Electrode catalyst, method for preparing same, and membrane electrode assembly and fuel cell comprising same

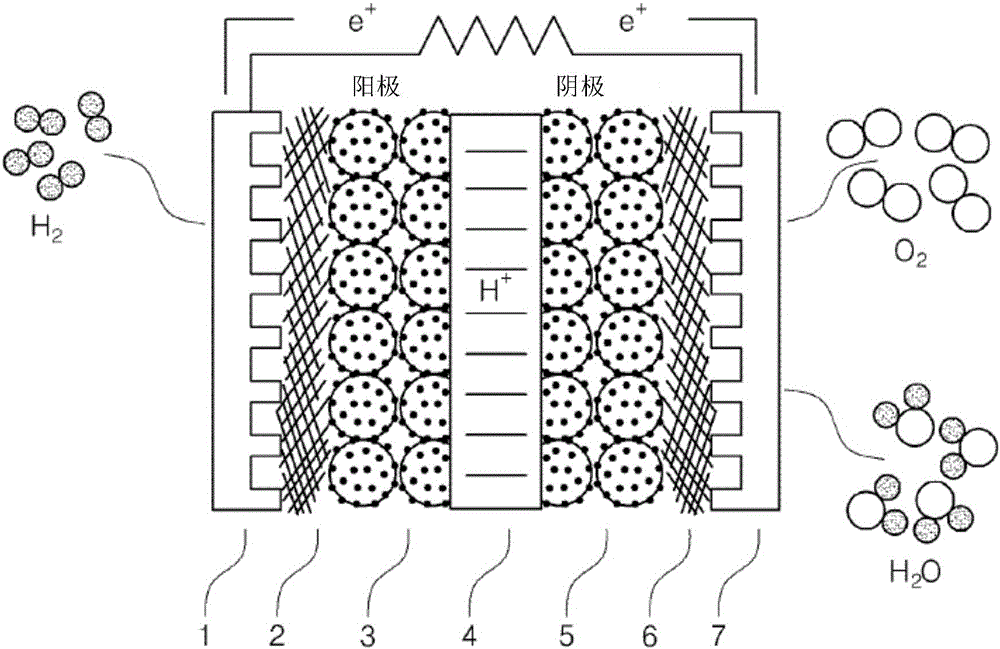

A technology of electrode catalyst and membrane electrode assembly, which is applied in the direction of fuel cells, fuel cell parts, electrical components, etc., can solve the problems of poor oxygen diffusion and mechanical stiffness of the catalytic layer, so as to promote flow and improve electrical components. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

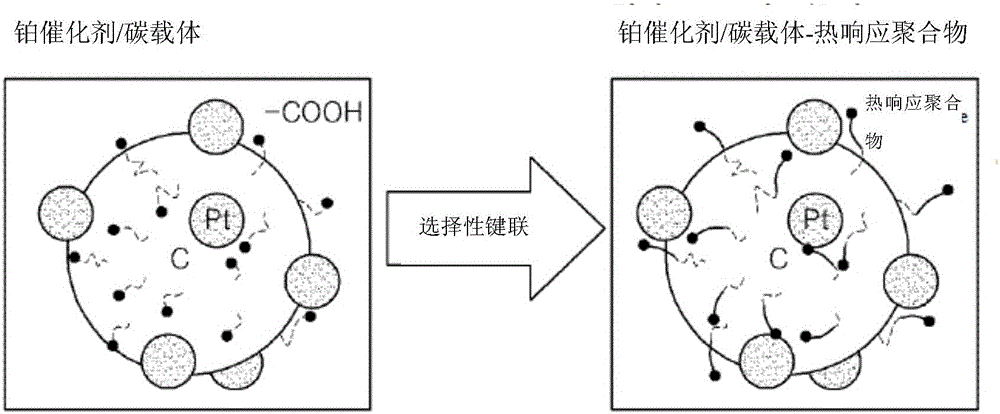

[0087] Example 1: Synthesis of Pt / C-PNIPAM

[0088] Disperse Pt / C (40wt%, Johnson Matthey) together with PNIPAM (Aldrich) terminal amino group represented by structural formula 4 in an acid solution with a pH value of 1.6. The acid solution was composed of 300 mL of isopropanol (IPA, Aldrich) and 0.6 mL of HClO 4 (Aldrich) composition. After the solution was stirred and mixed for 1 h, 1-ethyl-3-carbodiimide (3-dimethylaminopropyl) (EDC, Fluka) was added as a catalyst to the stirred solution to initiate -COOH and PNIPAM terminals on the carbon surface The -NH2 of the amino group undergoes an amide reaction. After 12 hours of EDC-induced amide reaction, the solution was filtered and washed with excess deionized (DI) water. The filtered Pt / C-PNIPAM was dried at 60 °C, and finally, the Pt / C-PNIPAM powder was deposited in a mortar.

[0089] General structural formula 4 is:

[0090]

[0091] where the value of n is 25.

example 2

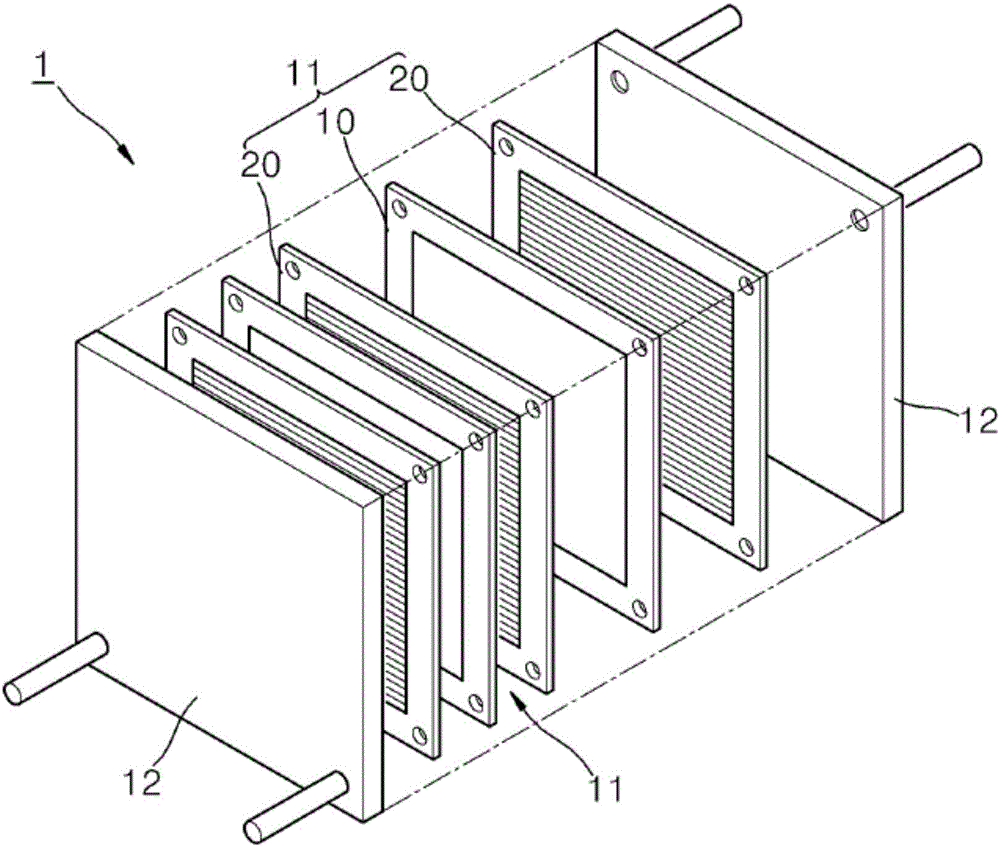

[0092] Example 2: Membrane Electrode Assembly (MEA) Preparation

[0093] In this example, a membrane electrode assembly was prepared whose cathode contained PNIPAM.

[0094] The catalyst slurry for the cathode catalytic layer containing PNIPAM was prepared by mixing 6.3 mg of Pt / C-PNIPAM, Nafion ionomer solution (Aldrich) (N / C ratio 0.5) and IPA (0.63 mL). A pretreated Nafion212 membrane (DuPont) was used. The catalyst slurry was boiled in 3% hydrogen peroxide solution and rinsed in deionized water. Then, the catalyst slurry was soaked in 0.5 M H 2 SO 4 and rinse again with deionized water. Each step in the solution was treated at 80°C for 1 hour. Spray the prepared catalyst slurry onto the anode and cathode parts of the Nafion212 membrane.

[0095] The catalyst-coated membranes were dried at room temperature for 12 h and sandwiched between the anode and cathode gas diffusion layers (SGL35BC) without autoclaving. The active geometric area of the MEA is 5cm 2 . Compa...

experiment example 1

[0099] For the unit cells prepared in Example 2 and Comparative Example 1, each catalytic surface was analyzed by x-ray photoelectron spectroscopy (XPS). The result is as Figure 5 shown.

[0100] from Figure 5 In the shown results, it can be known that the Pt / C-PNIPAM contained in the catalytic layer of Example 2 has an N1s peak at 400.5eV, indicating that PNIPAM is indeed located on the Pt / C, and forms between the carbon surface and the PNIPAM amide bond. Furthermore, this establishes that PNIPAM binds selectively only to carbon surfaces and has no effect on Pt surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com