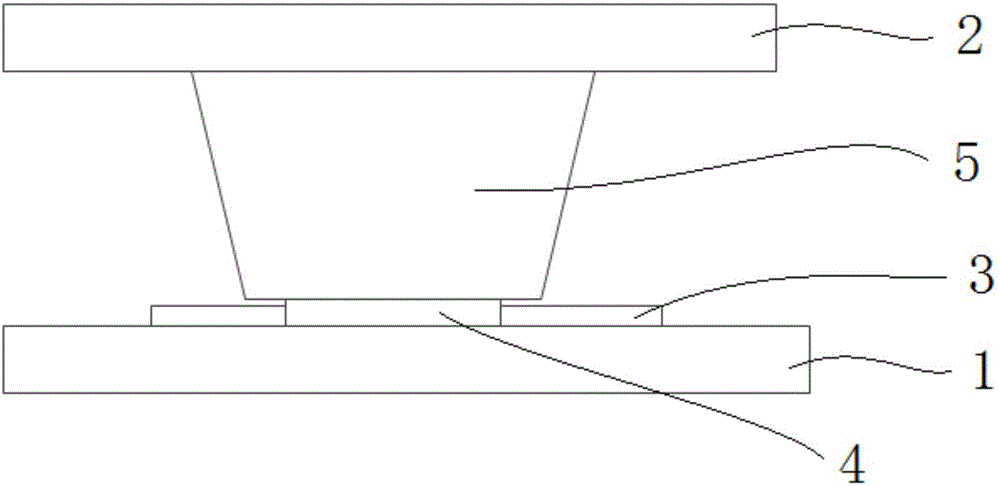

Cleaning agent adding device of sink type cleaning machine

ActiveCN105534461AOverall small sizeEasy to addTableware washing/rinsing machine detailsKitchen equipmentPulp and paper industryEngineering

The invention discloses a cleaning agent adding device of a sink type cleaning machine. The sink type cleaning machine comprises a sink body with the open upper end and a cover plate. The cover plate is arranged in the port of the sink body, and one end of the cover plate is hinged to one side of the port. The cleaning agent adding device comprises a box body, a flip cover and a driving module. The box body is arranged on the inner side wall of the cover plate and provided with a liquid storage cavity with a downward opening. One side of the flip cover is hinged to one side of the box body, and the flip cover seals the liquid storage cavity. Cleaning agents (comprising liquid detergents, solid detergents, rinse agents and the like) can be conveniently added into the cleaning agent adding device, the integrality of a table surface is not affected, the overall structure is compact, the cleaning agents can be smoothly poured into an inner cavity of the sink type cleaning machine to be mixed with washing water, and therefore the washing effect of the sink type cleaning machine is ensured.

Owner:NINGBO OULIN IND CO LTD

Graphene absorbing object and preparation method thereof

InactiveCN106890354AIncrease surface areaReduce contentAbsorbent padsBaby linensSurface layerFluff pulp

The invention relates to the field of sanitation supplies, and provides a graphene absorbing object and a preparation method thereof with an aim to solve problems about poor liquid absorption effect, slow liquid absorption speed and no antibacterial efficacy in the prior art. The graphene absorbing object comprises a permeable surface layer, an absorber and an impermeable bottom layer which are laminated sequentially from top to bottom, the absorber is formed by wrapping an absorbing core with non-woven fabric, and the absorbing core is formed by mixing fluff pulp, super absorbent polymer and graphene powder.

Owner:泉州信和石墨烯研究院有限公司

Built-in touch panel and display device

ActiveCN106773347AIncrease productivityDoes not affect thicknessNon-linear opticsInput/output processes for data processingLiquid-crystal displayDisplay device

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

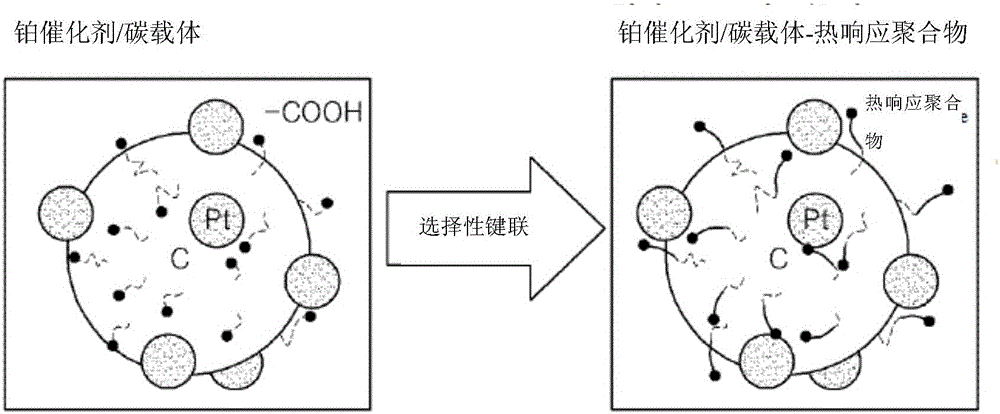

Electrode catalyst, method for preparing same, and membrane electrode assembly and fuel cell comprising same

InactiveCN104995774ASpeed up the flowImprove electrical performanceSolid electrolytesCell electrodesElectrochemical responseFuel cells

Owner:GLOBAL FRONTIER CENT FOR MULTISCALE ENERGY SYST +1

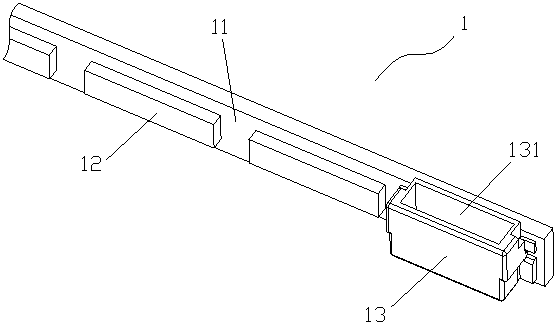

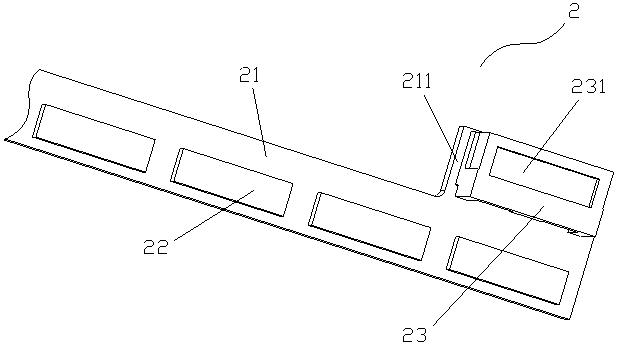

Novel LED lamp strip and liquid crystal module provided with same

ActiveCN103899993AExtreme narrow bezel effectMeet the design requirementsPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention relates to a novel LED lamp strip and a liquid crystal module provided with the same. The novel LED lamp strip comprises a strip-shaped PCB, a plurality of LEDs distributed at intervals are arranged on the surface of the PCB in the length direction of the PCB in a packaged mode, a wiring portion extends out of the side portion of the wiring end of the PCB in the width direction of the PCB, a wiring terminal is arranged on the surface of the wiring portion of the PCB, and the direction of the plug-and-pull port of the wiring terminal is perpendicular to the surface of the PCB. According to the novel LED lamp strip and the liquid crystal module provided with the same, the wiring terminal of the LED lamp strip is moved upwards, a viewing area is covered with the LEDs to the greatest extent, the narrow-bezel effect of the liquid crystal module is superlative, and design requirements of ultra-narrow-bezel models are met; in addition, the plug-and-pull direction of the wiring terminal of the LED lamp strip is changed to be perpendicular to the surfaces of the LEDs, and the overall thickness of a complete machine is not affected.

Owner:L&T DISPLAY TECH FUJIAN

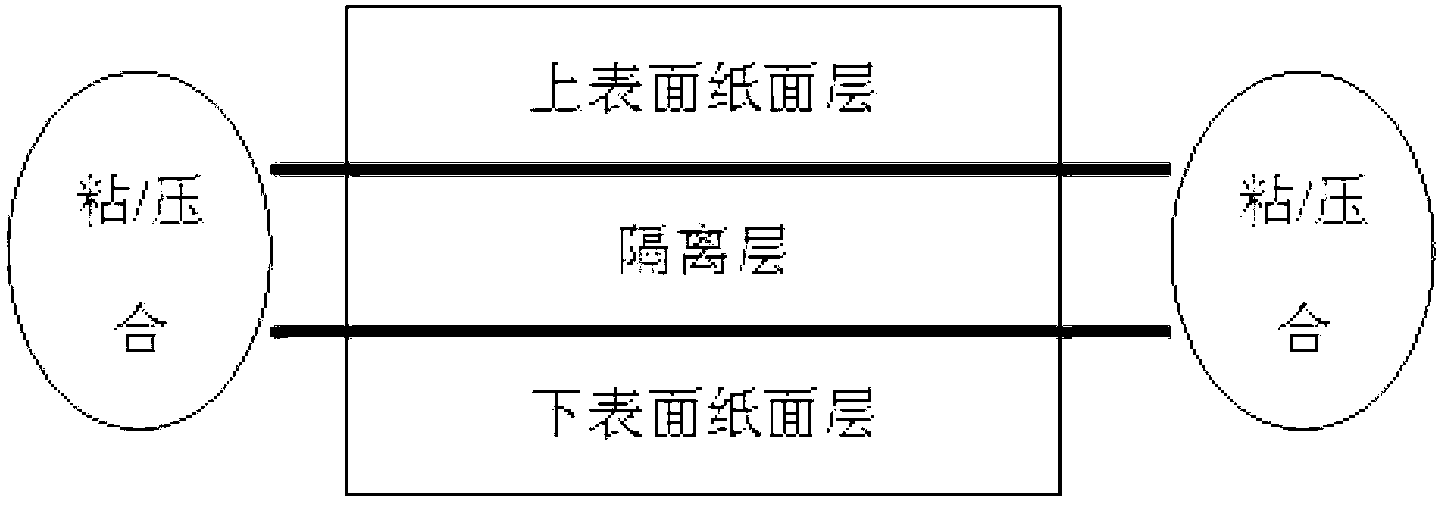

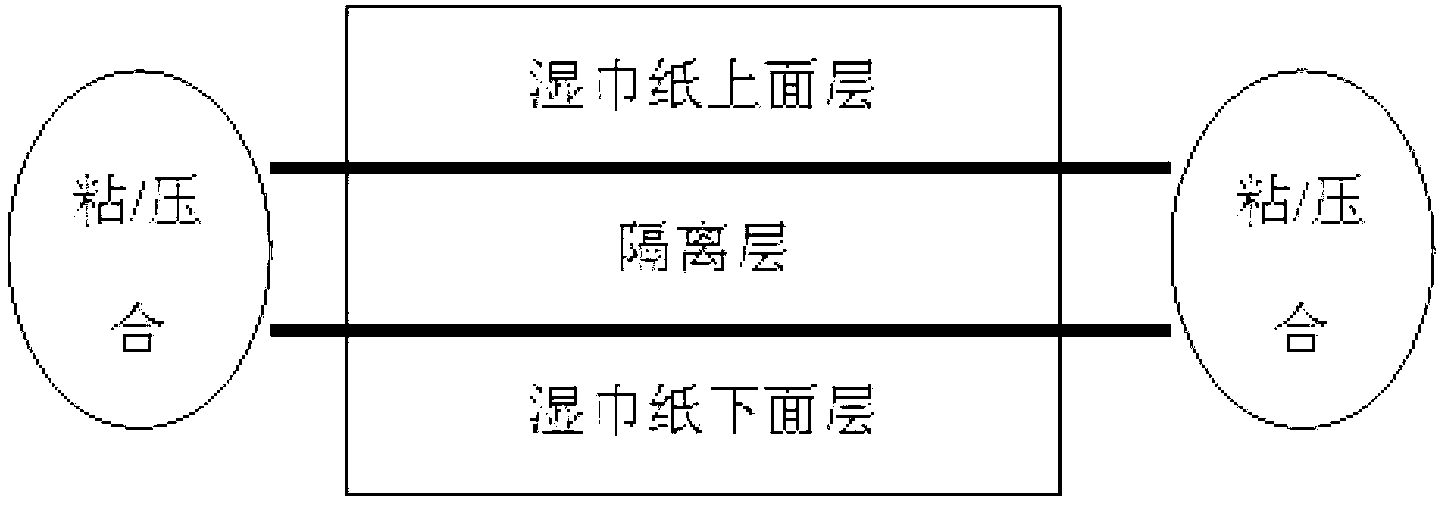

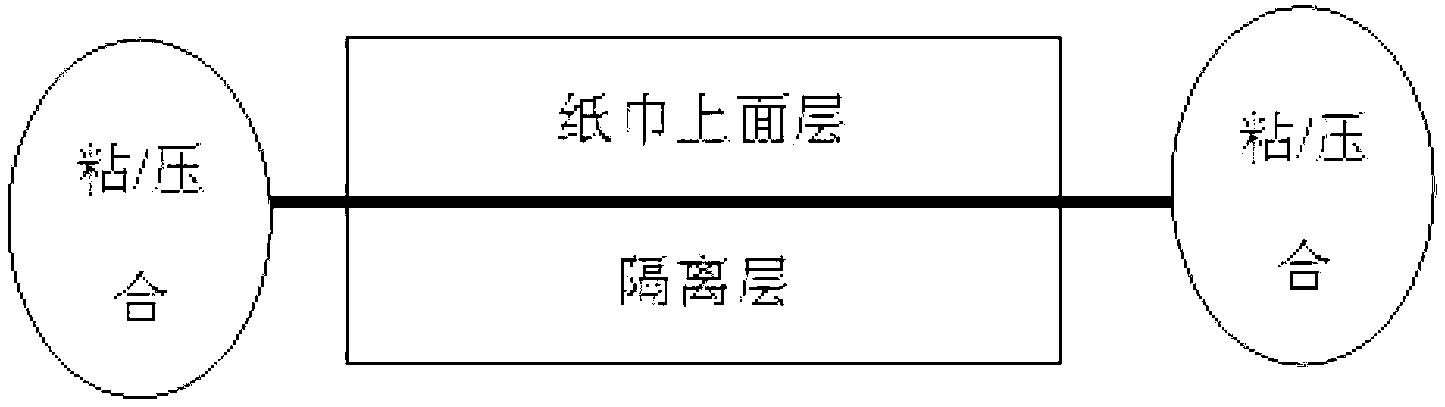

Processing method of interleaving paper product and interleaving paper

InactiveCN103255683ADoes not affect thicknessAffect normal useSurface covering paperLaminationPaper sheetFluorocarbon

The invention discloses a processing method of an interleaving paper product. The processing method comprises the steps of: mixing polyacrylate with a fluorocarbon chain to generate a waterproof agent, and after leaching an auxiliary assistant, drying to generate a waterproof membrane; after reacting various paper pulp or virgin pulp with a papermaking assistant, baking and pressing to generate a paper surface layer; and pasting or fixedly bonding an isolating layer with the paper surface layer to effectively prevent water seepage and the like. The production process is simple, and the isolating layer is of a thin film structure, so that the thickness of the paper product cannot be affected, the production cost cannot be increased, and a wide range of promotion and use is convenient; According to the interleaving paper towel provided by the invention, the problem of preventing water seepage of various facial paper towels, wet paper towels, toilet paper and pharmaceutical paper can be effectively solved, the normal use of the paper towels cannot be affected due to the damage to the paper surface layer in the using process, meanwhile, the single-sided use of double-sided paper towels (comprising the wet paper towels) is satisfied, the negative effects such as permeation cannot be produced on the unused other side, and the purpose of the use of the double-sided paper is truly achieved, so that resources are effectively saved, and the interleaving paper towel has a wide marketization prospect.

Owner:东莞市无极净化用品科技有限公司

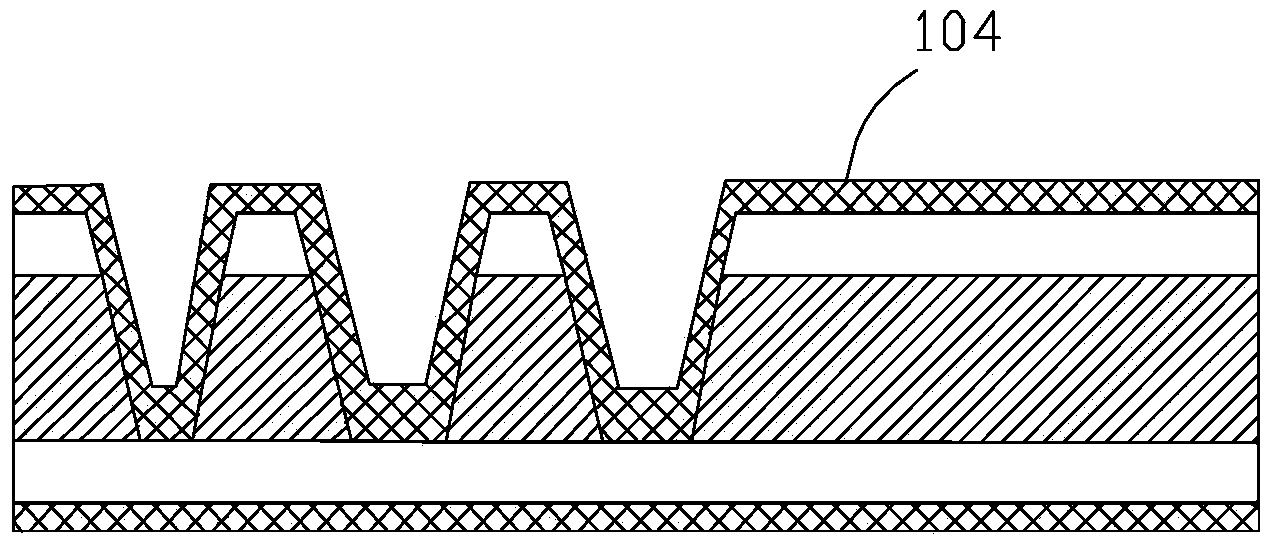

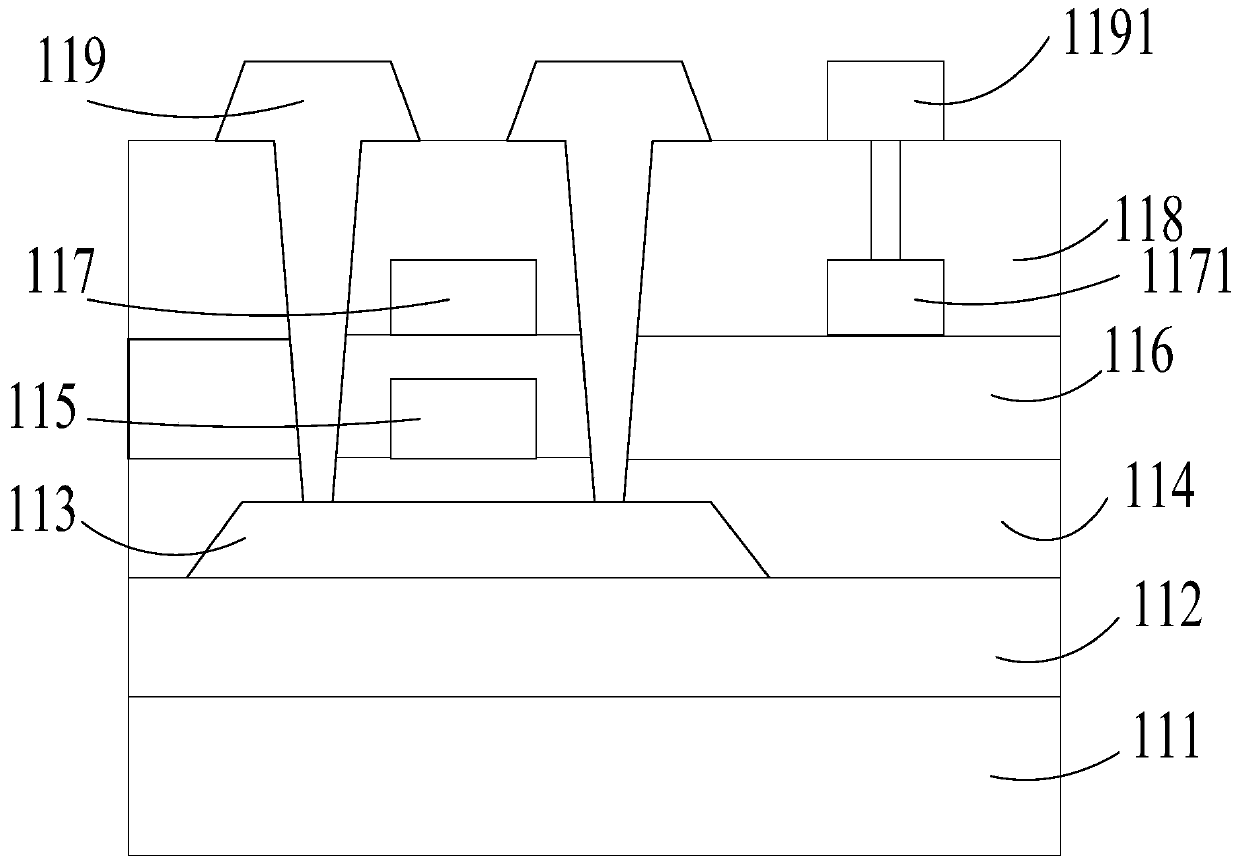

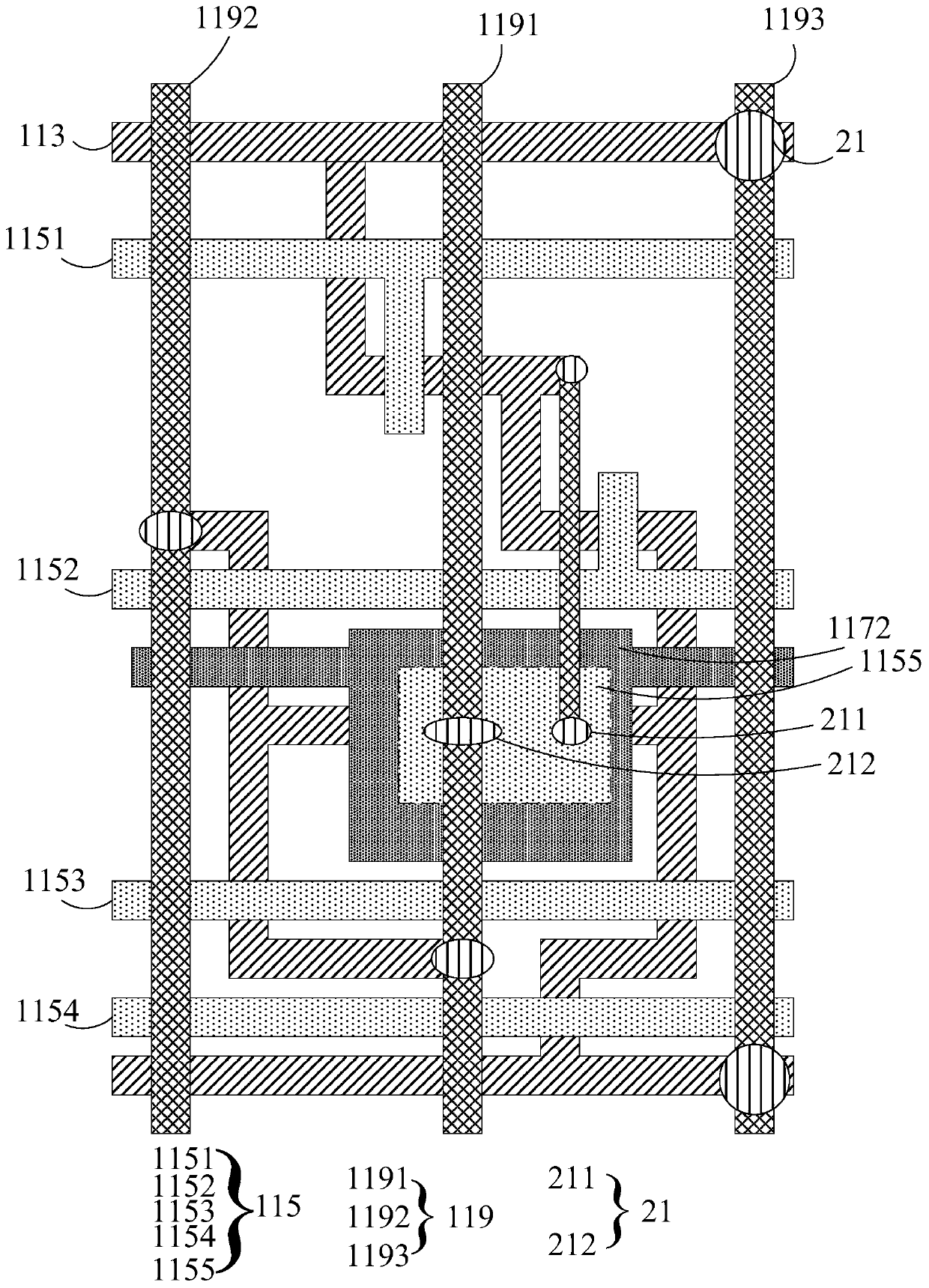

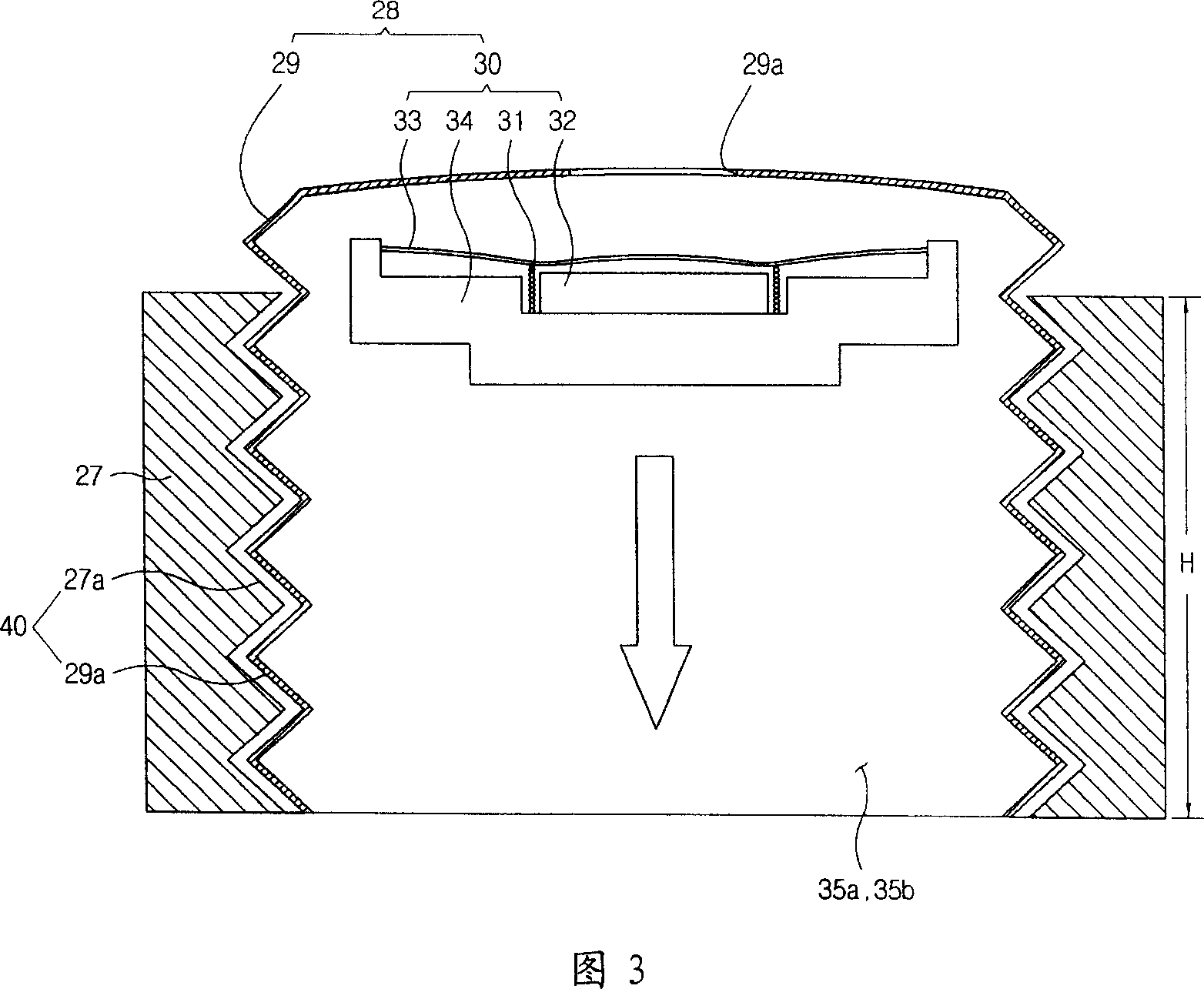

An MEMS bridge structure and a forming method thereof

InactiveCN109928357AReduce warpageAvoid warpingTelevision system detailsImpedence networksComposite filmSilicon oxide

The invention provides an MEMS bridge structure and a forming method thereof. The MEMS bridge structure comprises a substrate and a titanium-containing thin film layer located on the substrate, a silicon oxide film layer located on the titanium-containing film layer, and a composite film layer located on the silicon oxide film layer. The forming method of the MEMS bridge structure comprises the steps that a substrate is provided, and a titanium-containing thin film layer is formed on the substrate; a silicon oxide film layer is formed on the titanium-containing film layer; and a composite filmlayer is formed on the silicon oxide film layer. The stress of several films is neutralized by controlling the stress of the bridge structure: the films with multiple reaction stresses are added to be applied to the process with the bridge structure in the MEMS process, so that the bridge warpage caused by release of the bridge structure can be effectively reduced, and the subsequent packaging test is influenced. The thickness of the whole bridge structure is not affected, and meanwhile alignment of the follow-up photoetching process and control over a follow-up etching channel are facilitated. Due to the adoption of various composite films, the stress of the films is neutralized by the multilayer films, and the bridge is prevented from warping.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Mobile communication terminal with exterior protrusion speaker

InactiveCN1956465ADoes not affect thicknessEnhanced BassSubstation speech amplifiersRadio/inductive link selection arrangementsMethod selectionEngineering

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com