Method for preparing complex enzyme for wool fabric post-treatment

A compound enzyme and finishing technology, applied in the directions of biochemical equipment and methods, enzymes, enzymes, etc., can solve problems such as the unsatisfactory effect of wool scales, and achieve the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

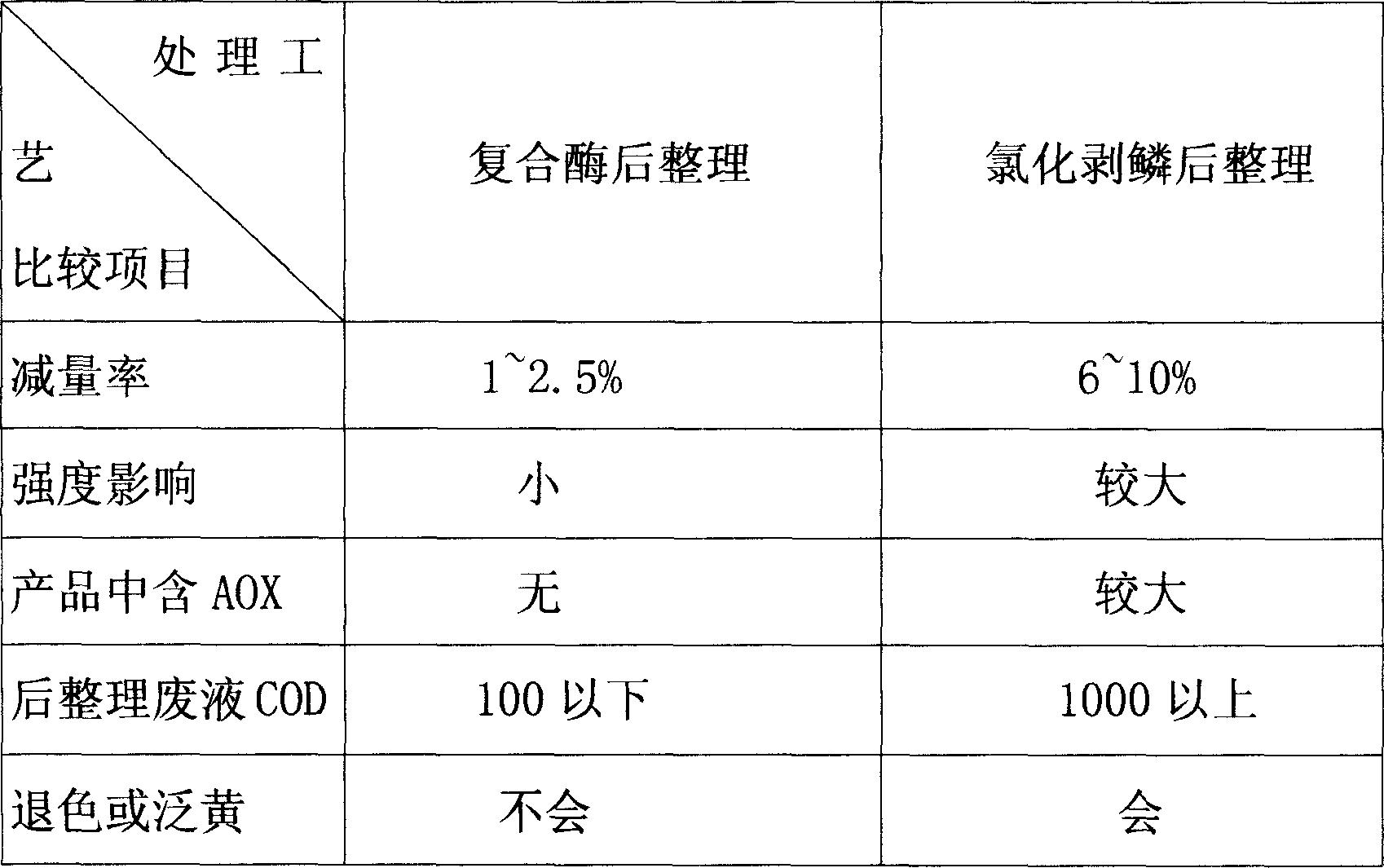

Image

Examples

Embodiment 1

[0016] Wool Example 1: Preparation of Compound Enzymes

[0017] Composite enzyme producing bacteria—→Culture on slant, add 0.5% wool powder to the medium—→Pick out high-incidence strains after cultivation—→Fermentation culture medium: 5% soybean flour, 1.0% corn flour, 1.0% fish meal, CaCL20 .5%, NH4CL 0.5%, Na2HPO4 1.0%, wool powder 0.5%, and the rest is water, at a temperature of 30°C and a shaker speed of 200 rpm, shaking culture for 88 hours—→fermentation broth coarse filtration—→filtrate separation , at 3000 rev / min, 10 minutes—→get compound enzyme liquid.

[0018] The composite enzyme prepared according to the above method is used for scale removal and post-finishing, such as taking a woolen sweater sample——→pretreatment, that is, 30% concentration of H 2 o 2 30ml / L, Na 2 CO 3 0.2%, Na 2 SO 3 0.7%, JFC 3%, bath ratio 1:25, treatment at 50°C for 35-40 minutes—→add H2O2 compound enzyme to remove excess H2O2—→water washing—→dehydration—→compound enzyme treatment: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com